- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How do you weld Pure Nickel Sheet?

2025-05-09 13:59:03

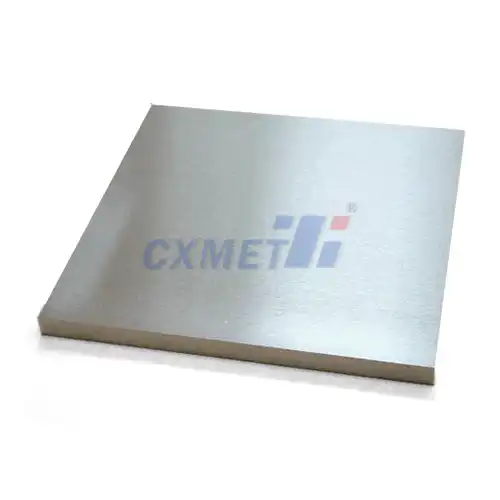

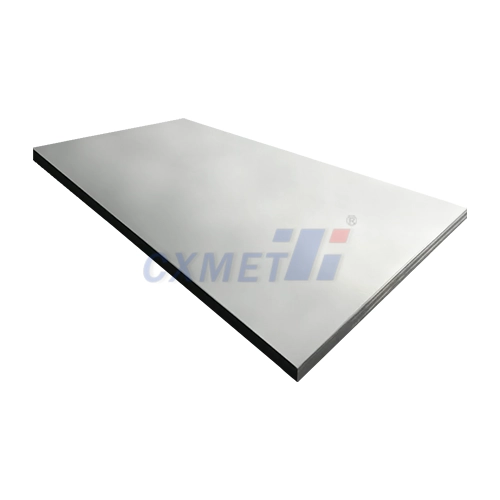

Welding pure nickel sheet is a specialized process that requires careful consideration of the material's unique properties. Pure nickel, known for its excellent corrosion resistance and high melting point, presents both challenges and opportunities in welding applications. This blog post will explore the techniques, considerations, and best practices for welding pure nickel sheet, providing valuable insights for engineers, fabricators, and welding professionals.

|

|

|

What are the best welding techniques for pure nickel sheet?

When it comes to welding pure nickel sheet, several techniques have proven effective, each with its own advantages and considerations. The choice of welding method depends on factors such as the thickness of the nickel sheet, the desired joint configuration, and the specific application requirements.

Gas Tungsten Arc Welding (GTAW), also known as TIG welding, is widely regarded as one of the best techniques for welding pure nickel sheet. This method offers excellent control over the weld pool and heat input, resulting in high-quality, clean welds. GTAW is particularly suitable for thin nickel sheets and applications requiring precise, aesthetically pleasing welds. When using GTAW for pure nickel, it's essential to use pure argon as the shielding gas to prevent oxidation and maintain weld integrity.

