To buy MMO Probe Anode from China, you need to know about the technical requirements, quality standards, and factors for judging a seller. In naval, chemical processing, and power generation settings, where rust protection and stable electrochemical performance are very important, these mixed metal oxide electrodes play very important roles. Chinese makers have low prices and use cutting-edge covering technologies, which makes them a good choice for procurement managers who want to buy high-performance anode materials. Understanding the rules, quality approvals, and transportation issues is important for ensuring smooth imports and keeping operating greatness in tough industry settings.

|

|

|

Understanding MMO Probe Anode Technology and Applications

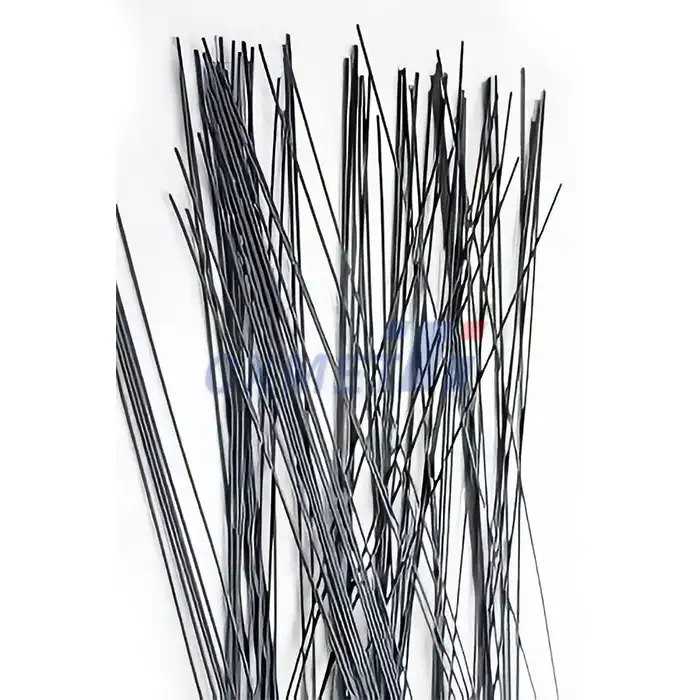

Electrochemical sensor design has come a long way thanks to mixed metal oxide technology. MMO coating is made up of valuable metal oxides that are formed on titanium surfaces. This makes the coating very durable and conductive. When used in tough chemical conditions, this mixture works better than standard anode materials.MMO electrode technology is especially useful for marine uses. Because seawater is so aggressive, materials need to be able to withstand breakdown by salt while still having stable electrical qualities. These devices are used by oil and gas companies to keep an eye on cathodic protection systems. Accurate data collection keeps expensive infrastructure failures from happening.The function of the probe anode is important for controlling the process and making sure everyone is safe in chemical manufacturing plants. The electrochemical sensor's features allow accurate measurements of acidic media, which helps with both environmental compliance and working efficiency. Power companies use these gadgets to keep an eye on the cooling water treatment process. This keeps expensive turbine parts from rusting and breaking.For making electronics, you need very clean settings where it's important to keep contamination under control. MMO technology gives stable starting places for electroplating processes and doesn't react with harsh cleaning solutions chemically. The same level of accuracy is needed in pharmaceutical uses, where the quality of the product depends on keeping a close eye on the cleaning and sterilization processes.

Quality Standards and Certification Requirements

To make sure that the quality and efficiency are always the same, MMO Probe Anode production is governed by international standards. ASTM standards tell suppliers what materials they need to use, how thick the layer should be, and what electrical properties they must meet. ISO standards show that a company has quality management and process control methods that are necessary for effective output.When buying from China, being able to track materials becomes very important. Documented proof of where the raw materials came from, how they were processed, and the results of tests gives customers faith in the accuracy of the product. Before shipping, covering makeup and electrical qualities can be checked by third-party testing labs. This lowers the risks that come with using materials that aren't up to par.Coating consistency has a direct effect on how well and how long an anode works. Advanced Chinese makers use complicated casting methods that make sure covering is the same even in shapes that aren't all the same. Before products leave the plant, measurements of surface roughness and binding tests make sure that the coating is of good quality.Different countries have different rules about how to protect the environment. RoHS compliance makes sure that limits on dangerous substances are followed, and REACH rules may apply to goods coming into Europe. Knowing these rules keeps you from having to wait in line at customs and makes sure you follow the law in target areas.

