- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

niobium wire

Place Of Origin: China

Shape: Round disc

Material Nb1 RO4200

Chemical Composition Nb:>99.95%

Basic Product Details

Niobium wire is a high-performance material known for its exceptional mechanical and chemical properties. It is manufactured from niobium, a lustrous, ductile, and corrosion-resistant metal with a high melting point of 2,468 °C. Niobium wire is widely used in various industries due to its excellent strength-to-weight ratio, electrical conductivity, and biocompatibility. This wire is typically available in different grades and diameters, catering to the specific needs of industries such as aerospace, electronics, and medical equipment manufacturing.

Niobium wire is highly valued for its ability to resist corrosion in environments containing acids such as hydrochloric and sulfuric acid. Additionally, it exhibits superconducting properties at cryogenic temperatures, making it a critical material in advanced technologies such as particle accelerators and MRI machines. The wire can be produced with high dimensional accuracy, uniform surface finish, and in compliance with international quality standards.

Product Standards

ASTM B392: Standard Specification for Niobium and Niobium Alloy Bar, Rod, and Wire.

GB/T 14842: Specifications for Niobium and Niobium Alloy Wires.

ISO 6848: Specifications for Filler Materials for Welding.

AMS 7852: Aerospace Material Specifications for Niobium.

Customized Standards: Available upon request for specific industrial requirements.

Basic Parameters

| Parameter | Specification |

|---|---|

| Material | Niobium (Nb) |

| Purity | ≥99.95% |

| Melting Point | 2,468 °C |

| Density | 8.57 g/cm³ |

| Wire Diameter | 0.05 mm – 5.0 mm |

| Tensile Strength | 300 MPa – 400 MPa |

| Elongation | ≥20% |

| Surface Finish | Bright, Smooth |

| Standards | ASTM B392, GB/T 14842, ISO 6848 |

|

|

|

|

|

|

Product Attributes

Material Composition: Pure niobium or niobium alloys.

Dimensional Precision: Tight tolerances as per client specifications.

Surface Quality: Free from defects, ensuring optimal performance in critical applications.

