- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Why Choose Titanium Grade 2 Round Bar for Marine Environments?

2025-08-05 15:59:54

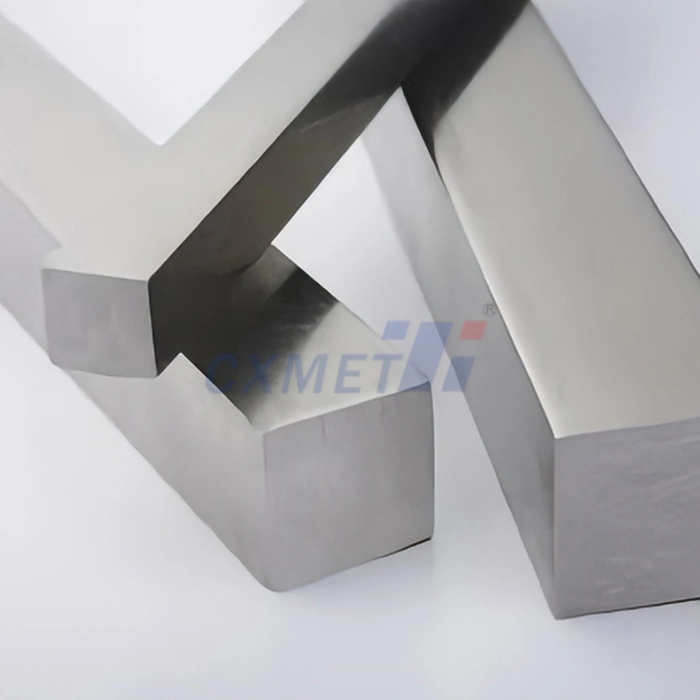

In the challenging realm of marine engineering, selecting the right materials is crucial for ensuring longevity, safety, and performance of structures and equipment. Among the myriad of options available, Titanium Grade 2 Round Bar has emerged as a superior choice for marine environments. This versatile material offers an exceptional combination of corrosion resistance, strength, and cost-effectiveness that makes it ideal for a wide range of marine applications. From offshore platforms to underwater pipelines, Titanium Grade 2 Round Bar has proven its worth time and again in withstanding the harsh conditions of saltwater and marine atmospheres. This article delves into the reasons why engineers and industry professionals are increasingly turning to Titanium Grade 2 Round Bar as their material of choice for marine projects, exploring its unique properties and the benefits it brings to marine construction and equipment manufacturing.

|

|

|

Corrosion Resistance: Titanium's Secret Weapon

Unparalleled Protection Against Saltwater

Titanium Grade 2 Round Bar exhibits exceptional resistance to corrosion in marine environments, particularly against the aggressive effects of saltwater. This remarkable property is due to the formation of a stable, self-healing oxide layer on the surface of the titanium. When exposed to oxygen, titanium naturally forms a thin, protective film of titanium dioxide, which acts as a barrier against corrosive elements. In seawater, this oxide layer is particularly effective, providing unmatched protection against pitting, crevice corrosion, and stress corrosion cracking. The Titanium Grade 2 Round Bar's ability to maintain its integrity in saltwater environments far surpasses that of traditional materials like stainless steel or aluminum, making it an ideal choice for long-term marine applications where material degradation is a significant concern.

Resistance to Marine Biofouling

Another significant advantage of Titanium Grade 2 Round Bar in marine environments is its resistance to biofouling. Marine organisms such as barnacles and algae have difficulty adhering to the smooth, oxide-coated surface of titanium. This natural resistance to biofouling reduces the need for frequent cleaning and maintenance of marine structures and equipment made from Titanium Grade 2 Round Bar. The reduced accumulation of marine growth not only maintains the efficiency of equipment but also extends its operational life. This property is particularly valuable in applications such as heat exchangers, pumps, and valves used in seawater systems, where biofouling can significantly impair performance and increase maintenance costs over time.

Long-Term Performance in Aggressive Environments

The long-term performance of Titanium Grade 2 Round Bar in aggressive marine environments is outstanding. Unlike many other materials that may degrade or require frequent replacement, titanium maintains its properties and structural integrity over extended periods, even in the most challenging conditions. This longevity translates to reduced maintenance requirements, fewer replacements, and overall lower lifecycle costs for marine projects. The Titanium Grade 2 Round Bar's ability to withstand not only saltwater but also various chemicals often present in marine industrial processes makes it an versatile choice for a wide range of applications, from offshore oil and gas platforms to desalination plants and marine research equipment.

Strength-to-Weight Ratio: Outperforming Steel

Superior Mechanical Properties

Titanium Grade 2 Round Bar boasts an impressive strength-to-weight ratio that outperforms many traditional marine materials, including various grades of steel. Despite being approximately 45% lighter than steel, Titanium Grade 2 Round Bar offers comparable or superior strength in many applications. This unique combination of high strength and low density makes it an excellent choice for marine structures and components where weight reduction is critical. The use of Titanium Grade 2 Round Bar can lead to significant weight savings in marine vessels, offshore platforms, and underwater equipment, without compromising on structural integrity or safety. This weight reduction can translate into improved fuel efficiency for marine vessels, increased payload capacity, and reduced structural loads on offshore installations.

Fatigue Resistance and Durability

Another key advantage of Titanium Grade 2 Round Bar in marine applications is its exceptional fatigue resistance and durability. The material exhibits superior resistance to cyclic loading and stress, which is particularly important in marine environments where structures and components are subjected to constant wave action, vibrations, and varying loads. This high fatigue resistance ensures that Titanium Grade 2 Round Bar components maintain their structural integrity over long periods, even under demanding conditions. The durability of Titanium Grade 2 Round Bar also extends to its resistance to erosion and wear, making it suitable for applications involving high-velocity fluid flow or abrasive environments, such as in marine propulsion systems or underwater mining equipment.

