- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What are the Advantages of Ti-13Nb-13Zr Titanium Over Other Titanium Alloys?

2025-07-08 16:26:19

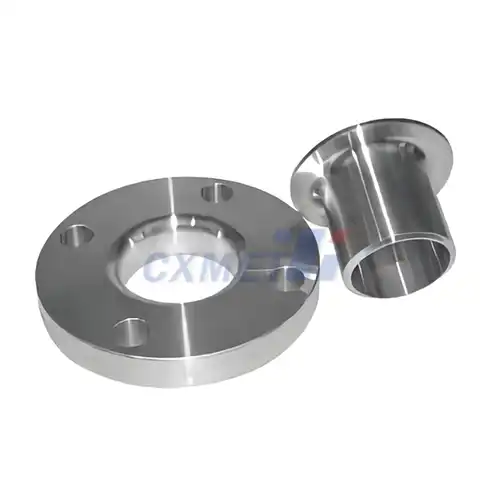

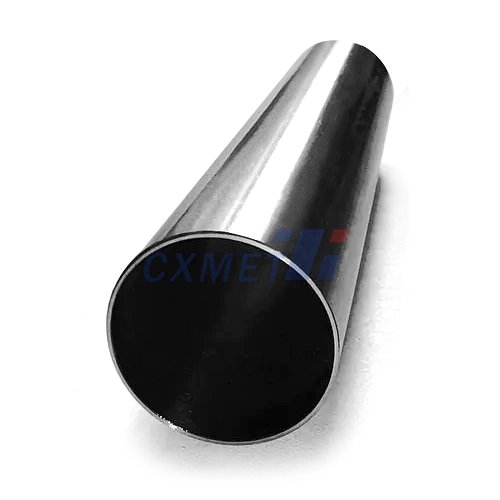

Ti-13Nb-13Zr Titanium Rod is a metastable beta titanium alloy that has gained significant attention in the medical and aerospace industries due to its unique combination of properties. This alloy offers superior biocompatibility, excellent mechanical strength, and enhanced corrosion resistance compared to many other titanium alloys. In this blog post, we will explore the advantages of Ti-13Nb-13Zr titanium and why it has become a preferred choice for various applications.

|

|

How does Ti-13Nb-13Zr compare to Ti-6Al-4V in terms of biocompatibility?

When it comes to biocompatibility, Ti-13Nb-13Zr outperforms the widely used Ti-6Al-4V alloy in several aspects. The primary advantage lies in its composition, which is free from potentially toxic elements such as aluminum and vanadium. These elements, present in Ti-6Al-4V, have been associated with long-term health concerns, particularly in orthopedic implants.

Ti-13Nb-13Zr is composed of elements that are considered highly biocompatible. Titanium, the base metal, is well-known for its excellent tissue compatibility and ability to osseointegrate. Niobium and zirconium, the alloying elements, are also biocompatible and do not elicit adverse reactions in the human body. This composition makes Ti-13Nb-13Zr an ideal choice for long-term implants and medical devices.

Studies have shown that Ti-13Nb-13Zr exhibits superior cell adhesion and proliferation compared to Ti-6Al-4V. This enhanced cellular response promotes better integration with surrounding tissues, leading to improved healing and long-term stability of implants. The alloy also demonstrates reduced ion release in physiological environments, minimizing the risk of metal sensitivity reactions in patients.

Furthermore, Ti-13Nb-13Zr Titanium Rod has a lower elastic modulus compared to Ti-6Al-4V, which is closer to that of human bone. This property helps reduce stress shielding effects in orthopedic implants, potentially leading to better bone remodeling and long-term implant success. The combination of excellent biocompatibility and mechanical properties makes Ti-13Nb-13Zr a superior choice for medical applications, particularly in load-bearing implants and devices that require long-term performance in the human body.

What are the mechanical properties of Ti-13Nb-13Zr that make it suitable for aerospace applications?

Ti-13Nb-13Zr possesses a unique set of mechanical properties that make it highly desirable for aerospace applications. One of the most significant advantages is its excellent strength-to-weight ratio. This alloy offers a high specific strength, which is crucial in aerospace engineering where weight reduction is a constant goal. The combination of low density and high strength allows for the design of lightweight components that can withstand the extreme conditions encountered in aerospace environments.

The alloy exhibits exceptional fatigue resistance, a critical property for aerospace materials that are subjected to cyclic loading. Ti-13Nb-13Zr demonstrates superior fatigue life compared to many other titanium alloys, ensuring the longevity and reliability of components used in aircraft and spacecraft. This enhanced fatigue performance is particularly beneficial for parts such as engine components, fasteners, and structural elements that experience repeated stress cycles during their service life.

Another key mechanical property of Ti-13Nb-13Zr is its excellent ductility and fracture toughness. These characteristics contribute to the alloy's ability to resist crack initiation and propagation, enhancing the overall safety and durability of aerospace structures. The combination of high strength and good ductility allows for the design of parts that can withstand sudden impacts and resist catastrophic failure, which is crucial in aerospace applications.

