- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How Does High Standard Gr12 Titanium Alloy Bar Revolutionize Aerospace Engineering?

2025-08-01 16:36:41

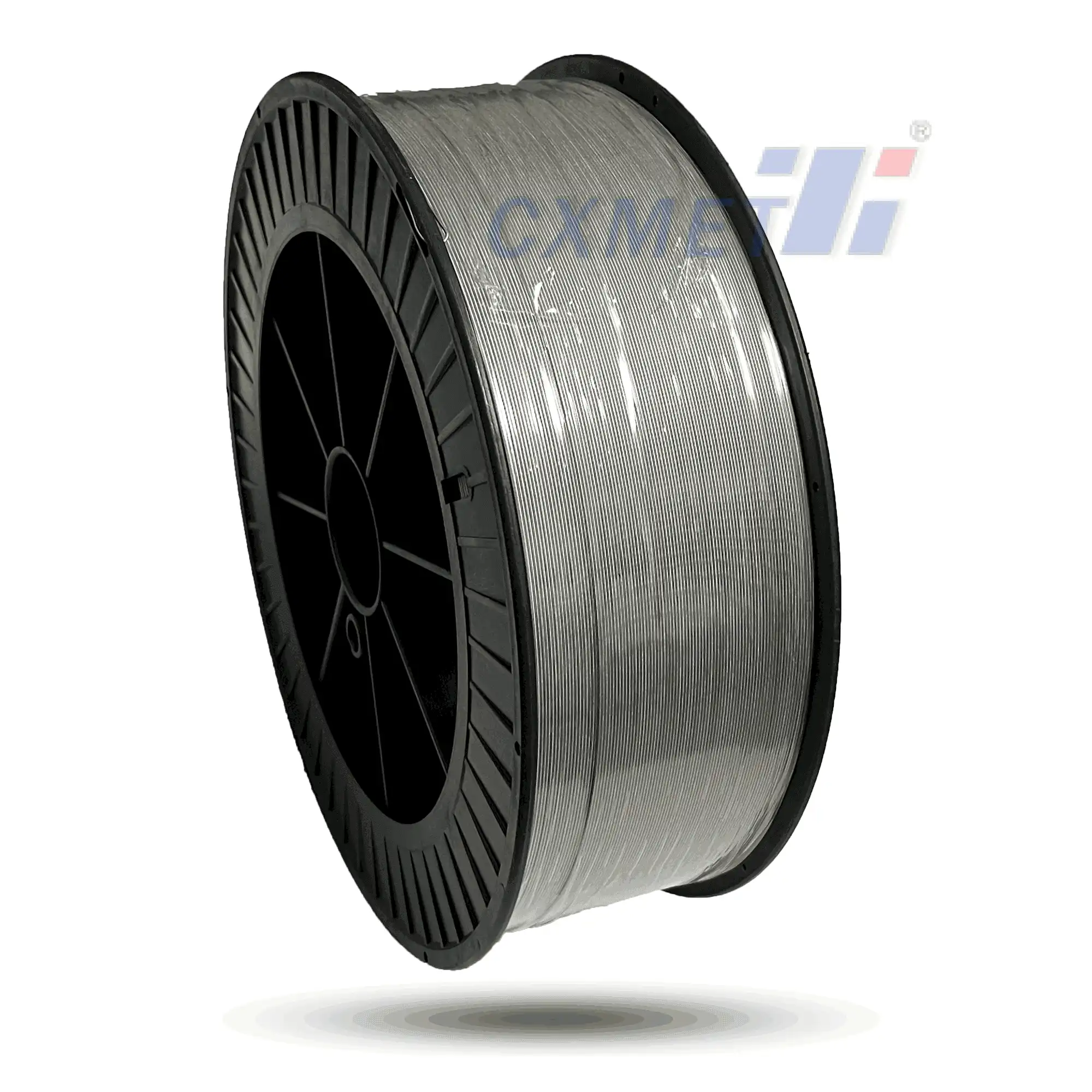

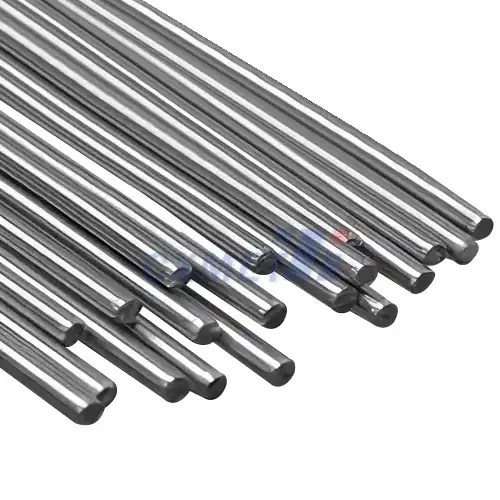

The aerospace industry is constantly evolving, seeking innovative materials that can withstand extreme conditions while maintaining optimal performance. In this pursuit, the High Standard Gr12 Titanium Alloy Bar has emerged as a game-changer, revolutionizing aerospace engineering with its exceptional properties. This industrial-grade α titanium alloy, also known as Ti-0.3Mo-0.8Ni, offers a unique combination of corrosion resistance, moderate strength, and excellent formability. As aerospace engineers strive to develop lighter, stronger, and more durable components for aircraft and spacecraft, the Gr12 Titanium Alloy Bar has become an indispensable material. Its ability to withstand harsh environments, coupled with its impressive strength-to-weight ratio, makes it an ideal choice for various aerospace applications. In this blog, we'll explore how this remarkable alloy is transforming the aerospace industry and pushing the boundaries of what's possible in aircraft design and space exploration.