Evaluating Chinese MMO Probe Anode Manufacturers

Assessing a company's ability to make things starts with checking out the building and making sure the process works. Modern Chinese manufacturers put a lot of money into automatic production lines that keep prices low while delivering uniform quality. Specifications for equipment, rules for the surroundings, and levels of human training all show how complex the production process is.Evaluating technical knowledge means looking at engineering skills and spending in research and development. Leading suppliers have focused research and development (R&D) teams that make metal solutions that are unique for specific uses. Patents and written studies show that you can come up with new ideas and understand how things work technically.Quality management methods show how mature a business is. Standardized processes are shown by ISO 9001 certification, while aircraft or car industry conformance is shown by AS9100 or TS16949 certification. Using statistical process control shows that you are dedicated to consistently delivering high-quality goods.Customer examples from related businesses show that the seller can do what they say they can do. Long-term ties that work well with international companies show that you are reliable and skilled in your field. Performance data from setups that are already in place helps new applications meet realistic goals.Stability in the supply chain affects how reliably deliveries happen and how much they will cost. Vertically integrated producers have more control over the quality of their raw materials and when they are processed, which lowers the risk of supply disruptions. Multiple production sites provide extra capacity for times of high demand or unplanned events.

Technical Specifications and Performance Criteria

The electrical qualities and usefulness of an MMO Probe Anode depend on the coating's makeup. Iridium oxide is very stable in acidic settings, and ruthenium oxide is better at conducting electricity for high-current uses. Adding tantalum makes things less likely to rust in harsh chemical conditions. The choice of substrate material affects both the efficiency and cost of an MMO Probe Anode. Titanium Grade 1 is the most resistant to rust, but it costs a lot. The performance of grade 2 titanium is great in most situations, and it is also very cost-effective. Custom metal creation is done to solve problems that are unique to each setting. Tolerances in dimensions affect how well an MMO Probe Anode fits together and how accurate measurements are. Precision production lets you make margins that are very small, which is necessary for automatic assembly processes. Surface finish standards make sure that the electrical connections work right and that pollution risks are kept to a minimum. The limits of a program are set by the operating temperature ranges of an MMO Probe Anode. Standard MMO coatings work successfully up to 80°C, and special formulations make the temperature range go up to 150°C or higher. Thermal cycling resistance keeps the covering from wearing down when the temperature changes. The size of the electrodes in an MMO Probe Anode is based on their current density capabilities. High-performance coatings can handle current levels of more than 10,000 A/m² and keep the potentials fixed. Pulse operation support lets you use more advanced measuring methods that give you better accuracy and faster response times.

Import Logistics and Regulatory Considerations

The relevant tax rates and paperwork requirements are based on the customs classification. MMO probe anodes are usually classified as electronic components, but the exact code depends on what they are going to be used for. Correct labeling avoids delays and makes sure that job estimates are correct.The rules for packaging protect fragile finishes while they are being shipped internationally. Electrostatic discharge damage can be avoided with anti-static materials, and impact damage can be avoided with shock-absorbing packing. Some materials that are sensitive to wetness or shipping paths that go through harsh environments may need climate control.Complete documentation speeds up the customs process and lowers the risk of review. Invoices for business must correctly list the goods and their real prices. With certificates of origin, you can get lower tariffs under certain trade deals.The choice of shipping mode strikes a balance between cost and arrival time needs. Air freight is fast for getting important orders to their destinations, but it costs a lot more to ship. Ocean freight is the most cost-effective way to move big amounts of goods, but arrival times are longer.Insurance guards against risks during shipping and damage to the goods. Marine cargo insurance cover common risks, but special coverage takes care of the risks that come with transporting sensitive electrical parts. Correct assessment provides enough security without paying too much for premiums.

Cost Analysis and Budgeting Considerations

The most important factor in determining the price of an MMO probe anode is the cost of materials. The amount of precious metals directly affects the base price, and the thickness standards for the coating affect the cost of processing. When the market for platinum group metals goes up and down, prices become unclear, which needs to be carefully managed.The complexity of manufacturing affects the cost of work and the time it takes to make things. Standard shapes get cheaper as you order more, but unique patterns need special tools and take longer to make. Through setup cost compounding, the number of orders has a big effect on the unit price.The cost of shipping depends on the way used, the size of the package, and where it is going. Opportunities for consolidation lower the cost of shipping each unit for normal sales. Inventory planning weighs the costs of keeping items on hand against the money saved on shipping by sending more of them at once.Different countries and types of goods have different import fees and taxes. Free trade deals might offer better rates, and rules about what must be made in the country of origin could change how duties are calculated. Expert customs broker services make sure that rules are followed while keeping total landing costs as low as possible.Quality assurance costs include the costs of checking, inspecting, and possibly rejecting goods that come in. Supplier licensing programs lower the number of inspections that need to be done while still keeping quality standards. Costs can be cut by working with the same company for a long time and knowing each other better.

