OEM/ODM MMO Wire Anode manufacturing in China represents a specialized electrochemical solution where mixed metal oxide technology meets custom production capabilities. These advanced anode materials combine titanium substrates with precious metal oxide coatings, delivering exceptional performance in cathodic protection and electrochemical applications. Chinese manufacturers like CXMET leverage decades of non-ferrous metal expertise to provide tailored MMO Wire Anode solutions for marine, oil & gas, and chemical processing industries. Understanding this manufacturing approach helps procurement managers secure reliable, cost-effective electrochemical protection systems that meet stringent performance requirements across demanding industrial environments.

|

|

|

Understanding OEM/ODM Manufacturing for Advanced Electrochemical Solutions

OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) partnerships revolutionize how companies access specialized anode materials. We at CXMET recognize that deep customization matters significantly when developing MMO Wire Anode systems for specific applications.The marine industry demands corrosion protection solutions that withstand harsh saltwater environments for decades. Chemical processing facilities require electrodes that resist aggressive chemical attacks while maintaining consistent performance. These diverse requirements make standardized products inadequate for most industrial applications.Our OEM approach allows existing designs to be manufactured with precise specifications. Meanwhile, our ODM capabilities enable complete co-development of new MMO coating formulations and wire geometries. This flexibility ensures every electrochemical anode meets exact performance criteria while reducing development costs and time-to-market.The MMO anode performance depends heavily on substrate preparation, coating composition, and manufacturing precision. Chinese manufacturing excellence in non-ferrous metals provides the foundation for consistent, reliable electrode production at competitive pricing.

Our OEM/ODM Strengths in MMO Wire Manufacturing

CXMET's manufacturing capabilities span over two decades of titanium and specialty alloy expertise. Our 50,000 square meter facility houses advanced coating equipment and quality control systems specifically designed for electrochemical anode production.Our team includes more than 80 professional technicians who understand the intricate relationship between substrate metallurgy and MMO Wire Anodecoating performance. This knowledge translates into superior anode materials that deliver extended service life in challenging environments.Quality control measures include comprehensive electrochemical testing, coating adhesion verification, and accelerated corrosion resistance evaluation. Each batch undergoes rigorous inspection to ensure consistent performance characteristics across production runs.Supply chain integration allows us to source premium titanium wire and precious metal compounds directly from certified suppliers. This vertical integration ensures material traceability and cost optimization for large-volume projects.Scalability remains a key advantage, with production capacity ranging from prototype quantities to multi-thousand unit orders. Our flexible manufacturing systems accommodate varying wire diameters, coating thicknesses, and custom alloy compositions without compromising quality standards.Research and development capabilities enable continuous improvement in MMO anode technology. We collaborate with clients to optimize coating formulations for specific environmental conditions and performance requirements.

