- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What Are The Applications for Grade 9 Titanium Alloy?

2024-08-30 15:16:07

Grade 9 titanium alloy, also known as Ti-3Al-2.5V, is a remarkable material that has gained significant attention across various industries due to its exceptional properties and versatile applications. This alpha-beta titanium alloy combines the strength of titanium with enhanced formability and weldability, making it an ideal choice for a wide range of demanding applications. In this blog post, we'll explore the unique characteristics of Grade 9 titanium and delve into its diverse applications, focusing on its use in aerospace, aviation, and medical industries.

What are the key properties of Grade 9 titanium alloy (Ti-3Al-2.5V)?

Grade 9 titanium alloy, composed of 3% aluminum and 2.5% vanadium, offers a compelling blend of properties that make it suitable for various applications. Understanding these properties is crucial to appreciating why this alloy is so widely used across different industries.

First and foremost, Grade 9 titanium boasts an exceptional strength-to-weight ratio. This characteristic is particularly valuable in industries where weight reduction is critical, such as aerospace and automotive. The alloy's high strength allows for the creation of components that can withstand significant stress while remaining lightweight, contributing to improved fuel efficiency and performance in vehicles and aircraft.

Corrosion resistance is another standout property of Grade 9 titanium. The alloy forms a stable, protective oxide layer on its surface when exposed to oxygen, providing excellent resistance to various corrosive environments. This makes it ideal for use in marine applications, chemical processing equipment, and medical implants where exposure to bodily fluids is a concern.

The alloy's biocompatibility is a key factor in its widespread use in the medical field. Grade 9 titanium is non-toxic and does not elicit adverse reactions when in contact with human tissue or bodily fluids. This property, combined with its strength and corrosion resistance, makes it an excellent choice for medical implants and surgical instruments.

Grade 9 titanium also exhibits good formability and weldability compared to other titanium alloys. This characteristic allows for easier manufacturing processes, including cold working and welding, which are essential for creating complex shapes and structures. The alloy's ability to be formed into various shapes without compromising its strength makes it valuable in industries requiring intricate components.

Temperature resistance is another notable property of Grade 9 titanium. The alloy maintains its strength and structural integrity across a wide range of temperatures, from cryogenic conditions to moderately high temperatures. This temperature stability makes it suitable for applications in both extremely cold environments and those involving heat, such as aircraft engines and industrial processing equipment.

Furthermore, Grade 9 titanium demonstrates excellent fatigue resistance. This means it can withstand repeated cycles of stress without failure, a crucial property for components subject to cyclic loading, such as aircraft parts and medical implants.

The alloy also possesses good crack resistance, which enhances its reliability in critical applications. This property, combined with its high strength, allows for the design of components with thinner walls, further contributing to weight reduction in various applications.

Lastly, Grade 9 titanium exhibits low thermal expansion. This property is particularly valuable in applications where dimensional stability is crucial, such as in precision instruments and spacecraft components.

Understanding these key properties helps explain why Grade 9 titanium alloy has found such widespread use across various industries. Its unique combination of strength, lightweight, corrosion resistance, biocompatibility, formability, and temperature resistance makes it an invaluable material in modern engineering and manufacturing.

How is Grade 9 titanium used in aerospace and aviation industries?

The aerospace and aviation industries have long been at the forefront of materials innovation, constantly seeking alloys that can meet the demanding requirements of flight. Grade 9 titanium alloy (Ti-3Al-2.5V) has emerged as a crucial material in these sectors, offering a unique combination of properties that make it ideal for various aircraft and spacecraft components.

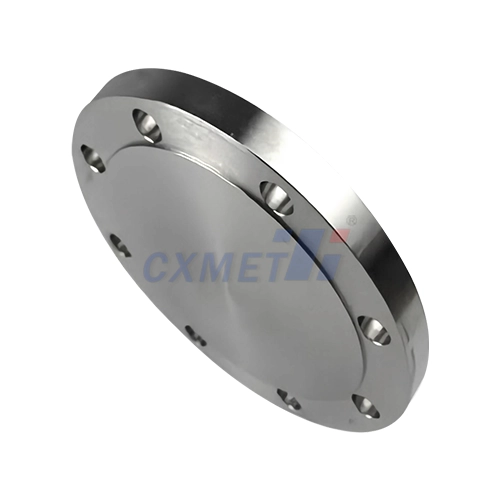

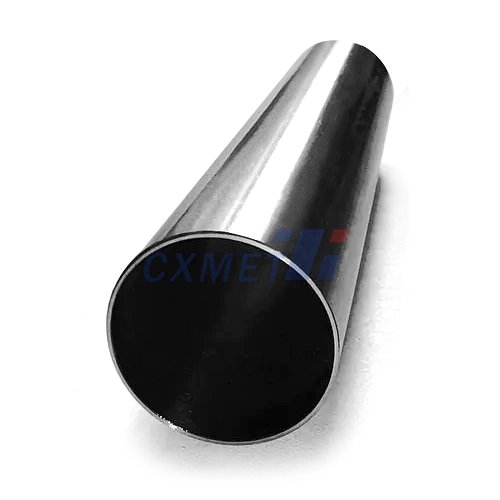

One of the primary applications of Grade 9 titanium in aerospace is in the construction of hydraulic and pneumatic systems. The alloy's excellent strength-to-weight ratio, combined with its superior corrosion resistance, makes it an ideal choice for tubing in these systems. Aircraft hydraulic systems operate under high pressure and must withstand significant stress while remaining lightweight. Grade 9 titanium tubing meets these requirements perfectly, allowing for the design of efficient and reliable hydraulic systems that contribute to overall aircraft performance and safety.

