- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What are the Applications of Titanium 3Al-2.5V Grade 9 Sheet?

2025-03-01 14:55:55

Titanium 3Al-2.5V Grade 9 sheet, also known as Ti 3-2.5, is a high-strength alpha-beta titanium alloy that offers an excellent combination of strength, ductility, and corrosion resistance. This versatile material finds applications in various industries due to its unique properties. In this blog post, we'll explore the diverse applications of Titanium 3Al-2.5V Grade 9 sheet and answer some frequently asked questions about this remarkable alloy.

|

|

|

What are the mechanical properties of Titanium 3Al-2.5V?

Titanium 3Al-2.5V Grade 9 sheet possesses exceptional mechanical properties that make it suitable for a wide range of applications. This alpha-beta titanium alloy offers a balanced combination of strength, ductility, and formability. Some key mechanical properties of Ti 3-2.5 include:

- Tensile Strength: Typically ranging from 620 to 795 MPa (90 to 115 ksi)

- Yield Strength: Approximately 485 to 620 MPa (70 to 90 ksi)

- Elongation: 10% to 15% (depending on the material condition)

- Modulus of Elasticity: Around 100 GPa (14.5 x 10^6 psi)

- Fatigue Strength: Excellent resistance to cyclic loading

The mechanical properties of Titanium 3Al-2.5V can be further enhanced through heat treatment and cold working processes. This alloy exhibits good formability in the annealed condition, allowing for complex shapes to be fabricated. Its strength-to-weight ratio is superior to many other metals, making it an ideal choice for weight-critical applications.

In addition to its impressive mechanical properties, Titanium 3Al-2.5V demonstrates excellent corrosion resistance in various environments. It performs well in saltwater, marine atmospheres, and many chemical environments, making it suitable for applications in the aerospace, marine, and chemical processing industries.

The combination of high strength, low density, and corrosion resistance makes Titanium 3Al-2.5V Grade 9 sheet an attractive material for engineers and designers seeking to optimize performance while minimizing weight. This alloy's properties allow for the creation of lightweight, durable components that can withstand harsh operating conditions and prolonged exposure to corrosive environments.

How does Titanium 3Al-2.5V compare to other titanium alloys?

Titanium 3Al-2.5V Grade 9 sheet occupies a unique position among titanium alloys, offering a balance of properties that sets it apart from other grades. When comparing Ti 3-2.5 to other titanium alloys, several factors come into play:

- Strength-to-Weight Ratio: Titanium 3Al-2.5V offers an excellent strength-to-weight ratio, making it suitable for applications where weight reduction is crucial. While it may not be as strong as some beta alloys like Ti-6Al-4V, it provides a good balance of strength and formability.

- Formability: Ti 3-2.5 exhibits better formability compared to many other titanium alloys, especially in the annealed condition. This property makes it ideal for applications requiring complex shapes or cold forming operations.

- Weldability: The alloy demonstrates good weldability, which is advantageous in fabrication processes and allows for easier integration into complex assemblies.

- Corrosion Resistance: Like most titanium alloys, Ti 3-2.5 offers excellent corrosion resistance in various environments, including saltwater and chemical solutions.

- Cost: Titanium 3Al-2.5V is generally less expensive than some higher-performance titanium alloys, making it a cost-effective choice for many applications.

When compared to commercially pure (CP) titanium grades, Titanium 3Al-2.5V offers higher strength while maintaining good formability. This makes it suitable for applications that require more strength than CP titanium but don't necessarily need the highest strength levels offered by alloys like Ti-6Al-4V.

In comparison to Ti-6Al-4V, which is one of the most widely used titanium alloys, Ti 3-2.5 has lower strength but better formability and lower cost. This makes it an attractive option for applications where the extreme strength of Ti-6Al-4V is not required, but good formability and moderate strength are desired.

The unique properties of Titanium 3Al-2.5V make it particularly well-suited for applications in the aerospace industry, especially in the manufacture of hydraulic and pneumatic tubing systems. Its combination of strength, formability, and corrosion resistance allows for the creation of lightweight, durable components that can withstand the demanding conditions of aircraft operation.

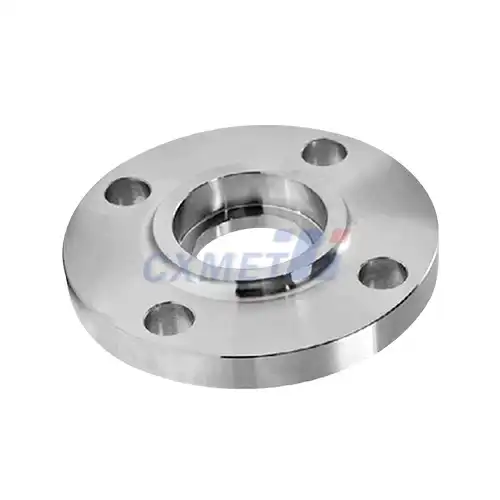

|

|

|

What industries use Titanium 3Al-2.5V Grade 9 sheet?