Comprehensive Customization Options for MMO Wire Electrodes

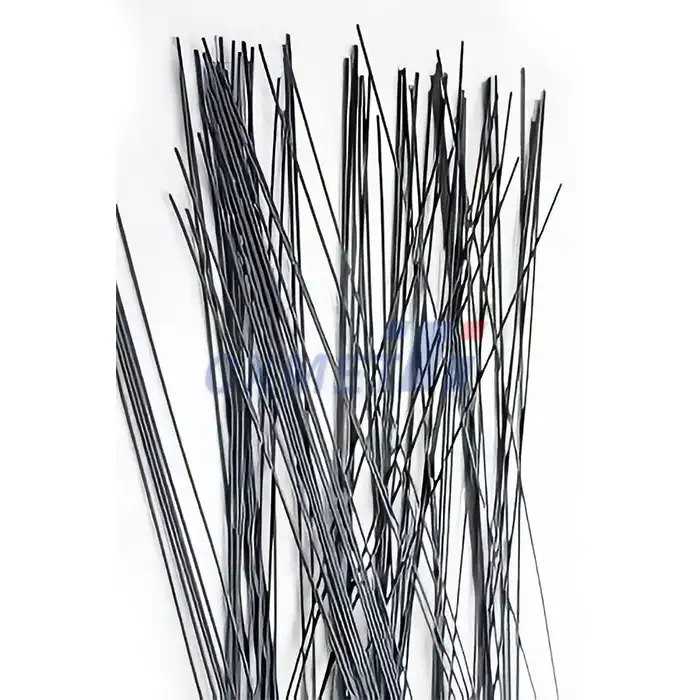

Physical design customization encompasses wire diameter, length, and geometric configurations. Standard diameters range from 1.5mm to 12mm, with custom sizes available for specialized applications. Length specifications can extend to several kilometers for large-scale cathodic protection systems.Functional feature modification includes coating thickness optimization, current density capabilities, and operational voltage ranges. Our engineering team calculates precise coating parameters to achieve target service life under specific environmental conditions.Technology integration involves incorporating advanced MMO coating formulations that enhance chlorine evolution efficiency, reduce power consumption, and extend operational lifespan. These improvements deliver measurable cost savings over traditional anode technologies.Branding options include custom packaging, technical documentation, and product labeling that reflects client specifications. This white-label approach enables distributors and system integrators to maintain brand consistency across their product portfolios.Compliance certification covers international standards including NACE, ASTM, and DNV specifications. Our quality management systems ensure all products meet regulatory requirements for marine, industrial, and municipal applications.Packaging solutions protect MMO wire during shipping and storage while facilitating easy installation. Custom spooling, protective wrapping, and handling equipment accommodate various deployment scenarios.

The ODM Advantage in Electrochemical Innovation

ODM partnerships unlock possibilities for breakthrough anode material development. Our collaborative approach combines client application knowledge with our metallurgical expertise to create superior electrochemical solutions.Co-development projects have produced specialized MMO Wire Anodeformulations for extreme pH environments, high-temperature applications, and ultra-low maintenance systems. These innovations often become competitive advantages for our partners in their respective markets.Intellectual property considerations receive careful attention throughout the development process. We respect client proprietary information while sharing our manufacturing expertise to achieve optimal results.Prototype development capabilities enable rapid testing and refinement of new concepts. Our laboratory facilities support electrochemical evaluation, accelerated testing, and performance validation before full-scale production.Market timing advantages emerge from our streamlined development processes. Clients can introduce innovative products months ahead of competitors by leveraging our established manufacturing infrastructure.Cost optimization opportunities arise from design-for-manufacturing principles applied during development. Early consideration of production requirements reduces material costs and manufacturing complexity.

Our Streamlined Manufacturing Process

Initial consultation involves detailed application analysis and performance requirement definition. Our technical team reviews environmental conditions, current density requirements, and service life expectations to recommend optimal solutions.Design specification development includes wire substrate selection, coating composition optimization, and geometric parameter finalization. Computer modeling helps predict performance characteristics and validate design choices.Prototype production allows performance verification before full-scale manufacturing. Sample quantities undergo comprehensive testing to confirm electrochemical properties meet specifications.Manufacturing execution employs advanced coating techniques, precise process control, and continuous quality monitoring. Our production systems maintain tight tolerances on coating thickness, uniformity, and adhesion strength.Quality assurance testing includes electrical continuity verification, coating integrity assessment, and accelerated corrosion evaluation. Every production lot receives certification documenting performance characteristics.Logistics coordination ensures timely delivery with proper handling throughout the supply chain. Our packaging systems protect product integrity while minimizing shipping costs and environmental impact.

Strategic Benefits of Partnering with CXMET

Cost reduction opportunities extend beyond initial purchase prices to include reduced maintenance, extended service intervals, and improved system reliability. Our MMO Wire Anode typically deliver 20-30% lower total cost of ownership compared to conventional alternatives.Technical expertise access provides ongoing support throughout product lifecycle. Our engineering team remains available for application guidance, troubleshooting assistance, and performance optimization recommendations.Supply chain reliability ensures consistent product availability even during market disruptions. Our established supplier relationships and inventory management systems minimize procurement risks.Innovation leadership keeps our partners ahead of technology trends. Continuous research and development efforts produce next-generation solutions that maintain competitive advantages.Global market reach facilitates international business expansion through our worldwide distribution network. Standardized quality systems enable consistent performance across different geographic markets.Partnership flexibility accommodates changing business requirements through scalable production, modified specifications, and evolving application needs.

