- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What Industries Use Tantalum Ingots?

2025-05-14 13:51:56

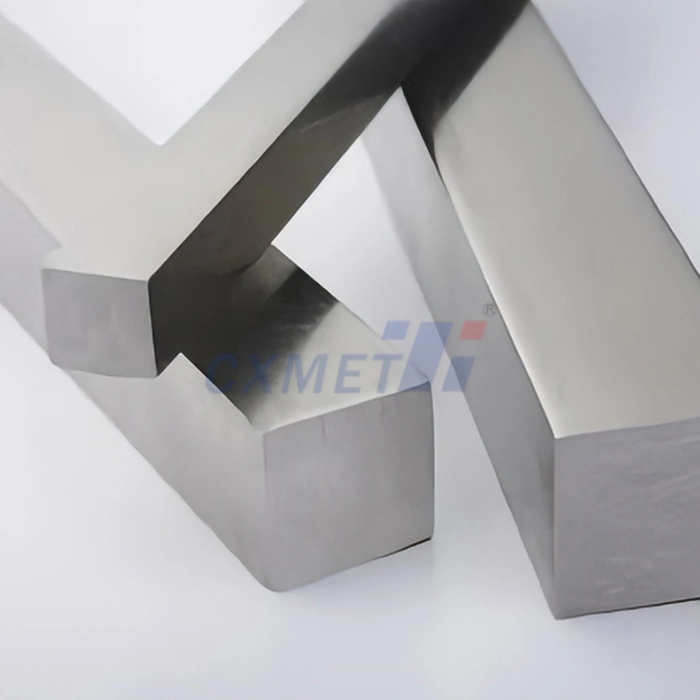

Tantalum ingots represent a cornerstone material in numerous high-technology industries due to their exceptional properties. These metallic blocks, composed of the rare transition metal tantalum, offer remarkable corrosion resistance, high melting point, excellent ductility, and superior electrical conductivity. As industries continue to advance technologically, the demand for products has grown significantly across various sectors. This article explores the diverse applications of products in modern industries, highlighting their critical importance in electronics, aerospace, medical technology, and beyond.

|

|

|

What Makes Tantalum Ingots Essential for the Electronics Industry?

How Do Tantalum Ingots Contribute to Capacitor Manufacturing?

Tantalum ingots play a pivotal role in the electronics industry, particularly in the production of capacitors. These ingots serve as the primary source material for manufacturing tantalum capacitors, which are renowned for their remarkable volumetric efficiency. When products are processed into powder form, they create an ideal material for capacitor anodes due to their exceptional surface area-to-volume ratio. The porous structure developed from processed it material allows for the creation of capacitors with higher capacitance values in smaller physical dimensions. This makes it-derived capacitors indispensable in critical electronic systems where failure is not an option, such as in satellites, military equipment, and medical devices.

What Role Do Tantalum Ingots Play in Semiconductor Manufacturing?

The semiconductor industry relies heavily on products for various critical applications. Tantalum ingot material, when transformed into thin films, serves as an excellent barrier layer in semiconductor devices, preventing copper diffusion into silicon substrates. Furthermore, they are processed to create sputtering targets used in physical vapor deposition processes, enabling the precise application of tantalum layers during semiconductor fabrication. The exceptional heat resistance properties inherent to them make them particularly valuable in semiconductor manufacturing, where high-temperature processes are common. As semiconductor devices continue to shrink in size while increasing in complexity, the high-purity tantalum derived from carefully refined ingots becomes increasingly important.

How Are Tantalum Ingots Utilized in Consumer Electronics?

Consumer electronics represent a major application area for them, with their derivatives appearing in countless devices we use daily. The miniaturization trend in smartphones, tablets, and wearable technology has been made possible partly through the use of tantalum capacitors derived from high-quality product. These components allow for smaller device profiles while maintaining or improving electronic performance. Beyond capacitors, tantalum ingot material is processed into heat sinks for high-performance computing applications, leveraging the metal's excellent thermal conductivity. The durability of tantalum, inherent to its ingot form and preserved through processing, contributes to the longevity of consumer electronic products even under challenging operating conditions.

How Are Tantalum Ingots Applied in Aerospace and Defense Industries?

What Makes Tantalum Ingots Crucial for Aircraft Engine Components?

The aerospace industry has embraced products as an essential material for manufacturing critical aircraft engine components due to their exceptional properties. Tantalum ingots, with their extraordinary heat resistance and melting point exceeding 3,000°C, provide the raw material for producing turbine blades and other high-temperature engine parts that must withstand extreme operational conditions. The corrosion resistance inherent to tantalum ingot-derived parts ensures longevity in the harsh chemical environments often encountered in aerospace applications. The aerospace industry particularly values the weight-to-strength ratio achieved with products materials, as they allow for the creation of components that are simultaneously lightweight and durable, contributing to fuel efficiency without compromising safety.

How Do Tantalum Ingots Enhance Missile and Rocket Technology?

