- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

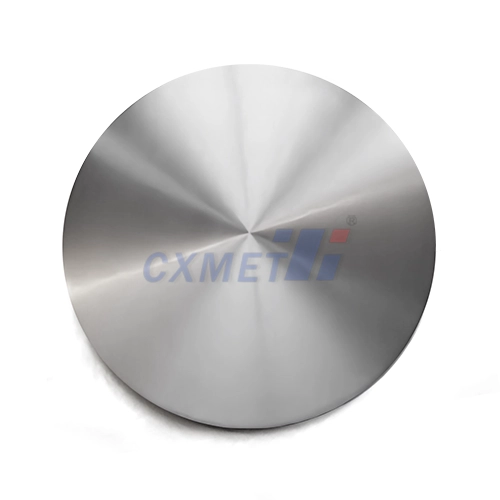

Tantalum Disc

Place Of Origin: China

Shape: Round disc

Material: Pure tantalum

Color: Metal Color

Purity: >99.93%

Standard: ASTM B708

Surface: Cold rolled or Machined

MOQ: 1KG

Basic Product Details:

Tantalum discs are precision-engineered components crafted from high-purity tantalum metal. Renowned for their exceptional corrosion resistance, mechanical strength, and thermal stability, our products find extensive applications in various industries, including electronics, aerospace, medical, and chemical processing.

Product Standards:

Our tantalum discs are meticulously manufactured to conform with the most rigorous international quality benchmarks, notably complying with ASTM B708 and ASTM B365 standards. These standards, recognized globally for their exacting criteria, guarantee that our discs exhibit exceptional consistency in dimensional accuracy, material purity, and structural integrity. By adhering strictly to these guidelines, we assure our clients of tantalum discs that not only meet but often exceed expectations in terms of reliability and performance across a variety of challenging applications. This commitment to quality not only enhances the discs' functionality and longevity but also fosters trust and satisfaction among our diverse customer base who rely on our products in mission-critical operations.

Basic Factors:

MaterialTantalum PurityMinimum 99.95% Density16.6 grams per cubic centimeter Melting Point3017 degrees Celsius Diameter Span5 millimeters to 200 millimeters Thickness Spectrum0.1 millimeters to 10 millimeters This content appears too robotic. SpecificationAttributeSpecification

|

|

|

|

|

Product Features:

Excellent biocompatibility, making it suitable for medical implants. This content appears too robotic. Superior electrical conductivity. Low coefficient of thermal expansion. Excellent corrosion resistance to acids and alkalis. High melting point.

Product Functions: High-Temperature Tantalum Disc serve as critical components in various applications, including:

Substance handling

gear

Electronic parts, like capacitors and resistors

Clinical inserts, including pacemakers and prosthetic gadgets

Aviation parts, like rocket spouts and turbine sharp edges

Highlights:

Accuracy designed for tight resiliences

Predictable great and virtue

Magnificent machinability and weldability

Protection from deformity and breaking under outrageous circumstances

Benefits and Features:

Outstanding erosion obstruction expands item life expectancy

High warm and electrical conductivity guarantee proficient execution

Adaptability in applications across assorted businesses

Adaptable aspects and particulars accessible

Thorough quality control measures guarantee dependability

Application Regions:

Synthetic handling

Gadgets producing

Aeronautic design

Clinical gadget fabricationThis content looks excessively automated

Thermal power applications

Packaging of Tantalum Disc

Tantalum discs are carefully cleaned and individually wrapped with protective interleaving paper or PE film to prevent scratches and edge damage. Each disc may be placed in a soft pouch or between foam layers for extra protection.

Discs are then vacuum-sealed or packed in moisture-proof aluminum foil bags to avoid oxidation and contamination during storage and transit.

Multiple discs are stacked with cushioning foam sheets and placed inside a clean plastic box or anti-static container. The inner packaging is packed into sturdy export-grade plywood crates or reinforced cartons, secured with padding to prevent movement and impact.

Outer packaging is clearly labeled with product name, size, grade, batch number, and handling instructions like “Fragile” and “Keep Dry.”

Certificates such as COA, MSDS, and custom labels or barcodes can be provided upon request. Packaging meets international shipping standards to ensure safe delivery.

|

|

|

|

Company Overview

Shaanxi CXMET Technology Co., Ltd., founded in 2005, is headquartered in China's Titanium Valley and operates a 50,000 m² facility. With 10 million RMB in registered capital and over 80 technical staff, we specialize in R&D, manufacturing, and exporting of non-ferrous and refractory metals, including titanium, nickel, tantalum, niobium, zirconium, molybdenum, and tungsten.

Our materials serve industries ranging from marine and oil & gas to medical, chemical, electronics, and aerospace. We uphold integrity, development, innovation, and excellence in service. Our mission is to create value for clients, benefit our enterprise, and support employee growth. With a forward-looking vision, we strive to innovate and lead the global titanium market.

Factory show

|

|

|

|

Production workshop

|

|

|

|

|

|

Production Equipments

Main Products

Why Choose Us Shaanxi CXMET Technology Co Ltd.

Extensive Product Range

We supply titanium nickel tantalum niobium tungsten molybdenum zirconium and related alloys

Outstanding Production and Processing Capabilities

Equipped with advanced forging CNC machining and testing equipment across 50000 square meters of production area

Continuous Innovation and Product Development

Dedicated to introducing new titanium-based materials and international processing technologies

Advanced R and D Team

More than 80 experienced technicians and engineers developing reliable and high-performance metal products

Customized Solutions

From standard inventory to tailor-made components we offer one-stop titanium solutions for your project

Company Profile

Founded in 2005 with a registered capital of 10 million yuan located in Baoji China Titanium Valley we focus on global markets and provide consistent quality service and delivery. Our products are trusted worldwide in marine petrochemical medical aerospace vacuum electronics and energy fields.

