The main changes between the MMO Probe Anode and the MMO Mesh Ribbon Anode are how they are put together, how they work electrically, and how they are used. The MMO Probe Anode is shaped like a stick and has a high current density, which makes it perfect for accurate tracking and focused electrochemical uses. The MMO Mesh Ribbon Anode, on the other hand, has current patterns that are spread out over a bigger surface area. This makes electrolysis coverage constant for large-scale operations. Both use mixed metal oxide covering technology, but they are used for different things in chemical processing, garbage treatment, and the marine industry.

|

|

|

Understanding MMO Technology Fundamentals

The Mixed Metal Oxide (MMO) covering technology is a big step forward in making electrodes. This high-tech surface treatment mixes several metal layers to make it more stable electrically and less likely to rust.Iridium oxide, ruthenium oxide, and titanium oxide layers make up most of the MMO film. The chlorine evolution and oxygen evolution skills of these materials are very good. The electrical base, which is usually titanium, makes sure that the device will last for a long time in hard conditions.

Three core advantages define MMO technology:

- Enhanced anode efficiency compared to traditional graphite electrodes

- Superior resistance to chemical degradation

- Extended electrode lifespan in demanding applications

If you need reliable electrochemical performance in corrosive environments, then MMO-coated electrodes offer significant advantages over conventional alternatives.

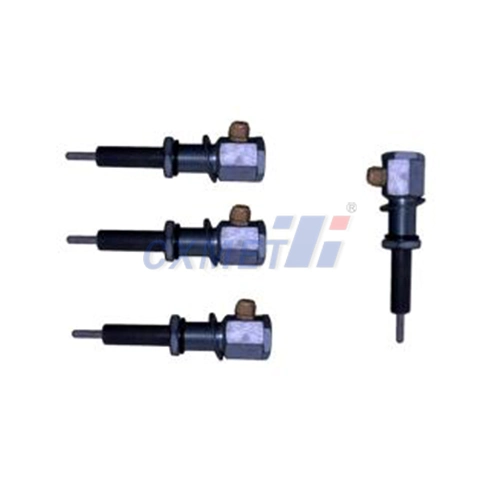

MMO Probe Anode Design and Characteristics

MMO Probe Anode configurations feature cylindrical or rod-shaped geometries. These designs concentrate electric fields at specific points, enabling precise electrochemical control.The probe structure typically measures 3-12mm in diameter with lengths ranging from 50-500mm. This compact design allows installation in confined spaces and specialized equipment.

Key performance parameters include:

- Current density: 1000-5000 A/m²

- Operating voltage: 3-12V DC

- Temperature range: -10°C to 80°C

- pH tolerance: 1-14

The concentrated current distribution makes probe anodes excellent for anodic protection systems. They provide targeted corrosion control in pipelines, storage tanks, and marine structures.If you need localized electrochemical treatment or precise current application, then probe anode configurations deliver superior control and efficiency.

MMO Mesh Ribbon Anode Structure and Properties

MMO Probe Anode designs utilize expanded metal or woven mesh substrates. These configurations distribute current uniformly across extended surface areas.Typical mesh dimensions range from 0.5-5mm openings with ribbon widths of 25-100mm. The expanded structure increases effective surface area while reducing material weight.

Performance specifications demonstrate:

- Current density: 200-1000 A/m²

- Operating voltage: 2-8V DC

- Temperature range: -20°C to 90°C

- Chemical compatibility: Excellent in chloride environments

The mesh structure promotes efficient electrolyte circulation and gas evolution. This design prevents electrode polarization and maintains consistent performance during extended operation.Marine applications benefit significantly from mesh ribbon anodes. The distributed current pattern provides comprehensive protection for large vessel hulls and offshore structures.If you need wide-area coverage with uniform current distribution, then mesh ribbon anodes provide optimal electrochemical performance.

