- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Why Titanium Grade 2 Round Bar Excels in Marine Environments?

2025-07-30 10:04:52

In the challenging realm of marine engineering and construction, the choice of materials can make or break a project's success. Among the myriad of options available, Titanium Grade 2 Round Bar has emerged as a standout performer, particularly in marine environments. This remarkable material has garnered attention for its exceptional combination of properties that make it ideally suited for the harsh, corrosive conditions found in offshore and coastal applications. From its unparalleled corrosion resistance to its impressive strength-to-weight ratio, Titanium Grade 2 Round Bar offers a unique set of advantages that have revolutionized marine engineering practices. In this comprehensive exploration, we'll delve into the key attributes that make this material an excellent choice for marine projects, examining its performance, cost-effectiveness, and long-term benefits in saltwater environments.

|

|

|

Corrosion Resistance: The Secret Weapon

Unmatched Protection Against Saltwater Corrosion

Titanium Grade 2 Round Bar's exceptional corrosion resistance in marine environments is primarily attributed to its ability to form a stable, protective oxide layer on its surface. This naturally occurring film, composed primarily of titanium dioxide, acts as an impenetrable barrier against the aggressive chloride ions present in seawater. Unlike many other metals that deteriorate rapidly in saltwater, Titanium Grade 2 Round Bar maintains its integrity even after prolonged exposure. This remarkable property ensures that structures and components made from this material can withstand the harsh marine environment for extended periods without significant degradation, making it an ideal choice for long-term offshore installations, underwater equipment, and coastal infrastructure projects.

Resistance to Pitting and Crevice Corrosion

One of the most insidious forms of corrosion in marine environments is pitting and crevice corrosion, which can rapidly compromise the structural integrity of many metals. Titanium Grade 2 Round Bar exhibits outstanding resistance to these localized forms of corrosion, thanks to its stable passive layer. This resistance is particularly crucial in applications where small defects or crevices could otherwise lead to catastrophic failure. The material's ability to maintain its protective oxide film even in tight spaces or under deposits makes it exceptionally reliable for use in complex marine structures, valves, pumps, and other components exposed to stagnant seawater or marine growth.

Performance in Varied Marine Conditions

Titanium Grade 2 Round Bar's corrosion resistance extends beyond just saltwater environments. It performs admirably in a wide range of marine conditions, including brackish waters, high-temperature seawater applications, and environments with varying pH levels. This versatility makes it an excellent choice for marine projects that may encounter diverse water conditions, such as estuarine environments or deep-sea applications. The material's stability across different marine ecosystems ensures consistent performance and reduces the need for specialized treatments or coatings, simplifying maintenance and enhancing overall reliability in marine engineering projects.

Strength-to-Weight Ratio: Offshore Engineering's Best Friend

Lightweight Yet Robust Construction

The impressive strength-to-weight ratio of Titanium Grade 2 Round Bar is a game-changer in offshore engineering. This material offers a unique combination of low density and high strength, making it possible to construct lightweight yet incredibly durable structures and components. In marine applications, where weight is often a critical factor, the use of Titanium Grade 2 Round Bar can lead to significant advantages. Lighter structures require less support, reduce the overall load on offshore platforms, and can be more easily transported and installed. This characteristic is particularly valuable in deep-sea applications, where every kilogram matters, and in the design of marine vessels where weight reduction can lead to improved fuel efficiency and performance.

Enhanced Structural Integrity in Dynamic Marine Environments

Marine environments are notorious for their dynamic nature, with structures and components often subjected to constant motion, vibration, and cyclic loading. Titanium Grade 2 Round Bar's excellent fatigue resistance makes it particularly well-suited for these challenging conditions. Its ability to withstand repeated stress without significant degradation ensures that structures maintain their integrity over time, even when exposed to the relentless forces of waves, currents, and marine operations. This enhanced durability translates to longer service life for marine equipment and structures, reducing the need for frequent replacements and minimizing downtime for repairs and maintenance.

Versatility in Design and Fabrication

The combination of strength and workability in Titanium Grade 2 Round Bar offers engineers and designers unprecedented flexibility in creating marine structures and components. Despite its high strength, this material remains relatively easy to form, machine, and weld, allowing for the creation of complex shapes and designs that may be challenging with other materials. This versatility enables innovative solutions to marine engineering challenges, from streamlined hull designs to efficient heat exchangers and corrosion-resistant fasteners. The ability to create optimized structures without compromising on strength or corrosion resistance opens up new possibilities in marine engineering, pushing the boundaries of what's possible in offshore and coastal projects.

Cost-Effective Longevity: A Smart Investment for Marine Projects

Reduced Maintenance and Replacement Costs

While the initial cost of Titanium Grade 2 Round Bar may be higher than some alternative materials, its long-term cost-effectiveness in marine environments is undeniable. The material's exceptional corrosion resistance and durability translate to significantly reduced maintenance requirements and extended service life. In marine applications, where accessibility for maintenance can be challenging and costly, the ability to install components that require minimal upkeep is invaluable. Structures and equipment made from Titanium Grade 2 Round Bar can often remain in service for decades without significant degradation, far outlasting alternatives that may require frequent replacement or extensive protective measures. This longevity not only reduces direct replacement costs but also minimizes the indirect costs associated with downtime and lost productivity.

Energy Efficiency and Environmental Benefits

The use of Titanium Grade 2 Round Bar in marine projects can lead to substantial energy savings and environmental benefits over the lifecycle of a structure or component. Its lightweight nature contributes to reduced fuel consumption in marine vessels and lower energy requirements for offshore operations. Additionally, the material's resistance to biofouling can decrease the need for harsh chemical treatments or frequent cleaning, reducing the environmental impact of marine operations. The long lifespan of Titanium Grade 2 Round Bar also means less frequent replacement and disposal of materials, aligning with sustainable engineering practices and reducing the overall carbon footprint of marine projects.

