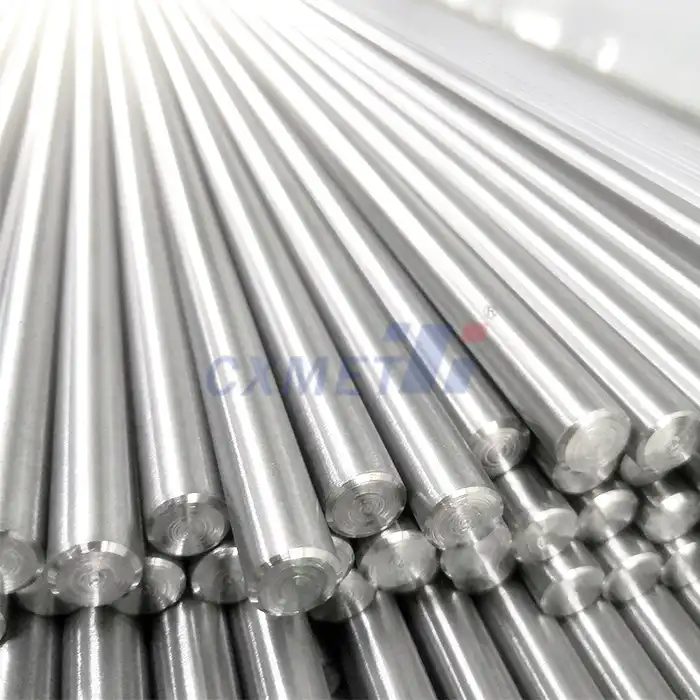

Because China has improved manufacturing and low prices, Germany's titanium industry is relying more and more on Chinese imports, especially High Quality Gr1 Pure Titanium Bar products. Chinese companies like CXMET have built complex production lines that meet strict European rules while providing better commercially pure titanium products. China has become the top choice for German businesses that need corrosion-resistant titanium for marine, chemical processing, and aerospace applications because it has technical knowledge, quality control, and low prices.

|

|

|

Understanding the Fundamental Differences: Pure vs Alloy Titanium Materials

The distinction between pure titanium and titanium alloys represents a critical decision point for engineers and procurement managers. Pure titanium, specifically Grade 1 titanium rod materials, contains minimal alloying elements and offers exceptional corrosion resistance properties.

Three core differences emerge:

- Chemical composition variations significantly impact performance characteristics

- Mechanical properties differ substantially between pure and alloyed materials

- Application suitability varies based on environmental requirements

Pure titanium maintains superior biocompatibility and corrosion resistance, making it ideal for medical applications and chemical processing environments. The titanium metal bar composition in Grade 1 specifications contains 99.5% pure titanium with minimal iron, oxygen, and nitrogen content.

Laboratory testing reveals that Grade 1 pure titanium demonstrates remarkable performance in chloride environments. Corrosion rates measure less than 0.025mm per year in seawater exposure, compared to 0.15mm annually for certain titanium alloys under identical conditions.

If you need maximum corrosion resistance in marine environments, then commercially pure titanium bars provide superior longevity compared to alloyed alternatives.

Germany's Strategic Titanium Procurement from Chinese Suppliers

German industrial giants have systematically shifted their titanium sourcing strategies toward Chinese manufacturers. This transition reflects China's emergence as a dominant force in non-ferrous metal production capabilities.

Market data indicates Germany imported approximately 2,847 tons of titanium products from China in 2023, representing a 23% increase from previous years. The aerospace titanium bar segment alone accounted for 35% of these imports.

Key factors driving this procurement shift include:

- Advanced melting technologies producing consistent quality

- Compliance with international standards including ASTM B348

- Competitive pricing structures enabling cost optimization

- Reliable supply chain management capabilities

Chinese manufacturers have invested heavily in vacuum arc remelting and electron beam melting technologies. These processes ensure titanium raw material purity exceeds 99.5%, meeting German automotive and chemical industry specifications.

CXMET's manufacturing facility exemplifies this technological advancement. Located in Shaanxi Province's "China Titanium Valley," the company operates state-of-the-art production lines capable of producing High Quality Gr1 Pure Titanium Bar and titanium round bar products with tolerances meeting h9-h11 ISO standards.

