- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

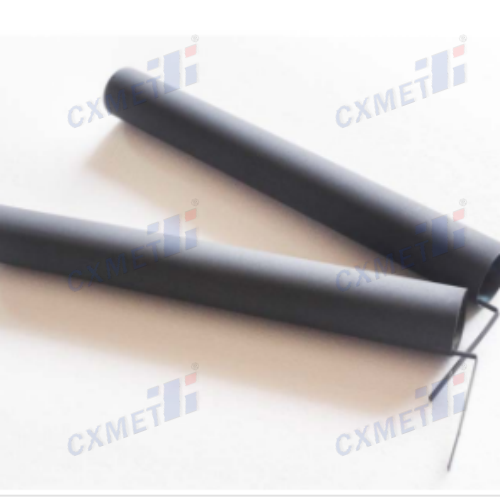

MMO Titanium Tubular Anode

Place Of Origin:China

Material: GR1

Standard: ASTM B381

Material:Titanium Gr1

Size: Customizable.

Processing method: coating, brushing and sintering

Shipping: Support Air freight, Sea freight, Express freight

Chemical Composition: Titanium and mixed mental oxides

MMO Titanium Tubular Anode: Advanced Corrosion Protection for Industrial Applications

Welcome to Shaanxi CXMET Technology Co., Ltd., your trusted manufacturer and supplier of high-quality MMO Titanium Tubular Anodes. With over 20 years of experience in the titanium industry, we specialize in delivering superior corrosion protection solutions for various industrial applications. Our MMO Titanium Tubular Anodes are engineered to provide exceptional performance, longevity, and cost-effectiveness in cathodic protection systems.

Product Introduction

【MMO Titanium Tubular Anodes】 are advanced electrochemical devices designed to combat corrosion in harsh environments. These anodes utilize Mixed Metal Oxide (MMO) coatings on a titanium substrate, offering superior durability and electrochemical efficiency. Our tubular design ensures optimal current distribution and extended service life, making them ideal for a wide range of industrial applications.

Key Features and Benefits

- Extended Lifespan: Our MMO coating technology significantly prolongs anode life, reducing replacement frequency and maintenance costs.

- High Current Capacity: Engineered to handle high current densities, ensuring effective cathodic protection even in demanding environments.

- Corrosion Resistance: Titanium substrate provides excellent resistance to chemical attack and physical wear.

- Uniform Current Distribution: Tubular design allows for even current distribution, enhancing protection efficiency.

- Lightweight and Flexible: Easy to install and handle, reducing installation time and labor costs.

- Low Consumption Rate: Minimal dimensional change over time, ensuring consistent performance throughout the anode's lifespan.

- Environmentally Friendly: Non-toxic materials and low dissolution rates contribute to minimal environmental impact.

OEM and Customization Services: Customized Geometries and Exact Dimensions

At Shaanxi CXMET, we understand that one size doesn't fit all. Our OEM and customization services allow us to tailor 【MMO Titanium Tubular Anodes】 to your specific project requirements:

- Custom lengths and diameters

- Specialized coating compositions for unique environments

- Integrated connection systems for easy installation

- Bespoke packaging solutions for efficient transportation and storage

Our engineering team works closely with clients to develop anodes that meet exact specifications, ensuring optimal performance in your specific application.

Product Features

- High-purity titanium substrate (Grade 1 or 2)

- Advanced MMO coating (IrO2-Ta2O5 based)

- Seamless tubular construction

- Various diameter options (10mm to 50mm standard, custom sizes available)

- Lengths up to 3 meters (longer lengths available upon request)

- Optional end caps and connection accessories

Technical Specifications

- Operating Current Density: Up to 100 A/m²

- Design Life: 20+ years in typical environments

- Operating Temperature Range: -40°C to +85°C

- pH Tolerance: 0-14

- Chloride Resistance: Excellent (up to saturated brine)

Applications and Industries

【MMO Titanium Tubular Anodes】 find extensive use across various sectors:

