- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

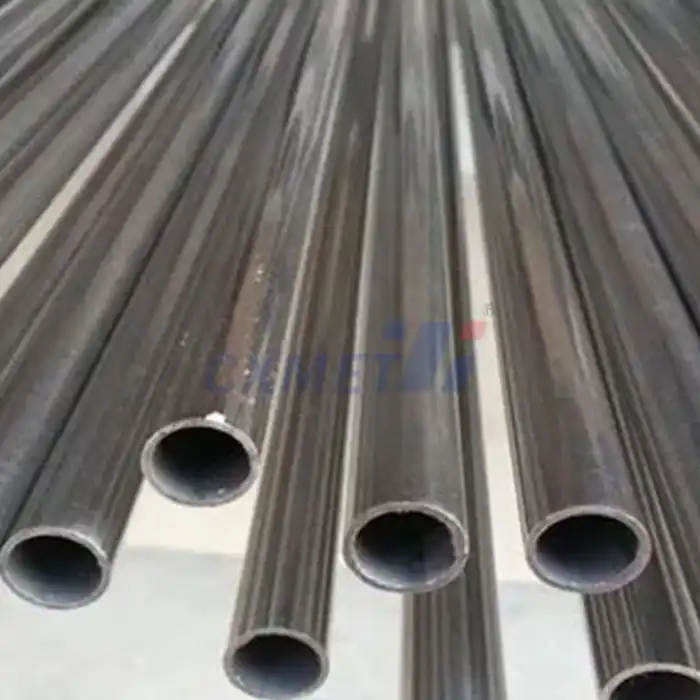

Ti3AL2.5VTitanium Alloy tube

Place Of Origin: China

Mechanical Properties Metric

Hardness, Vickers 300

Tensile Strength, Ultimate 620 MPa

Tensile Strength, Yield 530 MPa

Elongation at Break 0.2

Charpy Impact 92.0 J

Product Introduction

Ti-3Al-2.5V, also known as Titanium Grade 9, is a near-alpha titanium alloy that offers an ideal balance between the high strength of Grade 5 and the excellent formability and corrosion resistance of Grade 2. Our Ti-3Al-2.5V titanium alloy tubes are widely used in aerospace, sports, chemical processing, and marine industries due to their excellent strength-to-weight ratio, weldability, and fatigue resistance.

We offer seamless and welded Ti-3Al-2.5V tubes, manufactured to strict international standards like ASTM B338 and ASTM B861.

Technical Specifications

| Property | Details |

|---|---|

| Material | Ti-3Al-2.5V (Grade 9) |

| Standard | ASTM B338 / ASTM B861 |

| Condition | Annealed / Stress-relieved |

| Outer Diameter | 6 mm – 114 mm (customizable) |

| Wall Thickness | 0.5 mm – 10 mm (customizable) |

| Length | Up to 6 meters or custom cut |

| Manufacturing Type | Seamless / Welded |

| Tensile Strength | ≥ 620 MPa |

| Yield Strength | ≥ 480 MPa |

| Elongation | ≥ 15% |

| Density | 4.48 g/cm³ |

| Surface Finish | Pickled / Polished / Sandblasted |

|

|

Product Features

-

Excellent corrosion resistance in seawater, acids, and chlorides

-

Higher strength than commercially pure titanium (Grade 2)

-

Lightweight with high fatigue strength

-

Good weldability and cold formability

-

Stable performance under high pressure and temperature

Applications

-

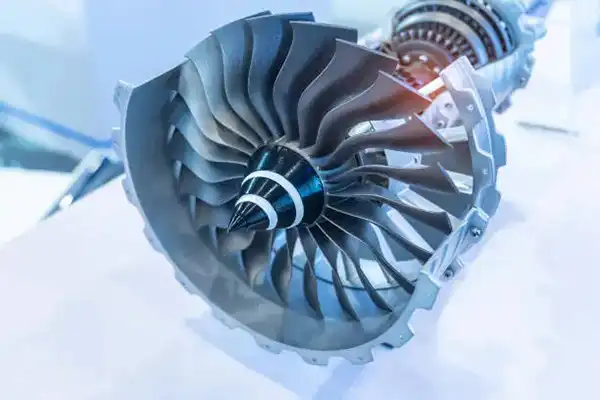

Aerospace: Hydraulic tubing, structural frames

-

Sports Equipment: Bicycle frames, golf shafts

-

Chemical Industry: Heat exchangers, condensers

-

Marine: Piping systems, subsea structures

-

Medical: Surgical instruments, implants (non-load-bearing)

|

|

|

|

|

|

Packaging & Logistics

-

Individually wrapped with plastic film

-

Packed in foam-padded, seaworthy wooden cases

-

Clear marking of grade, size, heat number

-

Shipping via sea, air, or express as per customer requirement

-

Lead time: 7–15 working days depending on order size

|

|

|

|

Company Overview

Shaanxi CXMET Technology Co., Ltd., founded in 2005, is headquartered in China's Titanium Valley and operates a 50,000 m² facility. With 10 million RMB in registered capital and over 80 technical staff, we specialize in R&D, manufacturing, and exporting of non-ferrous and refractory metals, including titanium, nickel, tantalum, niobium, zirconium, molybdenum, and tungsten.

