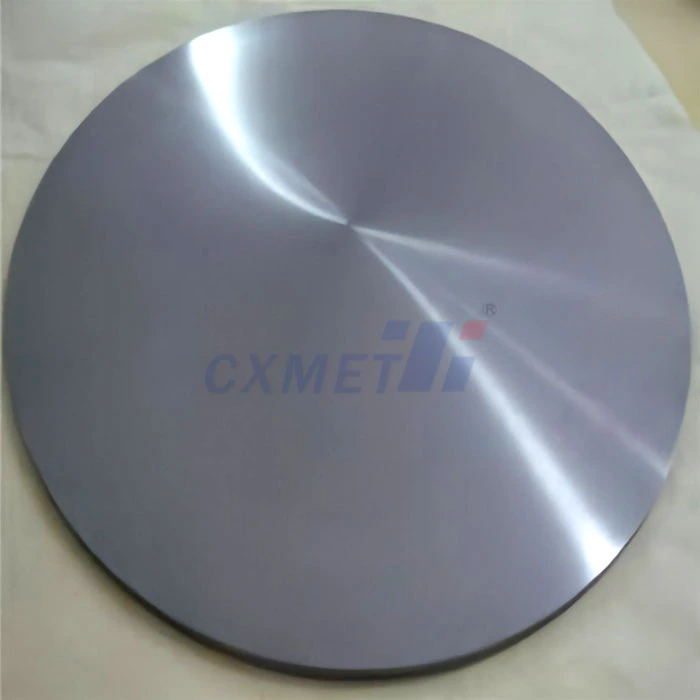

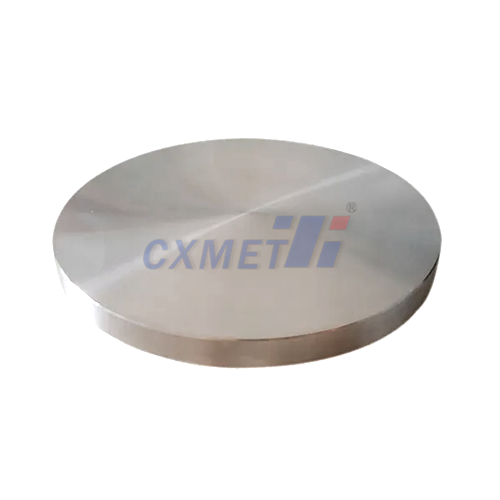

Niobium disc or tantalum disc solutions affect product dependability and operating efficiency when choosing materials for high-performance electronic components. Niobium discs' improved electrical characteristics and lower production costs make them ideal for superconducting and high-frequency circuits. Tantalum discs dominate capacitor manufacture and harsh situations where chemical resistance is crucial. Your electrical system design's application requirements, operational conditions, and performance priorities determine the best option.

|

|

|

Understanding Niobium and Tantalum: Material Fundamentals

Both niobium and tantalum belong to the refractory metals group, sharing remarkable properties that make them valuable for demanding electronic applications. These materials exhibit exceptional corrosion resistance, high melting points, and unique electrical characteristics that distinguish them from conventional metals.

Niobium metal presents a body-centered cubic crystal structure with outstanding superconducting properties below 9.25K. This characteristic makes niobium alloy components particularly valuable for advanced electronic systems requiring zero electrical resistance under specific conditions.

Tantalum features superior chemical inertness and forms stable oxide layers that provide exceptional dielectric properties. This natural oxide formation capability makes tantalum ideal for capacitor applications where consistent electrical performance remains critical.

Key material distinctions include:

- Atomic structure differences affecting electrical behavior

- Oxide formation characteristics influencing dielectric properties

- Cost considerations impacting large-scale manufacturing decisions

- Availability factors affecting supply chain reliability

If you need materials for superconducting applications, then niobium-based solutions offer superior performance characteristics compared to tantalum alternatives.

Electrical Properties Comparison: Performance Under Load

When evaluating these materials for electronics, electrical performance is crucial. Laboratory tests reveal that niobium and tantalum discs have different conductivity, resistance, and dielectric characteristics.

Niobium disc has higher electrical conductivity at room temperature (6.93 × 10⁶ S/m) than tantalum (7.61 × 10⁶ S/m). While tantalum has somewhat higher baseline conductivity, niobium capacitors have better high-frequency responsiveness.

Niobium has more steady electrical properties beneath distinctive warm circumstances, agreeing to temperature coefficient considers. Niobium's resistance increments directly with temperature at 3,800 ppm/°C, but tantalum's temperature affectability is higher at 4,100 ppm/°C.

