- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Is Titanium Grade 4 Round Bar Biocompatible for Medical Use?

2025-05-09 13:54:55

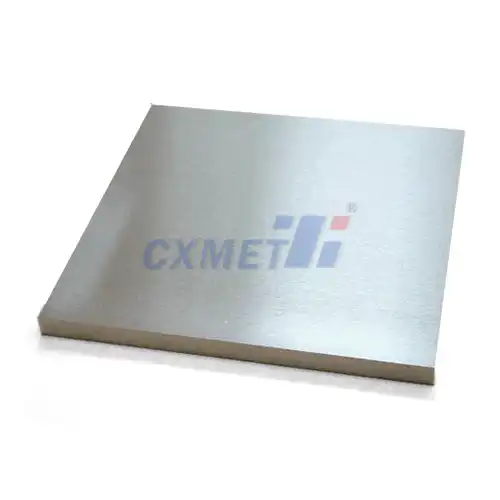

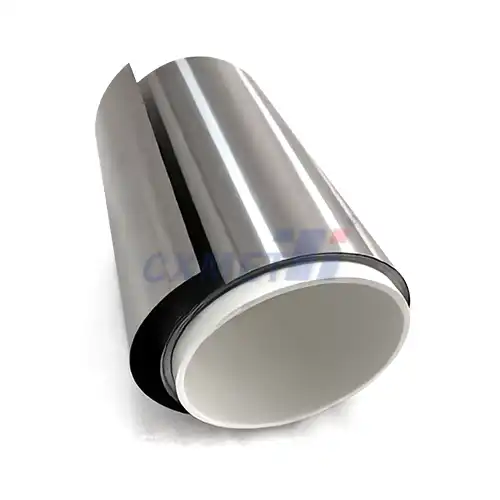

Titanium Grade 4 Round Bar, also known as commercially pure (CP) titanium grade 4, is a widely used material in various industries, including the medical field. Its exceptional properties, such as high strength-to-weight ratio, excellent corrosion resistance, and biocompatibility, make it an attractive option for medical applications. In this blog post, we'll explore the biocompatibility of Titanium Grade 4 Round Bar for medical use and address some common questions related to its properties and applications.

|

|

|

What are the key properties of Titanium Grade 4 Round Bar that make it suitable for medical implants?

Titanium Grade 4 Round Bar possesses several key properties that make it highly suitable for medical implants:

- Biocompatibility: One of the most crucial properties of Titanium Grade 4 Round Bar is its excellent biocompatibility. The human body readily accepts titanium, and it does not cause adverse reactions or rejections when used in medical implants. This biocompatibility is attributed to the formation of a stable oxide layer on the surface of the titanium, which prevents corrosion and interaction with surrounding tissues.

- Corrosion Resistance: Titanium Grade 4 Round Bar exhibits exceptional resistance to corrosion, even in harsh environments such as the human body. This property is essential for long-term implant success, as it prevents degradation of the material and minimizes the release of potentially harmful ions into the body.

- High Strength-to-Weight Ratio: Despite being lightweight, Titanium Grade 4 Round Bar offers excellent strength. This combination of low density and high strength makes it ideal for medical implants, as it reduces the overall weight of the implant while maintaining the necessary structural integrity.

- Low Modulus of Elasticity: Compared to other metals used in medical implants, such as stainless steel or cobalt-chromium alloys, Titanium Grade 4 has a lower modulus of elasticity. This property allows for better stress distribution between the implant and surrounding bone, reducing the risk of stress shielding and promoting better osseointegration.

- Non-Magnetic Properties: Titanium Grade 4 Round Bar is non-magnetic, which is crucial for patients who may require MRI scans in the future. This property ensures that the implant will not interfere with medical imaging procedures or cause complications during diagnostic tests.

- Osseointegration: The surface of Titanium Grade 4 Round Bar promotes excellent osseointegration, which is the direct structural and functional connection between living bone tissue and the surface of the implant. This property is essential for the long-term success of dental and orthopedic implants, as it ensures a strong and stable bond between the implant and the surrounding bone.

These properties collectively contribute to the suitability of Titanium Grade 4 Round Bar for medical implants, making it a preferred choice for various applications in the medical field. Its biocompatibility, combined with its mechanical and chemical properties, ensures that implants made from this material can function effectively and safely within the human body for extended periods.

How does Titanium Grade 4 Round Bar compare to other materials used in medical implants?

When comparing Titanium Grade 4 Round Bar to other materials used in medical implants, several factors come into play. Let's examine how it stacks up against some common alternatives:

- Stainless Steel: While stainless steel has been widely used in medical implants due to its strength and affordability, Titanium Grade 4 offers several advantages. Titanium is significantly lighter than stainless steel, which can be beneficial for patient comfort, especially in larger implants. Additionally, titanium's biocompatibility is superior to that of stainless steel, as some patients may develop allergic reactions to the nickel content in certain stainless steel alloys.