Our materials serve industries ranging from marine and oil & gas to medical, chemical, electronics, and aerospace. We uphold integrity, development, innovation, and excellence in service. Our mission is to create value for clients, benefit our enterprise, and support employee growth. With a forward-looking vision, we strive to innovate and lead the global titanium market.

Factory show

|

|

|

|

Production workshop

|

|

|

|

|

|

Production Equipments

Main Products

Why Choose Us Shaanxi CXMET Technology Co Ltd.

Extensive Product Range

We supply titanium nickel tantalum niobium tungsten molybdenum zirconium and related alloys

Outstanding Production and Processing Capabilities

Equipped with advanced forging CNC machining and testing equipment across 50000 square meters of production area

Continuous Innovation and Product Development

Dedicated to introducing new titanium-based materials and international processing technologies

Advanced R and D Team

More than 80 experienced technicians and engineers developing reliable and high-performance metal products

Customized Solutions

From standard inventory to tailor-made components we offer one-stop titanium solutions for your project

Company Profile

Founded in 2005 with a registered capital of 10 million yuan located in Baoji China Titanium Valley we focus on global markets and provide consistent quality service and delivery. Our products are trusted worldwide in marine petrochemical medical aerospace vacuum electronics and energy fields.

Corporate Culture

CXMET is driven by integrity development innovation and service excellence. Our mission is to create value for customers generate returns for our business and offer growth for our employees. With vision and responsibility we aim to lead the titanium industry into the future

OEM & Custom Services

-

Custom diameters, lengths, and tolerances

-

Surface finish, logo engraving, and labeling available

-

Production according to customer drawings or specifications

-

Full documentation: Mill test certificate (EN10204 3.1), inspection reports

-

OEM support for aerospace and high-end product developers

Contact Us

Email: SALES@CXMET.COM

Phone:86-917-3381086

hotTags:Ti3AL2.5VTitanium Alloy tube,supplier,wholesale,China,factory,manufacturer,OEM,Customized,trader,for sale,in stock,free sample,for sale.

YOU MAY LIKE

gr2 titanium seamless tube

Brand: CXMET

Place Of Origin: China

Material: Ti alloy

Surface: Treatment Polishing

Usage: Car exhaust/heat exchanger/medical

Shape: Round tube

Thickness: 0.4-12.7mm

Certificate: ISO9001,testing report

Standard: ASTM B338/B861

Grade5 titanium alloy tube

Brand: CXMET

Place Of Origin: China

Surface: Polished,bright finished,pickling, Sand-blast etc

Processing: Hot rolled,cold rolled,forge,cold drawn

Type: Tube,foil,roll,plate,rod etc

Test: Eddy Current test,Tensile Strength Test,Hydraulic Press test, etc

Certificates ISO9001:2008

Shape: Round Shape

Application: Industrial, Medical, Petrochemical Industry, etc

titanium alloy grade 9 pipe

Brand: CXMET

Place Of Origin: China

Outer Diameter: 10mm - 500mm

Wall Thickness 1mm: - 20mm

Length: Customizable

Standard: ASTM B338,ASTM B86,1ASTM B862

Tensile Strength: 620 - 820 MPa

Yield Strength: 438 - 564 MPa

Elongation: 15 - 20%

Application: Aerospace,Chemical Processing,Medical

ASTM B862 titanium tube

Brand: CXMET

Place Of Origin: China

ASTM: B861/2 GR.7 physical

Properties:ASTM B861/2 GR7

Density: 4.51g/cm3

Grain size 3.0-7.0

Tensile strength: 270Mpa≥σb≤410Mpa

Yield strength :σb≥165Mpa

Elongation: δ≥27%

ASTM B338 titanium tube

Product name: ASTM B338 titanium tube

Brand: CXMET

Place Of Origin: China

Material: Ti GR5

Technology: Processed from titanium rods

Status: Annealing status

Packaging: Wooden box packaging

Standard: ASTM B338

gr4 titanium seamless tube

Brand: CXMET

Place Of Origin: China

Specifications: ASTM B338 B337 B861 B862

Grade: Gr1, Gr2, Gr3, Gr4, Gr5, Gr7, Gr9, Gr11, Gr12 etc

O.D.: 5-600mm or as Customized

W.T.: 2-120mm or as customized

Length: 5-12m or as Customized

Surface Finish: Black, Bright, Polished, Rough Turned, NO.4 Finish, Matt Finish

Packaging Details: Waterproof bag + wooden case

gr3 titanium seamless tube

Brand: CXMET

Place Of Origin: China Specifications : ASTM B338 B337 B861 B862

Grade: Gr1, Gr2, Gr3, Gr3, Gr5, Gr7, Gr9, Gr11, Gr12 etc

O.D.: 5-600mm or as Customized

W.T.: 2-120mm or as customized

Length: 5-12m or as Customized

Surface Finish: Black, Bright, Polished, Rough Turned, NO.4 Finish, Matt Finish

Packaging Details: wooden case

gr1 titanium seamless tube

Brand: CXMET

Place Of Origin: China

Material: Titanium

Length: 500~900mm

Application: Industrial

Technique: Seamless

Grade: Titanium Alloy

Processing Service: Bending, Welding, Decoiling, Cutting, Punching, welded

Material :Titanium tube pipes

Surface: Pickled,polished

Density: 4.51 G/cm3

Application: industry,medical

Type: Titanium alloy tube,welding tube pipes,seamless tube