Titanium 3Al-2.5V Grade 9 sheet finds applications across various industries due to its unique combination of properties. Some of the key industries that utilize this alloy include:

- Aerospace Industry: This is one of the primary users of Ti 3-2.5. The alloy is extensively used in aircraft hydraulic and pneumatic systems, fuel lines, and other components where high strength-to-weight ratio and excellent corrosion resistance are crucial. It's particularly favored for tubing applications in commercial and military aircraft.

- Marine Industry: The corrosion resistance of Titanium 3Al-2.5V makes it an excellent choice for marine applications. It's used in components exposed to saltwater, such as heat exchangers, pumps, and valves in desalination plants.

- Chemical Processing Industry: The alloy's resistance to various chemicals makes it suitable for use in chemical processing equipment, including pipes, valves, and reactor components.

- Oil and Gas Industry: Ti 3-2.5 is used in offshore oil and gas exploration and production equipment due to its corrosion resistance and high strength-to-weight ratio.

- Medical Industry: While not as common as some other titanium alloys in medical applications, Ti 3-2.5 can be used in certain medical devices and surgical instruments due to its biocompatibility and strength.

- Sports and Recreation: The alloy is sometimes used in high-performance sports equipment, such as bicycle frames and golf club components, where lightweight strength is desirable.

- Automotive Industry: Although not as widespread as in aerospace, Ti 3-2.5 is used in some high-performance automotive applications, particularly in racing vehicles where weight reduction is critical.

In the aerospace industry, which is the largest consumer of Titanium 3Al-2.5V Grade 9 sheet, the material is primarily used for hydraulic and pneumatic system tubing. These systems are critical for the operation of various aircraft components, including landing gear, flight controls, and braking systems. The use of Ti 3-2.5 in these applications allows for weight reduction compared to traditional materials like stainless steel, contributing to improved fuel efficiency and performance of aircraft.

The marine industry benefits from the corrosion resistance of Titanium 3Al-2.5V, particularly in applications involving seawater exposure. Heat exchangers in desalination plants, for example, can be made more durable and efficient by using this alloy. Its resistance to pitting and crevice corrosion in chloride environments makes it an excellent choice for components that are in constant contact with seawater.

In the chemical processing industry, the alloy's resistance to a wide range of chemicals, combined with its strength and formability, makes it suitable for various components in processing plants. This includes piping systems, reaction vessels, and heat exchangers that may be exposed to corrosive chemicals or high temperatures.

The oil and gas industry utilizes Titanium 3Al-2.5V in offshore applications where its corrosion resistance and high strength-to-weight ratio provide advantages over traditional materials. Components such as risers, tubing, and downhole tools can benefit from the use of this alloy, particularly in deep-sea environments where weight reduction and corrosion resistance are critical factors.

While the applications of Titanium 3Al-2.5V Grade 9 sheet are diverse, its use is often driven by the need for a material that combines strength, lightweight properties, and excellent corrosion resistance. As industries continue to seek ways to improve performance, efficiency, and durability, the unique properties of Ti 3-2.5 make it a valuable material choice across a wide range of applications.

At SHAANXI CXMET TECHNOLOGY CO., LTD, we take pride in our extensive product range, which caters to diverse customer needs. Our company is equipped with outstanding production and processing capabilities, ensuring the high quality and precision of our products. We are committed to innovation and continuously strive to develop new products, keeping us at the forefront of our industry. With leading technological development capabilities, we are able to adapt and evolve in a rapidly changing market. Furthermore, we offer customized solutions to meet the specific requirements of our clients. If you are interested in our products or wish to learn more about the intricate details of our offerings, please do not hesitate to contact us at sales@cxmet.com. Our team is always ready to assist you.

|

|

|

|

References

- ASM Aerospace Specification Metals Inc. "Titanium Ti-3Al-2.5V (Grade 9)."

- ASTM International. "ASTM B265 - Standard Specification for Titanium and Titanium Alloy Strip, Sheet, and Plate."

- Boyer, R., Welsch, G., & Collings, E. W. (1994). Materials Properties Handbook: Titanium Alloys. ASM International.

- Lutjering, G., & Williams, J. C. (2007). Titanium (2nd ed.). Springer-Verlag Berlin Heidelberg.

- Peters, M., Kumpfert, J., Ward, C. H., & Leyens, C. (2003). Titanium alloys for aerospace applications. Advanced Engineering Materials, 5(6), 419-427.

- Titanium Industries. "Titanium Grade 9 (3Al-2.5V)."

- United Performance Metals. "Titanium 3-2.5 Sheet."

- Veiga, C., Davim, J. P., & Loureiro, A. J. R. (2012). Properties and applications of titanium alloys: A brief review. Reviews on Advanced Materials Science, 32(2), 133-148.

- Williams, J. C., & Starke Jr, E. A. (2003). Progress in structural materials for aerospace systems. Acta Materialia, 51(19), 5775-5799.

- Yamada, M. (1996). An overview on the development of titanium alloys for non-aerospace application in Japan. Materials Science and Engineering: A, 213(1-2), 8-15.

.webp)