- Cobalt-Chromium Alloys: Cobalt-chromium alloys are known for their high strength and wear resistance, making them popular in joint replacement implants. However, Titanium Grade 4 has a lower modulus of elasticity, which more closely matches that of human bone. This property helps to reduce stress shielding and promote better bone remodeling around the implant.

- Other Titanium Alloys: While other titanium alloys, such as Ti-6Al-4V (Grade 5), offer higher strength, Titanium Grade 4 Round Bar provides a better balance of strength and ductility. This makes it easier to work with during the manufacturing process and allows for more design flexibility in implant creation.

- Polymers: Some medical implants use polymers like polyethylene or PEEK (polyether ether ketone). While these materials have their place in certain applications, Titanium Grade 4 offers superior strength and longevity, making it a better choice for load-bearing implants or those requiring long-term stability.

- Ceramics: Ceramic materials like zirconia are sometimes used in dental implants due to their aesthetic properties. However, Titanium Grade 4 Round Bar offers better mechanical properties and a longer track record of successful use in medical implants.

The choice of material for medical implants depends on various factors, including the specific application, patient needs, and implant design requirements. Titanium Grade 4 Round Bar often emerges as a top contender due to its unique combination of properties:

- Biocompatibility: Titanium Grade 4's exceptional biocompatibility reduces the risk of adverse reactions and promotes better integration with the body.

- Corrosion Resistance: Its superior corrosion resistance ensures long-term stability and minimizes the release of potentially harmful ions.

- Strength-to-Weight Ratio: The high strength-to-weight ratio of Titanium Grade 4 allows for the creation of strong yet lightweight implants, improving patient comfort and reducing strain on surrounding tissues.

- Osseointegration: Titanium Grade 4's ability to promote osseointegration is crucial for the long-term success of dental and orthopedic implants.

- Versatility: Its combination of properties makes it suitable for a wide range of medical applications, from dental implants to bone plates and screws.

While each material has its strengths and ideal applications, Titanium Grade 4 Round Bar's overall performance and versatility make it a preferred choice for many medical implant applications. Its proven track record of success and ongoing research into surface modifications and coatings continue to expand its potential uses in the medical field.

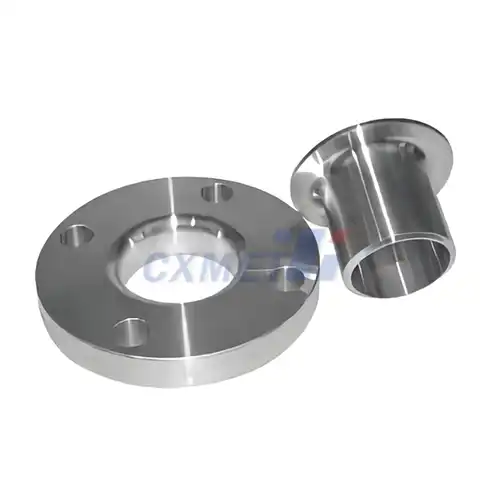

|

|

|

What are the potential long-term effects of Titanium Grade 4 Round Bar implants in the human body?

Understanding the long-term effects of Titanium Grade 4 Round Bar implants in the human body is crucial for both medical professionals and patients. While titanium is generally considered highly biocompatible, it's important to examine the potential long-term outcomes and considerations:

- Osseointegration and Implant Stability: One of the most significant long-term effects of Titanium Grade 4 implants is their ability to achieve and maintain osseointegration. This process, where the bone tissue grows directly onto the implant surface, ensures long-term stability and functionality of the implant. Studies have shown that titanium implants can maintain their integration with bone for decades, contributing to their long-term success rates.

- Corrosion Resistance: The excellent corrosion resistance of Titanium Grade 4 Round Bar plays a crucial role in its long-term performance. The stable oxide layer that forms on the surface of titanium implants provides protection against degradation in the body's environment. This resistance to corrosion helps maintain the structural integrity of the implant over time and minimizes the release of metal ions into the surrounding tissues.

- Tissue Response: Long-term studies have shown that the tissue response to Titanium Grade 4 implants remains favorable over extended periods. The biocompatible nature of titanium means that the body's immune system generally does not mount a significant response against the implant. This lack of chronic inflammation or rejection contributes to the overall success and longevity of titanium implants.

- Bone Remodeling: The lower modulus of elasticity of Titanium Grade 4 compared to some other implant materials allows for more natural stress distribution in the surrounding bone. This property can help maintain bone density around the implant over time, reducing the risk of bone loss due to stress shielding.