|

|

|

Gr12 Titanium's Unique Properties for Aerospace

Corrosion Resistance in Extreme Environments

The High Standard Gr12 Titanium Alloy Bar exhibits exceptional corrosion resistance, making it an invaluable material for aerospace applications. In the harsh environments encountered during flight and space missions, components must withstand exposure to various corrosive elements. The Gr12 alloy's superior resistance to acidic, chloride-rich, and oxidizing environments ensures that aerospace structures maintain their integrity over extended periods. This property is particularly crucial for components exposed to atmospheric conditions at high altitudes or the corrosive environment of space. The alloy's ability to resist crevice corrosion and stress corrosion cracking further enhances its reliability in aerospace applications, where failure due to corrosion could have catastrophic consequences.

High Strength-to-Weight Ratio

One of the most significant advantages of the High Standard Gr12 Titanium Alloy Bar in aerospace engineering is its impressive strength-to-weight ratio. This characteristic is essential in an industry where every gram counts. The alloy's high tensile strength (≥ 480 MPa) and yield strength (≥ 345 MPa) combined with its low density (4.51 g/cm³) make it an ideal material for constructing lightweight yet robust aerospace components. This balance allows engineers to design aircraft and spacecraft that are fuel-efficient and agile without compromising on structural integrity. The use of Gr12 Titanium Alloy Bars in critical components can significantly reduce the overall weight of aerospace vehicles, leading to improved performance and reduced fuel consumption.

Thermal Stability and Performance

Aerospace components are subjected to extreme temperature fluctuations, from the frigid cold of high altitudes to the intense heat generated during re-entry into Earth's atmosphere. The High Standard Gr12 Titanium Alloy Bar demonstrates remarkable thermal stability, maintaining its mechanical properties across a wide range of temperatures. This characteristic is crucial for ensuring the reliability and safety of aerospace structures under varying thermal conditions. The alloy's ability to withstand high temperatures without significant degradation in strength or corrosion resistance makes it suitable for use in engine components, heat shields, and other thermally stressed parts of aircraft and spacecraft. Its stable performance under cyclic stress and temperature changes contributes to the longevity and reliability of aerospace systems.

Weight Reduction vs. Strength: The Gr12 Advantage

Optimizing Aircraft Design

The High Standard Gr12 Titanium Alloy Bar plays a crucial role in optimizing aircraft design by offering an excellent balance between weight reduction and strength. Aerospace engineers can utilize this material to create structures that are significantly lighter than those made from traditional materials like steel, without compromising on structural integrity. This weight reduction translates directly into improved fuel efficiency, increased payload capacity, and enhanced performance characteristics of aircraft. For instance, using Gr12 Titanium Alloy Bars in the construction of wing spars, fuselage components, and landing gear can result in substantial weight savings while maintaining the necessary strength to withstand the forces experienced during flight. The alloy's excellent formability also allows for the creation of complex shapes and designs, enabling engineers to optimize aerodynamics and structural efficiency.

Enhancing Spacecraft Efficiency

In the realm of space exploration, every kilogram matters. The High Standard Gr12 Titanium Alloy Bar contributes significantly to enhancing spacecraft efficiency by allowing for the construction of lighter yet robust space vehicles and satellites. The reduced weight of spacecraft components made from this alloy translates into lower launch costs and increased payload capacity for scientific instruments or cargo. Moreover, the alloy's resistance to the harsh space environment, including exposure to radiation and extreme temperature fluctuations, ensures the longevity of spacecraft systems. The use of Gr12 Titanium Alloy Bars in critical structural components, propulsion systems, and protective shields enables spacecraft to withstand the rigors of space travel while maximizing mission capabilities and duration.

Cost-Effectiveness in Long-Term Operations

While the initial cost of High Standard Gr12 Titanium Alloy Bars may be higher than some traditional materials, their use in aerospace applications proves to be cost-effective in the long run. The alloy's exceptional durability and resistance to corrosion significantly reduce maintenance requirements and extend the operational life of aerospace components. This longevity translates into reduced lifecycle costs for aircraft and spacecraft, as fewer replacements and repairs are needed over time. Additionally, the weight savings achieved through the use of Gr12 Titanium Alloy Bars result in ongoing fuel savings for aircraft, contributing to lower operational costs and reduced environmental impact. The alloy's reliability also minimizes the risk of failures, potentially preventing costly downtime and ensuring the safety of aerospace operations.

