When engineers choose the best MMO probe anode for cathodic protection systems, they have to make important choices that affect how long the infrastructure lasts and how much it costs to run. The mixed metal oxide technology is a huge step forward in protecting electrochemical systems; it works better than standard sacrificial anodes. These high-tech anode materials are very resistant to rust and keep their stable electrochemical qualities in a wide range of commercial settings.In naval settings, oil and gas sites, and chemical processing plants, it's very important to choose cathodic protection tools that you can trust. Engineering teams need tried-and-true methods that work consistently in all kinds of situations. Modern MMO coating technology gives you exact control over electrochemical processes, which means you can get the best defense for a long time. Knowing how to choose the best goods and what makes them work well helps procurement managers make smart choices that protect important infrastructure investments.

|

|

|

Why Focus on Advanced MMO Probe Anodes

It's an important turning point in the history of cathodic protection technology: old ways can't keep up with the needs of current industrial uses. Engineers who work in the chemical processing, oil and gas, and naval industries have to deal with situations that are getting more dangerous and don't respond well to standard safety measures. Electrochemical tracking is more accurate and lasts longer with advanced probe anodes that use mixed metal oxide technology.These complex gadgets let you check the amount of safety in real time and give you stable points to work from when you're trying to make the system work better. When you combine advanced anode materials with precise production methods, you get goods that can handle tough chemical exposure, high temperatures, and mechanical stress. This new technology directly meets the growing need for long-lasting, reliable solutions in apps that protect key systems.

Selection Criteria for Superior Performance

To evaluate MMO probe anodes, you need to look at a lot of different performance factors that have a direct effect on how well the system works. Our selection process puts electrical stability, material longevity, manufacturing quality, and proven field performance in a wide range of industrial settings at the top of the list. Each of the criteria is based on a real-life problem that tech teams have to deal with when they are in charge of keeping important things safe.The quality of the electrical base and the evenness of the MMO coating application are the main topics of the material makeup analysis. Precision in manufacturing affects long-term security and measurement accuracy, and data from the field gives us important information about how things really work. Cost-effectiveness factors balance the original investment against the performance over the product's lifetime, making sure that difficult uses get the best value.Environmental suitability is also very important, because probe anodes need to be able to work reliably in harsh environments with high and low temperatures, chemicals, and mechanical pressures that are typical in factories. As part of the evaluation process, the manufacturer's expert help, the availability of the product, and compliance with important industry standards and rules are all looked at.

Top 5 MMO Probe Anodes for Industrial Applications

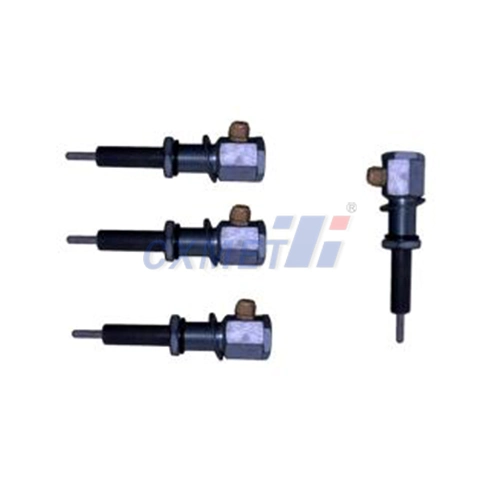

CXMET Industrial Grade MMO Reference Probe

CXMET's industrial-grade reference probe represents cutting-edge advancement in electrochemical monitoring technology. This precision-engineered device features a titanium substrate with optimized mixed metal oxide coating, delivering exceptional stability across aggressive chemical environments. The probe's advanced signal processing capabilities ensure accurate readings even in high-interference industrial settings.

Key advantages include:

- Superior corrosion resistance through proprietary MMO coating formulation

- Extended operational life exceeding 25 years in marine environments

- Precision manufacturing ensuring measurement accuracy within ±2mV

- Temperature stability from -40°C to +80°C

- Chemical resistance to acids, bases, and organic solvents

- Integrated cable protection system preventing moisture ingress

The device incorporates advanced electrochemical impedance characteristics optimized for industrial monitoring applications. Field testing across oil and gas facilities demonstrates consistent performance under extreme conditions, making it ideal for critical infrastructure protection. The robust construction includes specialized sealing technology preventing electrolyte contamination while maintaining electrical conductivity.Manufacturing quality control processes ensure each unit meets stringent performance specifications. The probe's design accommodates various installation configurations, providing flexibility for retrofit applications and new construction projects. Technical support includes comprehensive calibration protocols and maintenance guidelines developed through extensive field experience.