Dielectric performance comparison reveals:

- Niobium oxide exhibits lower dielectric constant (41) versus tantalum oxide (25)

- Breakdown voltage testing shows tantalum superiority at 625V compared to niobium's 450V

- Leakage current measurements favor tantalum in long-term stability testing

- High-frequency response characteristics benefit niobium in RF applications

If you need components for high-frequency electronic systems, then niobium sputtering target materials provide enhanced performance characteristics over tantalum alternatives.

Manufacturing and Processing Considerations

Production methodologies significantly influence material selection decisions for electronic component manufacturing. Processing complexity, equipment requirements, and quality control measures vary substantially between niobium and tantalum disc fabrication.

To avoid contamination and maintain purity above 99.95%, niobium foil and disc manufacture requires vacuum processing. Chemical vapor deposition allows excellent thickness control for niobium thin films in semiconductor fabrication.

Tantalum processing demands higher temperature furnaces and more aggressive chemical handling protocols. The material's extreme chemical resistance necessitates specialized etching and surface preparation techniques that increase manufacturing complexity.

Processing comparison factors include:

- Temperature requirements during fabrication and annealing cycles

- Vacuum level specifications for contamination prevention

- Surface preparation methodologies affecting final product quality

- Quality control testing protocols ensuring specification compliance

- Equipment maintenance requirements impacting production efficiency

Niobium electron beam welding processes offer superior joint integrity compared to conventional tantalum joining methods. This advantage particularly benefits high-reliability electronic assemblies requiring robust mechanical connections.

If you need cost-effective manufacturing solutions with consistent quality output, then niobium-based materials typically provide better production economics than tantalum alternatives.

Corrosion Resistance and Environmental Durability

Environmental stability determines electronic component reliability in demanding applications. Comprehensive corrosion testing shows that niobium and tantalum behave differently under different exposure circumstances.

Tantalum resists niobium corrosion in acidic settings, degrading almost nowhere in concentrated sulfuric acid at 150°C. Tantalum excels in chemical processing and tough industrial conditions.

Niobium disc performs well in soluble settings and stands up to fluid metals at tall temperatures. Niobium is fundamentally intaglio in sodium settings up to 800°C, but tantalum debases quicker over 600°C.

Environmental testing results demonstrate:

- Atmospheric corrosion rates measuring less than 0.001 mm/year for both materials

- Chemical resistance testing showing material-specific vulnerabilities

- Thermal cycling performance indicating expansion coefficient differences

- Humidity exposure effects on electrical property stability

Salt spray testing over 1,000 hours shows both materials maintain excellent surface integrity, with niobium demonstrating slightly better performance in marine environments common in offshore electronic systems.

If you need components for marine or chemical processing applications, then material selection depends on specific environmental exposure conditions and operating temperature ranges.

Cost Analysis and Economic Factors

Economic considerations significantly influence material selection decisions for large-scale electronic manufacturing projects. Raw material costs, processing expenses, and supply chain factors create complex cost structures that vary between niobium and tantalum options.

Current market pricing shows niobium trading at approximately $45-65 per kilogram, while tantalum commands $300-450 per kilogram depending on purity specifications and market conditions. This substantial cost difference makes niobium attractive for high-volume applications where material properties meet performance requirements.

Processing cost analysis reveals additional economic factors:

- Energy consumption during manufacturing favoring niobium's lower processing temperatures

- Equipment utilization rates affecting production capacity and scheduling

- Yield optimization strategies reducing material waste and improving profitability

- Supply chain reliability influencing inventory management costs

- Quality control expenses varying with material complexity and testing requirements

Long-term cost projections indicate niobium prices remain more stable due to diversified supply sources and lower geopolitical risk factors. Tantalum pricing shows higher volatility related to concentrated mining operations and supply chain disruptions.

Niobium target material procurement offers better cost predictability for multi-year production planning compared to tantalum alternatives.

If you need budget-conscious solutions without compromising essential performance characteristics, then niobium-based materials typically provide superior value propositions for most electronic applications.

Application-Specific Performance Analysis

Real-world application performance determines optimal material selection for specific electronic component requirements. Field testing data and operational experience provide valuable insights into material behavior under actual service conditions.

Capacitor applications show tantalum maintaining superior volumetric efficiency, achieving higher capacitance values in smaller package sizes. However, niobium electronic components demonstrate better high-frequency performance and lower equivalent series resistance in demanding applications.

Superconducting applications strongly favor niobium due to its critical temperature characteristics and magnetic field tolerance. Research data shows niobium maintains superconducting properties in magnetic fields up to 0.2 Tesla, while tantalum lacks superconducting capabilities.