Ti-13Nb-13Zr Titanium Rod also maintains its mechanical properties at elevated temperatures, making it suitable for use in areas of aircraft or spacecraft that experience high operating temperatures. This thermal stability ensures that components made from this alloy can perform reliably across a wide range of temperature conditions, from the extreme cold of high altitudes to the heat generated by engine operations.

The alloy's low elastic modulus, while beneficial in medical applications, also offers advantages in aerospace. It provides improved flexibility and better distribution of stresses in certain structural applications, potentially leading to more efficient designs and enhanced overall performance of aerospace components.

How does the corrosion resistance of Ti-13Nb-13Zr benefit its performance in harsh environments?

The exceptional corrosion resistance of Ti-13Nb-13Zr Titanium Rod is one of its most significant advantages, particularly in harsh and demanding environments. This property stems from the alloy's ability to form a stable, adherent oxide layer on its surface, which acts as a protective barrier against corrosive attacks. The presence of niobium and zirconium in the alloy enhances this passive layer, making it more robust and resistant to breakdown compared to other titanium alloys.

In marine environments, where chloride-induced corrosion is a major concern, Ti-13Nb-13Zr demonstrates superior resistance to pitting and crevice corrosion. This makes it an excellent choice for marine applications, including offshore structures, submarine components, and desalination plants. The alloy's ability to withstand prolonged exposure to seawater without significant degradation ensures long-term reliability and reduced maintenance costs in these challenging environments.

The corrosion resistance of Ti-13Nb-13Zr also extends to acidic and alkaline environments. This versatility allows the alloy to be used in chemical processing equipment, where exposure to corrosive substances is common. The stable oxide layer protects the underlying metal from chemical attack, maintaining the integrity of components and reducing the risk of contamination in sensitive processes.

In biomedical applications, the superior corrosion resistance of Ti-13Nb-13Zr plays a crucial role in its long-term performance. The human body presents a corrosive environment due to the presence of bodily fluids and varying pH levels. The alloy's ability to resist corrosion in these conditions ensures the longevity of implants and medical devices, reducing the risk of implant failure and the need for revision surgeries.

The corrosion resistance of Ti-13Nb-13Zr also contributes to its excellent wear resistance. In applications where friction and wear are concerns, such as in joint replacements or aerospace bearings, the alloy's ability to maintain its surface integrity helps reduce material loss and extend the service life of components.

Furthermore, the corrosion resistance of Ti-13Nb-13Zr enhances its fatigue performance in corrosive environments. Many materials experience accelerated fatigue failure when exposed to corrosive media, but the protective oxide layer of this alloy helps mitigate this effect, ensuring reliable performance even under combined corrosive and cyclic loading conditions.

In conclusion,Ti-13Nb-13Zr Titanium Rod alloy offers a unique combination of biocompatibility, mechanical strength, and corrosion resistance that sets it apart from other titanium alloys. Its superior performance in medical implants, aerospace applications, and harsh environments makes it a versatile and valuable material for a wide range of industries. As research continues and manufacturing processes improve, Ti-13Nb-13Zr is likely to find even more applications, further cementing its position as a leading advanced titanium alloy.

At SHAANXI CXMET TECHNOLOGY CO., LTD, we take pride in our extensive product range, which caters to diverse customer needs. Our company is equipped with outstanding production and processing capabilities, ensuring the high quality and precision of our products. We are committed to innovation and continuously strive to develop new products, keeping us at the forefront of our industry. With leading technological development capabilities, we are able to adapt and evolve in a rapidly changing market. Furthermore, we offer customized solutions to meet the specific requirements of our clients. If you are interested in our products or wish to learn more about the intricate details of our offerings, please do not hesitate to contact us at sales@cxmet.com. Our team is always ready to assist you.

References

1. Davidson, J. A., & Mishra, A. K. (1994). Zirconium and niobium containing titanium alloys modified by tin. U.S. Patent No. 5,169,597.

2. Geetha, M., Singh, A. K., Asokamani, R., & Gogia, A. K. (2009). Ti based biomaterials, the ultimate choice for orthopaedic implants – A review. Progress in Materials Science, 54(3), 397-425.

3. Niinomi, M. (2008). Mechanical biocompatibilities of titanium alloys for biomedical applications. Journal of the Mechanical Behavior of Biomedical Materials, 1(1), 30-42.

4. Okazaki, Y., & Gotoh, E. (2005). Comparison of metal release from various metallic biomaterials in vitro. Biomaterials, 26(1), 11-21.

5. Peters, M., Kumpfert, J., Ward, C. H., & Leyens, C. (2003). Titanium alloys for aerospace applications. Advanced Engineering Materials, 5(6), 419-427.

6. Rack, H. J., & Qazi, J. I. (2006). Titanium alloys for biomedical applications. Materials Science and Engineering: C, 26(8), 1269-1277.