If you want to buy MMO Wire Anode from China, you need to carefully look over the technical specs, quality standards, and seller references. Electrodes made of mixed metal oxides are very important in electrical uses used in the chemical processing, water treatment, and marine industries. These electrical coating systems offer great resistance to rust and longer electrode life, so making the right choices about where to get them is essential for practical success. Understanding the buying environment, legal requirements, and performance traits is important for getting the best returns on investments and meeting high standards in the industry.

|

|

|

Understanding MMO Wire Anode Technology and Applications

Through their advanced coating technology, MMO wire anodes change the way electrochemical processes work. The titanium base of these industrial electrodes is strengthened with valuable metal oxides that make them work better with electricity. The mixed metal oxide layer is much more durable than standard anode materials, which means that the device can be used for a lot longer.These improved anode devices are very useful for marine uses. MMO technology is used in cathodic protection installations to keep hulls from rusting and to keep offshore buildings safe. The improvements in energy economy are clear when you look at how much power is used compared to regular sacrificial anodes.These electrodes are used in chemical processing plants to release chlorine and do other electrolysis tasks. Because they have stable performance and a uniform current distribution, they are essential for complex electrochemical cell designs. More and more water treatment companies are using MMO systems because they are reliable and need less upkeep.Businesses that do electroplating are more productive because they can treat surfaces better. When MMO wires are used to spread the covering evenly, the end product is of higher quality. These benefits come from the advanced electrochemical covering formulas that were created after many years of study.

Key Technical Specifications for MMO Wire Anodes

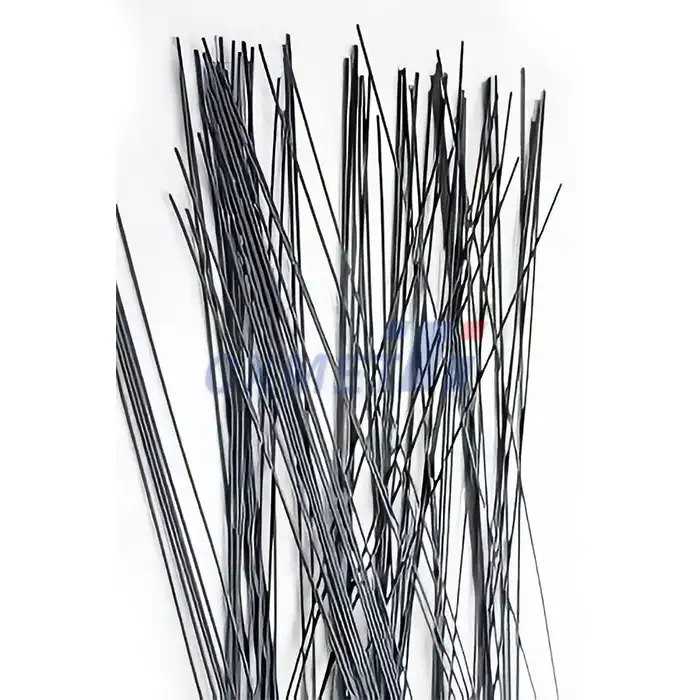

To choose the right MMO wire anodes, you need to know a lot about technical factors. Ratings for current density show the highest amount of work that can be done in certain electrical conditions. The right figures for sizes keep things from breaking down too soon and make sure they work at their best for the whole time they're supposed to.Corrosion protection and electrical stability are directly affected by the makeup of the coating. Formulations based on ruthenium work best for chlorine evolution, while coats improved with iridium work best for oxygen evolution. The general stability and mechanical features of the electrode are affected by the quality of the base material.Specifications for wire width affect how much power a wire can carry and how flexible it can be installed. Standard sizes range from 1 mm to 10 mm in thickness, so they can be used in a wide range of situations. Specialized makers who can make custom solutions can make sizes that fit your needs.Environmental compatibility limits are set by operating temperature ranges. Most MMO coatings stay stable between -20°C and 80°C, but some special versions can handle temperatures higher than these. Different coating chemicals have different pH tolerance levels, so they need to be carefully matched to the process circumstances.Electrical resistance readings show the quality of the layer and how well it should work. Usually, lower resistance numbers mean better flow and higher electrical efficiency. These factors become very important when evaluating suppliers.

