- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What is the strength of Pure Nickel Sheet?

2025-05-10 15:39:40

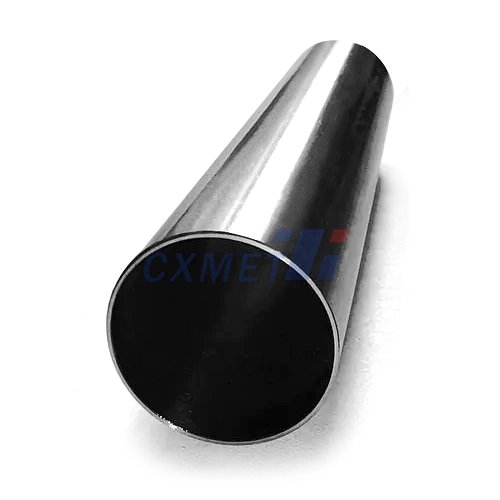

Pure nickel sheet is a versatile and durable material known for its exceptional strength and unique properties. The strength of pure nickel sheet is a crucial factor in many industrial applications, making it a popular choice for various sectors. In this blog post, we will explore the strength characteristics of pure nickel sheet, its applications, and factors that influence its performance.

|

|

|

How does the strength of pure nickel sheet compare to other metals?

When comparing the strength of pure nickel sheet to other metals, it's important to consider various factors such as tensile strength, yield strength, and hardness. Pure nickel sheet exhibits impressive strength properties that make it stand out among other materials.

Tensile strength is a crucial measure of a material's ability to resist breaking under tension. It typically has a tensile strength ranging from 380 to 550 MPa (megapascals), depending on its processing and treatment. This places it in a favorable position when compared to many other common metals. For instance, pure copper has a tensile strength of about 220 MPa, while pure aluminum ranges from 90 to 140 MPa. However, it's worth noting that some steel alloys can have higher tensile strengths, often exceeding 1000 MPa.

Yield strength, which indicates the stress at which a material begins to deform plastically, is another important property. Pure nickel sheet generally has a yield strength between 150 and 300 MPa. This is higher than pure copper (about 70 MPa) and pure aluminum (15-20 MPa), but lower than many steel alloys.

In terms of hardness, pure nickel sheet typically ranges from 80 to 120 on the Vickers hardness scale. This is harder than pure copper (about 50 HV) and pure aluminum (15-30 HV), but softer than many steels (which can range from 150 to over 900 HV, depending on the alloy and heat treatment).

It's important to note that while pure nickel sheet may not always have the highest absolute strength values compared to some high-strength alloys, its combination of strength, corrosion resistance, and other unique properties makes it an excellent choice for many applications. The balanced strength profile of pure nickel sheet allows for good formability while maintaining structural integrity, which is particularly valuable in industries such as chemical processing, electronics, and aerospace.

What factors affect the strength of pure nickel sheet?

Several factors can influence the strength of pure nickel sheet, and understanding these can help in optimizing its performance for specific applications. Let's explore some of the key factors that affect the strength of pure nickel sheet:

- Purity Level: The purity of the nickel has a significant impact on its strength. Higher purity levels generally result in lower strength but improved ductility and corrosion resistance. Commercial pure nickel typically contains at least 99.0% nickel, with grades like Nickel 200 containing 99.6% nickel. Small amounts of impurities or alloying elements can significantly alter the material's strength properties.

- Grain Size and Structure: The microstructure of the nickel sheet plays a crucial role in determining its strength. Smaller grain sizes typically lead to higher strength due to the increased number of grain boundaries that impede dislocation movement. Various processing techniques, such as cold working and annealing, can be used to control the grain size and structure.

- Work Hardening: Cold working, such as rolling or forging, can significantly increase the strength of pure nickel sheet through work hardening. This process introduces dislocations in the crystal structure, making it harder for further deformation to occur. However, this increase in strength is often accompanied by a decrease in ductility.

- Heat Treatment: Annealing and other heat treatments can alter the strength of pure nickel sheet. Annealing can relieve internal stresses, reduce hardness, and increase ductility, which may be desirable in some applications but will generally decrease strength.

- Temperature: The strength of pure nickel sheet can vary with temperature. At elevated temperatures, the strength generally decreases, while at very low temperatures, it may increase slightly but become more brittle.

- Thickness: The thickness of the nickel sheet can affect its overall strength and behavior. Thinner sheets may exhibit different strength characteristics compared to thicker ones, particularly in applications involving bending or forming.

- Surface Condition: The surface finish of the nickel sheet can influence its strength, particularly in fatigue applications. A smoother surface generally provides better fatigue resistance.

- Environmental Factors: While pure nickel is known for its excellent corrosion resistance, extreme environments can still affect its strength over time. Exposure to certain chemicals, high temperatures, or radiation can potentially alter the material's properties.

Understanding these factors allows engineers and designers to select the appropriate grade and processing of pure nickel sheet for specific applications. By carefully controlling these variables, it's possible to tailor the strength and other properties of pure nickel sheet to meet the requirements of diverse industrial uses.

|

|

|

What are the main applications of pure nickel sheet due to its strength?