In addition to hydraulic systems, Grade 9 titanium is extensively used in the manufacture of aircraft structural components. The alloy's high strength and low density allow engineers to design parts that are both lightweight and capable of withstanding the extreme forces experienced during flight. This includes components such as fuselage frames, wing structures, and landing gear parts. By using Grade 9 titanium in these applications, aircraft manufacturers can significantly reduce the overall weight of the aircraft, leading to improved fuel efficiency and increased payload capacity.

The aerospace industry also utilizes Grade 9 titanium in the production of engine components. The alloy's ability to maintain its strength at elevated temperatures makes it suitable for use in various parts of jet engines, including compressor blades, discs, and casings. These components must withstand high temperatures and stresses while resisting creep and fatigue. Grade 9 titanium's unique properties allow it to meet these demanding requirements, contributing to the efficiency and reliability of modern aircraft engines.

Another crucial application of Grade 9 titanium in aerospace is in the manufacture of fasteners. Aircraft assembly requires thousands of bolts, nuts, and other fasteners that must be strong, lightweight, and resistant to corrosion. Grade 9 titanium fasteners offer these properties, ensuring the structural integrity of the aircraft while minimizing weight. The alloy's good formability also allows for the production of complex fastener geometries, providing engineers with greater design flexibility.

In the realm of space exploration, Grade 9 titanium finds applications in spacecraft and satellite components. The extreme conditions of space, including vacuum, radiation, and temperature fluctuations, demand materials with exceptional properties. Grade 9 titanium's low thermal expansion, high strength-to-weight ratio, and excellent corrosion resistance make it an ideal choice for various spacecraft structures and components. This includes pressure vessels, propulsion system components, and structural support elements.

The alloy's use extends to unmanned aerial vehicles (UAVs) and drones as well. As these platforms become increasingly sophisticated and are required to perform complex missions, the need for lightweight, high-strength materials becomes more critical. Grade 9 titanium allows UAV manufacturers to create drones with extended flight times, improved payload capacities, and enhanced durability.

Moreover, Grade 9 titanium plays a role in the development of advanced aerospace technologies. For instance, it is used in the construction of heat exchangers for aircraft environmental control systems. The alloy's good thermal conductivity and corrosion resistance make it suitable for this application, ensuring efficient temperature regulation within the aircraft.

The use of Grade 9 titanium in aerospace and aviation is not limited to new construction. The alloy is also valuable in repair and maintenance operations. Its excellent weldability allows for the repair of damaged components, extending the service life of aircraft and reducing maintenance costs.

As the aerospace industry continues to push the boundaries of performance and efficiency, the role of Grade 9 titanium is likely to expand further. Research into new manufacturing techniques, such as additive manufacturing (3D printing), is opening up new possibilities for the use of this alloy in even more complex and optimized aerospace components.

In conclusion, Grade 9 titanium alloy has become an indispensable material in the aerospace and aviation industries. Its unique combination of properties – high strength, low weight, corrosion resistance, and temperature stability – makes it ideal for a wide range of applications, from critical structural components to intricate hydraulic systems. As these industries continue to evolve, Grade 9 titanium will undoubtedly play a crucial role in shaping the future of flight and space exploration.

What advantages does Grade 9 titanium offer for medical implants and devices?

The medical industry has long been in search of materials that can safely and effectively interface with the human body while providing the necessary mechanical properties for various implants and devices. Grade 9 titanium alloy (Ti-3Al-2.5V) has emerged as a frontrunner in this field, offering a unique set of advantages that make it an excellent choice for a wide range of medical applications.

One of the primary advantages of Grade 9 titanium in medical implants is its outstanding biocompatibility. The human body is known to tolerate titanium exceptionally well, with minimal risk of allergic reactions or rejection. Grade 9 titanium, in particular, does not release harmful ions into the surrounding tissues, making it safe for long-term implantation. This biocompatibility is crucial for ensuring the success of implants and reducing the risk of complications post-surgery.

The alloy's excellent corrosion resistance is another significant advantage in medical applications. When implanted in the body, medical devices are exposed to a highly corrosive environment due to the presence of bodily fluids. Grade 9 titanium's ability to form a stable, protective oxide layer on its surface provides superior resistance to corrosion, ensuring the longevity and integrity of the implant. This property is particularly important for devices that need to remain in the body for extended periods, such as joint replacements or dental implants.