Marine Environment Specialized Probe

Designed specifically for harsh marine applications, this specialized probe addresses unique challenges posed by saltwater environments and tidal variations. The enhanced coating formulation provides superior resistance to chlorine evolution and oxygen evolution reactions common in seawater cathodic protection systems.

Performance characteristics include:

- Optimized for seawater applications with enhanced chloride resistance

- Advanced surface morphology preventing biological fouling

- Integrated pressure compensation for underwater installations

- Specialized connector systems resistant to saltwater corrosion

- Extended cable options for deep water applications

- Compliance with marine industry standards and classifications

The MMO Probe Anode's construction incorporates lessons learned from offshore platform installations and marine infrastructure projects. Electrochemical testing validates performance across varying salinity levels and temperature ranges encountered in global marine environments. The design includes provisions for periodic inspection and maintenance without system shutdown. Installation flexibility accommodates various mounting configurations required for marine structures. The MMO Probe Anode's signal characteristics remain stable despite wave action and current variations common in marine environments. Comprehensive documentation supports regulatory compliance and inspection requirements.

High-Temperature Industrial Monitoring Probe

Engineered for power generation and metallurgical applications, this high-temperature probe maintains accuracy and stability under extreme thermal conditions. The specialized coating formulation and substrate selection ensure reliable operation in environments exceeding standard temperature limits.

Technical specifications include:

- Operational temperature range extending to 150°C

- Thermal shock resistance through specialized material selection

- Enhanced electrical conductivity at elevated temperatures

- Pressure-rated construction for high-temperature steam systems

- Specialized cable insulation for thermal applications

- Rapid thermal response for dynamic monitoring requirements

The probe's design addresses thermal expansion considerations and maintains calibration accuracy across temperature cycles. Field validation in power plant cooling systems demonstrates consistent performance under demanding operational conditions. The construction includes thermal barrier protection preventing heat-induced degradation of sensitive components.Application versatility supports monitoring requirements in boiler systems, heat exchangers, and high-temperature chemical processes. The probe's durability reduces maintenance requirements while providing reliable data for system optimization. Technical documentation includes installation guidelines for high-temperature environments.

Chemical Processing Resistant Probe

Specifically formulated for aggressive chemical environments, this probe delivers reliable performance in pharmaceutical, chemical processing, and coating applications. The advanced coating system provides exceptional resistance to organic solvents, acids, and specialty chemicals commonly encountered in process industries.

Chemical resistance features include:

- Broad chemical compatibility across pH ranges 0-14

- Resistance to organic solvents and specialty chemicals

- Non-contaminating construction for pharmaceutical applications

- Specialized sealing systems preventing chemical ingress

- Easy decontamination protocols for process flexibility

- Compliance with chemical industry safety standards

The probe's material selection prioritizes chemical inertness while maintaining electrochemical functionality. Testing protocols validate performance across representative chemical exposures encountered in process industries. The design facilitates integration into existing process monitoring systems without modification.Installation options accommodate various process configurations including inline monitoring and batch processing applications. The probe's construction includes provisions for cleaning and sterilization procedures required in pharmaceutical manufacturing. Documentation supports regulatory compliance for controlled environments.

Precision Laboratory Reference Probe

Designed for research and development applications requiring exceptional accuracy and stability, this laboratory-grade probe provides reference-quality measurements for electrochemical research and product development. The precision manufacturing and calibration protocols ensure measurement traceability and repeatability.

Precision characteristics include:

- Measurement accuracy within ±1mV under laboratory conditions

- Long-term stability enabling extended research programs

- Minimal drift characteristics for reliable baseline measurements

- Rapid equilibration for efficient testing protocols

- Comprehensive calibration documentation and traceability

- Compatibility with automated measurement systems

The probe's construction prioritizes measurement precision while maintaining durability for routine laboratory use. Quality control processes ensure consistent performance across production batches. The design accommodates various experimental configurations required for research applications.Integration capabilities support data analysis systems and neural network processing for advanced research applications. The probe's stability enables long-term studies and comparative analysis programs. Technical support includes calibration verification and measurement uncertainty analysis.

