- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How Does GR23 Titanium Wire Resist Corrosion?

2024-09-09 15:04:49

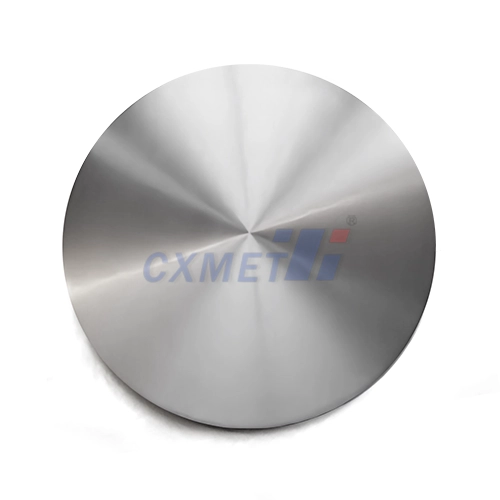

GR23 Titanium Wire, a high-performance alloy in the titanium family, has gained significant attention in various industries due to its exceptional corrosion resistance properties. This remarkable material combines the inherent corrosion-resistant nature of titanium with specific alloying elements, resulting in a wire that can withstand harsh environments and maintain its structural integrity over extended periods. In this blog post, we'll explore the mechanisms behind GR23 Titanium Wire's corrosion resistance and delve into its applications and advantages.

What are the key properties of GR23 Titanium Wire?

GR23 Titanium Wire, also known as Ti-6Al-4V ELI (Extra Low Interstitial), is a premium grade of titanium alloy that offers an impressive combination of properties. This alloy contains 6% aluminum and 4% vanadium, with trace amounts of other elements carefully controlled to enhance its performance.

The key properties of GR23 Titanium Wire include:

1. Excellent strength-to-weight ratio: GR23 Titanium Wire boasts a high tensile strength while maintaining a relatively low density, making it ideal for applications where weight reduction is crucial.

2. Superior corrosion resistance: The alloy forms a stable, protective oxide layer on its surface, which provides exceptional resistance to various corrosive environments, including saltwater, acids, and industrial chemicals.

3. Biocompatibility: GR23 Titanium Wire is well-tolerated by the human body, making it a popular choice for medical implants and devices.

4. High fatigue strength: The wire exhibits excellent resistance to cyclic loading, ensuring long-term reliability in dynamic applications.

5. Good ductility and formability: Despite its high strength, GR23 Titanium Wire can be easily formed and shaped into various configurations without compromising its properties.

6. Wide temperature range performance: The alloy maintains its mechanical properties across a broad range of temperatures, from cryogenic to moderately elevated temperatures.

7. Low magnetic susceptibility: GR23 Titanium Wire is non-magnetic, making it suitable for applications where magnetic interference must be minimized.

8. Excellent weldability: The wire can be easily joined using various welding techniques, allowing for versatile manufacturing processes.

These properties make GR23 Titanium Wire an exceptional choice for industries such as aerospace, marine engineering, chemical processing, and medical technology. Its ability to resist corrosion in challenging environments while maintaining high strength and low weight has led to its widespread adoption in critical applications.

How does the composition of GR23 Titanium Wire contribute to its corrosion resistance?

The composition of GR23 Titanium Wire plays a crucial role in its outstanding corrosion resistance. The alloy's carefully balanced mixture of elements works synergistically to create a material that can withstand aggressive environments and maintain its integrity over long periods.

1. Titanium base: The primary component of GR23 Titanium Wire is titanium, which inherently possesses excellent corrosion resistance. Titanium's natural tendency to form a stable, passive oxide layer (primarily titanium dioxide, TiO2) on its surface provides the foundation for the alloy's corrosion-resistant properties.

2. Aluminum content: The addition of 6% aluminum to the alloy serves multiple purposes. Aluminum enhances the formation and stability of the protective oxide layer, making it more resistant to breakdown in corrosive environments. Additionally, aluminum improves the alloy's strength and reduces its density, contributing to the favorable strength-to-weight ratio.

3. Vanadium addition: The 4% vanadium in GR23 Titanium Wire acts as a beta-stabilizer, improving the alloy's strength and formability. Vanadium also contributes to the overall corrosion resistance by enhancing the stability of the passive layer and improving its resistance to pitting corrosion.