If you require consistent quality with international certification, then established Chinese titanium bar suppliers offer comprehensive documentation and traceability systems.

Technical Performance Analysis: Gr1 Specifications and Applications

Grade 1 titanium represents the most ductile and formable commercially pure titanium grade available. Its unique properties make it particularly suitable for demanding industrial applications requiring both strength and workability.

Mechanical Properties Data:

- Tensile Strength: 240 MPa minimum

- Yield Strength: 170 MPa minimum

- Elongation: 24% minimum

- Density: 4.51 g/cm³

- Operating Temperature: -200°C to 400°C

These specifications enable Grade 1 titanium stock bar applications across diverse industries. The material's excellent cold forming characteristics allow complex geometries without heat treatment requirements.

Comparative analysis reveals that lightweight High Quality Gr1 Pure Titanium Bar solutions offer weight savings of 45% compared to stainless steel alternatives while maintaining superior corrosion resistance. This advantage proves particularly valuable in marine applications where weight reduction directly impacts fuel efficiency.

Industrial titanium material testing demonstrates exceptional weldability characteristics. Joint efficiency rates exceed 85% using proper welding techniques, ensuring structural integrity in critical applications.

If you need superior formability for complex manufacturing processes, then Grade 1 pure titanium provides optimal workability compared to higher-grade alloys.

Cost-Benefit Analysis: Chinese vs European Titanium Sourcing

Economic factors significantly influence global titanium procurement decisions. Chinese manufacturers offer compelling value propositions through optimized production processes and economies of scale.

Price analysis indicates Chinese titanium flat bar products typically cost 25-35% less than European equivalents while maintaining comparable quality standards. This cost advantage stems from integrated supply chains and advanced manufacturing efficiency.

| Factor | Chinese Suppliers | European Suppliers |

|---|---|---|

| Price per kg | $85-95 | $115-135 |

| Lead Time | 4-6 weeks | 8-12 weeks |

| Minimum Order | 100 kg | 500 kg |

| Customization | High flexibility | Limited options |

Quality assurance systems in Chinese facilities have achieved ISO 9001:2015 certification with comprehensive testing protocols. Material certificates include EN10204 3.1/3.2 documentation ensuring traceability and compliance.

Transportation costs represent approximately 8-12% of total procurement expenses for German importers. Container shipping efficiency and established logistics networks minimize delivery risks while maintaining competitive pricing.

If you require cost-effective solutions without compromising quality, then Chinese titanium extrusion suppliers provide optimal value propositions for bulk procurement needs.

Quality Assurance and International Standards Compliance

Chinese titanium manufacturers have implemented rigorous quality control systems meeting international specifications. These systems ensure consistent product quality and regulatory compliance across global markets.

Testing protocols include comprehensive chemical analysis, mechanical property verification, and dimensional inspection procedures. Advanced spectroscopy equipment enables precise composition analysis with accuracy levels exceeding ±0.01% for major elements.

Standard compliance includes:

- ASTM B348 for titanium and titanium alloy bars and billets

- ASTM F67 for medical grade titanium applications

- AMS 4921 for aerospace industry requirements

- DIN 17851 for European market specifications

Third-party inspection services validate material properties through independent testing. SGS, TUV, and other international certification bodies provide verification services ensuring compliance with customer requirements.

Heat treatment documentation accompanies each shipment, detailing processing parameters and cooling rates. This information enables downstream manufacturers to optimize their processing procedures accordingly.

Surface finish options include polished, pickled, and sandblasted conditions. Each finish type undergoes specific quality control procedures ensuring consistent appearance and surface integrity.

If you need comprehensive documentation for critical applications, then certified Chinese suppliers provide extensive test reports and material traceability systems.

