- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What are the Properties of Titanium 6Al-2Sn-4Zr-6Mo Sheet?

2025-03-22 15:10:10

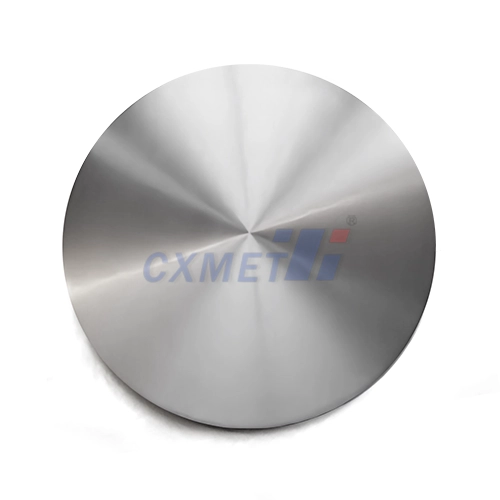

Titanium 6Al-2Sn-4Zr-6Mo Sheet, also known as Ti-6246, is a high-strength alpha-beta titanium alloy that offers excellent mechanical properties and corrosion resistance. This alloy is widely used in aerospace, marine, and industrial applications due to its unique combination of strength, toughness, and temperature resistance. In this blog post, we'll explore the properties of Ti-6246 sheet and discuss its various applications and advantages.

|

|

|

How does Ti-6246 compare to other titanium alloys?

Titanium 6Al-2Sn-4Zr-6Mo Sheet is an advanced titanium alloy that offers superior performance compared to many other titanium alloys. When comparing Ti-6246 to other commonly used titanium alloys, such as Ti-6Al-4V, several key differences become apparent:

- Strength: Ti-6246 exhibits higher strength levels than Ti-6Al-4V, particularly at elevated temperatures. The ultimate tensile strength of Ti-6246 can reach up to 1380 MPa (200 ksi) in the solution-treated and aged condition, compared to about 900-1100 MPa for Ti-6Al-4V.

- Temperature resistance: Ti-6246 maintains its strength and mechanical properties at higher temperatures than Ti-6Al-4V. It can be used in applications up to 540°C (1000°F), whereas Ti-6Al-4V is typically limited to around 400°C (750°F).

- Creep resistance: The addition of molybdenum and zirconium in Ti-6246 significantly improves its creep resistance, making it more suitable for long-term exposure to high temperatures and stresses.

- Fatigue strength: Ti-6246 demonstrates superior fatigue strength compared to Ti-6Al-4V, especially at elevated temperatures. This makes it an excellent choice for components subjected to cyclic loading in high-temperature environments.

- Fracture toughness: While Ti-6246 has slightly lower fracture toughness than Ti-6Al-4V, it still offers good crack resistance and damage tolerance, particularly in thin sheet applications.

The unique composition of Ti-6246, with its higher molybdenum content and the addition of zirconium, contributes to its improved mechanical properties and temperature resistance. These characteristics make Ti-6246 an excellent choice for applications that require high strength, good fatigue resistance, and the ability to withstand elevated temperatures.

What are the main applications of Ti-6246 sheet?

Titanium 6Al-2Sn-4Zr-6Mo Sheet finds applications in various industries due to its exceptional properties. Some of the main applications include:

- Aerospace: Ti-6246 is widely used in aircraft engines, particularly in compressor sections where high temperatures and stresses are encountered. It is also used in airframe structures that require high strength-to-weight ratios and good fatigue resistance.

- Gas turbines: The alloy's high-temperature strength and creep resistance make it ideal for components in industrial gas turbines, such as blades, discs, and casings.

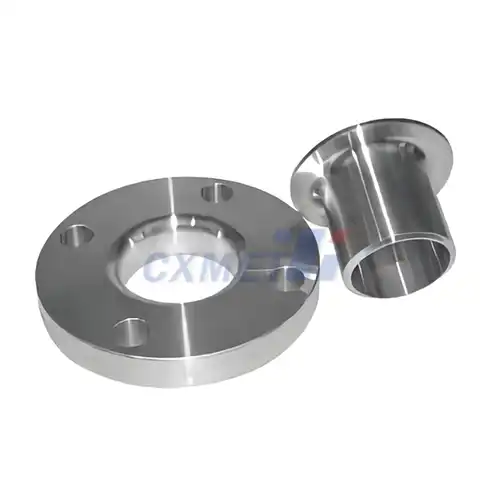

- Marine applications: Ti-6246 sheet is used in marine environments due to its excellent corrosion resistance, particularly in seawater. It is employed in the construction of submarine components, propulsion systems, and other marine structures.