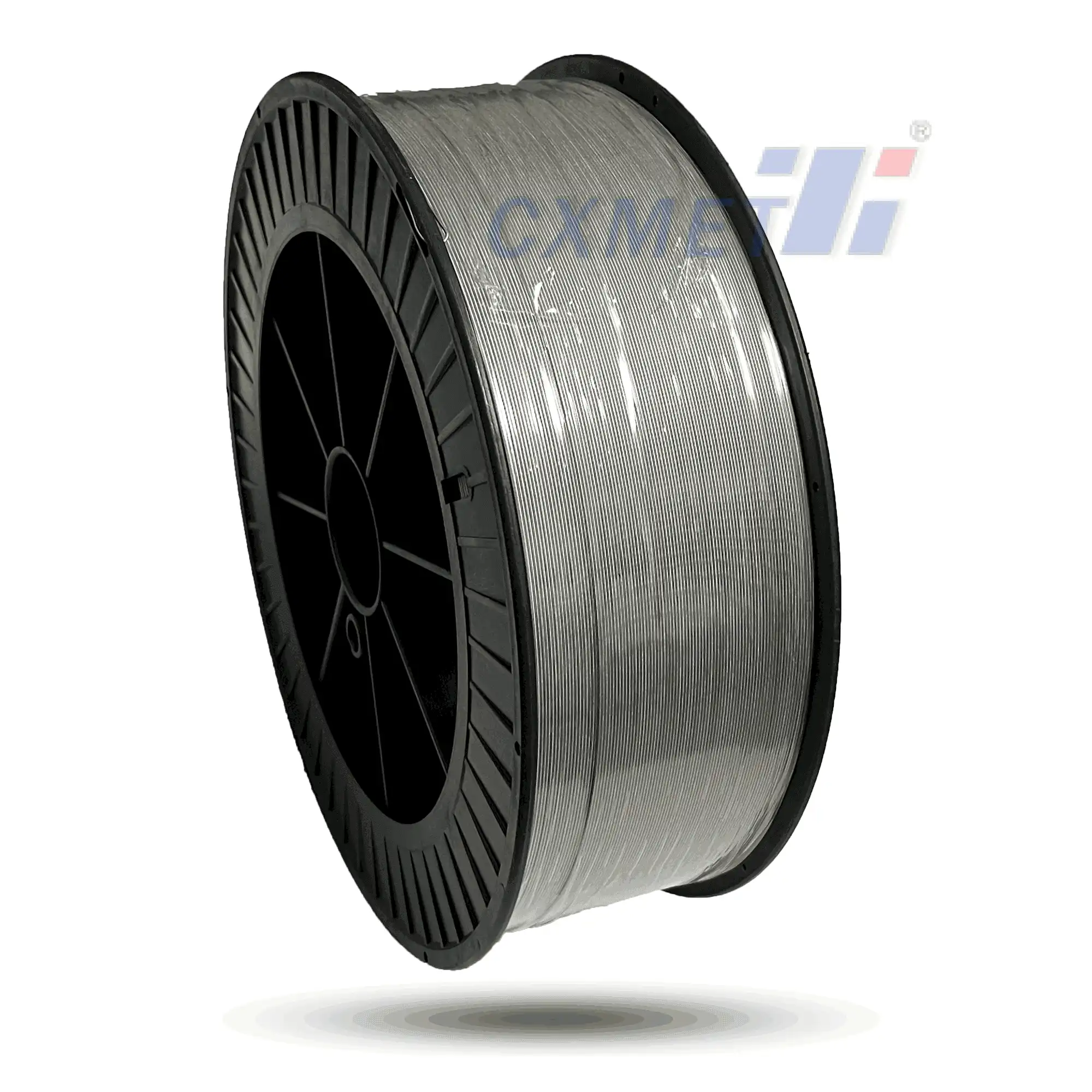

Gas Metal Arc Welding (GMAW), or MIG welding, is another viable option for welding pure nickel sheet, especially for thicker materials. This method offers higher deposition rates compared to GTAW, making it more efficient for larger projects. When using GMAW, it's crucial to select the appropriate filler metal composition to match the base material and ensure proper fusion.

Plasma Arc Welding (PAW) is a specialized technique that can be highly effective for welding pure nickel sheet. This method uses a constricted plasma arc, which provides high energy density and deep penetration. PAW is particularly useful for automated welding processes and can produce high-quality welds with minimal distortion.

Regardless of the chosen technique, proper preparation of the nickel sheet is crucial. This includes thorough cleaning to remove any contaminants, oxides, or oils that could compromise weld quality. Preheating the nickel sheet may also be necessary, especially for thicker materials, to prevent cracking and ensure proper fusion.

What are the challenges in welding pure nickel sheet?

Welding pure nickel sheet presents several unique challenges that welders and fabricators must address to achieve high-quality, reliable welds. Understanding these challenges is crucial for developing effective welding procedures and ensuring the integrity of the final product.

One of the primary challenges in welding pure nickel sheet is its high thermal conductivity. Nickel conducts heat rapidly, which can lead to excessive heat dissipation during welding. This characteristic makes it difficult to achieve proper fusion, especially in thicker materials. To overcome this challenge, welders often need to use higher heat inputs and slower travel speeds compared to welding other materials. Preheating the nickel sheet can also help maintain the required temperature for effective welding.

Another significant challenge is the susceptibility of pure nickel to oxidation at high temperatures. When exposed to oxygen during the welding process, nickel can form oxides that compromise weld quality and strength. To mitigate this issue, it's crucial to use proper shielding gas techniques, such as employing high-purity argon or argon-hydrogen mixtures. Additionally, maintaining a clean welding environment and thoroughly preparing the nickel sheet surface before welding can help minimize oxidation.

Pure nickel is also prone to hot cracking, particularly in the heat-affected zone (HAZ) adjacent to the weld. This phenomenon occurs due to the material's tendency to develop low-melting-point constituents at grain boundaries during welding. To prevent hot cracking, welders must carefully control heat input and cooling rates. Techniques such as using appropriate filler metals, employing pulsed welding currents, and implementing proper joint designs can help mitigate the risk of hot cracking.

The high coefficient of thermal expansion of pure nickel can lead to significant distortion during welding. As the material heats and cools, it undergoes substantial dimensional changes, which can result in warping or misalignment of the welded components. To address this challenge, welders may need to employ strategies such as using fixture designs, implementing balanced welding sequences, and applying intermittent welding techniques to minimize overall heat input and distortion.

|

|

|

How do you choose the right filler metal for welding pure nickel sheet?