4. Low interstitial content: The "ELI" designation in GR23 Titanium Wire stands for Extra Low Interstitial, indicating that the levels of interstitial elements such as oxygen, nitrogen, and carbon are tightly controlled. These low interstitial levels contribute to improved ductility and fracture toughness without compromising the alloy's corrosion resistance.

5. Trace elements: Small amounts of other elements, such as iron and residual elements, are carefully controlled in GR23 Titanium Wire. These trace elements can influence the alloy's properties, including its corrosion resistance, and their precise control ensures consistent performance across different batches of the material.

The combination of these elements results in a complex microstructure that enhances the wire's overall corrosion resistance. The alpha-beta microstructure of GR23 Titanium Wire, with its fine-grained structure, provides numerous sites for the formation of a stable passive layer. This microstructure also contributes to the alloy's mechanical properties and its ability to maintain these properties in corrosive environments.

The passive oxide layer formed on the surface of GR23 Titanium Wire is the primary mechanism by which it resists corrosion. This layer, predominantly composed of titanium dioxide, is extremely thin (typically a few nanometers thick) but highly effective in protecting the underlying metal. The oxide layer acts as a barrier, preventing direct contact between the metal and corrosive species in the environment.

When exposed to oxygen-containing environments, including air and water, the titanium in GR23 Titanium Wire rapidly reacts to form this protective oxide layer. If the layer is damaged or removed, it quickly reforms, providing continuous protection. This self-healing property is crucial in maintaining long-term corrosion resistance, even in applications where the wire may be subjected to mechanical stress or abrasion.

The presence of aluminum and vanadium in the alloy further enhances the stability and protective nature of this oxide layer. Aluminum, in particular, can incorporate into the oxide layer, forming a mixed oxide that is even more resistant to breakdown than pure titanium dioxide. This mixed oxide layer is particularly effective in resisting chloride-induced corrosion, which is a common challenge in marine and chemical processing environments.

What are the applications of GR23 Titanium Wire in corrosive environments?

GR23 Titanium Wire's exceptional corrosion resistance, combined with its other favorable properties, makes it an ideal material for a wide range of applications in corrosive environments. Its ability to withstand harsh conditions while maintaining its mechanical properties has led to its adoption across various industries:

1. Aerospace Industry:

In the aerospace sector, GR23 Titanium Wire is extensively used in aircraft components exposed to corrosive environments. It's particularly valuable in coastal regions where aircraft are subjected to salt-laden air. The wire is used in structural elements, fasteners, and hydraulic systems where its corrosion resistance and high strength-to-weight ratio are crucial. For example, it's used in landing gear components, engine mounts, and airframe structures where exposure to de-icing fluids, jet fuel, and atmospheric corrosion is a concern.

2. Marine Applications:

The marine environment is notoriously corrosive, with constant exposure to saltwater and varying temperatures. GR23 Titanium Wire excels in this challenging setting. It's used in offshore oil and gas platforms, underwater remotely operated vehicles (ROVs), and marine research equipment. The wire is also employed in desalination plants, where its resistance to both saltwater and the chemicals used in the desalination process is invaluable. In shipbuilding, it's used for propeller shafts, hull fittings, and other components that require high strength and corrosion resistance.

3. Chemical Processing Industry:

In chemical plants and refineries, GR23 Titanium Wire finds applications in areas exposed to corrosive chemicals and high temperatures. It's used in heat exchangers, reaction vessels, and piping systems where its resistance to a wide range of acids, alkalis, and organic compounds is essential. The wire's ability to maintain its properties in chlorine-containing environments makes it particularly useful in chlor-alkali plants.

4. Medical and Biomedical Applications:

The biocompatibility of GR23 Titanium Wire, coupled with its corrosion resistance, makes it an excellent choice for medical implants and devices. It's used in orthopedic implants, dental implants, and cardiovascular devices such as stents and pacemaker leads. In these applications, the wire's resistance to bodily fluids and its ability to integrate with bone tissue are crucial. Its non-magnetic properties also make it suitable for use in medical devices used in conjunction with MRI machines.

