- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

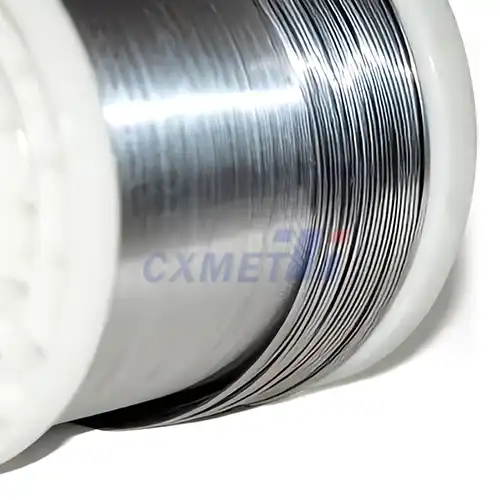

Is Gr23 ERTi-23 Medical Titanium Wire Biocompatible?

2025-03-04 16:35:53

Gr23 ERTi-23 Medical Titanium Wire is a specialized material widely used in the medical industry, particularly in implantable devices and surgical applications. This titanium alloy is known for its excellent mechanical properties, corrosion resistance, and biocompatibility. In this blog post, we will explore the biocompatibility of Gr23 ERTi-23 Medical Titanium Wire and address some common questions related to its use in medical applications.

|

|

|

What are the advantages of using Gr23 ERTi-23 Medical Titanium Wire in implants?

Gr23 ERTi-23 Medical Titanium Wire offers numerous advantages when used in implants, making it a preferred choice for many medical applications. These advantages stem from its unique combination of physical, chemical, and biological properties that make it highly suitable for use in the human body.

One of the primary benefits of using Gr23 ERTi-23 Medical Titanium Wire in implants is its exceptional biocompatibility. Biocompatibility refers to the ability of a material to perform its intended function without eliciting any undesirable local or systemic effects in the recipient. Titanium and its alloys, including Gr23 ERTi-23, have demonstrated excellent biocompatibility in numerous studies and clinical applications over the years.

The biocompatibility of Gr23 ERTi-23 Medical Titanium Wire can be attributed to several factors. Firstly, titanium has a natural tendency to form a stable oxide layer on its surface when exposed to oxygen. This oxide layer acts as a protective barrier, preventing the release of metal ions into the surrounding tissues and reducing the risk of adverse reactions or corrosion. Additionally, the surface of titanium implants can be modified or treated to enhance their biocompatibility further, promoting better integration with the surrounding tissues.

Another significant advantage of Gr23 ERTi-23 Medical Titanium Wire is its excellent mechanical properties. This alloy offers a high strength-to-weight ratio, making it ideal for applications where both strength and lightweight characteristics are crucial. The mechanical properties of Gr23 ERTi-23 are similar to those of human bone, which helps reduce stress shielding and promotes better load distribution in orthopedic implants.

Furthermore, Gr23 ERTi-23 Medical Titanium Wire exhibits superior corrosion resistance in the physiological environment. This resistance to corrosion is essential for long-term implant stability and reduces the risk of implant failure or the release of potentially harmful metal ions into the body. The corrosion resistance of titanium alloys also contributes to their overall biocompatibility and longevity in medical applications.

The versatility of Gr23 ERTi-23 Medical Titanium Wire is another advantage that makes it suitable for a wide range of implant applications. It can be easily shaped, machined, and welded to create complex implant designs tailored to specific medical needs. This adaptability allows for the development of customized implants that can better match the anatomy and requirements of individual patients.

Lastly, Gr23 ERTi-23 Medical Titanium Wire is non-magnetic, which is crucial for patients who may need to undergo magnetic resonance imaging (MRI) scans after implantation. This property ensures that the implants do not interfere with the imaging process or pose any safety risks during MRI procedures.

How does the biocompatibility of Gr23 ERTi-23 Medical Titanium Wire compare to other materials?

When comparing the biocompatibility of Gr23 ERTi-23 Medical Titanium Wire to other materials used in medical implants, it is essential to consider various factors such as tissue response, long-term stability, and overall performance in the physiological environment. Titanium alloys, including Gr23 ERTi-23, are generally considered to be among the most biocompatible materials available for medical implants.

