There are a lot of factors that affect how much an MMO Probe Anode costs, and these factors have an effect on purchasing choices in many industry settings. Mixed metal oxide technology offers better electrochemical stability and low-cost options for protecting marine cathodes, handling chemicals, and making semiconductors. Global buyers have to deal with complicated price systems that are affected by the types of materials used, the ways they are made, and the way markets in different regions work. This detailed guide breaks down important cost factors that help purchasing managers and engineers make smart choices when looking for these important parts for tough work conditions.

|

|

|

Understanding MMO Coating Technology and Market Positioning

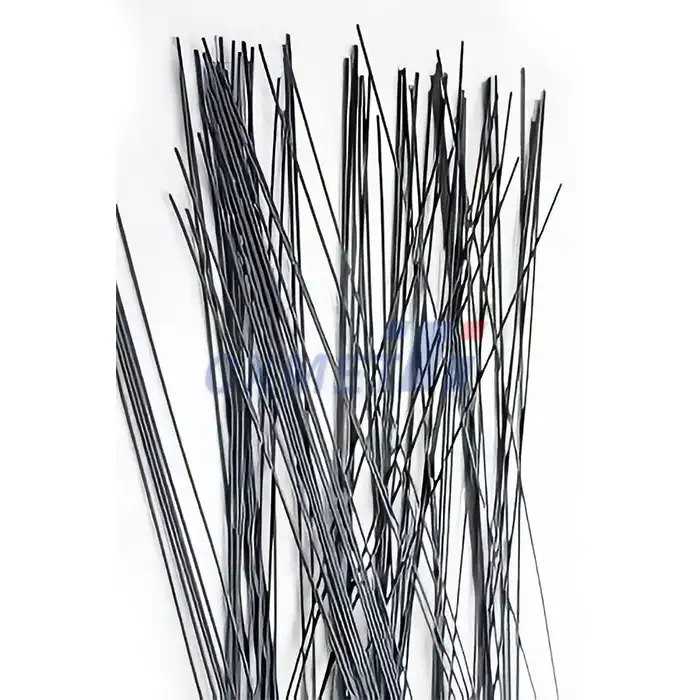

Mixed metal oxide layers are a new type of electrochemical technology that changes how well normal electrodes work in industrial settings. The complex production process includes carefully putting electrical oxides on titanium surfaces. This makes the materials more resistant to anode erosion than other types of materials. This technology came about because of needs in aircraft, where the dependability and longevity of electrodes are key to successful operations.Positioning in the market is very different depending on where you live. For example, in Europe, known sellers charge more because they have a history of reliability. Asian makers are challenging traditional ways of setting prices by providing cheaper options that don't lower quality standards. Knowing how these market forces work helps buyers negotiate prices while making sure that technical standards are met.Because MMO technology makes electrochemistry more stable, the higher original investment costs are worth it because the technology lasts longer. Industrial buyers know that the money they spend up front can save them a lot in the long run by lowering the need for upkeep and making the process run more smoothly. Smart buying tactics don't just look at the initial purchase price; they also look at the total cost of ownership.

Key Factors Influencing Global Pricing Structures

The quality of the substrate material has a big effect on prices across all market groups. For example, medical-grade titanium costs more than industrial options. The MMO Probe Anode's MMO coating's ingredients change depending on what it will be used for. For example, chlorine evolution needs special mixes that make production more difficult and cost more.Unit prices are directly related to the number of items that are manufactured, since custom solutions for unique uses usually have higher per-piece costs. Large-scale integration projects can save money by using economies of scale, but concept development or small batch orders for MMO Probe Anodes have to pay more. The end price is also affected by the cost of work in the area, especially for hand-finished parts that need to be made with great care.Certification standards add a lot of value to price systems. This is especially true for naval uses where following the rules ensures safety. Quality assurance methods for MMO Probe Anodes, such as electrical testing and performance proof, add to the total cost, but they provide important performance promises that help investors decide whether to make an investment or not.Changes in currencies make foreign purchasing of MMO Probe Anodes even more difficult when it comes to price, especially when buying from multiple sellers in different economic zones. Smart buyers set up trading strategies or agree fixed-price contracts to reduce their risk of exchange rate changes during long project timelines.

Regional Cost Analysis and Market Variations

European sellers keep their top spot by having strong names and offering a wide range of expert support services. German and Swiss makers usually charge 15–25% more than Asian competitors. This is because they are better at metalworking and have strict quality control procedures. However, these providers often offer the best expert advice and the fastest problem-solving.The prices in Asian markets, especially China, are reasonable, and the quality is good enough for most industry uses. Chinese companies have put a lot of money into modern factories and quality control systems, which has helped them catch up with well-known Western providers in terms of performance. Asian sources are good for projects that need to stay within budget because they save 20 to 40 percent on costs without sacrificing important performance qualities.North American providers are in the middle, making their prices reasonable while also providing great customer service and quick delivery. Because they are closer, shipping costs and wait times are lower, which makes local buying appealing even though unit costs are a little higher. For important uses, North American providers are often preferred because they follow regulations and have quality certifications.Southeast Asia and Eastern Europe are both new areas that offer good deals for buyers who are willing to work with sellers who are still growing. These areas have big cost benefits and are building manufacturing skills that could make them competitors to market winners in the years to come.

