- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

titanium sputtering target

Place Of Origin: China

Material: Titanium

Type Laser Machining, Milling, Other Machining Services, Turning, Wire EDM

Micro Machining or Not Not Micro Machining

Material: Pure Titanium

Size: Custom

Color: Black

Shape: Round ,Sheet

Product Introduction

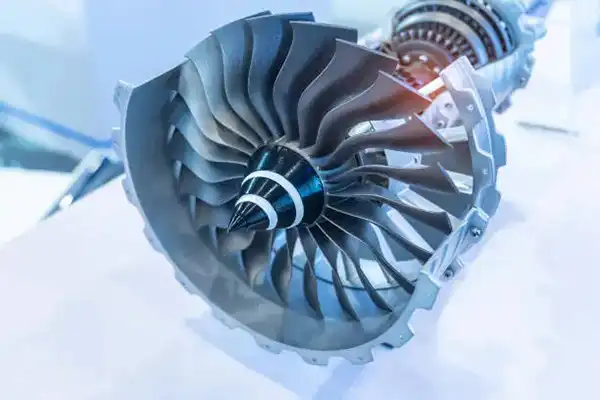

Titanium Sputtering Targets are high-purity titanium materials designed for use in physical vapor deposition (PVD) processes such as sputtering coating. These targets are essential for producing thin films and coatings with excellent adhesion, corrosion resistance, and mechanical properties across industries including electronics, optics, automotive, and aerospace.

Shaanxi CXMET Technology Co., Ltd offers premium titanium sputtering targets manufactured with strict quality control to ensure uniform composition, density, and surface finish for high deposition efficiency and film quality.

Technical Specifications

| Parameter | Specification |

|---|---|

| Material Grade | Commercially Pure Titanium (Grade 1 or 2) or Titanium Alloy (e.g., Grade 5) |

| Purity | ≥ 99.5% |

| Density | ≥ 4.43 g/cm³ |

| Target Type | Flat, Round, Tubular |

| Diameter Range | 50 mm – 500 mm |

| Thickness Range | 3 mm – 25 mm |

| Surface Finish | Machined, Polished |

| Hardness | Vickers HV 120 – 220 |

| Cooling Plate Compatibility | Compatible with water-cooled systems |

|

|

|

Product Features

-

High purity and uniform microstructure

-

Excellent density and minimal porosity for stable sputtering

-

Superior mechanical strength and thermal conductivity

-

Precision machining and surface polishing

-

Available in various shapes and sizes to fit multiple sputtering systems

Applications

-

Semiconductor and electronics thin films

-

Optical coatings and decorative films

-

Automotive and aerospace surface treatments

-

Medical device coatings

-

Solar panels and energy devices

|

|

|

|

|

|

Manufacturing Process

-

Raw titanium sponge melting by vacuum arc remelting (VAR) or electron beam (EB) melting

-

Forging and rolling to required thickness and dimensions

-

Precision CNC machining and polishing

-

Rigorous non-destructive testing and surface inspection

-

Packaging to prevent contamination and oxidation

Quality Assurance

-

Certified to ASTM B348 and related standards

-

Mill Test Reports (MTR) with detailed chemical and mechanical data

-

Surface roughness and flatness controlled within tight tolerances

-

ISO 9001:2015 quality system certified

-

Third-party inspection available

Packaging and Logistics

-

Protected with anti-oxidation packaging material

-

Vacuum sealing or inert gas purging available on request

-

Packed in sturdy wooden crates or custom packaging

-

Global shipping via air, sea, or express courier

-

Flexible Incoterms including FOB, CIF, and DAP

|

|

|

|

Company Overview

Shaanxi CXMET Technology Co., Ltd., founded in 2005, is headquartered in China's Titanium Valley and operates a 50,000 m² facility. With 10 million RMB in registered capital and over 80 technical staff, we specialize in R&D, manufacturing, and exporting of non-ferrous and refractory metals, including titanium, nickel, tantalum, niobium, zirconium, molybdenum, and tungsten.

