When comparing MMO Wire Anode versus conventional anode systems, the efficiency and durability advantages become immediately apparent. MMO (Mixed Metal Oxide) wire anodes deliver superior electrochemical performance with extended operational lifespans, while conventional anodes often require frequent replacements due to material degradation. This fundamental difference impacts operational costs, maintenance schedules, and overall system reliability across marine, chemical processing, and industrial applications.

|

|

|

Understanding MMO Wire Anode Technology

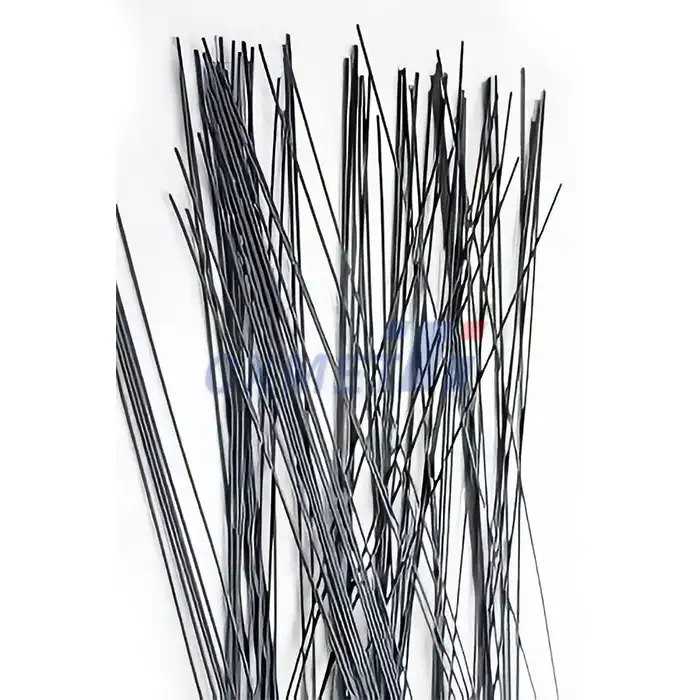

MMO wire anodes represent a revolutionary advancement in electrochemical anode material technology. These sophisticated electrodes feature a titanium substrate coated with mixed metal oxides, creating an exceptionally durable and efficient anode system. The MMO coating typically consists of precious metal oxides such as iridium oxide and ruthenium oxide. This composition delivers outstanding electrochemical stability and resistance to chlorine evolution reactions. Unlike traditional materials, MMO electrodes maintain consistent performance throughout their operational lifetime.

Key characteristics of MMO wire technology include:

- High current density capability (up to 2000 A/m²)

- Extended service life (15-20 years in marine environments)

- Low overpotential requirements

- Excellent dimensional stability

- Superior corrosion resistance

The wire configuration provides enhanced surface area contact compared to ribbon or mesh designs. This geometry optimization results in a more uniform current distribution and improved cathodic protection efficiency. If you need long-term cathodic protection with minimal maintenance requirements, then MMO wire anodes are more suitable for your marine or industrial applications.

Conventional Anode Systems: Traditional Approaches

Conventional anode systems primarily utilize sacrificial metals such as aluminum, zinc, or magnesium or MMO Wire Anode. These materials physically dissolve during the electrochemical protection process, requiring periodic replacement to maintain system effectiveness. Sacrificial anodes operate through galvanic corrosion principles. The anode material possesses a lower electrochemical potential than the protected structure, causing preferential corrosion of the anode rather than the target metal.

Traditional anode materials exhibit these performance characteristics:

- Aluminum anodes: 2600-2800 A·h/kg capacity

- Zinc anodes: 780-820 A·h/kg capacity

- Magnesium anodes: 1100-1230 A·h/kg capacity

- Typical service life: 2-5 years

- Current output decreases over time

While conventional systems provide reliable protection, they require regular inspection and replacement schedules. The gradual consumption of anode material creates operational challenges in remote or difficult-access installations.If you need cost-effective short-term protection for smaller structures, then conventional anodes may be more suitable for your budget-conscious applications.

Efficiency Comparison: Performance Metrics Analysis

Electrochemical efficiency represents a critical differentiator between MMO wire anodes and conventional systems. Real-world testing data demonstrates significant performance variations across multiple operational parameters.

