- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

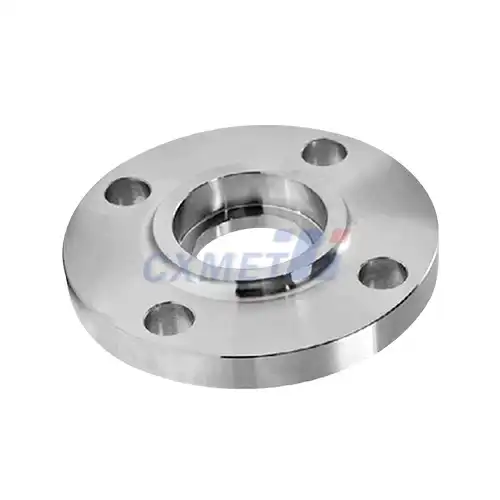

Titanium Socket Weld Flange

Place Of Origin: China

Type: Titanium Tube Titanium Prices

Surface: Pickling

Shape: Round.Square.Rectangle

Processing: Processed

Test: Eddy Current Test

Advantage: High Performance

MOQ: 1pcs

Certificates: ISO9001:2008

Color: Sliver

Introduction:

Titanium socket weld flanges, crafted with precision engineering, are essential components in various industrial applications requiring high corrosion resistance and exceptional strength-to-weight ratio. Manufactured by SHAANXI CXMET TECHNOLOGY CO. LTD, a leading name in titanium products, these flanges represent the pinnacle of quality and performance. Engineered to withstand harsh operating conditions, our titanium socket weld flanges ensure reliable connections and minimal maintenance requirements, contributing to enhanced operational efficiency. With a focus on innovation and technological advancement, we continuously strive to exceed industry standards and meet the evolving needs of our customers. Whether used in aerospace, chemical processing, or marine engineering, our titanium socket weld flanges deliver unparalleled durability and reliability, making them the preferred choice for critical applications where performance is paramount. Trust SHAANXI CXMET for superior quality titanium socket weld flanges that meet the most demanding requirements with ease.

Standards:

Our Socket Weld Flange in Titanium adhere to stringent international standards, ensuring reliability and compatibility across diverse industrial settings. Common standards include ASTM B381, ASTM B16.5, ASME B16.47, DIN, and JIS.

Basic Parameters:

| Parameter | Value |

|---|---|

| Material | Titanium Grade 2 or 5 |

| Size Range | 1/2" to 24" |

| Pressure Rating | Class 150 to Class 2500 |

| Temperature Range | -50°C to 500°C |

| Surface Finish | Smooth, Machined |

|

|

|

Attributes:

- Exceptional Corrosion Resistance

- High Strength-to-Weight Ratio

- Superior Durability

- Precise Dimensional Accuracy

- Enhanced Fatigue Strength

- Excellent Weldability

Functions:

Titanium socket weld flanges serve as crucial components in piping systems, facilitating easy assembly and disassembly while ensuring leak-proof connections. They provide a secure method for joining pipes to valves, fittings, and other equipment, maintaining structural integrity under high-pressure and high-temperature conditions.

Features:

- Socket weld design for easy installation and maintenance.

- Precision machining for tight tolerances.

- Smooth surface finish for enhanced corrosion resistance.

- Compatible with various piping materials.

- Suitable for critical applications in chemical, petrochemical, and aerospace industries.

Advantages and Highlights:

- Lightweight yet sturdy construction for reduced installation complexity.

- Longevity and reliability, even in harsh environments.

- Resistance to corrosion, erosion, and chemical damage.

- Wide temperature and pressure operating range.

- Conformance to international standards ensures compatibility and interchangeability.

Application Areas:

Titanium socket weld flanges find extensive usage in industries such as:

- Chemical Processing

- Oil and Gas

- Marine Engineering

- Aerospace

- Pharmaceutical

- Power Generation

Packaging of Titanium Socket Weld Flange

-

Individual Protection

Each titanium socket weld flange is individually wrapped with plastic film or packed in sealed moisture-resistant bags to protect against humidity, oxidation, and surface abrasion. -

Flange Face Protection

Raised faces and socket welding areas are covered with rubber or plastic protectors to avoid impact damage and preserve the sealing surface integrity during handling and transportation. -

Grouped Packing

Flanges of the same size and specification are grouped in sets and securely strapped using nylon ties or foam interlayers. Each group includes an identification label showing:-

Grade (e.g., Gr2, Gr5, Gr12)

-

Dimensions and Pressure Class

-

Quantity per set

-

Heat Number or Batch Number

-

-

Outer Carton or Wooden Box

-

Small Quantities: Placed in heavy-duty, non-fumigation plywood boxes lined with cushioning materials.