- Oil and Gas: Pipeline protection, offshore platforms, storage tanks

- Marine: Ship hulls, port structures, offshore wind farms

- Water Treatment: Desalination plants, water storage tanks, cooling systems

- Chemical Processing: Reaction vessels, storage facilities, transport systems

- Mining: Tailings ponds, leach fields, underground structures

- Power Generation: Cooling towers, heat exchangers, hydroelectric dams

- Infrastructure: Bridges, reinforced concrete structures, underground utilities

|

|

|

|

|

|

Tips and Tricks

- Ensure proper anode spacing for optimal current distribution

- Regularly inspect and maintain electrical connections

- Monitor system performance using reference electrodes

- Consider environmental factors when designing your cathodic protection system

- Consult with our experts for site-specific recommendations

Manufacturing Process

Our 【MMO Titanium Tubular Anodes】 undergo a rigorous manufacturing process:

- High-purity titanium tube selection and preparation

- Precision surface treatment for optimal coating adhesion

- Advanced MMO coating application using proprietary techniques

- High-temperature sintering to ensure coating durability

- Comprehensive quality control and performance testing

- Custom finishing and connection system integration (as required)

Factory show

|

|

|

|

Production workshop

|

|

|

|

|

|

Production Equipments

Main Products

How to Choose Products and Why Choose Products Made by Us

When selecting MMO Titanium Tubular Anodes, consider:

- Environmental conditions (pH, temperature, chloride levels)

- Required current output and distribution

- Expected service life and maintenance intervals

- Compatibility with existing systems

- Supplier expertise and support

Choose Shaanxi CXMET for:

- Industry-leading quality and performance

- Extensive customization capabilities

- Comprehensive technical support and after-sales service

- Competitive pricing for both standard and custom solutions

- Commitment to innovation and continuous improvement

Certifications and Compliance

Our 【MMO Titanium Tubular Anodes】 meet or exceed industry standards:

- ISO 9001:2015 Quality Management System

- NACE SP0290 and SP0387 compliant

- DNV-GL Type Approval (for marine applications)

- ASTM B338 for titanium tube quality

Quality Control and Testing

Every batch of anodes undergoes rigorous testing:

- Coating adhesion and thickness measurements

- Electrochemical performance evaluation

- Accelerated life testing

- Chemical composition analysis

- Dimensional and visual inspections

Packaging and Shipping

We ensure safe delivery of your 【MMO Titanium Tubular Anodes】:

- Custom protective packaging to prevent damage

- Secure crating for bulk shipments

- Worldwide shipping with tracking

- Express delivery options available

- Full documentation and quality certificates provided

Testimonials and Case Studies

"Shaanxi CXMET's MMO Titanium Tubular Anodes have significantly reduced our maintenance costs and improved the reliability of our pipeline protection systems." - John D., Corrosion Engineer, Major Oil & Gas Company

Case Study: A desalination plant in the Middle East achieved a 30% increase in system longevity after switching to our customized MMO Titanium Tubular Anodes.

FAQ

- Q: What is the typical lifespan of your MMO Titanium Tubular Anodes?

A: In standard conditions, our anodes can last 20+ years. However, lifespan can vary based on environmental factors and current output. - Q: Can these anodes be used in seawater applications?

A: Yes, our anodes are specifically designed to perform excellently in seawater environments. - Q: Do you offer installation support?

A: We provide comprehensive technical support, including installation guidelines and on-site consultation if required. - Q: What is the lead time for custom orders?

A: Lead times vary based on specifications and quantity. Typically, custom orders are fulfilled within 4-8 weeks. - Q: Are your anodes compatible with impressed current cathodic protection (ICCP) systems?

A: Yes, our MMO Titanium Tubular Anodes are ideal for use in ICCP systems across various applications.

Contact Us

Ready to enhance your corrosion protection strategy with our 【MMO Titanium Tubular Anodes】? Contact our expert team today:

Email: sales@cxmet.com

Tel&WhatsApp: 8615891192169

Let Shaanxi CXMET Technology Co., Ltd. be your partner in achieving superior corrosion protection and extended asset life. Reach out now to discuss your specific requirements and discover how our MMO Titanium Tubular Anodes can benefit your operations.

hotTags:MMO Titanium Tubular Anode,supplier,wholesale,China,factory,manufacturer,OEM,Customized,trader,for sale,in stock,free sample,for sale.

YOU MAY LIKE