Compared to stainless steel, which has been widely used in medical implants for many years, Gr23 ERTi-23 Medical Titanium Wire offers superior biocompatibility. While stainless steel is relatively inert and has good mechanical properties, it contains nickel, which can cause allergic reactions in some patients. Titanium alloys, on the other hand, are nickel-free and have a significantly lower risk of causing allergic reactions or hypersensitivity.

Cobalt-chromium alloys are another group of materials commonly used in medical implants, particularly in joint replacements. While these alloys offer excellent wear resistance and mechanical properties, they may release metal ions into the surrounding tissues over time. Gr23 ERTi-23 Medical Titanium Wire, with its stable oxide layer and corrosion resistance, has a lower tendency to release metal ions, making it a more biocompatible option for long-term implantation.

Polymeric materials, such as polyethylene and polyurethane, are also used in certain medical implant applications. While these materials can offer advantages in terms of flexibility and ease of manufacturing, they generally do not match the mechanical properties and long-term stability of titanium alloys. Gr23 ERTi-23 Medical Titanium Wire provides a better balance of strength, durability, and biocompatibility for many implant applications.

Ceramic materials, such as alumina and zirconia, are known for their excellent biocompatibility and wear resistance. However, they can be brittle and may not be suitable for applications requiring ductility or the ability to withstand high loads. Gr23 ERTi-23 Medical Titanium Wire offers a combination of biocompatibility and mechanical properties that make it suitable for a broader range of implant applications.

One of the key factors contributing to the superior biocompatibility of Gr23 ERTi-23 Medical Titanium Wire is its ability to promote osseointegration. Osseointegration refers to the direct structural and functional connection between living bone tissue and the surface of an implant. Titanium alloys have been shown to promote better bone cell adhesion, proliferation, and differentiation compared to many other implant materials. This enhanced osseointegration leads to improved implant stability and long-term success rates.

The surface properties of Gr23 ERTi-23 Medical Titanium Wire can be further modified to enhance its biocompatibility and promote tissue integration. Various surface treatments, such as plasma spraying, acid etching, or the application of bioactive coatings, can be used to optimize the surface topography and chemistry of titanium implants. These modifications can improve cell adhesion, accelerate healing, and enhance the overall biocompatibility of the implant.

Another aspect to consider when comparing the biocompatibility of different materials is their interaction with the immune system. Gr23 ERTi-23 Medical Titanium Wire has been shown to elicit minimal immune responses, reducing the risk of chronic inflammation or foreign body reactions. This low immunogenicity contributes to better long-term acceptance of titanium implants by the body.

|

|

|

What are the potential applications of Gr23 ERTi-23 Medical Titanium Wire in medical devices?

Gr23 ERTi-23 Medical Titanium Wire has a wide range of potential applications in medical devices, owing to its excellent biocompatibility, mechanical properties, and versatility. This material is used in various fields of medicine, including orthopedics, dentistry, cardiovascular surgery, and neurosurgery.

In orthopedic applications, Gr23 ERTi-23 Medical Titanium Wire is commonly used in the fabrication of bone plates, screws, and intramedullary nails for fracture fixation. The material's high strength-to-weight ratio and biocompatibility make it ideal for these load-bearing applications. Additionally, titanium alloys are used in joint replacement implants, such as hip and knee prostheses, where their mechanical properties and ability to promote osseointegration contribute to long-term implant stability and success.

Dental implants represent another significant application area for Gr23 ERTi-23 Medical Titanium Wire. Titanium dental implants have become the gold standard for tooth replacement due to their excellent biocompatibility and ability to integrate with the jawbone. The material is used to create the implant fixture, which serves as an artificial tooth root, as well as other components of the implant system, such as abutments and prosthetic screws.

In cardiovascular applications, Gr23 ERTi-23 Medical Titanium Wire is used in the manufacture of heart valve components, pacemaker casings, and vascular stents. The material's corrosion resistance and hemocompatibility make it suitable for long-term implantation in the cardiovascular system. Titanium alloys are also used in the production of surgical instruments and devices used in cardiovascular procedures.