-

Bulk Orders: Neatly arranged on solid wooden pallets, wrapped in stretch film and reinforced with steel belts for secure international shipping.

-

-

Markings & Labels

Outer packaging is clearly labeled with product description, weight, dimensions, order number, and customer details for easy identification and customs clearance. -

Export-Standard Compliance

Packaging conforms to international logistics and shipping regulations (e.g., ISPM-15), ensuring safe delivery via air, sea, or land transport. -

Customized Solutions Available

OEM packaging, private labeling, barcode printing, and special protective materials can be arranged upon customer request.

|

|

|

|

Company Overview

Shaanxi CXMET Technology Co., Ltd., founded in 2005, is headquartered in China's Titanium Valley and operates a 50,000 m² facility. With 10 million RMB in registered capital and over 80 technical staff, we specialize in R&D, manufacturing, and exporting of non-ferrous and refractory metals, including titanium, nickel, tantalum, niobium, zirconium, molybdenum, and tungsten.

Our materials serve industries ranging from marine and oil & gas to medical, chemical, electronics, and aerospace. We uphold integrity, development, innovation, and excellence in service. Our mission is to create value for clients, benefit our enterprise, and support employee growth. With a forward-looking vision, we strive to innovate and lead the global titanium market.

Factory show

|

|

|

|

Production workshop

|

|

|

|

|

|

Production Equipments

Main Products

Why Choose Us Shaanxi CXMET Technology Co Ltd.

Extensive Product Range

We supply titanium nickel tantalum niobium tungsten molybdenum zirconium and related alloys

Outstanding Production and Processing Capabilities

Equipped with advanced forging CNC machining and testing equipment across 50000 square meters of production area

Continuous Innovation and Product Development

Dedicated to introducing new titanium-based materials and international processing technologies

Advanced R and D Team

More than 80 experienced technicians and engineers developing reliable and high-performance metal products

Customized Solutions

From standard inventory to tailor-made components we offer one-stop titanium solutions for your project

Company Profile

Founded in 2005 with a registered capital of 10 million yuan located in Baoji China Titanium Valley we focus on global markets and provide consistent quality service and delivery. Our products are trusted worldwide in marine petrochemical medical aerospace vacuum electronics and energy fields.

Corporate Culture

CXMET is driven by integrity development innovation and service excellence. Our mission is to create value for customers generate returns for our business and offer growth for our employees. With vision and responsibility we aim to lead the titanium industry into the future

OEM Services:

At Shaanxi CXMET Technology Co., Ltd. we offer comprehensive OEM services, allowing customers to customize flange designs, sizes, and specifications to meet specific project requirements. Our experienced engineers and state-of-the-art facilities ensure precise manufacturing and timely delivery of OEM orders.

FAQs:

- What is the difference between Grade 2 and Grade 5 titanium? Grade 2 titanium offers excellent weldability and corrosion resistance, while Grade 5 titanium (Ti-6Al-4V) provides higher strength and heat resistance.

- Can titanium flanges be used in seawater applications? Yes, titanium's inherent corrosion resistance makes it ideal for seawater environments, offering long-term durability and performance.

- Are titanium socket weld flanges compatible with stainless steel piping? Yes, titanium flanges can be used with stainless steel piping systems, provided proper gasket materials are used to prevent galvanic corrosion.

Material Details:

Titanium SW Flange are typically manufactured from Grade 2 or Grade 5 titanium alloys. Grade 2 titanium offers excellent corrosion resistance and weldability, making it suitable for general-purpose applications. Grade 5 titanium, also known as Ti-6Al-4V, provides higher strength and heat resistance, ideal for demanding industrial environments.

For inquiries or orders, please contact us at sales@cxmet.com.

With unparalleled expertise and dedication to quality, SHAANXI CXMET TECHNOLOGY CO., LTD stands as your trusted partner for all titanium socket weld flange needs.

hotTags:Titanium Socket Weld Flange,supplier,wholesale,China,factory,manufacturer,OEM,Customized,trader,for sale,in stock,free sample,for sale.

