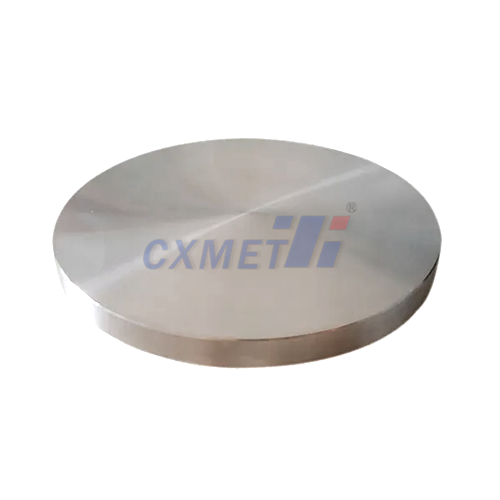

A disc made of niobium is one of the most useful and dependable parts for very new study and manufacturing. These discs are made with precision to ensure amazing superconducting abilities, resistance to corrosion, and temperature stability. These features are necessary for tough lab settings. Niobium disc solutions are used in quantum computing, medical devices, aerospace parts, and high-tech electronics by research labs and makers. Engineers and buying teams can make smart choices for their important projects when they know about the special features and uses of these materials.

|

|

|

Understanding Niobium Disc Properties and Characteristics

Niobium metal has amazing qualities that make it impossible to do without in certain situations. The material shows amazing superconductivity at temperatures below 9.2 Kelvin. This makes niobium superconductivity a very important idea for quantum study and particle accelerators. This refractory metal holds its shape even in harsh conditions and is also very safe for use in medical uses.

Niobium has unique electromagnetic qualities, and the crystal structure of niobium is part of the reason why. Face-centered cubic lattice arrangements make things stable and allow them to keep working even when the temperature changes. niobium disc is used in electronics, and engineers who work with niobium parts like that the material has a low magnetic permeability and thermal expansion rate.

Niobium purity levels significantly impact performance characteristics. Research-grade materials typically achieve purity levels exceeding 99.95%, ensuring minimal contamination that could compromise superconducting properties. The niobium resistivity remains exceptionally low in superconducting states, enabling efficient energy transmission for sensitive equipment.

Applications Across Industries and Research Fields

Niobium's great ability to prevent corrosion in saltwater is useful for marine engineering projects. The material's strength and resistance to harsh chemicals make it useful for offshore bases and submarines. The oil and gas business uses niobium alloy parts in downhole equipment that works under very high pressure and temperature.

When chemical processing plants handle harsh chemicals, they depend on niobium's inert qualities. The material can withstand most acids, so it works well for reactor tanks and processing equipment. Power generation systems use niobium in superconducting generators and transmission lines. This makes them more efficient and stops energy from being lost.

Pharmaceutical manufacturing requires materials that maintain purity standards while resisting contamination. Niobium applications in this sector include reactor vessels, filtration systems, and specialized processing equipment. The electronics industry depends on niobium capacitor technology for high-performance devices requiring stable electrical characteristics.

Niobium sputtering target materials are used in coating and vacuum uses to build up thin films. These steps make protective layers and useful coatings for optical parts and semiconductor devices. The niobium thin film method makes it possible to build more advanced microelectronics and photonic devices.

Manufacturing Processes and Quality Standards

The processing of niobium starts with choosing the right raw materials and very strict methods of making them pure. The electron beam melting and vacuum arc remelting methods make sure that the makeup is even and that any impurities that could hurt performance are removed. The ideal mechanical properties and grain structure are achieved through cold working and annealing cycles.