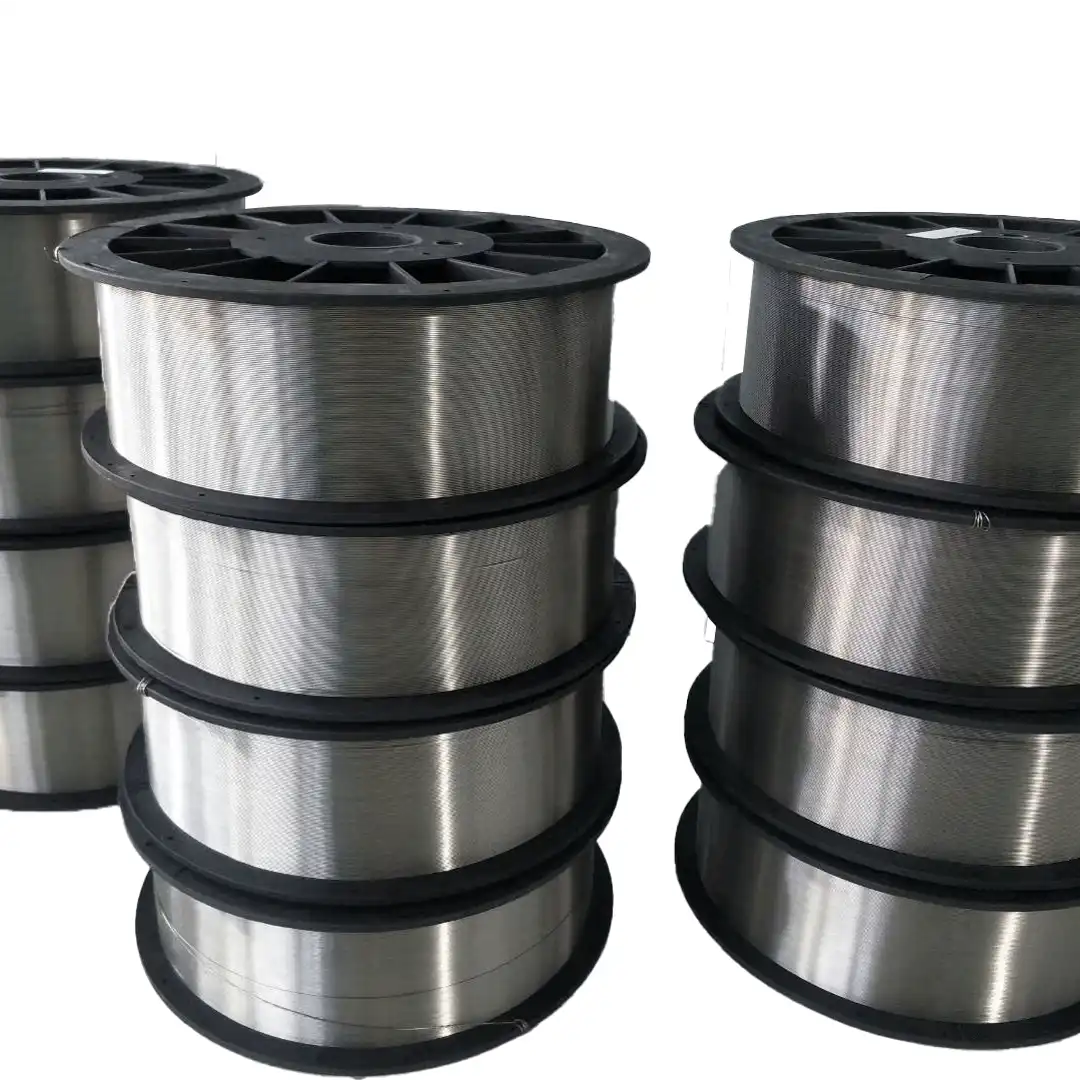

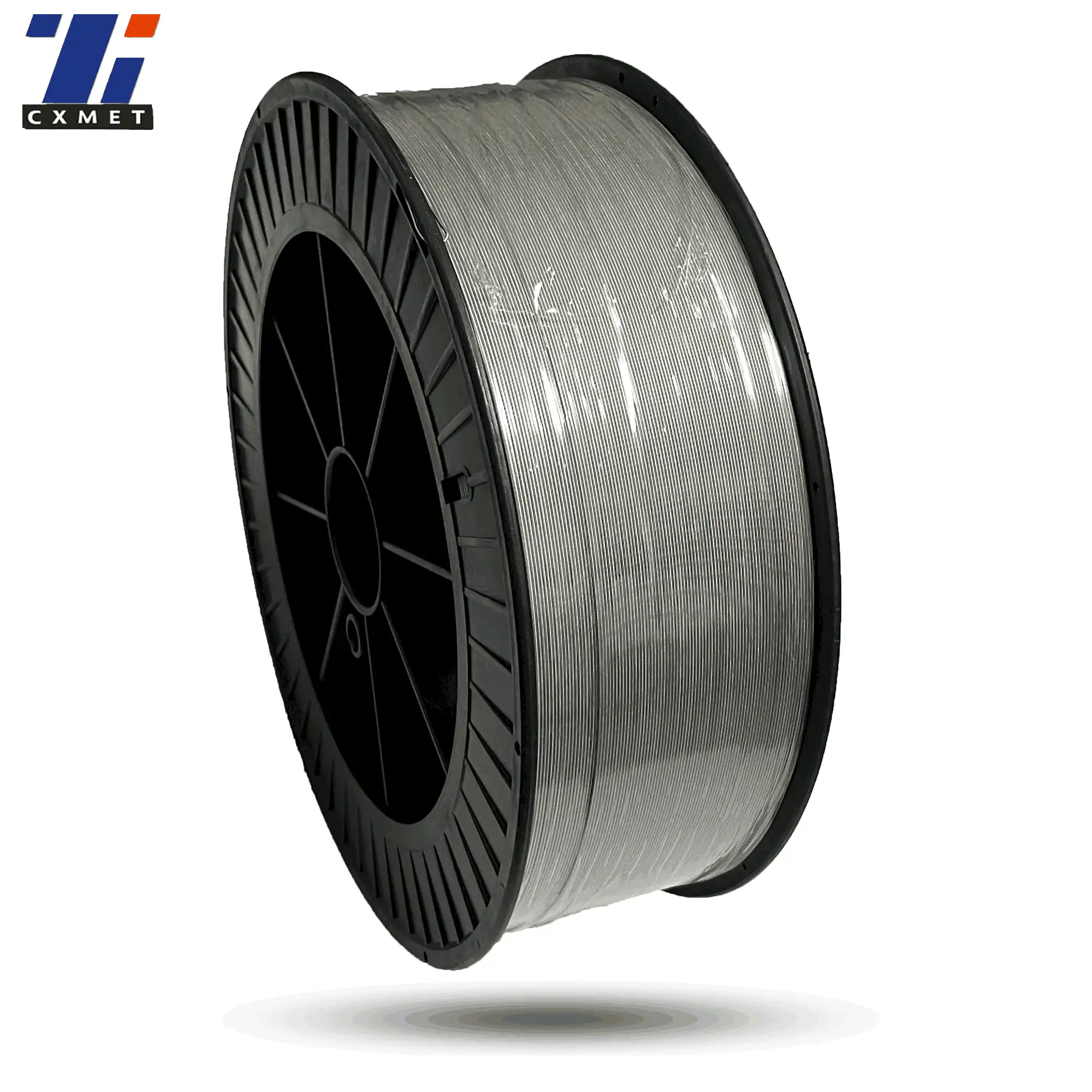

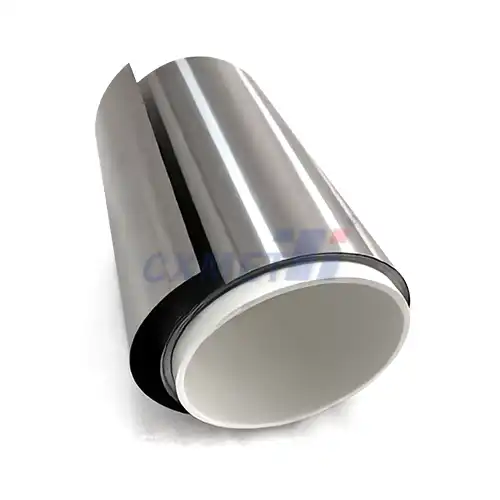

Packaging: Spools, coils, or straight lengths, customizable as per requirements.

Product Functions, Features, Advantages, and Highlights

Functions:

Conducts electricity efficiently, suitable for electronic components.

Provides structural integrity in high-temperature environments.

Exhibits biocompatibility, ideal for medical implants and devices.

Features:

High melting point and thermal stability.

Excellent resistance to corrosion and oxidation.

Superior ductility and formability.

High purity ensuring low contamination levels.

Advantages:

Reliable performance in extreme conditions.

Long lifespan due to superior corrosion resistance.

Compatibility with diverse industrial applications.

Supports customization to meet specific industry needs.

Highlights:

Ideal for high-tech industries including aerospace and medical fields.

Contributes to advancements in superconducting technologies.

Available in various grades and finishes.

Application Areas

Aerospace: Used in jet engines, rockets, and structural components due to its high strength and thermal resistance.

Electronics: Essential in capacitors, resistors, and superconducting circuits.

Medical: Biocompatibility makes it suitable for surgical tools and implantable devices.

Chemical Industry: Resists corrosive environments in chemical processing.

