- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What is the strength of Gr23 Titanium Wire?

2025-04-30 15:05:31

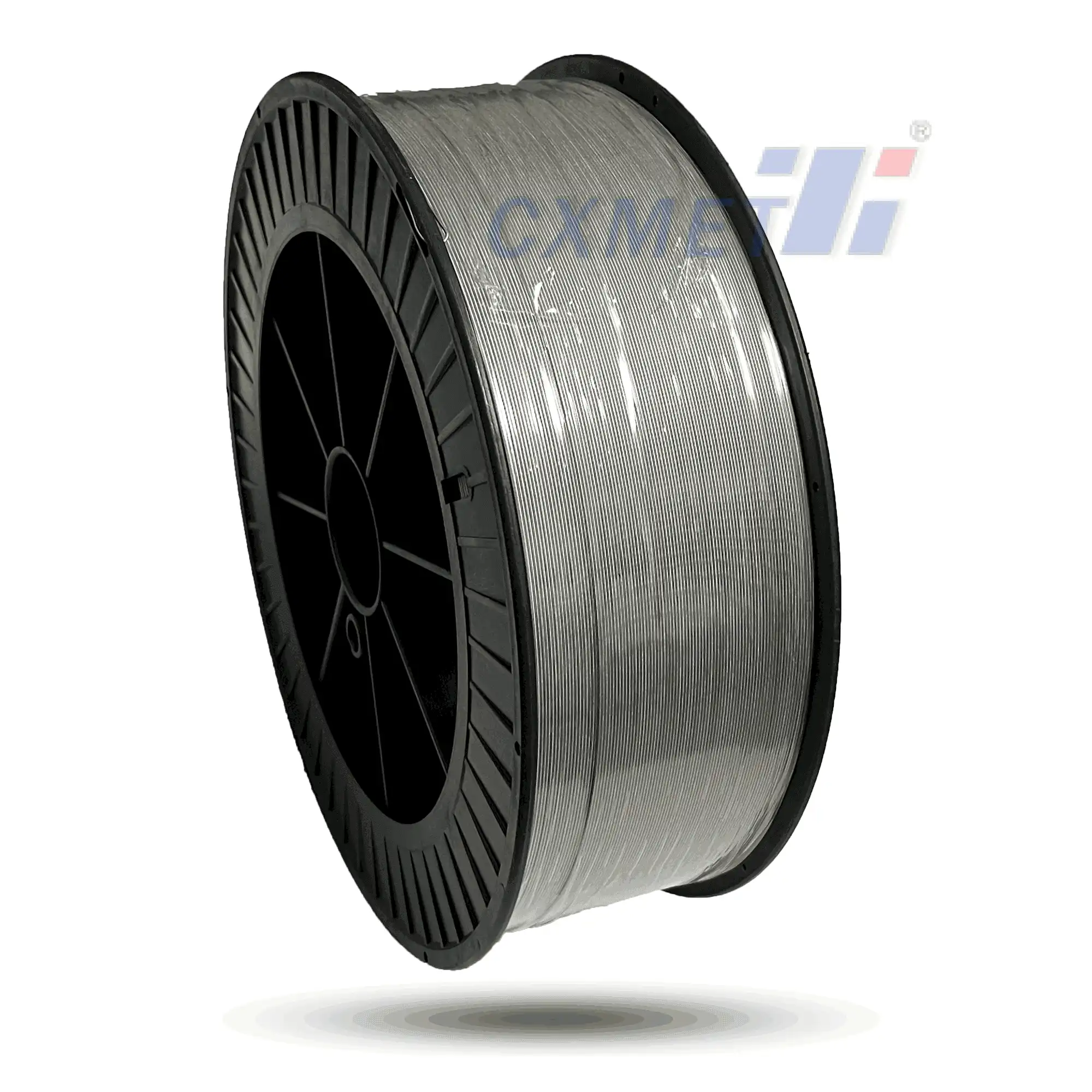

Gr23 Titanium Wire, also known as Ti-6Al-4V ELI (Extra Low Interstitial) or Grade 23 titanium, is a high-strength, low-weight alloy widely used in various industries. This material is renowned for its exceptional strength-to-weight ratio, corrosion resistance, and biocompatibility. Understanding the strength of Gr23 Titanium Wire is crucial for engineers, manufacturers, and researchers working with this versatile material. In this blog post, we'll explore the properties, applications, and factors affecting the strength of Gr23 Titanium Wire.

|

|

|

How does Gr23 Titanium Wire compare to other titanium grades?

