- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

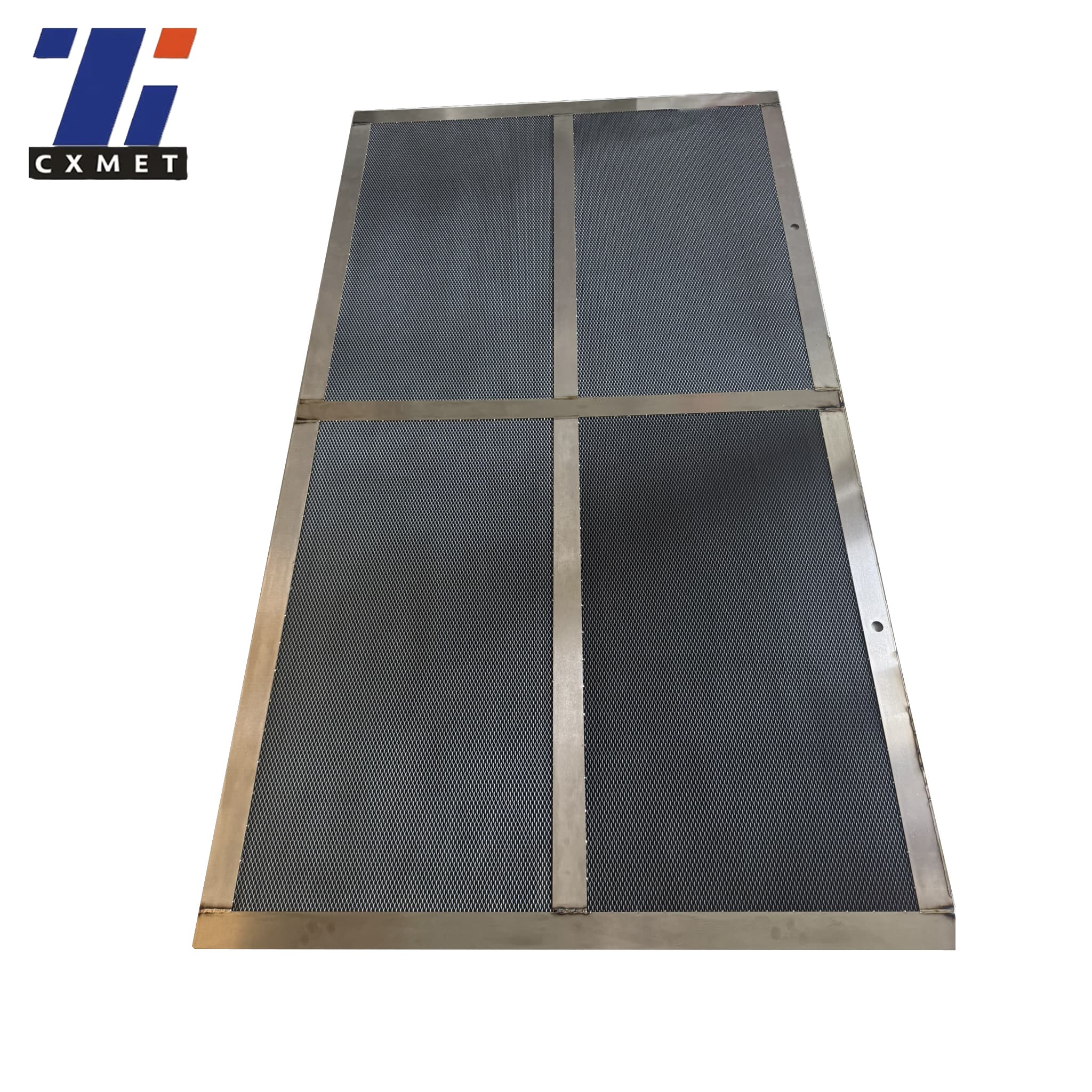

mmo titanium mesh anode

Place Of Origin:China

Grade: Ti+MMO

Material: GR1

Standard: ASTM B381

Material:Titanium Gr1

Ru-ir oxide Coating,8-12micron;ir-ta oxide coating 8-12micron;platinum coating 0.5-2.5micron.