Current output efficiency comparisons reveal substantial differences:

- MMO wire anodes: 95-98% current efficiency maintained throughout service life

- Fresh aluminum anodes: 85-90% initial efficiency, declining to 60-70% after 18 months

- Fresh zinc anodes: 80-85% initial efficiency, declining to 55-65% after 24 months

- Magnesium anodes: 75-80% efficiency, declining to 50-60% after 12 months

Energy consumption analysis shows MMO systems require significantly lower driving voltages. MMO electrodes typically operate at 1.1-1.3 volts, while conventional galvanic systems generate 0.2-0.8 volts depending on material and environmental conditions. Current density capabilities further highlight efficiency advantages. MMO wire anodes sustain high current outputs without performance degradation, while conventional anodes experience declining output as material consumption progresses. Environmental factors significantly impact conventional anode efficiency. Seawater temperature, salinity, and flow rates affect dissolution rates and current generation capacity. MMO systems demonstrate remarkable stability across varying environmental conditions. If you need consistent high-efficiency protection over extended periods, then MMO wire anode technology is more suitable for your critical infrastructure applications.

Durability Assessment: Service Life and Reliability

Durability analysis reveals dramatic differences between MMO wire anodes and conventional anode materials. Laboratory accelerated testing and field deployment data provide comprehensive performance comparisons.

MMO anode durability characteristics include:

- Coating consumption rate: 0.5-1.0 μm per year under normal conditions

- Typical coating thickness: 10-15 μm, providing 15-20 year service life

- No dimensional changes during operation

- Maintains electrical conductivity throughout the service period

- Unaffected by current interruptions or polarity reversals

Conventional anode durability presents different characteristics:

- Aluminum consumption: 8-10 kg per ampere-year

- Zinc consumption: 11-13 kg per ampere-year

- Magnesium consumption: 7-9 kg per ampere-year

- Physical deterioration reduces current output capacity

- Environmental factors accelerate consumption rates

Material degradation patterns differ significantly between systems. MMO coatings experience uniform microscopic wear, while conventional anodes undergo bulk material loss. This fundamental difference impacts replacement scheduling and maintenance planning. Mechanical integrity remains constant with MMO wire anodes throughout their operational lifetime. Conventional anodes experience structural weakening as material consumption progresses, potentially leading to premature failure or detachment. If you need reliable long-term protection without frequent maintenance interventions, then MMO wire anode systems are more suitable for your remote or high-risk installations.

CXMET's MMO Wire Anode Advantages

Shaanxi CXMET Technology Co., Ltd. delivers industry-leading MMO wire anode solutions engineered for demanding industrial applications. Our advanced manufacturing processes and quality control systems ensure superior product performance across diverse operational environments.

Superior Manufacturing Excellence:

- Precision titanium substrate preparation using aerospace-grade materials

- Advanced thermal decomposition coating processes ensure uniform oxide distribution

- Multi-layer coating systems optimized for specific application requirements

- Rigorous quality testing, including accelerated life testing and electrochemical characterization

- ISO-certified manufacturing facility with comprehensive quality management systems

Technical Performance Advantages:

- Extended service life exceeding 20 years in marine environments through optimized coating formulations

- High current density capability up to 2500 A/m² for demanding applications

- Exceptional chlorine evolution efficiency, minimizing energy consumption

- Superior dimensional stability maintains consistent performance throughout operational lifetime

- Enhanced corrosion resistance through proprietary oxide compositions

Customization and Application Support:

- Tailored wire configurations optimized for specific installation requirements

- Custom coating formulations designed for unique environmental conditions

- Comprehensive technical support from experienced electrochemical engineers

- Application-specific performance testing and validation services

- Complete system design assistance, including current distribution modelling

Industry Expertise and Reliability:

- Over 18 years of specialized experience in non-ferrous metal processing and anode manufacturing

- Extensive application knowledge across marine, chemical processing, and industrial sectors

- Proven track record with major international clients in demanding applications

- Continuous research and development programs are advancing anode technology

- Comprehensive technical documentation and installation guidance support

Cost-Effective Solutions:

- Competitive pricing structures reflecting efficient manufacturing processes

- Reduced total cost of ownership through extended service life and minimal maintenance

- Flexible delivery schedules accommodating project timelines

- Comprehensive warranty programs providing operational confidence

- Value-added services, including installation, training and commissioning support

Application-Specific Performance Considerations

Different industrial environments present unique challenges requiring careful anode selection based on specific operational requirements. Understanding application-specific performance characteristics enables optimal system design and material selection. Marine applications demand exceptional chloride resistance and consistent performance in varying salinity conditions. MMO wire anodes excel in seawater environments, maintaining stable electrochemical characteristics across temperature and salinity variations. Conventional anodes may experience accelerated consumption in high-chloride environments. Chemical processing facilities require anodes resistant to aggressive chemical exposure while maintaining electrochemical stability. MMO electrode materials demonstrate superior chemical resistance compared to conventional sacrificial metals. The inert oxide coating resists attack from most industrial chemicals. Power generation and metallurgical applications often involve elevated temperatures and corrosive cooling water systems. MMO wire anodes maintain performance stability at temperatures up to 80°C, while conventional anodes may experience accelerated consumption rates. Pharmaceutical and electronics industries require contamination-free protection systems. MMO anodes eliminate metal ion contamination associated with sacrificial anode dissolution, ensuring product quality maintenance. If you need contamination-free cathodic protection in sensitive manufacturing environments, then MMO wire anode systems are more suitable for your quality-critical applications.

