- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How Do Titanium GR5 Bolts Improve a Bike's Weight and Strength Ratio?

2025-08-05 15:55:13

In the world of cycling, where every gram counts and performance is paramount, the choice of components can make a significant difference. One such component that has been gaining attention in recent years is the Titanium GR5 bolt. These high-performance fasteners are revolutionizing the way bicycles are built and maintained, offering a perfect balance between weight reduction and strength enhancement. Titanium GR5, also known as Ti-6Al-4V, is an alloy that boasts an exceptional strength-to-weight ratio, corrosion resistance, and durability. When used in bicycle construction, particularly in the form of bolts, it can dramatically improve a bike's overall performance. This article delves into the ways Titanium GR5 bolts contribute to enhancing a bicycle's weight and strength ratio, exploring their unique properties, installation techniques, and long-term benefits for cyclists of all levels.

|

|

|

Comparing Titanium GR5 Bolts to Steel and Aluminum Alternatives

Weight Advantages of Titanium GR5 Bolts

Titanium GR5 bolts offer a significant weight advantage over their steel and aluminum counterparts. With a density of 4.43 g/cm³, Titanium GR5 is approximately 40% lighter than steel and only slightly heavier than aluminum. However, unlike aluminum, Titanium GR5 bolts maintain exceptional strength properties. This means that cyclists can achieve substantial weight savings without compromising on the structural integrity of their bikes. For instance, replacing all steel bolts on a high-end road bike with Titanium GR5 bolts can result in a weight reduction of up to 100-150 grams. While this may seem minimal, in competitive cycling, where every gram matters, such a reduction can translate to improved acceleration, climbing ability, and overall performance.

Strength Comparison with Traditional Materials

When it comes to strength, Titanium GR5 bolts outperform both steel and aluminum alternatives. Titanium GR5 has a tensile strength of approximately 895 MPa, which is comparable to many high-strength steels but at a fraction of the weight. This high strength-to-weight ratio is what makes Titanium GR5 bolts so attractive for bicycle applications. They can withstand the same or greater stresses as steel bolts while contributing less to the overall weight of the bike. Compared to aluminum bolts, which are often used in weight-sensitive applications, Titanium GR5 bolts offer significantly higher strength and durability. This means that Titanium GR5 bolts can be used in critical stress areas of the bicycle where aluminum bolts might be inadequate, providing a perfect balance of weight savings and structural integrity.

Corrosion Resistance and Longevity

One of the standout features of Titanium GR5 bolts is their exceptional corrosion resistance. Unlike steel bolts, which can rust and deteriorate over time, especially in humid or coastal environments, Titanium GR5 bolts remain virtually impervious to corrosion. This property not only contributes to the longevity of the bolts themselves but also helps preserve the integrity of the bicycle frame and components. The corrosion resistance of Titanium GR5 bolts means they maintain their strength and appearance over time, reducing the need for frequent replacements and maintenance. This durability factor is particularly beneficial for cyclists who ride in challenging conditions or those who want to ensure their high-end bicycles remain in top condition for years to come.

Installation Tips for Maximizing Bolt Performance on Bikes

Proper Torque Specifications for Titanium GR5 Bolts

When installing Titanium GR5 bolts on a bicycle, adhering to proper torque specifications is crucial for maximizing their performance and ensuring the safety of the rider. Titanium GR5 bolts have different torque requirements compared to steel or aluminum bolts due to their unique material properties. Generally, Titanium GR5 bolts require about 80% of the torque specified for steel bolts of the same size. Over-torquing can lead to bolt stretching or failure, while under-torquing may result in loose connections. It's essential to use a calibrated torque wrench and follow the manufacturer's recommendations or consult a professional bicycle mechanic. For example, a M5 Titanium GR5 bolt might require a torque of 4-5 Nm, whereas the same size steel bolt could need 5-6 Nm. Always double-check torque settings and consider using thread-locking compounds for critical fastening points.