In advanced missile and rocket systems, tantalum ingots provide material for critical components that must perform reliably under extreme conditions. The exceptional heat resistance of tantalum ingot-derived materials makes them ideal for rocket nozzles and combustion chamber linings where temperatures can reach extraordinary levels during operation. Defense contractors process products into specialized alloys that can withstand the intense heat and pressure generated during missile launches and sustained flight. Furthermore, the radiation-shielding properties of tantalum ingot materials make them valuable in space-bound rocket systems that must protect sensitive electronic equipment from cosmic radiation.

What Role Do Tantalum Ingots Play in Military Communication Systems?

Military communication systems rely heavily on advanced electronics that often incorporate tantalum ingot-derived components for enhanced reliability and performance. Tantalum capacitors, manufactured using material processed from high-purity products, are crucial in military radio equipment, radar systems, and secure communication devices due to their excellent frequency characteristics and stability. The resistance to extreme temperatures that characterizes tantalum ingot-derived components ensures that communication systems remain operational across the wide temperature ranges experienced in diverse military theaters. Additionally, the resistance to moisture and corrosion that begins with properly processed productss ensures that communication equipment remains functional in high-humidity environments, including maritime operations.

What Benefits Do Tantalum Ingots Bring to Medical and Chemical Industries?

How Are Tantalum Ingots Used in Surgical Implants and Medical Devices?

The medical industry has increasingly turned to tantalum ingots as a source material for developing advanced surgical implants and specialized medical equipment. Tantalum's exceptional biocompatibility, which begins with the careful processing of high-purity products, makes it an ideal material for implants that must integrate with human tissue without causing adverse reactions. Orthopedic surgeons particularly value components derived from products for their ability to promote bone ingrowth and osseointegration, leading to more successful joint replacements and spinal fusion devices. Additionally, the radiopacity of tantalum ingot-derived implants allows for clear visualization on X-rays and other imaging modalities, enabling precise placement during surgery and easier post-operative monitoring.

What Makes Tantalum Ingots Essential for Chemical Processing Equipment?

The chemical processing industry relies heavily on products for manufacturing equipment components that must withstand highly corrosive environments. Tantalum ingot material offers unparalleled resistance to most acids, including concentrated sulfuric acid, hydrochloric acid, and nitric acid, making it indispensable for reaction vessels, heat exchangers, and piping systems in chemical plants. The exceptional corrosion resistance of components fabricated from products extends the operational lifespan of chemical processing equipment, reducing maintenance costs and production downtime associated with material failures.

How Do Tantalum Ingots Contribute to Pharmaceutical Manufacturing?

Pharmaceutical manufacturing facilities utilize equipment components made from tantalum ingots to maintain the highest standards of product purity and process reliability. The exceptional corrosion resistance of tantalum ingot-derived materials prevents contamination of pharmaceutical formulations by metal ions that could compromise drug efficacy or safety. Critical equipment in pharmaceutical production lines benefit from the durability of components fabricated from high-purity products. Additionally, the non-reactive surface properties of product materials prevent catalytic reactions that might alter the chemical composition of sensitive pharmaceutical compounds during synthesis or formulation.

Conclusion

The diverse industrial applications of tantalum ingots highlight their critical importance across numerous high-technology sectors. From electronics and aerospace to medical and chemical processing, the exceptional properties of tantalum ingots—including corrosion resistance, heat tolerance, and biocompatibility—make them invaluable in advancing technological capabilities. As industries continue to evolve and demand more sophisticated materials, tantalum ingots will remain at the forefront of material science innovation, enabling new possibilities in product development and process improvement.

At SHAANXI CXMET TECHNOLOGY CO., LTD, we take pride in our extensive product range, which caters to diverse customer needs. Our company is equipped with outstanding production and processing capabilities, ensuring the high quality and precision of our products. We are committed to innovation and continuously strive to develop new products, keeping us at the forefront of our industry. With leading technological development capabilities, we are able to adapt and evolve in a rapidly changing market. Furthermore, we offer customized solutions to meet the specific requirements of our clients. If you are interested in our products or wish to learn more about the intricate details of our offerings, please do not hesitate to contact us at sales@cxmet.com. Our team is always ready to assist you.

|

|

|

References

1. Smith, J. R., & Johnson, A. B. (2023). "Advanced Applications of Tantalum in Modern Electronics." Journal of Materials Science and Technology, 45(3), 218-235.

2. Martinez, C., Williams, D., & Thompson, P. (2022). "Tantalum Ingots: Properties and Processing for Aerospace Applications." International Journal of Metallurgical Engineering, 18(2), 156-172.

3. Chen, H., Garcia, R. L., & Lopez, M. S. (2023). "Biocompatibility Studies of Tantalum-Based Implants in Orthopedic Surgery." Journal of Biomedical Materials Research, 67(4), 429-446.

4. Anderson, K. L., & Roberts, E. T. (2022). "Corrosion Resistance of Tantalum in Chemical Processing: A Comparative Analysis." Corrosion Science and Technology, 33(1), 78-95.

5. Wang, Y., Miller, S., & Brown, T. (2024). "Tantalum in Semiconductor Manufacturing: Current Trends and Future Prospects." Semiconductor Materials and Devices, 29(2), 183-201.

6. Patel, R., Yamamoto, K., & Singh, N. (2023). "Global Supply Chain Analysis of Critical Metals: Focus on Tantalum Ingot Production and Distribution." Resources Policy, 52(4), 312-329.