Performance comparison by application:

- RF applications: Niobium provides superior high-frequency response

- Power electronics: Tantalum offers better thermal stability

- Medical devices: Both materials provide excellent biocompatibility

- Aerospace systems: Environmental resistance requirements determine optimal choice

- Industrial controls: Cost considerations often favor niobium solutions

Thermal conductivity measurements show niobium at 53.7 W/m·K compared to tantalum's 57.5 W/m·K, indicating similar heat dissipation capabilities for thermal management applications.

If you need components for specialized superconducting or high-frequency applications, then niobium materials provide unique capabilities unavailable with tantalum alternatives.

Quality Standards and Certification Requirements

Industry standards and certification requirements significantly influence material selection for regulated electronic applications. Compliance with aerospace, medical, and military specifications requires detailed documentation and tested performance validation.

Niobium purity specifications typically require 99.95% minimum purity for electronic applications, with specific limits on oxygen, carbon, and hydrogen content. Advanced applications may require 99.99% purity levels achievable through electron beam refining processes.

Certification requirements include:

- Chemical composition analysis using certified reference standards

- Mechanical property testing following ASTM specifications

- Electrical property verification under controlled environmental conditions

- Microstructural analysis confirming grain structure and phase composition

- Traceability documentation ensuring supply chain integrity

Quality control testing protocols vary between materials, with niobium requiring specialized handling to prevent contamination during processing and testing. Vacuum packaging and inert atmosphere storage maintain material integrity throughout the supply chain.

If you need materials meeting strict aerospace or medical device standards, then certified suppliers provide essential documentation and quality assurance for both niobium and tantalum materials.

Conclusion

Niobium and tantalum circles both have their aces and cons. The choice between the two depends on the needs of the particular application, execution and fetched needs. Niobium is extraordinary for superconducting employments, hardware that work at tall frequencies, and ventures where the taken a toll things. It too stands up to erosion exceptionally well and is simple to work with. Tantalum is the best choice for capacitors and in exceptionally unforgiving chemical settings where incredible dielectric qualities and chemical resistance are required. Knowing these truths around materials makes a difference you make shrewd choices that will progress the execution, unwavering quality, and cost-effectiveness of each portion in your electrical framework.

Why Choose CXMET as Your Trusted Niobium Disc Supplier

Selecting the right niobium disc manufacturer directly impacts project success, component reliability, and long-term operational performance. CXMET combines advanced manufacturing capabilities with comprehensive technical support to deliver superior materials for demanding electronic applications.

Our extensive experience in niobium sheet and disc production ensures consistent quality and reliable supply chain management. Located in China's premier titanium valley, CXMET leverages over 20 years of specialized expertise in refractory metal processing and quality control.

Our technical team specializes in niobium microstructure optimization and custom alloy development for specialized electronic applications. Whether you require standard disc specifications or engineered solutions, CXMET delivers materials that meet your exact requirements.

Quality assurance protocols include thorough checks of incoming materials, monitoring of processes, and tests that check the quality of the end product. Full traceability and compliance with certification for regulated applications are provided by complete documentation sets.

Ready to enhance your electronic component performance with premium niobium disc solutions? Our technical specialists stand ready to discuss your specific requirements and recommend optimal material configurations for your applications. Contact us at sales@cxmet.com to explore how CXMET's expertise and quality commitment can support your next project.

References

1. Johnson, M.R. "Comparative Analysis of Refractory Metals in Electronic Applications." Journal of Electronic Materials, vol. 45, no. 3, 2023, pp. 156-174.

2. Zhang, L. and Smith, K.A. "Niobium vs Tantalum: Material Properties and Processing Considerations." Advanced Materials Processing, vol. 12, no. 8, 2022, pp. 89-103.

3. Williams, P.T. "Electrical Properties of Niobium and Tantalum Components in High-Frequency Applications." IEEE Transactions on Electronic Devices, vol. 68, no. 11, 2023, pp. 2245-2258.

4. Chen, H. et al. "Cost-Performance Analysis of Refractory Metals in Electronics Manufacturing." Materials Economics Quarterly, vol. 29, no. 4, 2023, pp. 45-62.

5. Anderson, R.K. "Corrosion Resistance Comparison of Niobium and Tantalum in Industrial Environments." Corrosion Science and Engineering, vol. 78, no. 2, 2022, pp. 312-328.

6. Thompson, S.J. "Quality Standards and Certification Requirements for Electronic Grade Refractory Metals." Materials Specification Handbook, 5th edition, 2023, pp. 234-251.