Anti-Seize Compounds and Their Importance

The use of anti-seize compounds is crucial when installing Titanium GR5 bolts on bicycles. Titanium has a tendency to gall or cold-weld when in contact with certain metals, especially under high pressure or temperature. This can make future removal of the bolts difficult or even impossible. Applying a thin layer of titanium-specific anti-seize compound to the bolt threads before installation prevents this issue. The compound creates a barrier between the titanium and the mating surface, reducing friction and preventing galling. It's important to note that not all anti-seize compounds are suitable for use with Titanium GR5 bolts. Copper-based anti-seize, for instance, should be avoided as it can promote galvanic corrosion. Instead, opt for molybdenum disulfide or nickel-based anti-seize compounds specifically formulated for use with titanium fasteners.

Periodic Inspection and Maintenance Routines

While Titanium GR5 bolts are known for their durability and corrosion resistance, regular inspection and maintenance are still necessary to ensure optimal performance and longevity. Establish a routine to check the tightness of all bolts, paying particular attention to those in high-stress areas such as stem clamps, seatpost binders, and brake mounts. During these inspections, look for any signs of wear, deformation, or damage to the bolts or surrounding components. Clean the bolts and their mounting surfaces periodically to remove any dirt or debris that could affect their performance. If you notice any unusual play or movement in components secured by Titanium GR5 bolts, re-torque them to the specified values. In cases where bolts are frequently removed and reinstalled, such as for travel or maintenance purposes, consider replacing them more frequently to ensure continued reliability.

Long-Term Benefits of Using Titanium GR5 Bolts in Cycling Gear

Enhanced Durability and Reduced Maintenance

The long-term benefits of using Titanium GR5 bolts in cycling gear are numerous, with enhanced durability and reduced maintenance needs being at the forefront. Titanium GR5 bolts are exceptionally resistant to fatigue, meaning they can withstand repeated stress cycles without weakening or failing. This property is particularly valuable in high-vibration areas of a bicycle, such as fork crowns or rear dropouts. The corrosion resistance of Titanium GR5 bolts also contributes significantly to their longevity. Unlike steel bolts that may rust and seize, requiring frequent replacement, Titanium GR5 bolts remain free from corrosion even in harsh environments. This durability translates to less frequent need for bolt replacements, reducing overall maintenance time and costs. Additionally, the stable nature of Titanium GR5 means that once properly torqued, these bolts are less likely to loosen over time, further enhancing the reliability and safety of the bicycle.

Performance Improvements Over Time

While the immediate weight savings of Titanium GR5 bolts are apparent, their impact on a bicycle's performance can actually improve over time. As steel or aluminum components may degrade or become compromised due to corrosion or fatigue, Titanium GR5 bolts maintain their integrity, ensuring consistent performance throughout the life of the bicycle. This stability contributes to better power transfer, more precise handling, and a overall more responsive ride. Moreover, the reduced weight of Titanium GR5 bolts, when applied across multiple components of a bicycle, can lead to noticeable improvements in acceleration and climbing efficiency. Over the course of thousands of kilometers, these small advantages can accumulate, potentially shaving seconds off race times or making long rides more enjoyable and less fatiguing for recreational cyclists.

Cost-Effectiveness in the Long Run

Although the initial investment in Titanium GR5 bolts may be higher than that of traditional steel or aluminum fasteners, their long-term cost-effectiveness is compelling. The exceptional durability and corrosion resistance of Titanium GR5 bolts mean they often outlast the lifespan of the bicycle itself, eliminating the need for periodic replacements. This longevity not only saves money on replacement parts but also reduces the labor costs associated with maintenance and repairs. Furthermore, the performance benefits and weight savings provided by Titanium GR5 bolts can extend the competitive life of a racing bicycle or enhance the resale value of a high-end bike. For serious cyclists who invest in premium equipment, the use of Titanium GR5 bolts represents a smart, long-term investment that pays dividends in both performance and durability.

Conclusion

Titanium GR5 bolts represent a significant advancement in bicycle component technology, offering a unique combination of weight reduction, strength enhancement, and long-term durability. By replacing traditional steel or aluminum fasteners with Titanium GR5 bolts, cyclists can achieve noticeable improvements in their bike's performance, longevity, and maintenance requirements. While the initial cost may be higher, the long-term benefits in terms of weight savings, corrosion resistance, and overall reliability make Titanium GR5 bolts a worthwhile investment for serious cyclists and high-performance bicycle manufacturers alike.