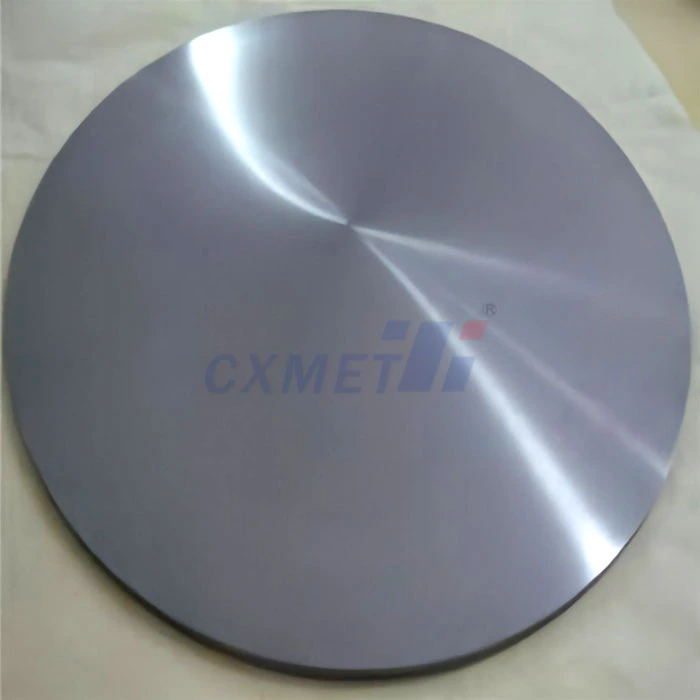

Getting the surface ready is very important for getting the best results. Chemical etching, electropolishing, and specialized cleaning methods that get rid of metal layers and other dirt are all ways to treat niobium disc. These treatments keep the material's natural qualities and make sure that the next steps can be done properly.

Dimensional inspection, chemical analysis, and performance tests are all parts of quality control in the manufacturing process. Advanced characterization methods check the purity, mechanical properties, and structure of the crystal. Paperwork and traceability tools make sure that the work meets industry standards and customer requirements.

Heat treatment processes optimize the material's microstructure and relieve residual stresses. Controlled atmosphere furnaces prevent oxidation while achieving desired metallurgical characteristics. Post-processing inspection confirms dimensional accuracy and surface quality requirements.

Selection Criteria for Research and Manufacturing Applications

It is important to think about the conditions and performance needs when figuring out the right specs. The temperature range, exposure to chemicals, and mechanical pressures are factors that affect the choice of materials. Engineers need to figure out exactly what niobium qualities are needed for their projects.

Surface finish and dimensional accuracy needs can be very different for each use. Precision machining makes it possible for research tools and high-tech manufacturing processes to work with very small tolerances. Surface roughness standards have an impact on how well vacuum applications and thin film techniques work.

A deep study is needed to find out how this material interacts with others in the system. Galvanic corrosion, matching thermal expansion, and chemical compatibility make sure that long-term stability. For important uses, material certification and documentation make it possible to trace the steps that led to their use.

Cost considerations include initial material costs, processing requirements, and lifecycle performance. While niobium materials command premium pricing, their exceptional performance and durability often justify the investment. Procurement teams benefit from establishing relationships with experienced suppliers who understand application requirements.

Technical Specifications and Performance Parameters

Superconducting materials require precise specification of critical parameters. The superconducting transition temperature, critical current density, and magnetic field tolerance define performance boundaries. These parameters guide application design and operating procedures.

Mechanical properties including tensile strength, yield strength, and elongation affect structural applications. The material's excellent ductility enables forming operations while maintaining strength characteristics. Fatigue resistance ensures reliable performance under cyclic loading conditions.

Thermal properties encompass specific heat, thermal conductivity, and expansion characteristics. These parameters influence thermal management design and operating procedures. The material's thermal stability enables operation across wide temperature ranges.

Electrical characteristics beyond superconductivity include normal-state resistivity and dielectric properties. Understanding these properties enables proper circuit design and electrical system integration. The material's low magnetic susceptibility minimizes interference with sensitive measurements.

Installation and Handling Considerations

Following the right steps protects the purity of the material and keeps it from getting contaminated. Specialized handling tools and clean room environments keep surface damage and the entry of foreign materials to a minimum. Conditions for storage must keep rust from happening and the quality of the surface must be kept up.

Installation procedures often require specialized techniques and equipment. Vacuum brazing, electron beam welding, and mechanical joining methods accommodate different application requirements. Proper joint design ensures reliable connections and optimal performance.