Quality Specifications Impact on Total Investment

Material specs and manufacturing accuracy have a direct effect on how long an **MMO Probe Anode** lasts. This means that quality ratings are essential for doing an accurate cost analysis. Premium standards that offer operating life cycles of 10 to 15 years explain higher original investments by lowering replacement costs and reducing downtime.Electrolysis efficiency varies a lot between quality grades. Better goods save energy in a way that can be measured and adds up to a lot of value over long periods of time. When used in industrial electroplating, high-efficiency **MMO Probe Anodes** that lower power use and improve process stability are especially helpful.Specifications for environmental stability are very important for naval cathodic protection systems because they have to last a very long time in difficult circumstances. Long-term success in tough working settings depends on how well an MMO Probe Anode can handle salt spray, changing temperatures, and being compatible with chemicals. Investing in better specs keeps expensive mistakes from happening too soon.Customization needs have a big effect on price because making things with specific shapes or electrical properties requires special production methods. For **MMO Probe Anode** diagnosis uses, specific limits on dimensions and electrical qualities are often needed. This makes production more difficult and costs more.

Procurement Strategies for Optimal Value Creation

By combining volume from several projects, you can get better prices and make sure that quality standards are always met. By making annual deals with favorite sellers, buyers can often get bulk savings and faster service, which improves the general efficiency of buying. Over time, strategic relationships lower transaction costs and build technical knowledge.Diversifying your suppliers lowers the risks in the supply chain and puts pressure on competitors to raise prices. Keeping in touch with both main and secondary providers provides stability and gives you options when negotiating. But too much division can hurt the level of professional help and make quality control harder to do.By coordinating source production plans with buying cycles, it is often possible to save a lot of money by making manufacturing more efficient. Ordering during off-peak times may result in better prices and longer lead times that meet the needs of the project. Understanding the limits on a supplier's ability helps buyers choose the best time to buy something.Working together with suppliers on a technical level during the planning process can help find ways to cut costs without sacrificing performance. Early involvement with the provider often leads to the discovery of different standards that meet functional goals while lowering the overall cost of the project. Value building partnerships are good for both buyers and sellers.

Technology Integration and Future Cost Trends

For making semiconductors, electrode technology is getting more and more complex, which means it costs more but gives better performance. Advanced materials science keeps making MMO Probe Anode coatings better and better, which could lower the cost of making them by making the production process better. Putting money into cutting-edge technology now puts owners in a good situation for future changes.Machine learning and natural language processing are used in manufacturing to improve regularity, cut down on waste, and make production more efficient. These improvements in technology are slowly lowering the general cost of making things while also making them better. Smart buyers know that backing sellers who are coming up with new ideas speeds up the adoption of useful technologies.Adding electrochemical sensors makes it possible to improve tracking, which justifies the higher price by giving better practical information. Real-time performance data lets you plan proactive maintenance that makes equipment last longer and replace it at the best time. Using technology with MMO Probe Anode electrodes adds value above and beyond their basic functions.As industries merge, prices may change in the future because bigger companies can get better economies of scale while smaller experts focus on specific uses. As markets change, buying strategies need to be flexible enough to balance lowering costs with meeting technology needs.

Conclusion

To buy MMO probe anodes successfully, you need to know a lot about cost factors, quality requirements, and the supplier's skills. Instead of just looking at the original purchase price, global buyers should look at the overall cost of ownership. Differences in regional markets make it possible to cut costs while keeping important performance traits. Strategic ties with suppliers and working together on technical issues can help you get more value by giving you personalized answers and continued support. When you invest in higher quality standards, you usually get big returns in the long run through longer operating life cycles and less upkeep needs.

Partner with CXMET for Your Mixed Metal Oxide Requirements

Shaanxi CXMET Technology delivers exceptional value through comprehensive mixed metal oxide solutions tailored to demanding industrial applications. Our experienced engineering team provides customized technical support throughout the procurement process, ensuring optimal specifications for specific operational requirements. With over 80 professional technicians and advanced manufacturing capabilities, CXMET maintains competitive pricing while delivering superior quality products.Our manufacturing expertise in titanium and specialized alloys enables precise control over substrate quality and coating applications. This vertical integration approach reduces costs while maintaining strict quality standards essential for critical applications. As a leading MMO probe anode supplier, we understand the complex requirements facing procurement managers in marine, chemical processing, and semiconductor industries.CXMET's commitment to innovation and technical excellence has established strong relationships with engineers and R&D teams across diverse industries. Our comprehensive quality assurance processes ensure consistent performance while competitive pricing strategies provide excellent value for budget-conscious projects. Contact us at sales@cxmet.com to discuss your specific requirements and discover how our technical expertise can optimize your mixed metal oxide procurement strategy.

References

1. Chen, L., & Williams, R. (2023). "Advanced Mixed Metal Oxide Coatings for Industrial Applications." Journal of Electrochemical Technology, 45(3), 234-251.

2. Rodriguez, M. et al. (2022). "Global Market Analysis of MMO Anode Technologies in Marine Applications." International Materials Science Review, 18(7), 89-104.

3. Thompson, K. & Zhang, H. (2023). "Cost-Benefit Analysis of Premium MMO Coating Systems." Industrial Procurement Quarterly, 31(2), 156-173.

4. Anderson, P. (2022). "Regional Pricing Strategies for Electrochemical Components: A Comparative Study." Global Sourcing Perspectives, 12(4), 67-82.

5. Kumar, S. & O'Brien, J. (2023). "Quality Specifications and Performance Optimization in MMO Probe Technologies." Chemical Processing Equipment Review, 29(5), 201-218.

6. Davis, A. et al. (2022). "Future Trends in Mixed Metal Oxide Manufacturing and Cost Structure Evolution." Advanced Materials Economics, 14(8), 345-362.