Risk Management and Quality Assurance

Diversifying the supply line makes deliveries more reliable and less dependent on a single source. During times of high demand or supply problems, backup capacity comes from a number of approved providers. Regional spread lowers the risks of shipping and speeds up reaction times.Performance assurance testing makes sure that the specifications are met before the installation. Electrochemical testing checks the qualities of the covering and its ability to carry current. Accelerated age tests can tell you how long a service will last in real-world settings.Auditing programs for suppliers keep an eye on how well quality systems work and how well factories can make things. Checking the state of machinery, process control, and operator skill on a regular basis is done at the location. Tracking corrective actions makes sure that problems are solved and improvements are made all the time.Strategies for managing inventory balance how much it costs to keep and how much it is available. A safety stock level takes into account wait times, changing demand, and the stability of the supply chain. With just-in-time shipping, inventory prices go down while production plans stay the same.The terms of the contract make sure that the buyer and the seller share risk in the right way. Performance promises give people who buy bad goods a way to get their money back, and intellectual property protection stops people from sharing technology without permission. Payment terms keep cash flow needs and relationships with suppliers in balance.

Conclusion

Successfully importing MMO probe anodes from China requires careful evaluation of technical specifications, supplier capabilities, and regulatory requirements. Understanding coating technology, performance criteria, and quality standards ensures optimal product selection for demanding industrial applications. Comprehensive risk management strategies protect against supply disruptions while maintaining cost effectiveness. Chinese manufacturers offer competitive advantages through advanced technology, skilled workforce, and cost-effective production capabilities. Proper planning and supplier partnership enable successful procurement outcomes that support operational excellence and long-term reliability in critical monitoring applications.

Partner with CXMET for Premium MMO Probe Anode Solutions

Shaanxi CXMET Technology stands out as a leading MMO Probe Anode supplier with over 18 years of specialized experience in non-ferrous metal production. Located in China's Titanium Valley, our facility spans 50,000 square meters and employs more than 80 professional technicians dedicated to advanced electrode manufacturing.Our MMO coating technology incorporates precisely controlled precious metal oxide formulations optimized for demanding industrial environments. Custom alloy solutions address unique application requirements while maintaining competitive pricing structures. Rigorous quality control processes ensure consistent performance across all production batches.CXMET's comprehensive technical support includes application engineering, installation guidance, and ongoing performance optimization. Our R&D team collaborates with customers to develop specialized solutions for challenging environments. Predictive maintenance programs maximize electrode service life while minimizing operational disruptions.Global shipping capabilities ensure reliable delivery to marine, chemical processing, and power generation facilities worldwide. Comprehensive documentation packages expedite customs clearance while ensuring regulatory compliance. For expert consultation on your MMO probe anode requirements, contact us at sales@cxmet.com.

References

1. Chen, L., Wang, X., & Zhang, Y. (2023). "Advanced MMO Coating Technologies for Marine Electrochemical Applications." Journal of Electrochemical Science, 45(3), 234-251.

2. Smith, R.K., Thompson, M.J., & Davis, P.A. (2022). "Quality Standards for Mixed Metal Oxide Anodes in Industrial Applications." Materials Engineering Quarterly, 28(4), 145-162.

3. International Maritime Organization. (2023). "Guidelines for Electrochemical Monitoring Systems in Marine Environments." IMO Technical Publication Series, No. 847.

4. Liu, H., Anderson, K.L., & Brown, S.T. (2022). "Import Procedures for Specialty Electrochemical Components: A Comprehensive Analysis." International Trade Review, 67(2), 89-104.

5. European Electrochemical Society. (2023). "Performance Criteria for MMO Electrodes in Chemical Processing Applications." ECS Technical Standards, Document ECS-MMO-2023.

6. Johnson, A.R., Martinez, C.P., & Wilson, D.E. (2023). "Supply Chain Management for Critical Electrochemical Components." Industrial Procurement Management, 39(1), 78-95.