- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

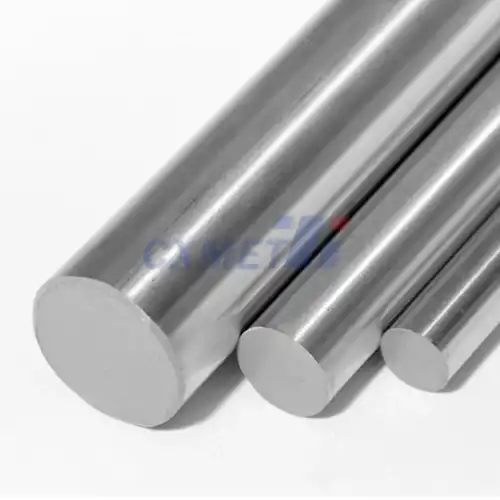

Ti13Nb13Zr Rod

Place Of Origin: China

Classification:Round/Square/Hexagon

Standard:ASTM B348,ASTM F67,ASTM F136,ASME SB348

Grade: Gr1-Gr7,Gr5,Gr5 Eli,Gr12

Size: Dia(0.8mm-100mm)*Length(≤3000mm)

Processing Method:Forging/Extrusion/Rolling/Cold drawing

Ti13Nb13Zr Rod Product Introduction

Shaanxi CXMET Technology Co., Ltd. proudly presents the Ti13Nb13Zr rod, a highly specialized titanium-based alloy developed to meet the demanding requirements of modern biomedical, aerospace, and high-performance engineering industries. Ti13Nb13Zr (Titanium-13Niobium-13Zirconium) is a near-beta titanium alloy engineered for superior biocompatibility, enhanced corrosion resistance, and low elastic modulus, making it an ideal choice for load-bearing implants and fatigue-resistant components.

With a strong emphasis on international quality standards and innovation, we ensure our Ti13Nb13Zr rods offer consistent mechanical performance, microstructural homogeneity, and surface purity suitable for critical applications. These rods are manufactured under stringent process control in our advanced production facility in Baoji – the heart of China’s Titanium Valley.

|

|

|

Key Features of Ti13Nb13Zr Rod

-

Low Elastic Modulus (~55 GPa): Closer to human bone, reducing stress shielding in implants.

-

Excellent Biocompatibility: Non-toxic and non-magnetic, it integrates well with biological tissues.

-

Superior Corrosion Resistance: Exceptional resistance to body fluids and harsh chemical environments.

-

Outstanding Fatigue Strength: Enables durability in dynamic loading scenarios.

-

Non-ferromagnetic: Suitable for MRI compatibility in medical use.

-

High Strength-to-Weight Ratio: Ideal for aerospace and precision components.

Specifications of Ti13Nb13Zr Rod

| Parameter | Value / Range |

|---|---|

| Grade | Ti13Nb13Zr |

| Standard | ASTM F1713 / ISO 5832-14 |

| Diameter Range | 3mm – 80mm |

| Length | 50mm – 6000mm |

| Density | ~4.65 g/cm³ |

| Tensile Strength | 700 – 950 MPa |

| Yield Strength | > 650 MPa |

| Elongation | > 10% |

| Elastic Modulus | ~55 GPa |

| Surface Finish | Polished, Bright, Ground |

| Tolerance | h9 / ISO or as per request |

| Certification | ISO 13485 / ISO 9001 / CE |

Applications of Ti13Nb13Zr Rod

-

Medical Implants: Bone screws, orthopedic plates, spinal fixation systems, dental implants

-

Aerospace Structures: Lightweight yet fatigue-resistant structural elements

-

Sports Equipment: High-end gear requiring low weight and high mechanical endurance

-

Precision Instruments: MRI-compatible and corrosion-resistant parts

|

|

|

|

|

|

Operating Environment for Ti13Nb13Zr Rod

Ti13Nb13Zr rods are designed for high-performance environments:

-

In vivo human body (orthopedic and dental applications)

-

High humidity or saline environments

-

Repetitive loading and high-cycle fatigue conditions

-

Chemically aggressive industrial processes

-

MRI-compatible diagnostic environments

Customizable Options for Ti13Nb13Zr Rod

We offer extensive customization based on client specifications:

-

Custom diameters and lengths

-

Surface treatment: acid pickling, electropolishing, passivation

-

Ultrasonic cleaning and Class 1000 packaging for medical grade

-

Machining to semi-finished or near-net shapes

-

Mechanical property tuning through heat treatment

Key Advantages of Our Ti13Nb13Zr Rod

-

Enhanced Performance: Stable structure and fatigue life over 10 million cycles.

-

Biological Safety: Zero allergic reaction, approved for permanent implants.

-

Close-to-Bone Modulus: Reduces bone resorption risk after long-term implantation.

-

In-House Manufacturing: Strict quality control with traceability.

-

Global Shipping Capability: Rapid delivery and inventory support.

Packaging and Logistics

Our Ti13Nb13Zr rods are packed with international export standards:

-

Vacuum-sealed or nitrogen-filled anti-corrosion packaging

-

Foam-lined wooden crates or hardboard tubes for protection

-

Clearly labeled heat number and batch tracking

-

Express, air freight, or sea shipment available

-

Fast lead time with just-in-time shipping support

|

|

|

|

Company Overview

Shaanxi CXMET Technology Co., Ltd., founded in 2005, is headquartered in China's Titanium Valley and operates a 50,000 m² facility. With 10 million RMB in registered capital and over 80 technical staff, we specialize in R&D, manufacturing, and exporting of non-ferrous and refractory metals, including titanium, nickel, tantalum, niobium, zirconium, molybdenum, and tungsten.