- Chemical processing: The alloy's resistance to corrosion and its ability to withstand high temperatures make it suitable for use in chemical processing equipment, such as heat exchangers and pressure vessels.

- Automotive: Ti-6246 is used in high-performance automotive applications, including racing car components and exhaust systems, where high strength and temperature resistance are required.

- Medical implants: Although less common than other titanium alloys in medical applications, Ti-6246 can be used in certain implant designs where higher strength is needed.

The versatility of Ti-6246 sheet allows it to be formed into various shapes and components, including flat and curved panels, forgings, and complex structural parts. Its ability to maintain strength at elevated temperatures makes it particularly valuable in applications where other titanium alloys or materials might fail.

|

|

|

How is Ti-6246 sheet manufactured and processed?

The manufacturing and processing of Titanium 6Al-2Sn-4Zr-6Mo Sheet involve several critical steps to achieve the desired properties and performance. The process typically includes:

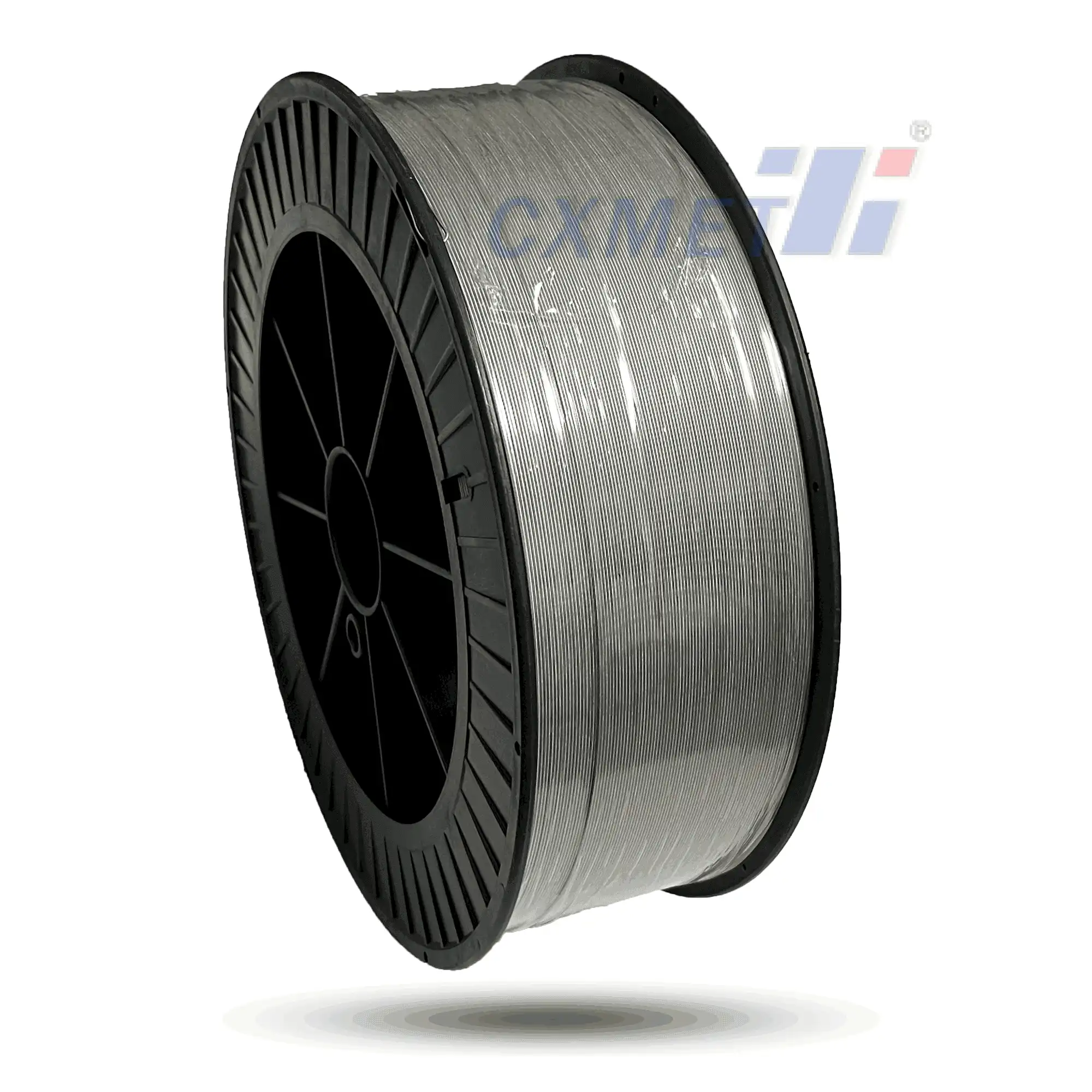

- Melting and ingot production: Ti-6246 is initially produced through vacuum arc remelting (VAR) or electron beam melting (EBM) processes. These methods ensure the removal of impurities and the achievement of the correct alloy composition.

