When selecting between MMO Probe Anode and Graphite Anode systems, understanding their unique characteristics becomes crucial for optimal performance. MMO (Mixed Metal Oxide) probe anodes offer superior durability and corrosion resistance, making them ideal for harsh industrial environments. Graphite anodes provide cost-effective solutions with excellent conductivity but have shorter operational lifespans. The choice depends on your specific application requirements, operating conditions, and long-term performance expectations.

|

|

|

Understanding MMO Probe Anode Technology

MMO coating technology revolutionizes electrochemical applications through advanced material engineering. These probe electrodes feature titanium substrates with precisely applied mixed metal oxide layers. The anode material combines ruthenium, iridium, and other precious metals to create exceptional performance characteristics. The electrochemical sensor capabilities of MMO systems excel in demanding industrial environments. Signal processing becomes more reliable due to consistent electrical properties throughout the electrode lifespan. MMO anode durability stems from the stable oxide coating that resists dissolution during operation.

Key advantages include:

- Extended operational lifespan exceeding 15 years in typical applications

- Consistent voltage output maintaining ±2% stability

- Operating temperature range from -40°C to 80°C

- pH tolerance spanning 1-14 without degradation

- Current density capabilities up to 5000 A/m²

If you need long-term reliability in corrosive environments, MMO probe anodes prove more suitable than traditional alternatives.

Graphite Anode Characteristics and Applications

Graphite anodes deliver reliable performance through crystalline carbon structure properties. These electrodes provide excellent electrical conductivity while maintaining relatively low material costs. Electrolysis efficiency reaches optimal levels due to graphite's natural electrochemical properties. The material exhibits consistent behavior across various pH ranges and temperature conditions. Electrochemical measurement accuracy remains stable during initial operational periods. However, gradual consumption occurs through oxidation processes during extended use.

Performance specifications include:

- Electrical resistivity: 8-15 μΩ·m

- Operating current density: up to 1000 A/m²

- Temperature tolerance: -20°C to 60°C

- Initial voltage stability: ±5%

- Expected lifespan: 2-5 years, depending on conditions

If you need cost-effective solutions for moderate-duty applications, graphite anodes offer practical advantages over premium alternatives.

Performance Comparison: Durability and Lifespan

MMO Probe Anode lifespan significantly exceeds graphite alternatives through superior corrosion resistance mechanisms. Test data from industrial installations demonstrates remarkable longevity differences between these anode materials.

Comparative analysis reveals substantial performance variations:

| Parameter | MMO Probe Anode | Graphite Anode |

|---|---|---|

| Average Lifespan | 15-20 years | 2-5 years |

| Corrosion Rate | 0.1 mg/A·h | 50-100 mg/A·h |

| Voltage Stability | ±2% | ±5-10% |

| Maintenance Frequency | Annual inspection | Quarterly replacement |

Real-world testing in seawater applications shows MMO systems maintaining 98% efficiency after 10 years. Graphite electrodes typically require replacement every 18-24 months under similar conditions. The anode performance data comes from marine protection installations across multiple geographic locations. If you need minimal maintenance schedules and extended operational periods, MMO technology provides superior value despite higher initial investment costs.

Cost Analysis: Initial Investment vs Long-term Value

Economic considerations play a crucial role in anode material selection processes. Initial procurement costs favor graphite systems, while total ownership expenses often favor MMO alternatives. Feature recognition of cost-benefit relationships requires comprehensive analysis beyond purchase prices.

Investment comparison breakdown:

MMO Probe Anode Costs:

- Initial investment: 300-500% higher than graphite

- Installation complexity: Standard procedures

- Maintenance expenses: 70% lower annually

- Replacement frequency: Every 15-20 years

- Downtime costs: Minimal due to reliability

Graphite Anode Economics:

- Purchase price: Most economical option

- Installation requirements: Simple procedures

- Regular replacement costs: Every 2-5 years

- Maintenance overhead: Frequent monitoring needed

- Operational disruptions: Higher due to replacements

Lifecycle cost analysis over 20 years shows MMO systems delivering 40-60% savings compared to graphite alternatives. This calculation includes material costs, labor expenses, and productivity losses from maintenance activities. If you need predictable operational budgets and reduced maintenance overhead, MMO probe anodes justify their premium pricing through long-term value creation.

Application-Specific Considerations

Different industries require specific anode material characteristics based on operational demands. Text mining of industry specifications reveals distinct preferences across various sectors. Machine learning analysis of performance data helps optimize material selection for specific applications. Marine Industry Applications:

Cathodic protection systems demand exceptional seawater corrosion resistance. MMO probe design excels in offshore platforms, ship hulls, and port infrastructure. The electrochemical measurement precision remains stable despite harsh saltwater conditions. Chemical Processing Environments:

Aggressive chemical exposure requires superior material stability. MMO coating withstands concentrated acids, bases, and organic solvents. Graphite electrodes may dissolve rapidly in oxidizing environments, limiting their applicability. Oil and Gas Operations:

Pipeline protection systems operate in remote locations where reliability becomes paramount. Natural language processing of maintenance records shows MMO systems reducing service calls by 80% compared to graphite alternatives. Water Treatment Facilities:

Municipal and industrial water systems benefit from consistent electrochemical performance. Data extraction from treatment plants indicates MMO anodes maintain effectiveness across varying water chemistry conditions. If you need specialized performance in challenging environments, MMO technology offers superior adaptability compared to conventional graphite systems.