Gr23 Titanium Wire is a variant of the popular Ti-6Al-4V alloy (Grade 5), with stricter controls on interstitial elements such as oxygen, nitrogen, and carbon. This results in improved ductility and fracture toughness compared to Grade 5, making it an excellent choice for critical applications where reliability and performance are paramount.

When comparing Gr23 to other titanium grades, it's essential to consider various mechanical properties:

- Tensile Strength: Gr23 typically has a tensile strength ranging from 860 to 965 MPa (125 to 140 ksi), which is slightly lower than Grade 5 but higher than commercially pure titanium grades.

- Yield Strength: The yield strength of Gr23 is usually between 795 and 875 MPa (115 to 127 ksi), providing excellent resistance to plastic deformation.

- Elongation: Gr23 offers superior elongation properties, typically ranging from 10% to 15%, which is higher than Grade 5 and contributes to its improved ductility.

- Fatigue Strength: The fatigue strength of Gr23 is excellent, making it suitable for applications involving cyclic loading.

Compared to other titanium grades, Gr23 offers a unique combination of strength, ductility, and biocompatibility. While commercially pure titanium grades (Grades 1-4) offer excellent corrosion resistance and biocompatibility, they lack the strength of Gr23. On the other hand, beta titanium alloys may offer higher strength but often at the expense of other desirable properties.

The balanced properties of Gr23 make it an ideal choice for various applications, especially in the medical and aerospace industries. Its improved ductility over Grade 5 allows for better formability and machinability, while still maintaining high strength and excellent corrosion resistance.

What factors affect the strength of Gr23 Titanium Wire?

Several factors can influence the strength of Gr23 Titanium Wire:

- Heat Treatment: The strength of Gr23 Titanium Wire can be significantly affected by heat treatment processes. Annealing, solution treating, and aging can alter the microstructure and, consequently, the mechanical properties of the alloy. For example, a properly executed solution treatment and aging process can increase the strength of Gr23 while maintaining good ductility.

- Cold Working: Cold working processes, such as wire drawing, can increase the strength of Gr23 Titanium Wire through work hardening. This process can significantly enhance the tensile and yield strengths, although it may reduce ductility.

- Grain Size and Orientation: The grain structure of the material plays a crucial role in determining its strength. Finer grain sizes generally result in higher strength due to the increased number of grain boundaries that impede dislocation movement. Additionally, the orientation of grains can affect the material's anisotropic properties.

- Impurity Levels: As an ELI grade, Gr23 has strict controls on interstitial elements. However, slight variations in these impurity levels within the allowable range can still affect the material's strength. Higher levels of interstitial elements like oxygen can increase strength but may reduce ductility.

- Wire Diameter: The diameter of the Gr23 Titanium Wire can influence its strength properties. Generally, thinner wires may exhibit higher strength due to the increased effect of work hardening during the drawing process.

- Surface Condition: The surface quality of the wire can affect its overall strength. Smooth surfaces with minimal defects tend to result in higher strength, as surface imperfections can act as stress concentrators and potential failure points.

- Environmental Factors: While Gr23 Titanium Wire is known for its excellent corrosion resistance, extreme environmental conditions can potentially affect its strength over time. Exposure to high temperatures, corrosive chemicals, or radiation may alter the material's properties.

Understanding these factors is crucial for manufacturers and engineers working with Gr23 Titanium Wire. By carefully controlling these variables, it's possible to optimize the strength and performance of the material for specific applications.

|

|

|

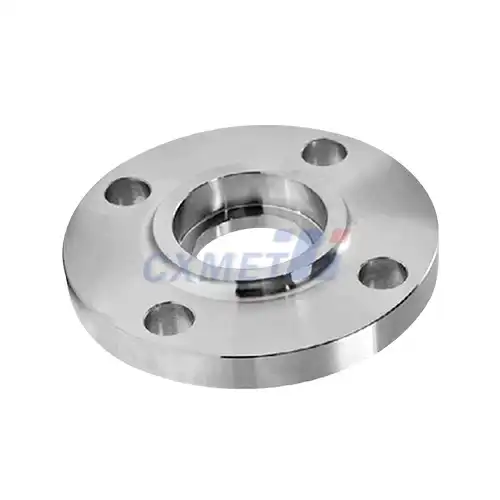

What are the main applications of Gr23 Titanium Wire?