Our materials serve industries ranging from marine and oil & gas to medical, chemical, electronics, and aerospace. We uphold integrity, development, innovation, and excellence in service. Our mission is to create value for clients, benefit our enterprise, and support employee growth. With a forward-looking vision, we strive to innovate and lead the global titanium market.

Factory show

|

|

|

|

Production workshop

|

|

|

|

|

|

Production Equipments

Main Products

Why Choose Us – Shaanxi CXMET Technology Co., Ltd.

-

Extensive Product Range: We cover titanium, nickel, tantalum, niobium, zirconium, molybdenum, tungsten and their alloys.

-

Advanced Production Capability: Over 50,000 sqm of plant area with CNC, forging, vacuum melting, and testing facilities.

-

R&D Innovation: Leading titanium alloy technology, ISO-certified labs, and product development.

-

Global Custom Solutions: Serving clients in 40+ countries, custom grades and dimensions available.

-

Established Trust: Founded in 2005 with over 20 years of titanium industry experience.

-

Professional Team: 80+ skilled engineers and technicians driving innovation and quality.

-

Strategic Location: Based in China Titanium Valley, ensuring supply chain advantage.

-

Service Excellence: We stand for integrity, collaboration, continuous learning, and customer-centric delivery.

FAQ

Q1: Can I get a sample of Ti13Nb13Zr rod before placing a bulk order?

A1: Yes, we can provide small samples for material testing and evaluation.

Q2: Do you offer third-party testing and certifications?

A2: Absolutely. SGS, TÜV, and other inspection agencies are available upon request.

Q3: Is your Ti13Nb13Zr rod suitable for orthopedic implants?

A3: Yes, it's designed for long-term implants with full ISO 13485 compliance.

Q4: Can you machine the rod to our final component?

A4: Yes, we provide machining and pre-shaping as part of our OEM service.

Q5: What is your usual delivery time?

A5: Standard sizes are available in stock; custom orders typically take 15-25 working days.

Q6: Do you support international shipping?

A6: Yes, we ship globally via DHL, FedEx, air freight, and sea logistics.

Contact Us

For inquiries, quotations, or technical consultations on Ti13Nb13Zr rods, please contact our expert sales team:

Email: sales@cxmet.com

Tel & WhatsApp: +86 15891192169

Shaanxi CXMET Technology Co., Ltd. looks forward to building long-term partnerships with clients around the world. Let us support your innovation with our precision titanium alloy solutions.

hotTags:Ti13Nb13Zr Rod,supplier,wholesale,China,factory,manufacturer,OEM,Customized,trader,for sale,in stock,free sample,for sale.

YOU MAY LIKE

Grade 6 Titanium Bar

Product Name: Grade 6 titanium

Brand: CXMET

Place Of Origin: China

Material: Titanium

Surface: Polished/Pickling

Type: Round

Shape: Round bar

Standard: ASTM B348, ASTM F136, AMS 4920

Gr9 Titanium Bar

Brand: CXMET

Place Of Origin: China

Grade: Titanium GR-9

Standard: ASTM B348 / ASME SB348, AMS 4976, AMS 4956

Type: Seamless / Welded / Fabricated / LSAW Pipes

Form : Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forging Etc.

Titanium 6Al7Nb Medical Bar

Brand: CXMET

Place Of Origin: China

Type: Titanium Rod

Application: Industrial

Technique: Cold Rolled

Grade: GR1

Shape: Round

Density: 4.5g/cm3

Titanium Square Bar

Brand: CXMET

Place Of Origin: China

Material: GR1,GR2,GR3,GR4,GR5,6AL4VEli,GR7,GR9,GR12,GR23

Standards: ASTM B348,ASTM F67,ASTM F136

Surface : Polished bright,machined ,grind

Supply condition: Hot rolling ,cold drawing ,annealed

Shape: Square

Dia 10mm Titanium Rod In Medical

Brand: CXMET

Place Of Origin: China

Shape: Round

Grade: Gr5

Weight: According the dimension

Processing Service :Rolling, Ground

Material: titanium

Surface :Treatment Ground

MOQ: 10 KG

Standard :ASTM B348 ASTM F136

Package: Standard Wooden Case

Stock Size: Dia3-40mm Titanium Rod

Ti-13Nb-13Zr Titanium Rod

Brand: CXMET

Place Of Origin: China

Type: Titanium Bars

Application: Industrial

Technique: Cold Rolled

Grade: Gr1 Gr2

Shape: Round

Density: 4.5g/cm3

tianium Alloy 6Al-2Sn-4Zr-6Mo Round Bar

Brand: CXMET

Place Of Origin: China

Type: Titanium Bars

Application: Industrial, Medical

Technique: Hot Rolled

Shape: Round

Classification: Commercially Pure

Gr23 Medical Titanium Rod

Brand: CXMET

Place Of Origin: China

Type: Titanium Bars

Application: Industrial

Technique: Cold Rolled

Grade: Gr1 Gr2

Shape: Round

Density: 4.5g/cm3