5. Energy Sector:

In the energy industry, GR23 Titanium Wire is used in various applications where corrosion resistance is paramount. It's employed in geothermal power plants, where exposure to high-temperature, mineral-rich fluids is common. The wire is also used in components of nuclear power plants, where its resistance to radiation-induced corrosion is valuable. In the emerging field of hydrogen energy, GR23 Titanium Wire is being explored for use in hydrogen storage and transport systems due to its resistance to hydrogen embrittlement.

6. Sports and Recreation:

While not typically considered a corrosive environment, the sports industry benefits from GR23 Titanium Wire's properties. It's used in high-end bicycle frames, golf club shafts, and tennis racket strings. In these applications, the wire's corrosion resistance helps maintain the equipment's performance and appearance, even when exposed to sweat, rain, and other potentially corrosive elements.

7. Automotive Industry:

In automotive applications, GR23 Titanium Wire is used in high-performance and luxury vehicles. It's employed in exhaust systems, suspension components, and engine parts where its corrosion resistance and high strength-to-weight ratio offer advantages over traditional materials. The wire's ability to withstand high temperatures and resist corrosion from automotive fluids and road de-icing salts makes it particularly valuable in these applications.

8. Architectural Applications:

In architecture, GR23 Titanium Wire is sometimes used in exposed structural elements or decorative features, particularly in coastal or industrial environments. Its corrosion resistance ensures long-term durability and maintains the aesthetic appeal of the structure. The wire can be used in tension structures, facades, and other architectural elements where its strength and corrosion resistance are beneficial.

The versatility of GR23 Titanium Wire in resisting corrosion across such a wide range of applications demonstrates its exceptional properties. Its ability to maintain structural integrity and performance in environments ranging from the human body to offshore oil platforms makes it a valuable material in modern engineering and design.

As industries continue to push the boundaries of material performance, particularly in challenging and corrosive environments, GR23 Titanium Wire remains at the forefront of material selection. Its unique combination of corrosion resistance, strength, and biocompatibility ensures its continued relevance and expanding applications in the future.

At SHAANXI CXMET TECHNOLOGY CO., LTD, we take pride in our extensive product range, which caters to diverse customer needs. Our company is equipped with outstanding production and processing capabilities, ensuring the high quality and precision of our products. We are committed to innovation and continuously strive to develop new products, keeping us at the forefront of our industry. With leading technological development capabilities, we are able to adapt and evolve in a rapidly changing market. Furthermore, we offer customized solutions to meet the specific requirements of our clients. If you are interested in our products or wish to learn more about the intricate details of our offerings, please do not hesitate to contact us at sales@cxmet.com. Our team is always ready to assist you.

References

1. Lutjering, G., & Williams, J. C. (2007). Titanium (2nd ed.). Springer-Verlag Berlin Heidelberg.

2. Donachie, M. J. (2000). Titanium: A Technical Guide (2nd ed.). ASM International.

3. Boyer, R., Welsch, G., & Collings, E. W. (1994). Materials Properties Handbook: Titanium Alloys. ASM International.

4. Rack, H. J., & Qazi, J. I. (2006). Titanium alloys for biomedical applications. Materials Science and Engineering: C, 26(8), 1269-1277.

5. Peters, M., Kumpfert, J., Ward, C. H., & Leyens, C. (2003). Titanium alloys for aerospace applications. Advanced Engineering Materials, 5(6), 419-427.

6. Schutz, R. W., & Watkins, H. B. (1998). Recent developments in titanium alloy application in the energy industry. Materials Science and Engineering: A, 243(1-2), 305-315.

7. Elias, C. N., Lima, J. H. C., Valiev, R., & Meyers, M. A. (2008). Biomedical applications of titanium and its alloys. JOM, 60(3), 46-49.

8. Geetha, M., Singh, A. K., Asokamani, R., & Gogia, A. K. (2009). Ti based biomaterials, the ultimate choice for orthopaedic implants – A review. Progress in Materials Science, 54(3), 397-425.

9. Faller, K., & Froes, F. H. (2001). The use of titanium in family automobiles: Current trends. JOM, 53(4), 27-28.

10. Antunes, R. A., & de Oliveira, M. C. L. (2012). Corrosion fatigue of biomedical metallic alloys: Mechanisms and mitigation. Acta Biomaterialia, 8(3), 937-962.