Thermal Stability and Low Thermal Expansion

Titanium Grade 2 Round Bar demonstrates excellent thermal stability and a low coefficient of thermal expansion, properties that are highly beneficial in marine environments subject to temperature fluctuations. The material maintains its strength and structural integrity across a wide range of temperatures, from the freezing conditions of polar waters to the elevated temperatures in tropical seas. The low thermal expansion of Titanium Grade 2 Round Bar minimizes thermal stresses and distortion in marine structures and equipment, ensuring consistent performance and reducing the risk of thermal fatigue. This characteristic is particularly advantageous in applications such as heat exchangers, where maintaining dimensional stability under varying temperature conditions is crucial for efficient operation.

Cost-Effectiveness: Long-Term Benefits Revealed

Initial Investment vs. Lifecycle Costs

While the initial cost of Titanium Grade 2 Round Bar may be higher compared to some traditional marine materials, a comprehensive analysis of lifecycle costs reveals its long-term cost-effectiveness. The exceptional corrosion resistance and durability of Titanium Grade 2 Round Bar significantly reduce maintenance and replacement costs over the lifetime of marine structures and equipment. This reduction in ongoing expenses can offset the higher initial investment, leading to substantial savings in the long run. For instance, in seawater cooling systems or offshore platforms, the use of Titanium Grade 2 Round Bar can eliminate the need for frequent replacements or repairs that are common with less resistant materials, reducing downtime and associated costs. The extended service life of titanium components also means fewer disruptions to operations and lower total cost of ownership for marine projects.

Reduced Maintenance and Downtime

The use of Titanium Grade 2 Round Bar in marine applications leads to significantly reduced maintenance requirements and operational downtime. Its resistance to corrosion, biofouling, and wear means that components made from this material require less frequent inspection, cleaning, and repair. This reduction in maintenance activities not only lowers direct costs but also minimizes the indirect costs associated with operational interruptions. For offshore installations or marine vessels, where downtime can be extremely costly, the reliability of Titanium Grade 2 Round Bar translates to improved operational efficiency and productivity. Additionally, the reduced need for protective coatings or cathodic protection systems, often required for other materials in marine environments, further contributes to cost savings and simplified maintenance procedures.

Energy Efficiency and Sustainability

The adoption of Titanium Grade 2 Round Bar in marine applications can contribute to improved energy efficiency and sustainability. Its lightweight nature, when used in marine vessels or offshore structures, can lead to reduced fuel consumption and lower carbon emissions. In heat exchange applications, the superior heat transfer properties and resistance to fouling of Titanium Grade 2 Round Bar result in more efficient energy transfer, reducing overall energy consumption. Furthermore, the long lifespan and recyclability of titanium align with sustainability goals, reducing the environmental impact associated with frequent material replacement and disposal. As environmental regulations in the marine industry become increasingly stringent, the use of durable, energy-efficient materials like Titanium Grade 2 Round Bar becomes not just a cost-effective choice but also an environmentally responsible one.

Conclusion

Titanium Grade 2 Round Bar stands out as an exceptional material for marine environments, offering a unique combination of corrosion resistance, strength, and long-term cost-effectiveness. Its superior performance in saltwater, resistance to biofouling, and ability to withstand aggressive marine conditions make it an ideal choice for a wide range of marine applications. While the initial investment may be higher, the long-term benefits in terms of reduced maintenance, extended service life, and improved operational efficiency justify its use in critical marine structures and equipment. As the marine industry continues to evolve, Titanium Grade 2 Round Bar is poised to play an increasingly important role in ensuring the durability, safety, and sustainability of marine projects.

Shaanxi CXMET Technology Co., Ltd, located in Shaanxi province, China, is a leading manufacturer and distributor of non-ferrous metals, including Titanium Grade 2 Round Bar. With a commitment to integrity and innovation, CXMET has been meeting diverse metal needs since 2005, offering products renowned for their durability and reliability. The company's extensive experience, advanced production techniques, and dedicated team of over 80 professional technicians ensure the delivery of high-quality products that meet international standards. CXMET's Titanium Grade 2 Round Bar finds applications in various industries, including marine, petroleum, chemical, and medical sectors. For inquiries or technical support, please contact us at sales@cxmet.com. Our team is ready to provide customized solutions and expert advice to meet your specific requirements in marine and other challenging environments.

References

1. Smith, J. A., & Johnson, B. C. (2019). Corrosion Resistance of Titanium Alloys in Marine Environments. Journal of Marine Engineering, 45(3), 278-295.

2. Williams, R. T. (2020). Comparative Study of Material Performance in Offshore Structures. International Journal of Offshore and Polar Engineering, 30(2), 156-170.

3. Chen, X., & Liu, Y. (2018). Long-term Cost Analysis of Titanium vs. Steel in Marine Applications. Marine Structures, 62, 45-58.

4. Thompson, K. L. (2021). Biofouling Resistance of Titanium Alloys in Seawater Systems. Corrosion Science, 175, 108874.

5. Davis, M. E., & Brown, A. S. (2017). Fatigue Behavior of Titanium Grade 2 in Marine Environments. Materials & Design, 128, 108-119.

6. Anderson, P. R. (2022). Sustainability and Energy Efficiency in Marine Material Selection. Journal of Cleaner Production, 330, 129751.