Our materials serve industries ranging from marine and oil & gas to medical, chemical, electronics, and aerospace. We uphold integrity, development, innovation, and excellence in service. Our mission is to create value for clients, benefit our enterprise, and support employee growth. With a forward-looking vision, we strive to innovate and lead the global titanium market.

Factory show

|

|

|

|

Production workshop

|

|

|

|

|

|

Production Equipments

Main Products

Why Choose Us Shaanxi CXMET Technology Co Ltd.

Extensive Product Range

We supply titanium nickel tantalum niobium tungsten molybdenum zirconium and related alloys

Outstanding Production and Processing Capabilities

Equipped with advanced forging CNC machining and testing equipment across 50000 square meters of production area

Continuous Innovation and Product Development

Dedicated to introducing new titanium-based materials and international processing technologies

Advanced R and D Team

More than 80 experienced technicians and engineers developing reliable and high-performance metal products

Customized Solutions

From standard inventory to tailor-made components we offer one-stop titanium solutions for your project

Company Profile

Founded in 2005 with a registered capital of 10 million yuan located in Baoji China Titanium Valley we focus on global markets and provide consistent quality service and delivery. Our products are trusted worldwide in marine petrochemical medical aerospace vacuum electronics and energy fields.

Corporate Culture

CXMET is driven by integrity development innovation and service excellence. Our mission is to create value for customers generate returns for our business and offer growth for our employees. With vision and responsibility we aim to lead the titanium industry into the future

Contact Us

Shaanxi CXMET Technology Co., Ltd

Email: SALES@CXMET.COM

Tel: 86-917-3381086

hotTags:titanium sputtering target,supplier,wholesale,China,factory,manufacturer,OEM,Customized,trader,for sale,in stock,free sample,for sale.

YOU MAY LIKE

titanium 6Al-2Sn-4Zr-6Mo sheet

Brand: CXMET

Place Of Origin: China

Grade: Gr1

Ti (Min): 99.6%

Processing Service: Bending, Welding, Decoiling, Cutting, Punching

titanium grade 23 sheet

Brand: CXMET

Place Of Origin: China

Ti (Min): 99.9%

Processing Service: Bending, Welding, Decoiling, Cutting, Punching

Material: Pure titanium and titanium alloy

Shape: Plate, sheet or customized

Size: Cusomized

Color: Sliver,or Customized

Density: 4.53 G/cm3

MOQ: 1kg

Packing: Wooden case

titanium 0.8Ni-0.3Mo Grade 12 sheet

Brand: CXMET

Place Of Origin: China Grade: GR12

Ti (Min): 90%

Processing Service: Welding, Cutting

Material: Titanium Alloy

Shape: Square

Standard: ASTM B 265

Density: 4.51g/cm3

MOQ: 1kg

Package: Standard Wooden Package

Base material: Titanium

titanium 3Al-2.5V Grade 9 sheet

Brand: CXMET

Place Of Origin: China

Ti (Min): 99.6%

Processing Service: Welding, Cutting

Material :Pure Titanium

Shape: Square

Standard: ASTM B 265

Density: 4.51g/cm3

Package :Standard Wooden Package

Purity: 99.6% Min

Titanium 6Al-4V ELI Sheet

Brand: CXMET

Place Of Origin:China

Grade: GR5

Ti (Min): 90%

Model Number: ASTM F136

Processing Service: Bending, Welding, Cutting, Punching

Standard: ASTM F136

Material: Grade 5 Grade 23

Surface: Bright

Density: 4.51 G/cm3

Titanium Grade 4 Sheet

product name: Titanium plate

Brand:CXMET

Place Of Origin: China

Processing Service: Bending, Welding,Decoiling, Cutting, Punching

Density :4.51g/cm3

Standard: ASTM B265

Material: Gr2

Titanium Grade 3 Sheet

Brand: CXMET

Place Of Origin: China

Thickness: 0.032

Grade: Grade 3

MTR Availability: Yes

Material: Titanium

Shape: Sheet

Titanium Grade 2 Sheet

Brand: CXMET

Place Of Origin: China

Thickness: 0.02

Max Width: 48

Max Length: 96

Grade: Grade 2

Full Length: true

Material: Titanium

Shape: Sheet/Plate