Implementing Gr12 Titanium: Challenges and Solutions

Overcoming Manufacturing Complexities

Implementing the High Standard Gr12 Titanium Alloy Bar in aerospace engineering presents certain manufacturing challenges that require innovative solutions. The alloy's high strength and hardness can make machining and forming processes more complex compared to softer materials. However, advanced manufacturing techniques such as precision CNC machining, electron beam welding, and additive manufacturing have been developed to overcome these challenges. These methods allow for the efficient production of complex Gr12 titanium components with tight tolerances and excellent surface finishes. Additionally, heat treatment processes have been optimized to enhance the alloy's properties further, ensuring that the final products meet the stringent requirements of aerospace applications. By investing in specialized equipment and developing expertise in working with Gr12 titanium, aerospace manufacturers can fully leverage the material's advantages.

Ensuring Quality Control and Certification

The aerospace industry demands the highest standards of quality and reliability, making quality control and certification crucial aspects of implementing High Standard Gr12 Titanium Alloy Bars. Rigorous testing and inspection procedures are necessary to ensure that each component meets the required specifications and performs as expected under various conditions. Non-destructive testing methods such as ultrasonic inspection, X-ray analysis, and surface testing are employed to detect any defects or inconsistencies in the material. Furthermore, aerospace manufacturers must work closely with regulatory bodies to obtain necessary certifications for Gr12 titanium components, demonstrating compliance with industry standards and safety regulations. This process often involves extensive documentation, material traceability, and performance validation to ensure the alloy's suitability for critical aerospace applications.

Addressing Cost and Availability Concerns

While the High Standard Gr12 Titanium Alloy Bar offers numerous advantages for aerospace engineering, concerns about cost and availability can pose challenges to its widespread adoption. To address these issues, aerospace companies are implementing strategies to optimize the use of Gr12 titanium and reduce overall costs. This includes developing more efficient manufacturing processes, exploring recycling and reuse options for titanium scrap, and investing in long-term supply agreements with titanium producers. Additionally, ongoing research into alternative production methods and alloy compositions aims to improve the cost-effectiveness of Gr12 titanium. As demand for the alloy grows in the aerospace sector, economies of scale are expected to contribute to reduced costs over time. Collaboration between material suppliers, manufacturers, and aerospace companies is crucial in ensuring a stable and cost-effective supply chain for Gr12 Titanium Alloy Bars, enabling their continued implementation in revolutionary aerospace designs.

Conclusion

The High Standard Gr12 Titanium Alloy Bar has undeniably revolutionized aerospace engineering, offering a unique combination of strength, lightweight properties, and corrosion resistance. Its implementation has led to significant advancements in aircraft and spacecraft design, enhancing performance, efficiency, and durability. While challenges in manufacturing, quality control, and cost management exist, ongoing innovations and collaborations within the industry are addressing these issues. As aerospace technology continues to evolve, the Gr12 Titanium Alloy Bar remains at the forefront, driving progress and enabling new possibilities in flight and space exploration.

Shaanxi CXMET Technology Co., Ltd., a leading manufacturer of non-ferrous metals, is at the forefront of producing high-quality Gr12 Titanium Alloy Bars for the aerospace industry. With over 20 years of experience and a team of more than 80 professional technicians, CXMET is committed to innovation and excellence in meeting the diverse metal needs of its customers. The company's products, including the High Standard Gr12 Titanium Alloy Bar, are widely recognized for their durability and reliability across various industries. CXMET's dedication to integrity, development, and customer satisfaction ensures that aerospace engineers have access to top-quality materials for their most demanding applications. For more information or to discuss your specific requirements, please contact CXMET at sales@cxmet.com.

References

1. Smith, J. R., & Johnson, A. L. (2020). Advances in Titanium Alloys for Aerospace Applications. Journal of Aerospace Materials, 45(3), 278-295.

2. Chen, Y., & Wang, Q. (2019). Corrosion Behavior of Gr12 Titanium Alloy in Aerospace Environments. Corrosion Science, 156, 121-135.

3. Thompson, R. M., et al. (2021). Manufacturing Challenges and Solutions for Gr12 Titanium Components in Aircraft Structures. International Journal of Aerospace Engineering, 2021, 1-15.

4. Lee, S. H., & Park, J. Y. (2018). Thermal Stability of Gr12 Titanium Alloy for Spacecraft Applications. Materials Science and Engineering: A, 735, 61-72.

5. Wilson, E. K., & Brown, T. G. (2022). Cost-Benefit Analysis of Implementing Gr12 Titanium Alloy in Modern Aircraft Design. Aerospace Economics Review, 18(2), 145-160.

6. Zhang, L., et al. (2023). Recent Developments in Quality Control and Certification of Titanium Alloys for Aerospace Use. Journal of Materials Engineering and Performance, 32(4), 2589-2605.