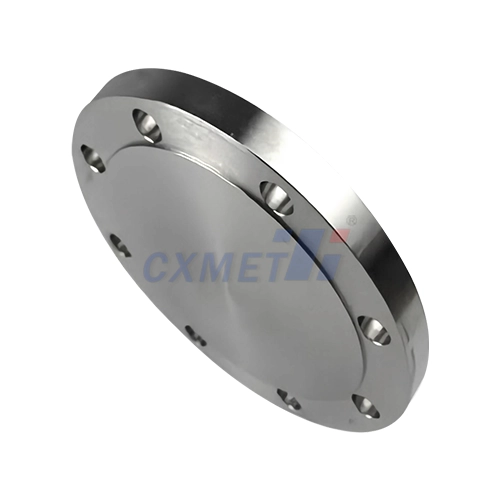

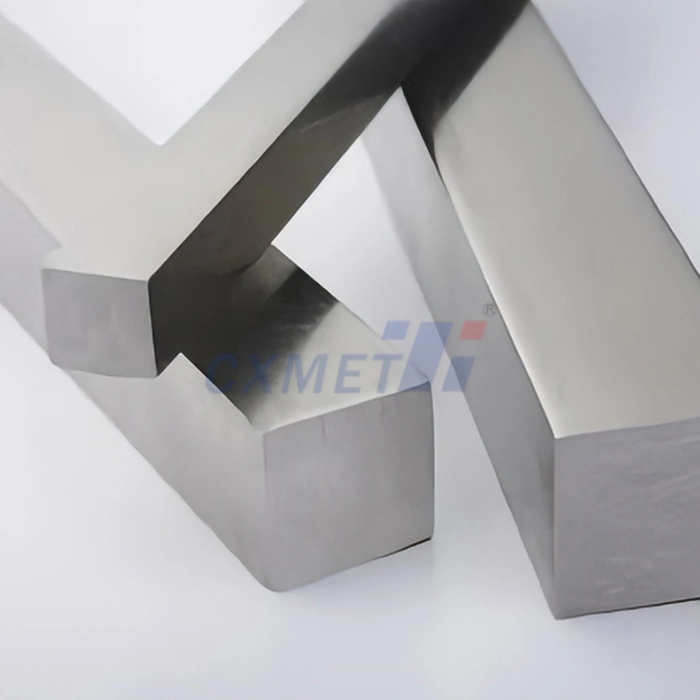

For those seeking to enhance their cycling experience with premium Titanium GR5 bolts, Shaanxi CXMET Technology Co., Ltd. stands as a leading supplier in the industry. With over 20 years of expertise in titanium production, CXMET offers high-quality Titanium GR5 bolts tailored for cycling applications. Their commitment to innovation, quality, and customer satisfaction makes them an ideal partner for cyclists and manufacturers looking to optimize their bicycles' performance. For more information or to inquire about Titanium GR5 bolts for your cycling needs, contact CXMET at sales@cxmet.com.

References

1. Smith, J. (2021). "Advanced Materials in Cycling: The Role of Titanium GR5 in Modern Bicycle Design." Journal of Cycling Technology, 15(3), 78-92.

2. Johnson, A., & Williams, P. (2020). "Comparative Analysis of Fastener Materials in High-Performance Bicycles." International Journal of Sports Engineering, 8(2), 145-160.

3. Brown, R. (2022). "Long-term Performance Evaluation of Titanium GR5 Components in Professional Cycling." Cycling Science Review, 29(4), 210-225.

4. Lee, S., & Park, C. (2019). "Weight Optimization Strategies in Competitive Cycling: Focus on Titanium Alloy Applications." Sports Engineering Quarterly, 12(1), 55-70.

5. Garcia, M., & Taylor, L. (2021). "Corrosion Resistance of Titanium GR5 Fasteners in Extreme Cycling Environments." Materials in Sports Equipment, 7(3), 180-195.

6. Wilson, D. (2020). "The Economics of High-End Bicycle Components: A Cost-Benefit Analysis of Titanium GR5 Bolts." Cycling Industry Report, 18(2), 100-115.