Size: Customizable.

Surface Treatment: Sand blasting,Acid cleaning, Polished,brushing.

Shaanxi CXMET Technology Co., Ltd.: Your Trusted MMO Titanium Mesh Anode Manufacturer

Welcome to Shaanxi CXMET Technology Co., Ltd., your premier source for high-quality MMO titanium mesh anodes. With over 20 years of experience, we've become a leading manufacturer and supplier in the titanium industry. Our MMO titanium mesh anodes offer superior performance, durability, and cost-effectiveness for a wide range of electrochemical applications. We pride ourselves on our advanced manufacturing processes, stringent quality control, and commitment to customer satisfaction.

Product Introduction

Our MMO titanium mesh anodes are engineered to provide exceptional electrochemical performance in demanding industrial environments. These anodes feature a titanium substrate coated with a mixed metal oxide (MMO) layer, typically composed of iridium, tantalum, and other precious metals. This unique combination results in a product that offers:

- Outstanding corrosion resistance

- High current density capacity

- Extended service life

- Low chlorine overpotential

- Excellent dimensional stability

Key Features and Benefits

- Durability: Our MMO titanium mesh anodes are designed to withstand harsh chemical environments, ensuring long-lasting performance and reducing replacement costs.

- Efficiency: The high catalytic activity of the MMO coating allows for efficient electron transfer, minimizing energy consumption in your electrochemical processes.

- Versatility: Available in various mesh sizes and dimensions, our anodes can be tailored to suit a wide range of applications and equipment configurations.

- Cost-effective: Despite the initial investment, the long service life and high performance of our anodes translate to significant cost savings over time.

- Environmentally friendly: Our anodes contribute to cleaner production processes by minimizing unwanted by-products and reducing energy consumption.

OEM and Customization Services: Customized Geometries and Exact Dimensions

At Shaanxi CXMET Technology Co., Ltd., we understand that one size doesn't fit all. That's why we offer comprehensive OEM and customization services for our MMO titanium mesh anodes. Our experienced engineering team can work with you to develop anodes that meet your specific requirements:

- Custom mesh sizes and wire diameters

- Tailored overall dimensions and shapes

- Specialized coating compositions for unique applications

- Integration of current distributors or connection points

- Packaging and labeling to your specifications

Whether you need a small modification to our standard products or a completely custom design, we're here to bring your vision to life.

Product Features

- Titanium substrate: Grade 1 ASTM B265 titanium for optimal strength and conductivity

- MMO coating: Proprietary blend of iridium, tantalum, and other precious metals

- Mesh construction: Precise weaving for uniform current distribution

- Edge treatment: Smooth, reinforced edges to prevent unraveling and ensure safety

- Connection options: Various attachment methods available (welded tabs, threaded studs, etc.)

Technical Specifications

- Standard mesh sizes: 20 to 80 mesh (customizable)

- Wire diameter range: 0.2mm to 1.0mm

- Typical sheet dimensions: Up to 1.2m x 2.4m (larger sizes available upon request)

- Coating loading: 12-15 g/m² (adjustable based on application requirements)

- Current density capacity: Up to 10,000 A/m² (application-dependent)

- Operating temperature range: -10°C to 95°C

- pH tolerance: 0-14

Applications and Industries

Our MMO titanium mesh anodes find use in a diverse range of applications across multiple industries:

|

|

|

|

|

|

Tips and Tricks

To maximize the performance and longevity of your MMO titanium mesh anodes:

- Ensure proper installation and electrical connections to prevent hotspots and uneven wear.

- Maintain recommended operating parameters (current density, temperature, pH) for your specific application.

- Implement regular cleaning and maintenance schedules to remove any buildup on the anode surface.

- Monitor anode performance over time and plan for replacement before significant degradation occurs.

- Consider using spacers or frames to maintain optimal distance between anodes and cathodes in your system.

Manufacturing Process

Our state-of-the-art manufacturing process ensures consistent quality and performance:

- Titanium mesh fabrication: Precision weaving of titanium wire to create the mesh substrate.