The high strength-to-weight ratio of Grade 9 titanium is a crucial advantage in the design of medical implants. This property allows for the creation of implants that are strong enough to withstand the mechanical stresses of the human body while remaining lightweight. Lighter implants reduce the burden on surrounding tissues and can contribute to faster patient recovery and improved comfort. For instance, in orthopedic applications, Grade 9 titanium implants can provide the necessary strength for load-bearing joints without adding excessive weight to the skeletal structure.

Another significant advantage of Grade 9 titanium in medical applications is its excellent fatigue resistance. Many medical implants, particularly those used in orthopedics, are subjected to cyclic loading over extended periods. The ability of Grade 9 titanium to withstand repeated stress cycles without failure ensures the long-term reliability of these implants, reducing the need for revision surgeries and improving patient outcomes.

The alloy's low modulus of elasticity, which is closer to that of human bone compared to other metals used in implants, is another advantage. This property helps to reduce stress shielding, a phenomenon where the implant bears most of the load, leading to bone resorption around the implant. By more closely matching the elasticity of bone, Grade 9 titanium implants promote better load distribution and can help maintain bone density around the implant site.

Grade 9 titanium's excellent formability and machinability offer significant advantages in the manufacturing of medical devices. The alloy can be easily formed into complex shapes and geometries, allowing for the creation of custom implants tailored to individual patient anatomy. This flexibility in design and manufacturing is particularly valuable in fields such as craniofacial surgery, where implants often need to match specific anatomical contours.

The alloy's compatibility with various surface treatments and coatings is another advantage in medical applications. Grade 9 titanium implants can be treated to enhance their surface properties, improving osseointegration (the direct structural and functional connection between living bone and the surface of a load-bearing artificial implant). Techniques such as plasma spraying or acid etching can create micro-textures on the implant surface, promoting better bone ingrowth and implant stability.

In the field of cardiovascular medicine, Grade 9 titanium offers advantages for devices such as heart valve frames and stents. The alloy's combination of strength, flexibility, and biocompatibility makes it suitable for these applications where the device must withstand the constant movement and pressure of the cardiovascular system while remaining inert to blood and tissue.

Grade 9 titanium's non-magnetic properties are particularly advantageous in medical applications. This characteristic makes it compatible with magnetic resonance imaging (MRI) procedures, allowing patients with titanium implants to safely undergo MRI scans without the risk of implant movement or image distortion.

Furthermore, the alloy's ability to osseointegrate – to form a direct bond with bone tissue – is a significant advantage in dental and orthopedic implants. This property ensures the long-term stability of the implant and promotes better healing and functionality.

In conclusion, Grade 9 titanium alloy offers a multitude of advantages for medical implants and devices. Its biocompatibility, corrosion resistance, high strength-to-weight ratio, fatigue resistance, and formability make it an ideal material for a wide range of medical applications. From orthopedic and dental implants to cardiovascular devices and surgical instruments, Grade 9 titanium continues to play a crucial role in advancing medical technology and improving patient outcomes. As research in biomaterials continues to evolve, it's likely that new applications and advantages of this versatile alloy will be discovered, further cementing its place in the medical industry.

At SHAANXI CXMET TECHNOLOGY CO., LTD, we take pride in our extensive product range, which caters to diverse customer needs. Our company is equipped with outstanding production and processing capabilities, ensuring the high quality and precision of our products. We are committed to innovation and continuously strive to develop new products, keeping us at the forefront of our industry. With leading technological development capabilities, we are able to adapt and evolve in a rapidly changing market. Furthermore, we offer customized solutions to meet the specific requirements of our clients. If you are interested in our products or wish to learn more about the intricate details of our offerings, please do not hesitate to contact us at sales@cxmet.com. Our team is always ready to assist you.

References

1. Lutjering, G., & Williams, J. C. (2007). Titanium (2nd ed.). Springer-Verlag Berlin Heidelberg.

2. Froes, F. H. (2015). Titanium: Physical Metallurgy, Processing, and Applications. ASM International.

3. Rack, H. J., & Qazi, J. I. (2006). Titanium alloys for biomedical applications. Materials Science and Engineering: C, 26(8), 1269-1277.

4. Boyer, R., Welsch, G., & Collings, E. W. (1994). Materials Properties Handbook: Titanium Alloys. ASM International.

5. Peters, M., Kumpfert, J., Ward, C. H., & Leyens, C. (2003). Titanium alloys for aerospace applications. Advanced Engineering Materials, 5(6), 419-427.

6. Niinomi, M. (2008). Mechanical biocompatibilities of titanium alloys for biomedical applications. Journal of the Mechanical Behavior of Biomedical Materials, 1(1), 30-42.

7. Banerjee, D., & Williams, J. C. (2013). Perspectives on titanium science and technology. Acta Materialia, 61(3), 844-879.

8. Elias, C. N., Lima, J. H. C., Valiev, R., & Meyers, M. A. (2008). Biomedical applications of titanium and its alloys. JOM, 60(3), 46-49.

9. Donachie, M. J. (2000). Titanium: A Technical Guide (2nd ed.). ASM International.

10. Geetha, M., Singh, A. K., Asokamani, R., & Gogia, A. K. (2009). Ti based biomaterials, the ultimate choice for orthopaedic implants – A review. Progress in Materials Science, 54(3), 397-425.