- Hot working: The ingot is then hot-worked through processes such as forging or rolling to break down the as-cast structure and improve the material's mechanical properties.

- Sheet production: To create Ti-6246 sheet, the material undergoes multiple rolling passes at elevated temperatures. This process reduces the thickness and helps achieve the desired sheet dimensions.

- Heat treatment: Ti-6246 sheet typically undergoes a solution treatment and aging (STA) process to optimize its mechanical properties. The solution treatment is performed at temperatures around 900-950°C (1652-1742°F), followed by rapid cooling. Aging is then carried out at lower temperatures, usually between 500-600°C (932-1112°F), to precipitate strengthening phases.

- Surface treatment: Depending on the application, Ti-6246 sheet may undergo various surface treatments to enhance its properties further. These can include chemical milling, anodizing, or the application of protective coatings.

The processing of Ti-6246 sheet requires careful control of parameters such as temperature, deformation rates, and cooling rates to achieve the desired microstructure and properties. The alloy's high strength and relatively low ductility can make it challenging to form into complex shapes, often requiring specialized forming techniques and equipment.

When working with Ti-6246 sheet, it's important to consider the following factors:

- Proper heat treatment is crucial for achieving optimal mechanical properties.

- The alloy's high strength can lead to springback during forming operations, which must be accounted for in tooling design.

- Ti-6246 is susceptible to hydrogen embrittlement, so care must be taken to avoid hydrogen pickup during processing and in service.

- Machining of Ti-6246 can be challenging due to its high strength and low thermal conductivity. Specialized cutting tools and machining techniques are often required.

- Welding of Ti-6246 sheet is possible but requires careful control of parameters to avoid embrittlement and maintain desired properties in the heat-affected zone.

Understanding these manufacturing and processing considerations is essential for effectively utilizing Titanium 6Al-2Sn-4Zr-6Mo Sheet in various applications. By carefully controlling the production process and subsequent treatments, manufacturers can take full advantage of the alloy's exceptional properties to create high-performance components for demanding environments.

At SHAANXI CXMET TECHNOLOGY CO., LTD, we take pride in our extensive product range, which caters to diverse customer needs. Our company is equipped with outstanding production and processing capabilities, ensuring the high quality and precision of our products. We are committed to innovation and continuously strive to develop new products, keeping us at the forefront of our industry. With leading technological development capabilities, we are able to adapt and evolve in a rapidly changing market. Furthermore, we offer customized solutions to meet the specific requirements of our clients. If you are interested in our products or wish to learn more about the intricate details of our offerings, please do not hesitate to contact us at sales@cxmet.com. Our team is always ready to assist you.

|

|

|

|

References

- ASM International. (2015). ASM Handbook, Volume 2: Properties and Selection: Nonferrous Alloys and Special-Purpose Materials.

- Boyer, R., Welsch, G., & Collings, E. W. (1994). Materials Properties Handbook: Titanium Alloys. ASM International.

- Donachie, M. J. (2000). Titanium: A Technical Guide. ASM International.

- Leyens, C., & Peters, M. (Eds.). (2003). Titanium and Titanium Alloys: Fundamentals and Applications. John Wiley & Sons.

- Lutjering, G., & Williams, J. C. (2007). Titanium. Springer Science & Business Media.

- Peters, M., Kumpfert, J., Ward, C. H., & Leyens, C. (2003). Titanium alloys for aerospace applications. Advanced Engineering Materials, 5(6), 419-427.

- Rack, H. J., & Qazi, J. I. (2006). Titanium alloys for biomedical applications. Materials Science and Engineering: C, 26(8), 1269-1277.

- Semiatin, S. L., & Bieler, T. R. (2001). The effect of alpha platelet thickness on plastic flow during hot working of Ti–6Al–4V with a transformed microstructure. Acta Materialia, 49(17), 3565-3573.

- Veiga, C., Davim, J. P., & Loureiro, A. J. R. (2012). Properties and applications of titanium alloys: A brief review. Reviews on Advanced Materials Science, 32(2), 133-148.

- Williams, J. C., & Starke Jr, E. A. (2003). Progress in structural materials for aerospace systems. Acta Materialia, 51(19), 5775-5799.