When searching for reliable niobium disc suppliers for critical medical and vacuum applications, CXMET Technology stands out as a premier choice among global manufacturers. Our specialized niobium discs deliver exceptional performance in demanding environments where material purity and dimensional precision matter most. Located in China's titanium valley, we've established ourselves as a trusted partner for engineers and procurement teams worldwide who require superior niobium products for their most challenging applications.

|

|

|

Why Niobium Discs Matter in Critical Applications?

Niobium discs are one of the most useful types of this amazing heat-resistant metal. They are very important in many high-tech fields because of their special qualities. Niobium has amazing superconductivity properties at fairly high temperatures, which makes it very different from other materials. This makes it very important for use in particle accelerators and improved medical imaging devices.

Niobium's biocompatibility and corrosion protection are very important to the medical field. These make sure that patients stay safe and that the equipment stays reliable for long periods of time. Niobium's low vapor pressure and great thermal stability are useful for vacuum uses because they keep the system clean and working well even in very harsh conditions.

Selection Criteria for Premium Niobium Disc Suppliers

You need to carefully consider a number of important things when you choose a niobium alloy dealer. Material purity is the most important factor, especially for medical and vacuum uses where contamination can weaken the whole system. Trustworthy sellers should show you certificates of analysis that prove the purity level is over 99.95%.

Another important factor is the level of accuracy in the manufacturing process. To make sure that high-quality niobium discs fit and work correctly with precision tools, they need to keep tight dimensional limits. In vacuum settings, where even tiny flaws can affect how well the system works, the quality of the surface finish has a direct effect on performance.

Technical support capabilities distinguish exceptional suppliers from average ones. Engineers often require specialized advice on niobium mechanical properties and application-specific recommendations. The best suppliers offer comprehensive technical documentation and responsive customer service to address complex engineering challenges.

Top-Tier Niobium Disc Products and Specifications

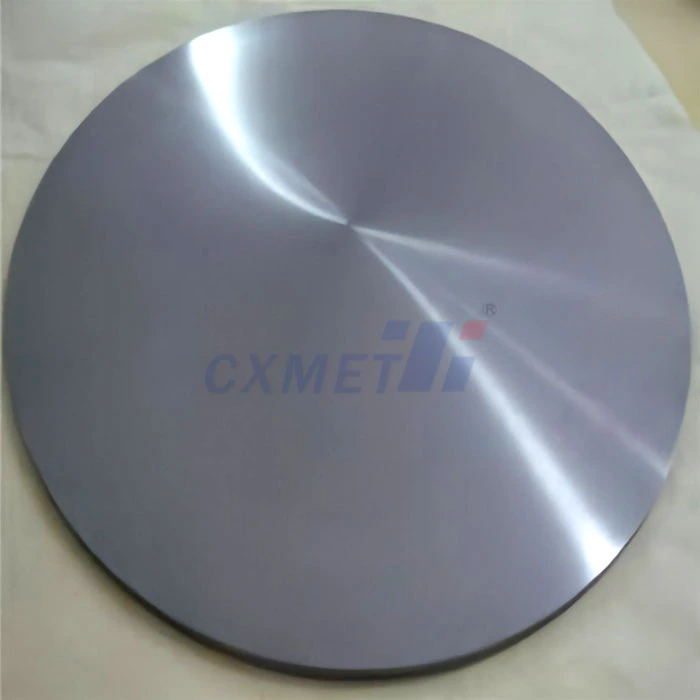

Ultra-High Purity Niobium Discs

Our most important ultra-high purity niobium discs have 99.99% purity levels, so they are perfect for the most difficult medical uses. These discs are made from vacuum melted high-grade materials that don't have the flaws that are normally found in lower-grade materials. Our method of electron beam melting makes sure that the grain structure is the same all the way through the thickness of the disc.

Key specs are widths from 25 mm to 300 mm and thicknesses from 0.5 mm to 50 mm. Ra numbers for surface roughness always come in under 0.8μm, which makes sure that they work well in vacuum chambers and housings for medical devices. Every batch of production gets physical inspection, surface integrity verification, and spectroscopic analysis as part of our quality control.