Neurosurgical applications of Gr23 ERTi-23 Medical Titanium Wire include the fabrication of cranial plates, mesh implants for skull reconstruction, and spinal fusion devices. The material's biocompatibility and ability to be shaped into complex geometries make it valuable for these delicate applications. Additionally, titanium alloys are used in the production of neurostimulation devices and implantable drug delivery systems.

In the field of maxillofacial surgery, Gr23 ERTi-23 Medical Titanium Wire is used to create custom implants for facial reconstruction. The material's ability to be 3D printed or machined into patient-specific shapes allows for precise and aesthetically pleasing outcomes in complex facial surgeries.

The use of Gr23 ERTi-23 Medical Titanium Wire extends to various other medical applications, including: 1. Surgical staples and clips 2. External fixation devices 3. Prosthetic limb components 4. Cochlear implants 5. Ophthalmic implants 6. Dental instruments and tools 7. Surgical meshes for hernia repair 8. Bone anchors and suture anchors 9. Spinal cages and disc replacements 10. Custom-made implants for craniofacial reconstruction

The versatility of Gr23 ERTi-23 Medical Titanium Wire also makes it suitable for emerging medical technologies, such as 3D-printed implants and tissue engineering scaffolds. As additive manufacturing techniques continue to advance, the ability to create complex, patient-specific implants using titanium alloys is expected to expand the range of potential applications further.

In conclusion, Gr23 ERTi-23 Medical Titanium Wire demonstrates excellent biocompatibility, making it a preferred material for a wide range of medical implants and devices. Its unique combination of mechanical properties, corrosion resistance, and ability to promote tissue integration contributes to its success in various medical applications. As research in biomaterials and medical technologies continues to advance, the potential applications of Gr23 ERTi-23 Medical Titanium Wire are likely to expand, further improving patient outcomes and quality of life.

At SHAANXI CXMET TECHNOLOGY CO., LTD, we take pride in our extensive product range, which caters to diverse customer needs. Our company is equipped with outstanding production and processing capabilities, ensuring the high quality and precision of our products. We are committed to innovation and continuously strive to develop new products, keeping us at the forefront of our industry. With leading technological development capabilities, we are able to adapt and evolve in a rapidly changing market. Furthermore, we offer customized solutions to meet the specific requirements of our clients. If you are interested in our products or wish to learn more about the intricate details of our offerings, please do not hesitate to contact us at sales@cxmet.com. Our team is always ready to assist you.

|

|

|

|

References

- Elias, C. N., Lima, J. H. C., Valiev, R., & Meyers, M. A. (2008). Biomedical applications of titanium and its alloys. JOM, 60(3), 46-49.

- Rack, H. J., & Qazi, J. I. (2006). Titanium alloys for biomedical applications. Materials Science and Engineering: C, 26(8), 1269-1277.

- Niinomi, M. (2008). Mechanical biocompatibilities of titanium alloys for biomedical applications. Journal of the mechanical behavior of biomedical materials, 1(1), 30-42.

- Chen, Q., & Thouas, G. A. (2015). Metallic implant biomaterials. Materials Science and Engineering: R: Reports, 87, 1-57.

- Liu, X., Chu, P. K., & Ding, C. (2004). Surface modification of titanium, titanium alloys, and related materials for biomedical applications. Materials Science and Engineering: R: Reports, 47(3-4), 49-121.

- Geetha, M., Singh, A. K., Asokamani, R., & Gogia, A. K. (2009). Ti based biomaterials, the ultimate choice for orthopaedic implants–a review. Progress in materials science, 54(3), 397-425.

- Wang, K. (1996). The use of titanium for medical applications in the USA. Materials Science and Engineering: A, 213(1-2), 134-137.

- Brunette, D. M., Tengvall, P., Textor, M., & Thomsen, P. (Eds.). (2012). Titanium in medicine: material science, surface science, engineering, biological responses and medical applications. Springer Science & Business Media.

- Williams, D. F. (2008). On the mechanisms of biocompatibility. Biomaterials, 29(20), 2941-2953.

- Ozcan, M., & Hämmerle, C. (2012). Titanium as a reconstruction and implant material in dentistry: advantages and pitfalls. Materials, 5(9), 1528-1545.