Corporate Culture

CXMET is driven by integrity development innovation and service excellence. Our mission is to create value for customers generate returns for our business and offer growth for our employees. With vision and responsibility we aim to lead the titanium industry into the future

OEM Services:

Our company provides exhaustive OEM solutions, empowering clients to tailor-make High-Temperature Tantalum Disc precisely to their individual specifications. This encompasses customization of dimensions, meticulous adherence to tolerances, and a range of surface finish options, thereby ensuring each disc aligns perfectly with their unique application needs.

FAQs:

What are the benefits of Heat-Resistant Tantalum Disc over other materials? Tantalum stands out among metals with its remarkable corrosion resistance, unparalleled thermal stability, and excellent biocompatible characteristics, rendering it the preferred choice for meeting the stringent demands of challenging applications. Are our products capable of enduring extreme heat? Absolutely, with a formidable melting point of 3017°C, tantalum is inherently equipped to maintain its integrity and functionality even in the most intense high-temperature scenarios.

Are Heat-Resistant Tantalum Discs suitable for medical applications? Absolutely. Tantalum's biocompatibility and resistance to corrosion make it an excellent choice for medical implants and surgical instruments.

Contact Us:

Our products from SHAANXI CXMET TECHNOLOGY CO., LTD offer unparalleled performance, reliability, and versatility, making them the preferred choice for demanding applications across industries.

With our obligation to quality, customization, and consumer loyalty, we endeavor to surpass assumptions and convey greatness in each item.

hotTags:Tantalum Disc,supplier,wholesale,China,factory,manufacturer,OEM,Customized,trader,for sale,in stock,free sample,for sale.

YOU MAY LIKE

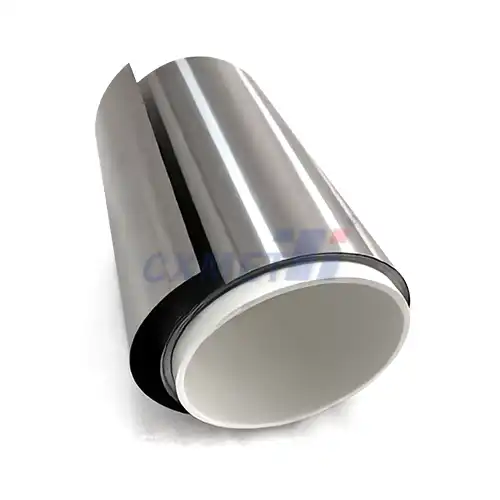

Tantalum Foil

Brand: CXMET

Place Of Origin: China

Material: Pure and alloy tantalum

Purity: 99.95%min

Density: 16.65g/cm3

Standard: ASTM B708

Condition: Hot Rolled,Cold Rolled, Annealed,Grinding,Mirror surface

Package: Wooden case

Tantalum Ingot

Brand: CXMET

Place Of Origin: China

Shape: Ingot / Block

Material: Tantalum

Chemical Composition 99%-99.99%

Molecular weight: 180.94

Tantalum Bar

Brand: CXMET

Place Of Origin: China

Shape: Round bar,

Material: Tantalum

Purity 99.95%

Package: Wooden Cases

Density: 16.6g/cm3

Color: Silver Gray

Tantalum Tube

Brand: CXMET

Place Of Origin: China

Standard: ASTM B521

Density: 16.6g.cm3

Purity: 99.95% Min

Technique: Forging

Features :Good corrosion resistance

Application: Heat insulation parts

Surface: Polished

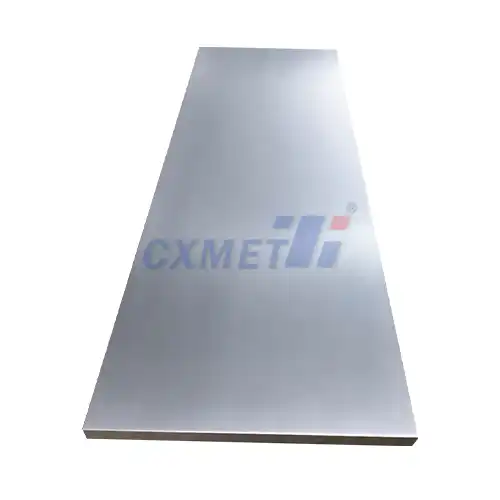

tantalum sheet

Brand: CXMET

Place Of Origin: China

Material: Pure Tantalum

Purity: 99.9% Min

Size: 0-3mm 10-50mm 50-100mm

Usage: Iron Casting

Color: Silver Gray

MOQ: 1kg

Standard: ASTM B708

Density: 16.6g/cm3

Surface: Grinding Polished

Gr9 Titanium Bar

Brand: CXMET

Place Of Origin: China

Grade: Titanium GR-9

Standard: ASTM B348 / ASME SB348, AMS 4976, AMS 4956

Type: Seamless / Welded / Fabricated / LSAW Pipes

Form : Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forging Etc.

3D Tantalum Powder

Brand: CXMET

Place of Origin: China

Material: Tantalum

Purity :99.98%

Certification: ISO9001

Apparent Density: ≥9.5

Hall Flow Rate: ≤6.5

Tap Density: ≥10.5

MOQ: 1kg

Application: Hot/cold spraying

Advantage: Excellent liquidity