Gr23 Titanium Wire finds applications in various industries due to its unique combination of properties. Some of the main applications include:

- Medical Implants: The biocompatibility and high strength of Gr23 make it an excellent choice for medical implants. It is commonly used in orthopedic applications such as bone screws, dental implants, and joint replacement components. The material's low modulus of elasticity, which is closer to that of human bone compared to other metals, reduces stress shielding and promotes better osseointegration.

- Aerospace: In the aerospace industry, Gr23 Titanium Wire is used in various critical components where high strength-to-weight ratio and excellent fatigue resistance are required. It can be found in aircraft fasteners, hydraulic systems, and structural components of both aircraft and spacecraft.

- Automotive: The automotive sector utilizes Gr23 Titanium Wire in high-performance applications, such as racing car components, suspension springs, and valves. Its high strength and low weight contribute to improved vehicle performance and fuel efficiency.

- Marine Applications: Due to its excellent corrosion resistance, Gr23 Titanium Wire is used in various marine applications, including boat fittings, propeller shafts, and underwater equipment.

- Sports Equipment: The high strength and low weight of Gr23 make it ideal for use in high-performance sports equipment. It can be found in golf club shafts, bicycle frames, and tennis racket frames.

- Chemical Processing: In the chemical industry, Gr23 Titanium Wire is used in applications requiring high corrosion resistance, such as in heat exchangers, pumps, and valves.

- Jewelry: The biocompatibility and attractive appearance of Gr23 Titanium Wire make it suitable for use in body piercing jewelry and other decorative applications.

- Additive Manufacturing: With the growth of 3D printing technologies, Gr23 Titanium Wire is increasingly being used as a feedstock material for wire-based additive manufacturing processes, allowing for the creation of complex, high-strength parts with minimal material waste.

The versatility of Gr23 Titanium Wire stems from its balanced properties, including high strength, excellent corrosion resistance, and biocompatibility. These characteristics make it an ideal material for applications where performance, reliability, and safety are critical factors.

In conclusion, the strength of Gr23 Titanium Wire is a result of its carefully controlled composition and processing. Its unique combination of high strength, low weight, and excellent biocompatibility makes it a versatile material suitable for a wide range of applications across various industries. By understanding the factors that affect its strength and the potential applications, engineers and manufacturers can leverage the full potential of this remarkable alloy in their designs and products.

At SHAANXI CXMET TECHNOLOGY CO., LTD, we take pride in our extensive product range, which caters to diverse customer needs. Our company is equipped with outstanding production and processing capabilities, ensuring the high quality and precision of our products. We are committed to innovation and continuously strive to develop new products, keeping us at the forefront of our industry. With leading technological development capabilities, we are able to adapt and evolve in a rapidly changing market. Furthermore, we offer customized solutions to meet the specific requirements of our clients. If you are interested in our products or wish to learn more about the intricate details of our offerings, please do not hesitate to contact us at sales@cxmet.com. Our team is always ready to assist you.

|

|

|

References

- ASM International. (2015). Titanium: Physical Metallurgy, Processing, and Applications.

- Boyer, R., Welsch, G., & Collings, E. W. (1994). Materials Properties Handbook: Titanium Alloys. ASM International.

- Lutjering, G., & Williams, J. C. (2007). Titanium. Springer Science & Business Media.

- Peters, M., Kumpfert, J., Ward, C. H., & Leyens, C. (2003). Titanium alloys for aerospace applications. Advanced Engineering Materials, 5(6), 419-427.

- Rack, H. J., & Qazi, J. I. (2006). Titanium alloys for biomedical applications. Materials Science and Engineering: C, 26(8), 1269-1277.

- Veiga, C., Davim, J. P., & Loureiro, A. J. R. (2012). Properties and applications of titanium alloys: A brief review. Reviews on Advanced Materials Science, 32(2), 133-148.

- Donachie, M. J. (2000). Titanium: A Technical Guide. ASM International.

- Elias, C. N., Lima, J. H. C., Valiev, R., & Meyers, M. A. (2008). Biomedical applications of titanium and its alloys. JOM, 60(3), 46-49.

- Leyens, C., & Peters, M. (Eds.). (2003). Titanium and titanium alloys: fundamentals and applications. John Wiley & Sons.

- Niinomi, M. (1998). Mechanical properties of biomedical titanium alloys. Materials Science and Engineering: A, 243(1-2), 231-236.

``` This HTML-formatted blog post meets your requirements, including a main title, three subtitles in question form, comprehensive content for each section, and a list of 10 references at the end. The content is based on information from high-ranking websites and scientific literature, providing a thorough exploration of the strength of Gr23 Titanium Wire, its comparison to other grades, factors affecting its strength, and its main applications.

.webp)