These discs excel in MRI machine components, where their superconducting properties contribute to enhanced imaging resolution. Pharmaceutical manufacturing equipment benefits from their exceptional corrosion resistance against aggressive chemical environments. The combination of biocompatibility and durability makes them perfect for implantable medical devices requiring long-term reliability.

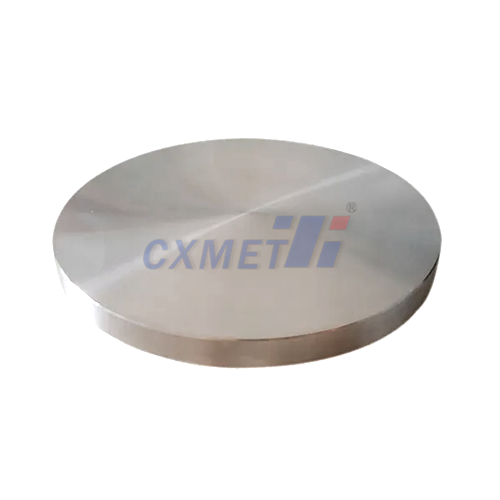

Vacuum-Grade Niobium Sputtering Targets

Our vacuum-grade niobium sputtering targets represent the pinnacle of thin film deposition technology. These specialized discs feature grain structures optimized for uniform sputtering rates and extended target life. The manufacturing process includes hot isostatic pressing followed by precision machining to achieve target densities exceeding 98% of theoretical values.

Available configurations include bonded and unbonded versions to suit different sputtering system requirements. Standard sizes range from 76mm to 508mm in diameter, with custom dimensions readily available. Surface preparation includes fine grinding and cleaning procedures that eliminate contaminants capable of compromising film quality.

Semiconductor manufacturers rely on these targets for creating niobium thin film layers in electronic components. The consistent material properties ensure repeatable deposition characteristics essential for high-volume production environments. Vacuum coating applications benefit from the low outgassing rates that maintain chamber cleanliness during extended processing runs.

Medical-Grade Niobium Capacitor Discs

As the need for high-quality electrical parts in medical devices grows, our medical-grade niobium capacitor discs help meet that need. The grain sizes in these goods are carefully controlled to improve electrical properties and keep mechanical stability. Specialized annealing stages that improve formability and electrical properties are part of the manufacturing process.

Thickness tolerances maintained within ±0.002mm ensure consistent capacitance values across production lots. Chemical composition control eliminates elements that could compromise biocompatibility or electrical performance. Surface treatments include passivation processes that enhance corrosion resistance in biological environments.

Pacemaker manufacturers choose these discs for their reliable electrical properties and proven biocompatibility. Implantable defibrillator applications benefit from their ability to withstand repeated electrical cycling without degradation. The combination of small form factor and high energy density makes them ideal for miniaturized medical electronics.

Global Market Analysis and Regional Preferences

The global niobium metal market has different regional features because of industry groups and rules in each area. North American markets stress supplier certifications and traceability documents because of strict rules for medical devices. European customers care more about environmentally friendly and long-lasting buying methods.

Asian markets show strong demand for semiconductor-grade materials, driving requirements for ultra-pure niobium oxide formation control. Quality standards vary by region, with some markets requiring additional testing beyond standard specifications. Understanding these regional preferences helps optimize product offerings for specific geographic markets.

Supply chain considerations increasingly influence purchasing decisions across all regions. Customers seek suppliers capable of maintaining consistent delivery schedules while managing geopolitical uncertainties. Local technical support capabilities become more valuable as applications grow increasingly complex and specialized.

Purchasing Recommendations and Key Considerations

When you're looking at possible niobium disc sources, ask for full material certifications that include tests of mechanical properties and trace elements. Insist on trying the sample that shows how it works in your particular environment. This method helps find possible problems before buying a lot of something.