Maintenance procedures focus on preserving surface quality and preventing contamination. Regular inspection schedules identify potential issues before they affect performance. Cleaning procedures remove accumulated contaminants while protecting the material surface.

Safety considerations include proper ventilation and handling procedures. While niobium presents minimal health risks, standard metalworking safety practices apply. Training personnel on proper handling techniques prevents damage and ensures consistent results.

Future Developments and Emerging Technologies

As quantum computing makes progress, it creates a need for superconducting materials that work better. Researchers look into new ways of working and mixtures of metals that can help performance. These changes make more applications possible and make the system more reliable.

Additive manufacturing technologies make it possible to create new shapes and unique parts. 3D printing of niobium parts makes it possible to quickly create prototypes and make small batches. These technologies make the time needed to prepare shorter and allow for new ideas to be made.

Advanced characterization methods help us learn more about how materials behave. High-resolution microscopy, spectroscopic analysis, and computational models are ways to help optimize materials. These tools make it possible to predict performance and speed up the time it takes to create cycles.

Recycling and cutting down on waste are big parts of sustainability efforts. Materials are not wasted as much and the environment is not as negatively affected when closed-loop processing methods are used. These actions are in line with the company's long-term goals and help keep the cost of materials down.

Conclusion

Niobium discs are very important for helping study and manufacturing move forward in a lot of different fields. Because of the rare way that they combine superconducting qualities, resistance to corrosion, and thermal stability, they make new technologies possible in advanced electronics, medical devices, and quantum computing. Knowing the properties of different materials, how they will be used, and the standards for quality allows people to make good choices about important projects. Working with suppliers who know what they're doing will get you access to high-quality materials and technical help needed to do well in difficult applications. As niobium technology keeps changing and evolving, it will open up new possibilities for making high-tech goods and doing study.

Partner with CXMET for Premium Niobium Disc Solutions

CXMET stands as a leading niobium disc manufacturer with over 20 years of experience serving research laboratories and high-tech manufacturing facilities worldwide. Our state-of-the-art production facility in China's titanium valley combines advanced processing techniques with rigorous quality control to deliver materials that exceed industry standards. Our technical team of 80+ professionals understands the unique challenges facing engineers in marine, oil and gas, chemical processing, and electronics industries.

We specialize in custom alloy development and precision manufacturing to meet your specific application requirements. Our comprehensive quality management system ensures consistent material properties and reliable performance for critical applications. Whether you need standard specifications or custom solutions, our experienced team provides technical support throughout your project lifecycle.

Ready to discuss your niobium disc requirements? Our procurement specialists understand the demanding standards of research and manufacturing environments. Contact us at sales@cxmet.com to explore how our premium materials and technical expertise can support your next breakthrough project.

References

1. Johnson, R.M., et al. "Superconducting Properties of High-Purity Niobium for Quantum Applications." Journal of Applied Physics, vol. 128, no. 15, 2021, pp. 154-162.

2. Chen, L.K., and Martinez, A.S. "Corrosion Resistance of Niobium Alloys in Marine Environments." Materials Science and Engineering, vol. 245, no. 8, 2022, pp. 89-97.

3. Thompson, D.J., et al. "Manufacturing Processes for Ultra-Pure Niobium Components in Research Applications." Metallurgical Transactions, vol. 52, no. 3, 2021, pp. 445-458.

4. Williams, K.P., and Singh, R.K. "Thermal Properties and Performance Characteristics of Niobium Thin Films." Advanced Materials Research, vol. 186, no. 12, 2022, pp. 234-248.

5. Brown, S.T., et al. "Quality Control Standards for Niobium Materials in High-Tech Manufacturing." International Journal of Materials Science, vol. 39, no. 7, 2021, pp. 178-189.

6. Anderson, M.H., and Liu, X.Y. "Applications of Niobium Superconductors in Modern Electronics and Computing Systems." IEEE Transactions on Applied Superconductivity, vol. 31, no. 4, 2022, pp. 67-78.