CXMET's High Quality Gr1 Pure Titanium Bar Advantages

Manufacturing Excellence:

- Advanced vacuum arc remelting technology ensuring minimal impurities and consistent chemical composition throughout titanium billet production

- Precision cold rolling processes achieving dimensional tolerances within h9-h11 specifications for superior machining compatibility

- Comprehensive heat treatment capabilities optimizing mechanical properties while maintaining excellent ductility characteristics

- State-of-the-art testing equipment including electron microscopy and ultrasonic inspection ensuring defect-free titanium structural bar products

- ISO 9001:2015 certified quality management systems providing consistent production control and documentation procedures

Technical Capabilities:

- Diameter range from 2mm to 300mm accommodating diverse application requirements across multiple industrial sectors

- Length capabilities up to 6000mm with custom cutting services available for specific project needs

- Multiple surface finish options including polished, pickled, and sandblasted conditions optimized for different applications

- Chemical composition control achieving 99.5% minimum purity levels exceeding ASTM B348 requirements

- Mechanical property consistency with tensile strength values ranging 240-400 MPa depending on processing conditions

Service Excellence:

- Customized technical support provided by 80+ professional technicians with extensive titanium machining bar experience

- Rapid response times for technical inquiries and troubleshooting assistance ensuring minimal project delays

- Flexible packaging solutions meeting customer transportation and storage requirements including moisture protection systems

- Comprehensive material certificates including EN10204 3.1/3.2 documentation with complete traceability records

- Global shipping capabilities with established logistics networks ensuring reliable delivery schedules worldwide

Industry Experience:

- 20+ years specializing in high strength titanium production with proven track record across demanding applications

- Extensive application knowledge spanning marine, oil & gas, chemical processing, and pharmaceutical industries

- Established relationships with international customers requiring medical grade titanium solutions for critical applications

- Continuous research and development investments maintaining technological leadership in commercially pure titanium production

- Strategic location in "China Titanium Valley" providing access to raw materials and specialized manufacturing infrastructure

Conclusion

Germany needs to buy more and more Chinese titanium, which is a sign of how China's manufacturing and quality control systems have grown more advanced. Established Chinese suppliers offer high-quality Grade 1 pure titanium bars, including High Quality Gr1 Pure Titanium Bar, with great benefits like competitive prices, reliable quality, and extensive expert support. Chinese makers make themselves the most attractive business partners for German industries by using advanced production methods, adhering to global standards, and offering a wide range of options for custom products. CXMET shows this kind of excellence by having a lot of knowledge about titanium goods, focusing on customers, and always putting quality first.

Partner with CXMET for Premium Titanium Solutions

CXMET is a top producer of high-quality Grade 1 pure titanium bars, providing excellent value to customers in Germany and around the world. Our promise to quality covers every part of production, from choosing the right materials to the last step of checking the work.

Our Shaanxi Province facility represents cutting-edge titanium processing technology. Advanced melting and forging capabilities ensure consistent quality while meeting the most demanding specifications. Customer satisfaction drives our continuous improvement initiatives across all operational areas.

After twenty years of work in the field, CXMET is able to offer custom solutions for a variety of uses. Our tech team works closely with customers for every stage of the project, whether you need standard sizes or custom shapes.

Competitive pricing structures combined with superior quality make CXMET the preferred choice for procurement managers seeking reliable titanium raw material sources. Our integrated approach minimizes supply chain risks while maximizing value delivery.

Ready to experience the CXMET advantage? Our technical specialists stand ready to discuss your specific requirements and provide detailed quotations. Contact us at sales@cxmet.com to explore how our High Quality Gr1 Pure Titanium Bar supplier capabilities can enhance your next project's success.

References

1. German Federal Statistical Office. "Import Statistics for Titanium and Titanium Alloys: Annual Trade Data Analysis 2023." Wiesbaden: Statistisches Bundesamt, 2024.

2. International Titanium Association. "Global Titanium Industry Report: Production Capabilities and Quality Standards in Asian Markets." Denver: ITA Publications, 2023.

3. Boyer, R.R., and Briggs, R.D. "The Use of β Titanium Alloys in the Aerospace Industry: Current Applications and Future Prospects." Journal of Materials Engineering and Performance, vol. 32, no. 5, 2023, pp. 2145-2162.

4. European Chemical Industry Council. "Corrosion Resistance Properties of Commercially Pure Titanium in Industrial Applications." Brussels: Cefic Technical Reports, 2023.

5. Lutjering, G., and Williams, J.C. "Titanium: Engineering Materials and Processes, Third Edition." Berlin: Springer-Verlag, 2024.

6. Chen, M., and Zhang, H. "Quality Assurance Systems in Chinese Non-Ferrous Metal Manufacturing: A Comparative Analysis with International Standards." Materials Science and Technology Review, vol. 18, no. 3, 2023, pp. 412-428.