- Surface preparation: Chemical etching and mechanical treatment to optimize coating adhesion.

- MMO coating application: Proprietary thermal decomposition process for uniform coating deposition.

- Heat treatment: Carefully controlled thermal cycles to achieve optimal coating properties.

- Quality control: Rigorous testing at each stage of production.

- Finishing: Edge treatment, size adjustment, and installation of connection points as required.

Factory show

|

|

|

|

Production workshop

|

|

|

|

|

|

Production Equipments

Main Products

How to Choose Products and Why Choose Products Made by Us

When selecting MMO titanium mesh anodes, consider the following factors:

- Application requirements: Match the anode specifications to your specific process needs.

- Operating conditions: Ensure the anode can withstand your system's chemical environment and operating parameters.

- Expected service life: Calculate the total cost of ownership, factoring in replacement frequency.

- Customization options: Choose a supplier capable of meeting your unique design requirements.

- Technical support: Look for a manufacturer offering comprehensive assistance throughout the product lifecycle.

Shaanxi CXMET Technology Co., Ltd. stands out as your ideal choice for MMO titanium mesh anodes because:

- We offer superior product quality backed by rigorous testing and quality control.

- Our extensive customization capabilities ensure you get exactly what you need.

- Our technical expertise and customer support are unmatched in the industry.

- We provide competitive pricing without compromising on quality or performance.

- Our commitment to innovation keeps you at the forefront of electrochemical technology.

Certifications and Compliance

Our MMO titanium mesh anodes and manufacturing processes meet or exceed industry standards:

- ISO 9001:2015 Quality Management System

- ISO 14001:2015 Environmental Management System

- ASTM B265 compliance for titanium substrate

- RoHS and REACH compliant

- CE marked for applicable products

Quality Control and Testing

We employ a comprehensive quality control system to ensure every MMO titanium mesh anode meets our high standards:

- Raw material inspection: Verification of titanium grade and purity

- In-process checks: Coating thickness, adhesion, and uniformity measurements

- Electrochemical testing: Performance validation under simulated operating conditions