- Wear and Fatigue Resistance: In applications where the implant is subjected to repeated loading or movement, such as in joint replacements, the wear and fatigue resistance of Titanium Grade 4 becomes crucial. While pure titanium may not be as wear-resistant as some alloys, its performance in many medical applications is still excellent, contributing to the longevity of the implant.

- Potential for Metal Ion Release: Although titanium is highly corrosion-resistant, there is still the potential for a very small amount of metal ion release over time. However, the levels of titanium ions released are generally considered to be well below the threshold for causing systemic effects in the body. Long-term studies have not shown significant adverse effects related to this minimal ion release.

- Imaging Compatibility: The non-magnetic properties of Titanium Grade 4 Round Bar ensure that patients with these implants can safely undergo MRI scans throughout their lives. This compatibility with imaging techniques is crucial for long-term patient care and monitoring.

- Potential for Allergic Reactions: While titanium allergies are extremely rare, there have been isolated reports of hypersensitivity reactions to titanium implants. However, these cases are far less common than allergic reactions to other metals used in implants, such as nickel in stainless steel.

- Long-term Functional Performance: The overall long-term effects of Titanium Grade 4 implants are generally positive in terms of functional performance. Whether used in dental implants, bone plates, or other medical devices, titanium implants have demonstrated the ability to maintain their function and integration with the body over many years, often lasting the lifetime of the patient.

- Potential for Revision Surgery: In some cases, particularly with orthopedic implants, there may be a need for revision surgery after many years. However, this is often due to wear of other components (such as polyethylene liners in joint replacements) rather than failure of the titanium components themselves.

In conclusion, the long-term effects of Titanium Grade 4 Round Bar implants in the human body are predominantly positive. Its biocompatibility, corrosion resistance, and ability to integrate with bone tissue contribute to excellent long-term outcomes in various medical applications. While no material is without potential drawbacks, the track record of Titanium Grade 4 in medical implants demonstrates its reliability and safety for long-term use in the human body. Ongoing research continues to explore ways to further enhance the performance and biocompatibility of titanium implants, ensuring their continued role in improving patient outcomes in the field of medical implants.

At SHAANXI CXMET TECHNOLOGY CO., LTD, we take pride in our extensive product range, which caters to diverse customer needs. Our company is equipped with outstanding production and processing capabilities, ensuring the high quality and precision of our products. We are committed to innovation and continuously strive to develop new products, keeping us at the forefront of our industry. With leading technological development capabilities, we are able to adapt and evolve in a rapidly changing market. Furthermore, we offer customized solutions to meet the specific requirements of our clients. If you are interested in our products or wish to learn more about the intricate details of our offerings, please do not hesitate to contact us at sales@cxmet.com. Our team is always ready to assist you.

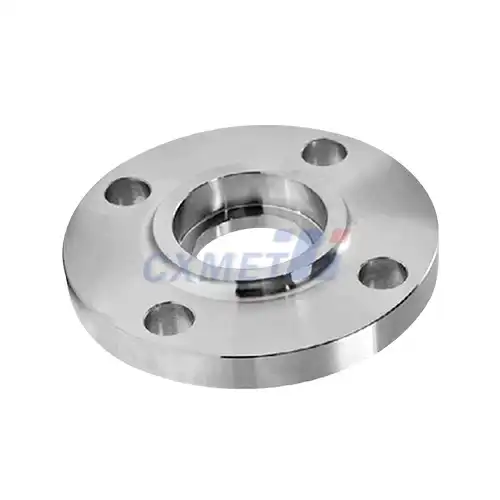

|

|

|

References

1. Elias, C. N., Lima, J. H. C., Valiev, R., & Meyers, M. A. (2008). Biomedical applications of titanium and its alloys. JOM, 60(3), 46-49.

2. Sidambe, A. T. (2014). Biocompatibility of Advanced Manufactured Titanium Implants—A Review. Materials, 7(12), 8168-8188.

3. Pohler, O. E. M. (2000). Unalloyed titanium for implants in bone surgery. Injury, 31, D7-D13.

4. Steinemann, S. G. (1998). Titanium—the material of choice? Periodontology 2000, 17(1), 7-21.

5. Liu, X., Chu, P. K., & Ding, C. (2004). Surface modification of titanium, titanium alloys, and related materials for biomedical applications. Materials Science and Engineering: R: Reports, 47(3-4), 49-121.

6. Geetha, M., Singh, A. K., Asokamani, R., & Gogia, A. K. (2009). Ti based biomaterials, the ultimate choice for orthopaedic implants – A review. Progress in Materials Science, 54(3), 397-425.