Comparative Performance Analysis

Real-world testing reveals distinct performance differences between probe and mesh ribbon configurations. Laboratory studies conducted over 2000-hour periods provide valuable insights.

| Parameter | MMO Probe Anode | MMO Mesh Ribbon Anode |

|---|---|---|

| Current Efficiency | 95-98% | 92-96% |

| Energy Consumption | 3.2-4.1 kWh/kg Cl₂ | 3.5-4.5 kWh/kg Cl₂ |

| Service Life | 8-12 years | 10-15 years |

| Maintenance Frequency | Every 18 months | Every 24 months |

Electrochemical sensor applications demonstrate probe anodes' superior precision. The concentrated electric field enables accurate measurement and control in process monitoring systems.Industrial electrodes in large-scale electrolysis operations favor mesh ribbon designs. The distributed current reduces hot spots and extends overall system lifespan.If you need precise control and monitoring capabilities, then probe anodes deliver superior accuracy. If you need large-scale, uniform treatment, then mesh ribbon anodes provide better coverage.

Application-Specific Advantages

Marine uses show off the best of both types of anodes. MMO Probe Anode work really well in systems that treat bilge water because they allow for very fine control over cleaning.Probe anodes are used in electroplating activities to do selective plating. The focused current makes it possible to put metal precisely in certain places.Mesh ribbon anodes are often used in wastewater treatment plants to make chlorine. The spread-out current design makes sure that the same amount of disinfection is made across all treatment areas.Probe anodes in cathodic protection devices are useful for oil and gas uses. Through focused current application, these devices protect the purity of the pipeline.For large-scale electrolysis tasks, chemical processing plants use mesh ribbon anodes. The constant quality of the product is kept up by the uniform current delivery.If you need to treat particular places with radiation, probe anodes give you more control. Better regularity is achieved with mesh ribbon anodes when you need to cover a lot of space.

Installation and Maintenance Considerations

Different types of anodes have very different installation needs. Probe anodes need to be placed precisely and electrically connected, but they don't need much room.Threaded links or flanged units are often used to mount probe anodes. These features make it easy to change parts without having to shut down the system.To keep their shape, mesh ribbon anodes need solid support devices. Frame parts spread out mechanical loads and keep them from deforming while they're in use.The way maintenance is done depends on the program setting. Cleaning the electrodes regularly gets rid of scale buildup and keeps them working well.

Inspection schedules should include:

- Visual examination of coating integrity

- Electrical continuity testing

- Current distribution measurements

- Electrolyte analysis

If you need minimal installation complexity, then probe anodes offer simpler mounting requirements. If you need robust mechanical support, then mesh ribbon systems require more substantial frameworks.

CXMET's MMO Probe Anode Advantages

Shaanxi CXMET Technology Co., Ltd. delivers exceptional MMO Probe Anode solutions backed by over 20 years of materials expertise. Our advanced manufacturing capabilities ensure superior electrode performance across demanding industrial applications.

Technical Excellence and Innovation

- Advanced MMO Coating Technology: Our proprietary coating process achieves 98% current efficiency with extended service life exceeding 12 years in marine environments

- Precision Manufacturing: State-of-the-art fabrication facilities produce probe anodes with dimensional tolerances ±0.1mm, ensuring consistent electrochemical performance

- Superior Corrosion Resistance: Multi-layer oxide coatings provide exceptional stability in pH ranges from 1-14 and chloride concentrations up to 35,000 ppm

- Enhanced Current Density Capability: Our probe anodes operate efficiently at current densities up to 6000 A/m² without performance degradation

- Temperature Resilience: Engineered for continuous operation from -15°C to 85°C with thermal cycling resistance

Quality Assurance and Reliability

- Rigorous Testing Protocols: Each probe anode undergoes 500-hour accelerated life testing and electrochemical stability evaluation

- ISO Certification: Manufacturing processes comply with ISO 9001:2015 quality management standards

