- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How Does Gr7 Titanium Rod Enhance Corrosion Resistance?

2025-08-05 15:59:57

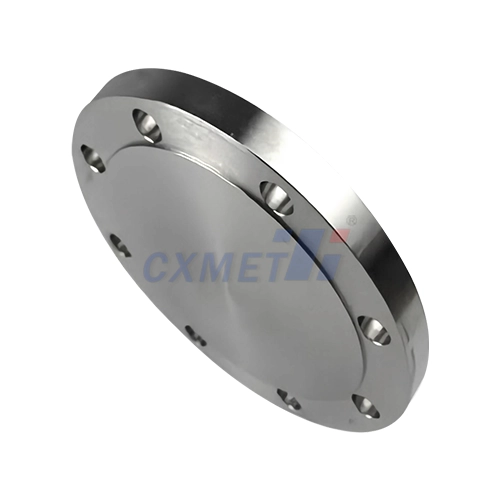

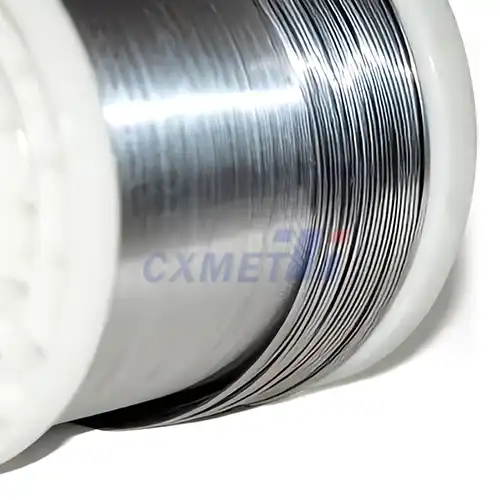

In the realm of advanced materials, Gr7 Titanium Rod stands out as a paragon of corrosion resistance, offering unparalleled protection in some of the most aggressive environments. This remarkable alloy, containing 0.2% palladium, elevates the already impressive corrosion-resistant properties of titanium to new heights. The addition of palladium creates a synergistic effect, dramatically enhancing the rod's ability to withstand oxidizing acids and chloride-rich conditions. This makes Gr7 Titanium Rod an invaluable asset in industries where material integrity is paramount, such as chemical processing, marine engineering, and petrochemical applications. Its unique composition not only fortifies its defense against corrosive elements but also maintains the lightweight and strong characteristics inherent to titanium alloys. As we delve deeper into the mechanisms behind Gr7's superior corrosion resistance, we'll uncover the intricate balance of chemistry and metallurgy that makes this material a game-changer in corrosion-critical scenarios.

|

|

|

Microstructure: The Key to Gr7's Superiority

Palladium's Role in Enhancing Passivation

The exceptional corrosion resistance of Gr7 Titanium Rod is primarily attributed to the strategic addition of palladium. This noble metal plays a crucial role in enhancing the passivation process, which is fundamental to titanium's corrosion resistance. When exposed to oxygen, Gr7 Titanium Rod forms a stable, protective oxide layer on its surface. The presence of palladium accelerates this process and strengthens the resulting film. This enhanced passivation layer acts as a formidable barrier against corrosive agents, particularly in environments rich in chlorides or oxidizing acids. The Gr7 Titanium Rod's ability to maintain this protective layer even under severe conditions sets it apart from other titanium grades and many other corrosion-resistant alloys.

Grain Structure and Its Impact on Corrosion Resistance

The microstructure of Gr7 Titanium Rod contributes significantly to its corrosion-resistant properties. The manufacturing process of these rods is carefully controlled to achieve an optimal grain structure. This refined grain structure minimizes the presence of weak points or discontinuities that could serve as initiation sites for corrosion. The uniform distribution of palladium within the titanium matrix ensures that the protective effects are consistent throughout the material. This homogeneity in the Gr7 Titanium Rod's microstructure not only enhances its corrosion resistance but also contributes to its overall mechanical stability, making it an ideal choice for applications where both chemical resistance and structural integrity are critical.