- Dimensional inspection: Ensuring adherence to specified tolerances

- Accelerated life testing: Projecting long-term performance and durability

- Final visual and functional inspection before packaging

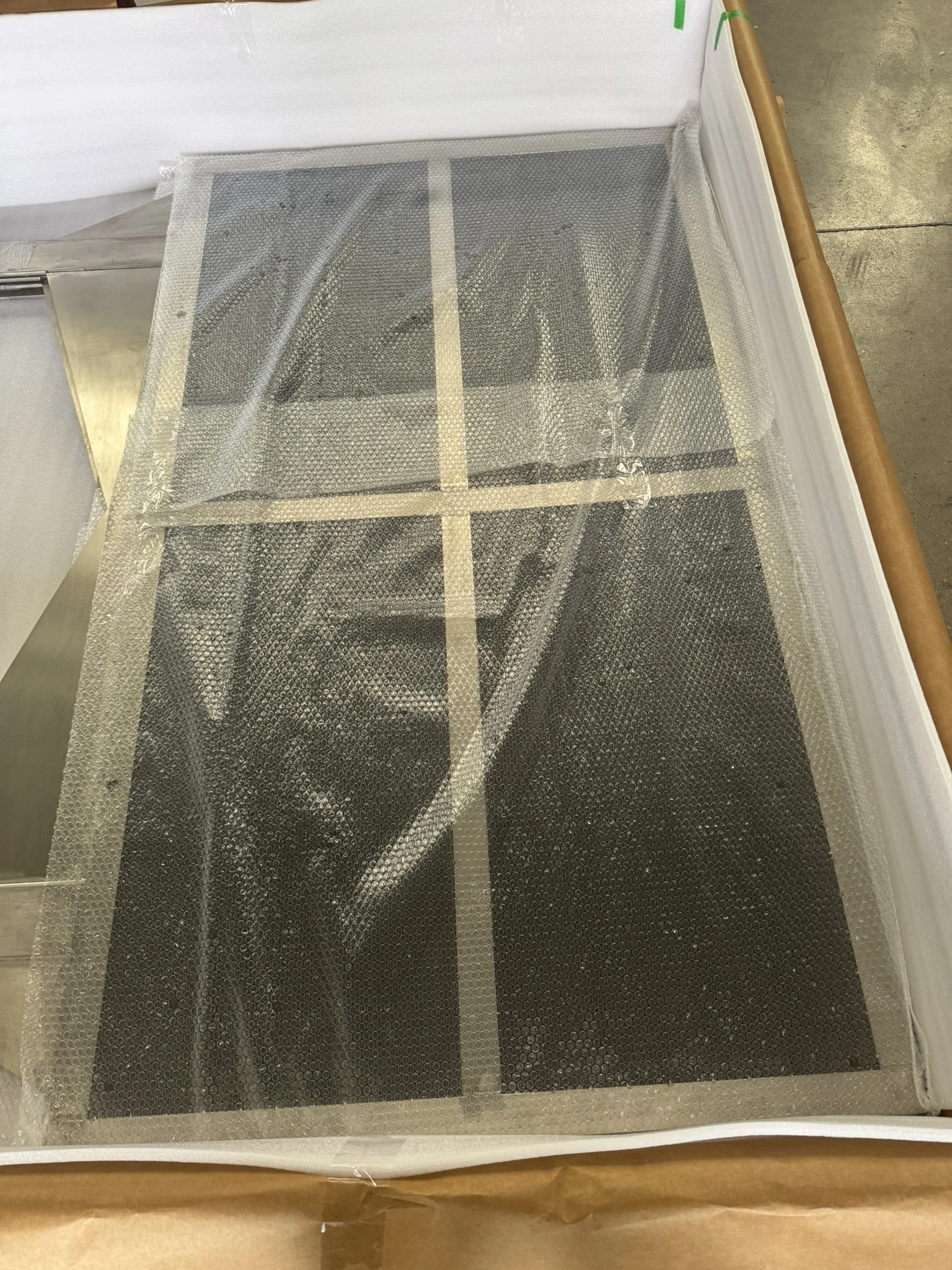

Packaging and Shipping

Our MMO titanium mesh anodes are carefully packaged to ensure they reach you in perfect condition:

- Individual protective wrapping for each anode

- Sturdy cardboard boxes or wooden crates for bulk orders

- Custom packaging options available for sensitive or uniquely shaped products

- Comprehensive shipping documentation and tracking

- Global logistics partners for efficient worldwide delivery

Testimonials and Case Studies

"Shaanxi CXMET's MMO titanium mesh anodes have significantly improved our chlor-alkali production efficiency. Their technical support team was invaluable during implementation." - John D., Chief Engineer at ChemCorp Inc.

Case Study: A major wastewater treatment plant reduced their operating costs by 30% after switching to our custom-designed MMO titanium mesh anodes. Read the full case study on our website.

FAQs

- What is the typical lifespan of your MMO titanium mesh anodes?

The service life varies depending on operating conditions but typically ranges from 5-10 years in most applications.

- Can your anodes be used in seawater applications?

Yes, our anodes are well-suited for seawater electrolysis and desalination processes.

- Do you offer samples for testing?

Certainly! We provide sample anodes for evaluation. Contact our sales team for details.

- What is the lead time for custom orders?

Lead times vary based on specifications and quantity. Generally, we can deliver custom orders within 4-8 weeks.

- How do I determine the right mesh size for my application?

Our technical team can assist you in selecting the optimal mesh size based on your specific requirements.

Contact Us

Ready to enhance your electrochemical processes with our high-performance MMO titanium mesh anodes? Contact our expert team today!

Email: sales@cxmet.com

Tel&WhatsApp: 8615891192169Discover the Shaanxi CXMET Technology Co., Ltd. difference – where quality, innovation, and customer satisfaction meet.

hotTags:mmo titanium mesh anode,supplier,wholesale,China,factory,manufacturer,OEM,Customized,trader,for sale,in stock,free sample,for sale.

YOU MAY LIKE