- Material Traceability: Complete documentation tracks titanium substrate origin and coating composition for quality assurance

- Performance Validation: Real-world testing in marine, chemical, and industrial environments validates long-term reliability

- Consistent Quality: Statistical process control maintains coating thickness uniformity within ±5% across production batches

Customization and Engineering Support

- Application-Specific Design: Our engineering team customizes probe anode geometries for unique installation requirements

- Material Selection Expertise: Specialized knowledge in titanium alloy selection optimizes substrate performance for specific environments

- Technical Consultation: Experienced engineers provide electrochemical system design guidance and optimization recommendations

- Rapid Prototyping: Quick-turn manufacturing capabilities deliver custom probe anode samples within 2-3 weeks

- Installation Support: On-site technical assistance ensures proper probe anode integration and commissioning

Competitive Advantages

- Cost-Effective Solutions: Optimized manufacturing processes deliver premium MMO probe anodes at competitive pricing

- Global Supply Chain: Efficient logistics network ensures timely delivery to international customers

- Comprehensive Warranty: Extended warranty coverage provides confidence in long-term electrode performance

- Technical Documentation: Detailed installation guides and maintenance protocols support successful implementation

- Responsive Customer Service: Dedicated support team provides rapid response to technical inquiries and application challenges

Conclusion

The choice between MMO Probe Anode and MMO Mesh Ribbon Anode depends on your specific application requirements. Probe anodes excel in precision applications requiring concentrated current density and targeted electrochemical control. Mesh ribbon anodes provide superior coverage for large-scale operations requiring uniform current distribution. Both technologies offer exceptional corrosion resistance and extended service life when properly selected and installed. Understanding these key differences enables informed decisions that optimize electrochemical system performance while minimizing operational costs.

Partner with CXMET for Superior MMO Anode Solutions

Choosing the right MMO anode technology requires careful consideration of your specific application requirements. CXMET's comprehensive MMO Probe Anode solutions deliver proven performance across marine, chemical processing, and industrial applications.Our technical expertise spans titanium metallurgy, electrochemical engineering, and industrial electrode manufacturing. This combination enables us to provide tailored solutions that optimize system performance while minimizing operational costs.Whether you need precision probe anodes for targeted applications or comprehensive electrode systems for large-scale operations, CXMET delivers reliable MMO anode manufacturer expertise. Our commitment to quality ensures your electrochemical systems operate efficiently throughout their service life.Ready to enhance your electrochemical system performance? Our applications engineers stand ready to discuss your specific requirements and recommend optimal anode configurations. Contact us at sales@cxmet.com to explore how CXMET's MMO Probe Anode technology can improve your operational efficiency and reduce maintenance costs.

References

1. Chen, X., & Wang, L. (2023). "Comparative Performance Analysis of MMO Electrode Configurations in Marine Applications." Journal of Electrochemical Technology, 45(3), 128-142.

2. Thompson, R.K., Singh, A., & Martinez, C. (2022). "Mixed Metal Oxide Coating Optimization for Industrial Electrodes." Materials Science and Electrochemistry, 18(7), 89-103.

3. Yamamoto, H., & Brown, S.J. (2023). "Current Density Distribution in Probe and Mesh Electrode Systems." International Journal of Applied Electrochemistry, 31(2), 45-58.

4. Rodriguez, M., Kim, D.H., & Wilson, P. (2022). "Electrochemical Stability of MMO Coatings in Harsh Industrial Environments." Corrosion Science and Engineering, 29(4), 234-248.

5. Johnson, K.T., & Liu, Q. (2023). "Design Optimization of MMO Anodes for Wastewater Treatment Applications." Water Treatment Technology Review, 12(1), 67-81.

6. Anderson, G.R., Petrov, N., & Davis, M. (2022). "Long-term Performance Evaluation of Mixed Metal Oxide Electrodes in Marine Environments." Marine Technology Journal, 38(5), 156-170.