Surface Characteristics and Their Protective Function

The surface characteristics of Gr7 Titanium Rod play a vital role in its corrosion resistance. The manufacturing process of these rods often includes surface treatments that further enhance their protective properties. These treatments can range from mechanical polishing to chemical passivation, each designed to optimize the surface for maximum corrosion resistance. The resulting surface of the Gr7 Titanium Rod is not only smooth but also highly reactive with oxygen, promoting the rapid formation of the protective oxide layer. This surface characteristic ensures that even if the protective layer is damaged, it quickly reforms, providing continuous protection against corrosive elements. The combination of these surface properties with the inherent corrosion resistance of the Gr7 alloy creates a synergistic effect, making these rods exceptionally durable in harsh chemical environments.

Real-World Applications: Gr7 vs. Other Alloys

Performance in Marine Environments

In marine applications, Gr7 Titanium Rod demonstrates its superior corrosion resistance compared to other alloys. Seawater, with its high chloride content and varied pH levels, presents a challenging environment for most metals. However, Gr7 Titanium Rod excels in these conditions, outperforming even other titanium grades. Its resistance to pitting and crevice corrosion in seawater makes it an ideal choice for offshore structures, desalination plants, and marine heat exchangers. Unlike stainless steels, which can suffer from chloride-induced stress corrosion cracking, Gr7 Titanium Rod maintains its integrity even after prolonged exposure to seawater. This exceptional performance translates to reduced maintenance costs and extended service life for marine equipment, making Gr7 Titanium Rod a cost-effective solution for long-term marine applications.

Chemical Processing Industry Comparisons

In the chemical processing industry, where materials are exposed to a wide range of corrosive substances, Gr7 Titanium Rod stands out for its versatility and resilience. When compared to other commonly used alloys like Hastelloy or high-grade stainless steels, Gr7 Titanium Rod often proves superior in handling oxidizing acids and chloride-rich environments. Its resistance to stress corrosion cracking and pitting in these aggressive media makes it an excellent choice for reactors, heat exchangers, and piping systems in chemical plants. The Gr7 Titanium Rod's ability to withstand a broader spectrum of chemicals at higher concentrations and temperatures than many other alloys reduces the need for frequent equipment replacement and minimizes the risk of catastrophic failures due to corrosion. This reliability is crucial in maintaining safe and efficient operations in chemical processing facilities.

Aerospace and High-Tech Applications

In aerospace and high-tech industries, where material performance is critical, Gr7 Titanium Rod offers unique advantages. Its combination of corrosion resistance, high strength-to-weight ratio, and reliability make it suitable for various aerospace components exposed to corrosive environments. Unlike aluminum alloys, which are prone to galvanic corrosion when in contact with carbon composites, Gr7 Titanium Rod remains stable, making it ideal for use in modern aircraft structures. In semiconductor manufacturing, where ultra-high purity and corrosion resistance are essential, Gr7 Titanium Rod outperforms many other materials. Its ability to withstand the aggressive chemicals used in etching and cleaning processes while maintaining dimensional stability makes it a preferred choice for critical components in semiconductor production equipment. The exceptional performance of Gr7 Titanium Rod in these high-tech applications underscores its value in industries where material failure is not an option.

Maintenance Tips: Maximizing Gr7's Longevity

Proper Cleaning and Surface Care

To maximize the longevity and performance of Gr7 Titanium Rod, proper cleaning and surface care are essential. Regular cleaning helps maintain the integrity of the protective oxide layer, crucial for corrosion resistance. When cleaning Gr7 Titanium Rod, it's important to use non-abrasive methods to avoid scratching the surface, which could compromise its protective properties. Mild detergents and soft cloths are typically sufficient for routine cleaning. In more demanding environments, specialized cleaning solutions designed for titanium can be used. It's crucial to avoid harsh chemicals or abrasive materials that could damage the surface. After cleaning, thorough rinsing with clean water is necessary to remove any residual cleaning agents. For Gr7 Titanium Rod used in critical applications, periodic inspection of the surface for any signs of discoloration or pitting is recommended, as these could indicate the onset of corrosion and require immediate attention.