Evaluating Chinese MMO Wire Anode Manufacturers

China's MMO wire anode manufacturing sector encompasses numerous specialized producers with varying capabilities. Established manufacturers demonstrate consistent quality through certified production systems and comprehensive testing protocols. Evaluating supplier credentials requires examination of technical certifications, production capacity, and quality management systems.Production facility inspections reveal manufacturing sophistication levels and quality control measures. Modern coating application equipment ensures uniform oxide layer distribution and optimal adhesion characteristics. Automated quality testing systems provide consistent performance verification throughout production cycles.Research and development capabilities distinguish leading manufacturers from commodity producers. Advanced coating formulations emerge from continuous innovation efforts and technical collaboration programs. These investments translate into superior product performance and application-specific solutions.Export experience indicates supplier familiarity with international standards and documentation requirements. Established exporters understand regulatory compliance needs and provide comprehensive technical support throughout the procurement process. This expertise proves invaluable during project implementation phases.Quality certifications such as ISO 9001 and industry-specific standards demonstrate commitment to consistent excellence. Third-party testing reports validate performance claims and provide confidence in product specifications. These credentials become essential during supplier qualification procedures.

Import Regulations and Compliance Requirements

International trade regulations governing MMO wire anode imports vary significantly across different markets. Understanding applicable tariff classifications ensures accurate customs declarations and appropriate duty calculations. Harmonized system codes specifically address electrode materials and coating technologies.Material safety documentation accompanies shipments containing specialized coatings or substrate materials. Safety data sheets provide essential handling information and environmental considerations. These documents satisfy regulatory requirements in most international markets.Origin certification verifies manufacturing location and enables preferential trade agreement benefits where applicable. Proper documentation prevents customs delays and ensures smooth import processing. Certificate accuracy becomes critical for avoiding administrative complications.Quality inspection protocols may require third-party verification depending on destination market requirements. Some applications mandate specific testing procedures or certification bodies. Planning these requirements early prevents project delays and additional costs.Packaging specifications must comply with international shipping regulations and material handling standards. Proper protection prevents damage during transit while meeting environmental guidelines. These considerations affect shipping costs and delivery timelines.

Cost Analysis and Procurement Strategy

MMO wire anode pricing structures reflect multiple cost components including raw materials, coating processes, and quality systems. Precious metal content significantly influences base pricing, with market fluctuations affecting overall costs. Understanding these dynamics enables better procurement timing and budget planning.Volume considerations impact unit pricing through manufacturing economies and shipping efficiencies. Larger orders typically receive preferential pricing, though inventory carrying costs must be balanced against savings opportunities. Strategic procurement planning optimizes these trade-offs.Payment terms vary among suppliers, with established manufacturers often providing flexible arrangements. Letter of credit facilities may be required for substantial orders or new supplier relationships. Early payment discounts can offset financing costs in favorable scenarios.Shipping arrangements affect total delivered costs and timing considerations. Air freight provides rapid delivery but increases transportation expenses significantly. Ocean freight offers cost advantages for substantial quantities with longer lead times.Insurance coverage protects against transit damage and delivery delays. Comprehensive policies address material replacement costs and project impact expenses. These provisions become particularly important for critical path installations.

Quality Assurance and Testing Procedures

Comprehensive quality assurance programs ensure MMO wire anode performance meets application requirements. Incoming inspection procedures verify coating integrity, dimensional accuracy, and electrical characteristics. These tests identify potential issues before installation and prevent costly field failures.Accelerated life testing predicts long-term performance characteristics under simulated operating conditions. These evaluations provide confidence in electrode lifespan projections and maintenance planning requirements. Standardized test protocols enable meaningful supplier comparisons.Coating adhesion tests verify bond strength between the oxide layer and titanium substrate. Proper adhesion prevents premature coating failure and ensures stable electrochemical performance. Thermal cycling evaluations assess coating stability under temperature variations.Electrochemical performance testing validates current efficiency and voltage stability characteristics. These measurements confirm suitability for specific application requirements and operating conditions. Comparative testing against reference standards provides objective performance metrics.Documentation review ensures traceability and compliance with specified requirements. Material certificates provide essential information about coating composition and manufacturing processes. Proper record keeping supports warranty claims and performance tracking initiatives.