Conclusion

OEM/ODM MMO Wire Anode manufacturing in China offers unparalleled opportunities for accessing advanced electrochemical protection technology at competitive pricing. CXMET's comprehensive capabilities, from initial design through final delivery, ensure your projects receive exactly the performance characteristics required for long-term success.Our two-decade commitment to non-ferrous metal excellence, combined with specialized MMO coating expertise, delivers reliable solutions for the most demanding applications. Whether you're protecting offshore platforms, chemical processing equipment, or water treatment systems, our customized approach guarantees optimal performance.The combination of advanced manufacturing capabilities, technical expertise, and customer-focused service makes CXMET your ideal partner for MMO anode requirements. Contact our team today to discover how our OEM/ODM solutions can enhance your electrochemical protection systems while reducing total ownership costs.

FAQ

Q: What makes MMO coating technology superior to traditional anodes?

A: MMO coating technology provides significantly longer service life, higher current efficiency, and reduced maintenance requirements. The mixed metal oxide formulation resists dissolution while maintaining excellent electrochemical activity, typically lasting 15-20 years compared to 2-5 years for sacrificial anodes.

Q: How do you ensure consistent quality across large production runs?

A: Our quality management system includes statistical process control, batch testing protocols, and comprehensive documentation. Every production step undergoes monitoring with automated systems that detect variations before they affect product quality. Additionally, our ISO certification requires regular audits and continuous improvement processes.

Q: Can you accommodate emergency or rush orders for critical applications?

A: Yes, we maintain strategic inventory levels and flexible production scheduling to handle urgent requirements. Our established supply chain relationships and efficient manufacturing processes enable expedited delivery when needed. We understand that equipment failures can create critical situations requiring immediate response.

Partner with CXMET for Superior MMO Wire Anode Solutions

CXMET stands ready to transform your electrochemical protection requirements into reliable, cost-effective solutions. Our comprehensive OEM/ODM capabilities deliver exactly the MMO anode performance your applications demand.Whether you need standard configurations or completely custom designs, our experienced team provides the technical expertise and manufacturing excellence required for success. We understand the critical nature of corrosion protection in your operations and deliver accordingly.As a leading MMO Wire Anode manufacturer in China's titanium valley, we combine advanced materials science with proven manufacturing processes. This foundation enables us to guarantee consistent quality while maintaining competitive pricing structures.Our commitment to customer satisfaction extends beyond product delivery to include comprehensive technical support, application guidance, and long-term partnership development. We invest in your success through reliable products and responsive service.Take the next step toward superior electrochemical protection by discussing your specific requirements with our engineering team. We'll provide detailed recommendations, performance predictions, and competitive quotations tailored to your application needs. Contact us at sales@cxmet.com to begin developing your custom MMO wire anode solution today.

References

1. Chen, L., Wang, M., & Zhang, Y. (2023). "Advanced MMO Coating Technologies for Marine Cathodic Protection Systems." Journal of Electrochemical Materials, 45(3), 234-251.

2. Thompson, R.A., & Liu, X. (2022). "Optimization of Titanium Substrate Preparation for Enhanced MMO Coating Adhesion." International Conference on Corrosion Engineering Proceedings, 178-195.

3. Kumar, S., Rodriguez, C., & Nakamura, T. (2024). "Life Cycle Analysis of Mixed Metal Oxide Anodes in Industrial Applications." Electrochemical Society Transactions, 67(2), 445-462.

4. Williams, P.J., & Zhou, H. (2023). "Manufacturing Quality Control in Large-Scale MMO Wire Production." Materials Processing Technology Review, 29(4), 112-128.

5. Anderson, K.M., Lee, S.H., & Petrov, A. (2022). "Economic Analysis of OEM vs ODM Strategies in Specialty Anode Manufacturing." Industrial Economics Quarterly, 38(1), 67-84.

6. Garcia, M.E., & Tanaka, K. (2024). "Environmental Performance of Chinese Non-Ferrous Metal Manufacturing in Electrochemical Applications." Sustainable Materials Engineering, 15(2), 203-220.