Selecting the appropriate filler metal is a critical aspect of successfully welding pure nickel sheet. The right choice of filler metal can significantly impact the weld's strength, corrosion resistance, and overall performance. When welding pure nickel, it's generally recommended to use a filler metal that closely matches the composition of the base material to ensure compatibility and optimal mechanical properties.

For pure nickel sheet welding, the most commonly used filler metals are from the ERNi-1 classification, such as ERNi-1 (AWS A5.14) or FM61 (EN ISO 18274). These filler metals have a high nickel content, typically 99% or more, which closely matches the composition of pure nickel sheet. Using a matching filler metal helps maintain the corrosion resistance and mechanical properties of the base material in the weld zone.

In some cases, depending on the specific application requirements, welders may opt for slightly alloyed nickel filler metals. For example, ERNiCu-7 (AWS A5.14) or FM65 (EN ISO 18274) contains a small amount of copper, which can improve weldability and reduce the risk of hot cracking in certain situations. However, it's essential to consider the potential impact on corrosion resistance and mechanical properties when using alloyed filler metals.

When choosing a filler metal, it's crucial to consider the following factors:

- Composition of the base material: Ensure that the filler metal closely matches the pure nickel sheet's composition to maintain material properties.

- Service conditions: Consider the environment in which the welded component will be used, including temperature, corrosive media, and mechanical stresses.

- Welding process: Different welding techniques may require specific filler metal forms (e.g., wire, rod, or strip) or compositions.

- Joint design: The type of joint and its configuration may influence the choice of filler metal to ensure proper penetration and fusion.

- Regulatory requirements: Certain industries or applications may have specific standards or certifications that dictate the use of particular filler metals.

It's also important to note that in some cases, autogenous welding (welding without filler metal) may be suitable for thin pure nickel sheets. This technique can be particularly effective when using processes like GTAW or electron beam welding, as it eliminates the need for filler metal selection and can produce high-quality, seamless welds.

Proper storage and handling of filler metals are crucial to maintain their quality and prevent contamination. Nickel filler metals should be stored in a clean, dry environment and protected from moisture and other contaminants. Before use, it's essential to clean the filler metal surface to remove any oxides or impurities that could affect weld quality.

In conclusion, welding pure nickel sheet requires careful consideration of various factors, including welding techniques, material challenges, and filler metal selection. By understanding these aspects and implementing best practices, welders and fabricators can achieve high-quality, reliable welds in pure nickel sheet applications. Whether using GTAW, GMAW, or other specialized techniques, proper preparation, process control, and material selection are key to success in welding this valuable and versatile material.

At SHAANXI CXMET TECHNOLOGY CO., LTD, we take pride in our extensive product range, which caters to diverse customer needs. Our company is equipped with outstanding production and processing capabilities, ensuring the high quality and precision of our products. We are committed to innovation and continuously strive to develop new products, keeping us at the forefront of our industry. With leading technological development capabilities, we are able to adapt and evolve in a rapidly changing market. Furthermore, we offer customized solutions to meet the specific requirements of our clients. If you are interested in our products or wish to learn more about the intricate details of our offerings, please do not hesitate to contact us at sales@cxmet.com. Our team is always ready to assist you.

|

|

|

References

- American Welding Society. (2018). AWS A5.14/A5.14M:2018, Specification for Nickel and Nickel-Alloy Bare Welding Electrodes and Rods.

- Davis, J. R. (Ed.). (2000). Nickel, cobalt, and their alloys. ASM international.

- Kou, S. (2003). Welding metallurgy. John Wiley & Sons.

- Lippold, J. C., & Kotecki, D. J. (2005). Welding metallurgy and weldability of stainless steels. Wiley-Interscience.

- Special Metals Corporation. (2013). Welding Product Catalogue.

- The Lincoln Electric Company. (2020). The Procedure Handbook of Arc Welding, 15th Edition.

- TWI Ltd. (n.d.). Welding of Nickel and Nickel Alloys. Retrieved from https://www.twi-global.com/technical-knowledge/job-knowledge/welding-of-nickel-and-nickel-alloys-105

- Weman, K. (2011). Welding processes handbook. Elsevier.

- DuPont, J. N., Lippold, J. C., & Kiser, S. D. (2009). Welding metallurgy and weldability of nickel-base alloys. John Wiley & Sons.

- American Welding Society. (2015). AWS D10.18/D10.18M:2008, Guide for Welding Ferritic/Austenitic Duplex Stainless Steel Piping and Tubing.