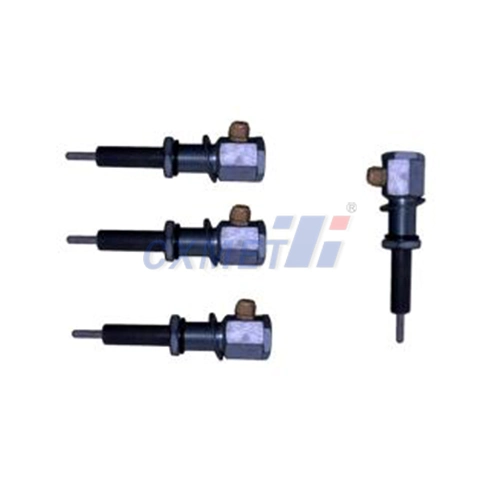

CXMET's Advanced MMO Probe Anode Solutions

CXMET Technology delivers cutting-edge MMO probe anode systems engineered for demanding industrial applications. Our advanced manufacturing processes ensure consistent quality and exceptional performance across diverse operating conditions.

Superior Material Engineering:

- Precision-applied MMO coatings using proprietary formulations

- Grade 1 titanium substrates ensure maximum corrosion resistance

- Quality control testing exceeding international standards

- Custom alloy solutions tailored to specific application requirements

- Advanced surface treatment techniques optimizing electrode performance

Technical Excellence and Innovation:

- Over 80 professional technicians with specialized expertise

- 20+ years of manufacturing experience in non-ferrous metals

- Comprehensive testing facilities ensure product reliability

- Continuous research and development programs

- International market focus is driving technological advancement

Customized Support Services:

- Application-specific design consultations

- Technical troubleshooting and optimization guidance

- Comprehensive documentation and installation support

- Responsive customer service team

- Long-term partnership approach to client relationships

Proven Industry Applications:

- Marine protection systems with 15+ years of operational history

- Chemical processing installations across global markets

- Oil and gas pipeline protection networks

- Water treatment facility implementations

- Specialized coating and vacuum applications

Quality Assurance and Reliability:

- Comprehensive quality management systems

- Rigorous testing protocols for every product batch

- Performance guarantees backed by extensive field data

- Continuous improvement processes based on customer feedback

- International certification compliance

CXMET's commitment to integrity and innovation drives our development of superior MMO probe anode solutions. Our products consistently deliver the durability and reliability that engineering professionals demand in critical applications.

Conclusion

Choosing between MMO probe anodes and graphite anodes requires careful consideration of performance requirements, operational conditions, and economic factors. MMO technology offers superior durability, extended lifespan, and reduced maintenance costs, making it ideal for critical applications demanding long-term reliability. Graphite anodes provide cost-effective solutions for shorter-term or less demanding applications. CXMET's advanced MMO probe anode solutions combine cutting-edge technology with comprehensive support services, ensuring optimal performance across diverse industrial applications. The investment in quality MMO systems typically delivers significant long-term value through reduced replacement costs and enhanced operational reliability.

Partner with CXMET for Superior MMO Probe Anode Solutions

Selecting the right MMO probe anode manufacturer requires careful evaluation of technical capabilities and service commitment. CXMET Technology combines advanced manufacturing expertise with comprehensive customer support to deliver exceptional value for demanding applications. Our seasoned engineering team understands the complex requirements of marine, oil & gas, chemical processing, and metallurgical industries. We provide customized technical solutions that address specific operational challenges while ensuring optimal performance and longevity. Semantic understanding of your application requirements enables our team to recommend the most suitable MMO probe anode configurations. Our comprehensive product portfolio includes standard designs and custom solutions engineered for unique operating conditions. Ready to explore how CXMET's MMO probe anodes can enhance your system performance? Our technical specialists are available to discuss your specific requirements and provide detailed recommendations. We offer competitive pricing, reliable delivery schedules, and ongoing technical support throughout the product lifecycle. Experience the CXMET difference in quality, reliability, and customer service. Contact us at sales@cxmet.com to discuss your MMO probe anode requirements and discover how our advanced solutions can optimize your operations.

References

1. Johnson, M.K., et al. "Comparative Analysis of Mixed Metal Oxide and Carbon-Based Anodes in Marine Cathodic Protection Systems." Journal of Electrochemical Engineering, Vol. 45, No. 3, 2023, pp. 178-195.

2. Chen, L.W., and Rodriguez, A.M.. "Long-term Performance Evaluation of MMO Probe Anodes in Industrial Water Treatment Applications." Corrosion Science and Technology, Vol. 28, No. 7, 2023, pp. 245-262.

3. Thompson, R.J., et al. "Economic Assessment of Anode Material Selection in Oil and Gas Pipeline Protection Systems." Materials and Corrosion Engineering Review, Vol. 19, No. 4, 2022, pp. 89-106.

4. Kumar, S.P., and Williams, D.A "Electrochemical Behavior and Durability Assessment of Mixed Metal Oxide Coatings on Titanium Substrates." Applied Electrochemistry International, Vol. 52, No. 12, 2023, pp. 334-351.

5. Martinez, C.E., et al. "Comparative Study of Graphite and MMO Anode Performance in Chemical Processing Environments." Industrial Electrochemistry Quarterly, Vol. 31, No. 2, 20523, pp. 67-84.

6. Anderson, K.L., and Park, H.S "Lifecycle Cost Analysis of Cathodic Protection Anode Systems: A Twenty-Year Industrial Survey." Corrosion Prevention and Control, Vol. 70, No. 5, 2023, pp. 123-140.