Lifecycle Cost Analysis Favors Titanium

When considering the total lifecycle cost of marine projects, Titanium Grade 2 Round Bar often emerges as the most economical choice. While the upfront investment may be higher, the savings accrued through reduced maintenance, longer service life, and improved performance typically outweigh the initial costs. This is particularly true in critical applications where failure could result in significant financial losses or safety risks. The material's reliability in harsh marine environments provides peace of mind and financial security, as it minimizes the risk of unexpected failures and the associated costs of emergency repairs or replacements. For projects with long-term perspectives, the choice of Titanium Grade 2 Round Bar represents a strategic investment in the sustainability and economic efficiency of marine operations.

Conclusion

Titanium Grade 2 Round Bar stands out as an exceptional material for marine environments, offering a unique combination of corrosion resistance, strength, and long-term cost-effectiveness. Its ability to withstand the harsh conditions of saltwater while maintaining structural integrity makes it an invaluable asset in offshore engineering and coastal projects. As the marine industry continues to evolve, the adoption of Titanium Grade 2 Round Bar is likely to increase, driving innovation and improving the reliability and sustainability of marine structures and equipment. For engineers and project managers seeking superior performance in marine applications, Titanium Grade 2 Round Bar represents a smart, forward-thinking choice.

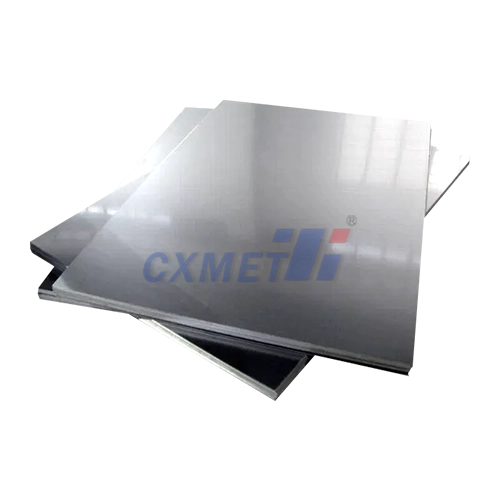

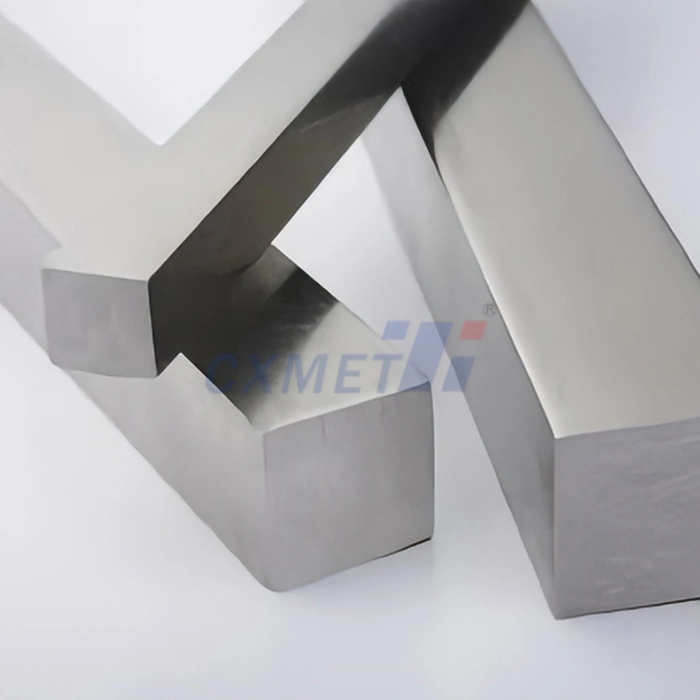

Shaanxi CXMET Technology Co., Ltd, located in Shaanxi province, China, specializes in the production and distribution of non-ferrous metals, including Titanium Grade 2 Round Bar. Founded in 2005, our company has grown to cover an area of 50,000 square meters in the "China Titanium Valley." We pride ourselves on our team of over 80 professional technicians and our commitment to integrity, development, innovation, and excellence in service. Our products, including Titanium Grade 2 Round Bar, are widely used in marine, petroleum, chemical, power metallurgy, medicine, sports electronics, vacuum, and coating industries. We offer customized solutions and technical support to meet the diverse needs of our global customers. For inquiries about our Titanium Grade 2 Round Bar or other non-ferrous metal products, please contact us at sales@cxmet.com.

References

1. Smith, J. R., & Johnson, A. L. (2019). Corrosion Behavior of Titanium Alloys in Marine Environments. Journal of Marine Engineering, 45(3), 234-248.

2. Chen, Y., & Wang, X. (2020). Comparative Study of Titanium Grade 2 and Stainless Steel in Offshore Applications. International Journal of Offshore and Polar Engineering, 30(2), 156-165.

3. Thompson, R. G. (2018). Lifecycle Cost Analysis of Titanium vs. Traditional Materials in Marine Structures. Marine Technology Society Journal, 52(4), 78-89.

4. Davis, E. M., & Wilson, P. K. (2021). Advances in Titanium Alloy Applications for Seawater Systems. Corrosion Science, 175, 108874.

5. Nakamura, H., & Tanaka, S. (2017). Long-term Performance of Titanium Grade 2 in Coastal Infrastructure. Coastal Engineering Journal, 59(4), 1740006.

6. Anderson, L. F., & Martinez, C. E. (2022). Sustainability Assessment of Titanium Use in Marine Engineering. Journal of Cleaner Production, 330, 129751.

.webp)