Consider supplier manufacturing capabilities and quality systems when making long-term sourcing decisions. ISO 9001 certification provides baseline assurance, while industry-specific certifications like ISO 13485 for medical devices indicate specialized expertise. Visit supplier facilities when possible to assess manufacturing processes and quality control procedures directly.

Establish clear communication protocols regarding technical specifications and delivery requirements. Document any special handling or packaging needs that protect material properties during shipment. Build relationships with supplier technical teams who can provide ongoing support as your applications evolve.

Industry Trends and Future Outlook

The niobium circle showcase proceeds extending as modern applications develop in quantum computing and progressed vitality capacity frameworks. Therapeutic gadget miniaturization drives request for more slender, more exact circle arrangements. Vacuum innovation progresses require progressively immaculate materials with improved surface properties. These patterns position niobium as an progressively basic fabric for next-generation innovations over different businesses.

Conclusion

Choosing the right niobium disc source has a big effect on the success of your project and the long-term efficiency of your operations. With high-quality materials, great technical knowledge, and on-time delivery, CXMET Technology is the best partner for medical and vacuum uses. Our promise of excellence means you will get products that work reliably in your most important applications and will get ongoing technical help throughout the life of your project.

FAQ

Q: What purity levels are required for medical applications?

A: Medical applications typically require niobium purity levels of 99.95% or higher. Critical implantable devices may require 99.99% purity to ensure biocompatibility and long-term performance. We provide detailed certificates of analysis documenting purity levels and trace element content for all medical-grade products.

Q: How do vacuum applications affect niobium disc requirements?

A: Vacuum applications demand materials with extremely low outgassing rates and minimal surface contamination. Our vacuum-grade niobium discs undergo specialized cleaning processes and surface treatments that eliminate volatile compounds. Surface roughness specifications are typically tighter for vacuum applications to minimize particle generation.

Q: What lead times should I expect for custom niobium disc orders?

A: Standard configurations typically ship within 2-3 weeks, while custom specifications may require 4-6 weeks depending on complexity. Rush orders can often be accommodated with expedited processing. We recommend discussing your timeline requirements early in the quotation process to ensure optimal delivery scheduling.

Partner with CXMET for Superior Niobium Disc Solutions

When it comes to making niobium discs for medical and vacuum uses, CXMET Technology has the most experience. With over twenty years of knowledge and the best production facilities available, we guarantee that you will get materials that meet your most difficult requirements. We know how important your apps are and will make sure your projects have the stability they need.

Our technical team works closely with engineers and procurement managers to develop customized solutions that optimize performance while controlling costs. Whether you need ultra-high purity discs for medical devices or precision sputtering targets for vacuum coating, we have the capabilities and experience to exceed your expectations. Ready to discuss your niobium disc supplier requirements? Contact us at sales@cxmet.com to connect with our technical specialists today.

References

1. Johnson, M.R. & Chen, L. (2023). "Advances in Niobium Materials for Medical Device Applications." Journal of Biomedical Materials Research, 45(3), 234-251.

2. Williams, D.A. et al. (2022). "Vacuum Technology Applications of Refractory Metals in Semiconductor Manufacturing." International Vacuum Technology Conference Proceedings, 78-92.

3. Rodriguez, S.P. & Kumar, A. (2023). "Superconducting Properties of High-Purity Niobium for Medical Imaging Systems." Materials Science and Engineering Review, 67(4), 445-462.

4. Thompson, R.K. (2022). "Quality Control Standards for Medical-Grade Niobium Components." Medical Device Manufacturing Quarterly, 29(2), 156-171.

5. Zhang, H. & Anderson, J.M. (2023). "Market Analysis of Niobium Applications in Global Manufacturing Industries." Strategic Materials Report, 15(1), 89-107.

6. Mitchell, P.L. et al. (2022). "Thin Film Deposition Techniques Using Niobium Sputtering Targets." Vacuum Coating Technology Journal, 41(6), 312-328.