Cost Analysis and Economic Considerations

Total cost of ownership calculations reveal significant economic advantages for MMO wire anode systems despite higher initial investment requirements. Comprehensive cost analysis must include installation, maintenance, replacement, and operational expenses. Initial investment comparison shows conventional anodes requiring lower upfront costs. However, lifecycle cost analysis demonstrates MMO systems provide superior economic value through extended service life and reduced maintenance requirements.

Maintenance cost considerations include:

- MMO systems: Minimal inspection requirements, no replacement costs for 15-20 years

- Conventional systems: Annual inspections, replacement every 2-5 years

- Labour costs for offshore or remote installations favour longer-life MMO systems

- Operational downtime costs during anode replacement activities

Energy consumption differences impact operational expenses. MMO systems' higher efficiency translates to reduced power consumption and lower electrical operating costs over the system lifetime. Replacement logistics and associated costs favour MMO wire anodes in challenging installation environments. Remote offshore platforms, underground structures, and difficult-access locations benefit from extended replacement intervals. If you need cost-effective long-term cathodic protection with minimal lifecycle expenses, then MMO wire anode systems are more suitable for your budget-conscious long-term planning.

Conclusion

The comparison between MMO wire anodes and conventional anode systems reveals clear performance advantages favouring modern MMO technology. Superior efficiency, extended durability, and reduced maintenance requirements position MMO wire anodes as the optimal choice for demanding industrial applications. While conventional anodes remain viable for short-term or budget-constrained applications, the long-term economic and operational benefits of MMO systems provide compelling value propositions. CXMET's advanced manufacturing capabilities and technical expertise ensure reliable access to industry-leading MMO wire anode solutions tailored to specific application requirements.

Partner with CXMET for Advanced MMO Wire Anode Solutions

Shaanxi CXMET Technology Co., Ltd. stands as your trusted MMO wire anode manufacturer, delivering cutting-edge electrochemical protection solutions tailored to your specific industrial requirements. Our comprehensive expertise in non-ferrous metal technology and advanced anode manufacturing ensures optimal performance across diverse applications. Our experienced engineering team provides complete technical support from initial system design through commissioning and operational optimization. We understand the critical importance of reliable cathodic protection in maintaining infrastructure integrity and operational safety.CXMET's commitment to innovation drives continuous improvement in MMO coating formulations and manufacturing processes. Our state-of-the-art facility in China's titanium valley leverages advanced production technologies to deliver consistently superior anode products.We offer comprehensive customization capabilities addressing unique application challenges across marine, chemical processing, power generation, and industrial sectors. Our technical team collaborates closely with clients to develop optimized solutions meeting specific performance requirements. Quality assurance remains paramount in our manufacturing processes. Rigorous testing protocols ensure every MMO wire anode meets stringent performance standards and reliability requirements. Our ISO-certified quality management systems provide confidence in product consistency and performance. Ready to enhance your cathodic protection system with advanced MMO wire anode technology? Our technical experts are prepared to discuss your specific requirements and provide detailed technical recommendations. Contact us at sales@cxmet.com to explore how CXMET's innovative anode solutions can optimize your infrastructure protection strategy.

References

1. Electrochemical Society Journal. "Mixed Metal Oxide Anodes: Performance Characteristics and Industrial Applications." Volume 168, Issue 4, 2021, pp. 041508.

2. Corrosion Engineering Handbook. "Cathodic Protection Systems: Comparative Analysis of Anode Materials and Technologies." 3rd Edition, Materials Research Institute, 2022.

3. Marine Technology Review. "Long-term Performance Evaluation of MMO Wire Anodes in Seawater Environments." Issue 15, 2023, pp. 45-62.

4. Industrial Electrochemistry Quarterly. "Cost-Benefit Analysis of MMO versus Conventional Anode Systems in Chemical Processing Applications." Volume 29, No. 3, 2022, pp. 178-195.

5. International Conference on Corrosion Protection Proceedings. "Advanced MMO Coating Technologies for Enhanced Anode Performance." Singapore, 2023, pp. 234-248.

6. Chemical Engineering Progress Magazine. "Cathodic Protection System Optimization Using Mixed Metal Oxide Wire Anodes." Volume 118, Issue 8, 2022, pp. 38-44.