YOU MAY LIKE

Titanium Lap Joint Flange

Brand: CXMET

Place Of Origin: China

Shape:Flange

Material:Titanium

Standards: ASME A182, ASME B16.5

Flange Thickness:11/16 in

Class/Pressure: Class 150

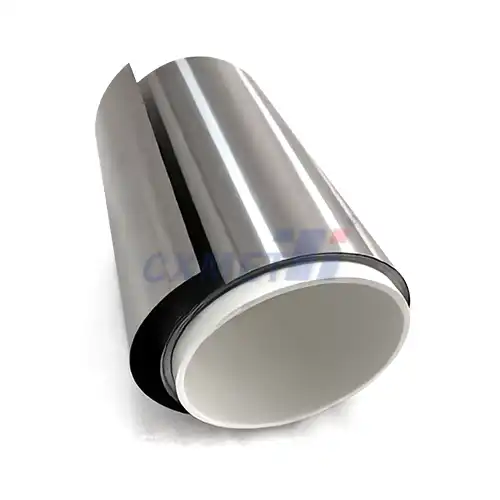

Tantalum Foil

Brand: CXMET

Place Of Origin: China

Material: Pure and alloy tantalum

Purity: 99.95%min

Density: 16.65g/cm3

Standard: ASTM B708

Condition: Hot Rolled,Cold Rolled, Annealed,Grinding,Mirror surface

Package: Wooden case

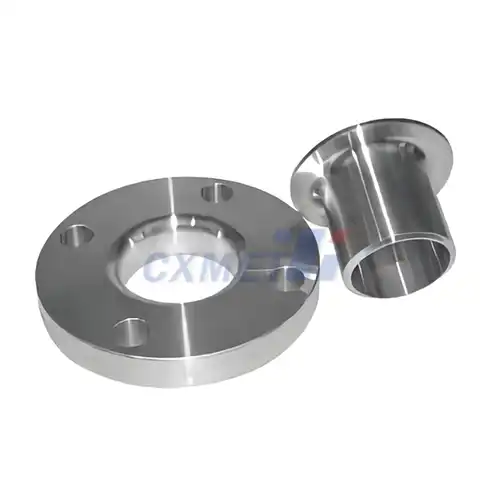

Titanium Weld Neck Flange

Brand: CXMET

Place Of Origin: China

Connection: Threaded

Material: Titanium

Application: General

Color: Silver

Size: 1/8"--4"

Certification: ISO 9001

Standard: ANSI

Body Material: titanium

Packaging Details: Wooden box

Titanium Slip-On Flange

Product name: Titanium Reducing Flanges

Brand: CXMET

Place Of Origin: China

Titanium Reducing Flange

ASTM B381 Titanium Reducing Flanges

Titanium Reducing Flange

Brand: CXMET

Place Of Origin: China

Material: Titanium Gr1, Gr2, Gr7, Gr12

Pressure: Class150/300/600/900//1500/2500

Size: All size

Color: Silver

MOQ: 1pcs

Application: Gas Oil Water System

Package: Plywooden Case

Titanium Flange Tube Sheet

Brand: CXMET

Place Of Origin:China

Material: Gr2

Size:Customized

Supply Condition: M (Anneal)

Standard: ASME B16.47 ANSI B16.5

Pressure Rating: 0.6~32Mpa

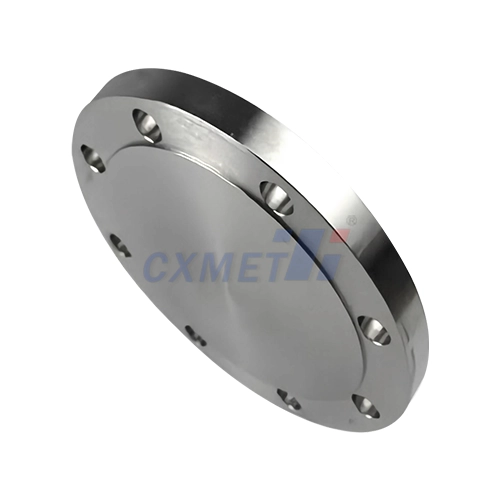

Titanium Blind Flange

Brand: CXMET

Place Of Origin: China

Material: Titanium

Size: Customized Size

MOQ: 50pcs

Package: Wooden Boxes Package

Stangard: ASTM B381