Global Market Characteristics and Considerations

The worldwide market for advanced cathodic protection equipment reflects diverse regional requirements and regulatory frameworks that influence product selection and application strategies. North American markets emphasize compliance with NACE standards and API recommendations, while European applications prioritize environmental sustainability and lifecycle performance metrics.Asian markets demonstrate growing demand for high-performance solutions supporting rapid industrial expansion and infrastructure development. The regulatory landscape varies significantly across regions, with some markets requiring specific certifications and testing protocols. Understanding these regional characteristics enables informed product selection and compliance planning.Cultural preferences for technology adoption and maintenance practices influence system design requirements and support expectations. Local availability of technical expertise and service capabilities affects long-term operational planning and cost considerations. The global supply chain dynamics impact product availability and pricing structures across different markets.

Purchasing Recommendations and Considerations

Successful procurement of MMO probe anodes requires careful evaluation of application-specific requirements and long-term performance expectations. Engineering teams should prioritize proven performance data over theoretical specifications when evaluating potential suppliers. The selection process should include comprehensive technical discussions with manufacturers to ensure product suitability for specific applications.Lifecycle cost analysis provides more accurate comparisons than initial purchase price alone, considering factors such as installation requirements, maintenance needs, and replacement intervals. Supplier technical support capabilities represent crucial factors for successful project implementation and ongoing system optimization.Quality assurance protocols and manufacturing standards significantly impact product reliability and performance consistency. Procurement specifications should include detailed performance requirements, testing protocols, and acceptance criteria. The evaluation process should consider supplier experience in similar applications and their ability to provide technical support throughout the product lifecycle.

Industry Trends and Summary

The cathodic protection industry continues evolving toward intelligent monitoring systems integrated with advanced data analysis capabilities. Modern MMO probe technology incorporates enhanced materials and manufacturing techniques that extend operational life while improving measurement accuracy. Industry adoption of digital monitoring systems creates opportunities for advanced probe designs with integrated signal processing and communication capabilities. These technological advances support more effective infrastructure protection strategies while reducing long-term operational costs.

Conclusion

Selecting the optimal MMO probe anode requires careful consideration of application-specific requirements, environmental conditions, and long-term performance expectations. The products highlighted in this analysis represent proven solutions that address diverse industrial protection needs while delivering reliable, long-term performance. Advanced mixed metal oxide technology continues revolutionizing cathodic protection strategies through enhanced durability, precision, and operational flexibility. Engineering teams benefit from partnering with experienced manufacturers who provide comprehensive technical support and proven product quality. Investment in premium probe technology delivers significant long-term value through reduced maintenance requirements, extended operational life, and improved protection effectiveness across critical infrastructure applications.

FAQ

Q: How long do MMO probe anodes typically last in marine environments?

A: High-quality MMO probe anodes designed for marine applications typically provide 20-25 years of reliable service when properly installed and maintained. The actual lifespan depends on specific environmental conditions, installation quality, and maintenance practices. Regular calibration and inspection can help maximize operational life and ensure continued accuracy.

Q: What maintenance requirements are associated with MMO probe anodes?

A: MMO probe anodes require minimal maintenance compared to traditional reference electrodes. Routine activities include periodic calibration verification, visual inspection of cables and connections, and cleaning of probe surfaces when accessible. Most probes are designed for minimal maintenance operation, with service intervals typically ranging from annual to biennial depending on application severity.

Q: Can MMO probe anodes be used in high-temperature applications?

A: Specialized MMO probe anodes are available for high-temperature applications up to 150°C. These probes feature enhanced materials and construction techniques specifically designed for thermal stability. Standard probes typically operate effectively up to 80°C, while specialized high-temperature versions incorporate thermal barrier protection and enhanced cable insulation for extreme conditions.

Partner with CXMET for Premium MMO Probe Anode Solutions

Shaanxi CXMET Technology Co., Ltd. stands as a trusted MMO probe anode manufacturer with over 20 years of expertise in non-ferrous metal technology and electrochemical protection systems. Our advanced manufacturing capabilities and rigorous quality control processes ensure each probe meets the demanding requirements of modern industrial applications.Our engineering team brings extensive experience in marine, oil and gas, chemical processing, and power generation applications. We provide comprehensive technical support including application analysis, product selection guidance, and installation assistance. Our commitment to innovation drives continuous improvement in probe design and manufacturing techniques.CXMET's quality management system ensures consistent product performance and reliability across all applications. Our global supply capabilities support project timelines while maintaining competitive pricing for volume requirements. Whether you need standard configurations or custom solutions, our team stands ready to support your cathodic protection requirements. Contact us at sales@cxmet.com to discuss your specific application needs and discover how our advanced MMO probe anode technology can enhance your infrastructure protection strategy.