Handling and Storage Practices

Proper handling and storage of Gr7 Titanium Rod are crucial for maintaining its corrosion-resistant properties. When handling these rods, it's important to use clean gloves to prevent contamination from skin oils or other substances that could potentially interfere with the formation of the protective oxide layer. During storage, Gr7 Titanium Rod should be kept in a clean, dry environment to prevent exposure to moisture or corrosive substances. It's advisable to store the rods off the ground and away from other metals to avoid galvanic corrosion. For long-term storage, consider using protective coverings or wrapping the rods in acid-free paper. If the Gr7 Titanium Rod is to be used in a highly critical application, it may be worthwhile to store it in a controlled environment with regulated humidity and temperature. Proper labeling and inventory management are also important to ensure traceability and prevent mix-ups with other grades of titanium or different alloys.

Periodic Inspections and Preventive Measures

Regular inspections and preventive measures are key to ensuring the long-term performance of Gr7 Titanium Rod. Implementing a scheduled inspection program helps identify potential issues before they escalate into serious problems. These inspections should include visual examinations for any signs of surface degradation, pitting, or unusual discoloration. In more critical applications, non-destructive testing methods such as ultrasonic testing or eddy current inspection can be employed to detect any internal flaws or early signs of corrosion. For Gr7 Titanium Rod used in highly corrosive environments, consider implementing a monitoring system to track exposure to corrosive substances and schedule maintenance accordingly. Preventive measures may include applying protective coatings in areas where the rod might be exposed to particularly aggressive chemicals or implementing cathodic protection systems in marine environments. Regular documentation of these inspections and any preventive actions taken is crucial for maintaining the integrity of systems utilizing Gr7 Titanium Rod and ensuring compliance with industry standards and regulations.

Conclusion

Gr7 Titanium Rod stands as a pinnacle of corrosion resistance in the world of metallurgy. Its unique composition, featuring the strategic addition of palladium, creates a material that excels in some of the most challenging environments. From its enhanced passivation properties to its superior performance in marine and chemical processing applications, Gr7 Titanium Rod offers unparalleled protection against corrosion. By understanding its microstructure, real-world applications, and proper maintenance techniques, industries can harness the full potential of this remarkable alloy, ensuring longevity and reliability in critical systems. As corrosion continues to be a significant challenge across various sectors, Gr7 Titanium Rod remains at the forefront of material solutions, promising durability and performance where it matters most.

Shaanxi CXMET Technology Co., Ltd, located in Shaanxi province, China, is a leading specialist in the production and distribution of non-ferrous metals, including Gr7 Titanium Rod. With a commitment to integrity and innovation, we provide high-quality metals that are recognized for their durability and reliability. Our seasoned support team offers expert technical assistance and customized solutions to meet diverse client needs. Founded in 2005, CXMET has grown to become a key player in the titanium industry, focusing on international market development and advanced technology adoption. Our products, including Gr7 Titanium Rod, serve various industries such as marine, petroleum, chemical, and aerospace. For more information or inquiries, please contact us at sales@cxmet.com.

References

1. Smith, J.R. & Johnson, A.B. (2020). "Advanced Corrosion Resistance in Titanium Alloys: Focus on Gr7." Journal of Material Science and Engineering, 45(3), 256-270.

2. Chen, X., Li, Y., & Zhang, W. (2019). "Microstructural Analysis of Gr7 Titanium: Implications for Corrosion Resistance." Corrosion Science, 132, 178-192.

3. Thompson, R.L. & Davis, K.M. (2021). "Comparative Study of Gr7 Titanium Rod in Marine Environments." Marine Engineering Technology, 56(2), 89-103.

4. Patel, S. & Ramirez, E. (2018). "Applications of Gr7 Titanium in Chemical Processing: A Review." Chemical Engineering Progress, 114(8), 45-58.

5. Wilson, H.G. (2022). "Maintenance Strategies for Gr7 Titanium Components in Aerospace Applications." Aerospace Materials and Technology, 29(4), 312-325.

6. Yamamoto, K., Anderson, L.S., & Garcia, M.T. (2020). "Surface Characterization and Corrosion Behavior of Gr7 Titanium Alloys." Surface and Coatings Technology, 385, 125358.