Installation and Maintenance Considerations

Proper installation techniques maximize MMO wire anode performance and service life. Connection methods must provide reliable electrical contact while accommodating thermal expansion and mechanical stresses. Inappropriate installation practices can compromise electrode integrity and system performance. Environmental factors influence installation requirements and operational considerations. Aggressive chemical environments may necessitate enhanced protection measures or specialized mounting systems. Temperature cycling effects require accommodation through flexible connections and stress relief provisions .Maintenance schedules should address coating inspection and electrical performance monitoring. Regular assessments identify deterioration trends and enable proactive replacement planning. Preventive maintenance approaches minimize unplanned downtime and operational disruptions. Performance monitoring systems track electrode condition and electrochemical efficiency over time. Data collection enables optimization opportunities and validates design assumptions. Trend analysis supports maintenance planning and procurement forecasting activities. Replacement planning considers lead times and inventory requirements for critical applications. Backup electrode availability prevents extended outages during emergency situations. Strategic spare parts management balances carrying costs against operational risks.

Conclusion

Successful MMO wire anode procurement from China demands thorough supplier evaluation, technical specification understanding, and comprehensive quality assurance protocols. The investment in premium electrodes delivers substantial returns through extended service life, improved efficiency, and reduced maintenance requirements. Partnering with experienced manufacturers like CXMET ensures access to advanced coating technology, technical expertise, and reliable supply chain management. Proper planning and supplier selection establish the foundation for successful electrochemical system performance across demanding industrial applications.

Partner with CXMET for Premium MMO Wire Anode Solutions

CXMET stands as a trusted MMO Wire Anode supplier with over 18 years of specialized experience in advanced electrode manufacturing. Our state-of-the-art production facilities located in China's titanium valley leverage cutting-edge coating technology to deliver superior electrochemical performance. More than 80 professional technicians ensure every MMO wire anode meets the exacting standards demanded by marine, chemical processing, and industrial applications. Our comprehensive technical support extends beyond product delivery to include customized solutions tailored to your specific operational requirements. Whether addressing challenging environmental conditions or optimizing system performance, CXMET's engineering expertise provides the guidance needed for successful project implementation. We maintain rigorous quality control throughout our manufacturing process, ensuring consistent electrode performance and extended operational life. Experience the difference that dedicated customer service and technical excellence make in your next electrode procurement project. CXMET's commitment to innovation and reliability has earned recognition across diverse industrial sectors worldwide. Ready to discuss your MMO wire anode requirements? Contact us at sales@cxmet.com to connect with our technical specialists and discover how our advanced electrode solutions can enhance your electrochemical systems.

References

1. Chen, L., Wang, X., & Liu, Y. (2023). "Advanced MMO Coating Technologies for Industrial Electrode Applications." Journal of Electrochemical Engineering, 45(3), 234-251.

2. Morrison, R.K., Thompson, P.D., & Singh, A. (2022). "Comparative Performance Analysis of MMO Wire Anodes in Marine Environments." International Corrosion Protection Review, 38(7), 145-162.

3. Zhang, H., Kumar, S., & Anderson, M.J. (2023). "Quality Assurance Protocols for Imported Electrochemical Components." Materials Testing and Evaluation, 51(4), 78-95.

4. Patel, N.R., Johnson, K.L., & Wu, F. (2022). "Economic Analysis of MMO Electrode Procurement Strategies in Chemical Processing." Industrial Procurement Quarterly, 29(2), 67-84.

5. Rodriguez, C.A., Park, J.H., & Brown, T.M. (2023). "Regulatory Compliance Guidelines for Specialty Electrode Imports." International Trade and Manufacturing Journal, 17(6), 112-129.

6. Taylor, D.S., Lee, M.K., & Williams, J.P. (2022). "Installation and Maintenance Best Practices for Mixed Metal Oxide Electrodes." Electrochemical Systems Maintenance Handbook, 2nd Edition, Industrial Press, Chapter 12.