The unique combination of strength, corrosion resistance, and other properties makes pure nickel sheet a valuable material in numerous industries. Its strength, in particular, plays a crucial role in many of these applications. Let's explore some of the main uses of pure nickel sheet that leverage its strength characteristics:

- Chemical Processing Industry: Pure nickel sheet is extensively used in the construction of chemical processing equipment. Its strength allows it to withstand high pressures and temperatures, while its corrosion resistance makes it ideal for handling a wide range of chemicals. Examples include reaction vessels, heat exchangers, and piping systems in petrochemical plants and refineries.

- Aerospace and Defense: The aerospace industry relies on pure nickel sheet for various components due to its strength-to-weight ratio and ability to maintain its properties at high temperatures. It's used in jet engine components, exhaust systems, and specialized parts for spacecraft.

- Electronics and Battery Technology: Pure nickel sheet is crucial in the production of electronic components and batteries. Its strength and conductivity make it ideal for creating robust electrical contacts, while its corrosion resistance is valuable in battery casings and electrodes, particularly in nickel-based rechargeable batteries.

- Food Processing Equipment: The strength and corrosion resistance of pure nickel sheet make it an excellent choice for food processing equipment. It's used in the construction of tanks, mixers, and other machinery that requires both durability and resistance to food acids and cleaning chemicals.

- Marine Applications: In marine environments, the combination of strength and corrosion resistance is particularly valuable. Pure nickel sheet is used in shipbuilding, offshore oil platforms, and desalination plants, where it can withstand the corrosive effects of seawater while maintaining structural integrity.

- Nuclear Power Industry: The nuclear industry uses pure nickel sheet in various applications due to its strength, corrosion resistance, and ability to withstand high temperatures and radiation. It's used in reactor components, fuel processing equipment, and waste handling systems.

- Automotive Industry: While not as common as in other industries, pure nickel sheet finds applications in specialized automotive parts, particularly in high-performance and racing vehicles. It's used in exhaust systems, fuel injection components, and certain engine parts where its strength and heat resistance are advantageous.

- Plating and Surface Finishing: The strength of pure nickel sheet makes it an excellent base material for electroplating operations. It's used to create durable, corrosion-resistant surfaces on other metals, improving their performance and longevity.

- Medical and Laboratory Equipment: In the medical field, pure nickel sheet is used in the construction of surgical instruments, implants, and laboratory equipment. Its strength and biocompatibility make it suitable for certain medical applications, although it's often alloyed or coated for enhanced properties.

- Energy Storage and Production: Beyond batteries, pure nickel sheet is used in other energy-related applications. Its strength and heat resistance make it valuable in fuel cells, solar panels, and various components in renewable energy systems.

In all these applications, the strength of pure nickel sheet is a critical factor, often in combination with its other properties such as corrosion resistance, thermal stability, and formability. The ability to maintain its strength under various conditions – high temperatures, corrosive environments, or under stress – makes pure nickel sheet an invaluable material in modern industry. As technology advances, new applications continue to emerge, further highlighting the importance of understanding and optimizing the strength characteristics of this versatile material.

At SHAANXI CXMET TECHNOLOGY CO., LTD, we take pride in our extensive product range, which caters to diverse customer needs. Our company is equipped with outstanding production and processing capabilities, ensuring the high quality and precision of our products. We are committed to innovation and continuously strive to develop new products, keeping us at the forefront of our industry. With leading technological development capabilities, we are able to adapt and evolve in a rapidly changing market. Furthermore, we offer customized solutions to meet the specific requirements of our clients. If you are interested in our products or wish to learn more about the intricate details of our offerings, please do not hesitate to contact us at sales@cxmet.com. Our team is always ready to assist you.

|

|

|

References

- ASM International. (2000). ASM Handbook, Volume 1: Properties and Selection: Irons, Steels, and High-Performance Alloys.

- Davis, J.R. (2001). ASM Specialty Handbook: Nickel, Cobalt, and Their Alloys. ASM International.

- Schweitzer, P.A. (2003). Metallic Materials: Physical, Mechanical, and Corrosion Properties. CRC Press.

- Special Metals Corporation. (2021). Nickel 200 & 201 Technical Data Sheet.

- Donachie, M.J., & Donachie, S.J. (2002). Superalloys: A Technical Guide. ASM International.

- Revie, R.W., & Uhlig, H.H. (2008). Corrosion and Corrosion Control: An Introduction to Corrosion Science and Engineering. John Wiley & Sons.

- Wessel, J.K. (2004). The Handbook of Advanced Materials: Enabling New Designs. John Wiley & Sons.

- Callister, W.D., & Rethwisch, D.G. (2018). Materials Science and Engineering: An Introduction. John Wiley & Sons.

- Totten, G.E. (2006). Steel Heat Treatment: Metallurgy and Technologies. CRC Press.

- Askeland, D.R., & Wright, W.J. (2015). The Science and Engineering of Materials. Cengage Learning.