Nuclear Industry: Employed in reactors for its stability and heat resistance.

Jewelry: Valued for its aesthetic appeal and hypoallergenic properties.

Packaging of Niobium Wire

Niobium wire is carefully cleaned and dried before packaging to remove any surface contaminants. Depending on the length and diameter, the wire is either coiled onto plastic spools or cut into straight lengths.

Each coil or bundle is wrapped with PE film or sealed in a vacuum/inert gas bag to protect against moisture and oxidation. Anti-static foam or bubble wrap is added for shock absorption.

The protected wire is then placed in a clean plastic container or bag and packed into a reinforced carton or export-grade plywood case. The outer packaging is moisture-proof, impact-resistant, and labeled with product name, size, batch number, and handling instructions such as “Handle with Care” and “Keep Dry.”

Customized labels, barcodes, and certificates (COA, MSDS) are available upon request. All packaging complies with international shipping standards to ensure safe delivery.

|

|

|

|

Company Overview

Shaanxi CXMET Technology Co., Ltd., founded in 2005, is headquartered in China's Titanium Valley and operates a 50,000 m² facility. With 10 million RMB in registered capital and over 80 technical staff, we specialize in R&D, manufacturing, and exporting of non-ferrous and refractory metals, including titanium, nickel, tantalum, niobium, zirconium, molybdenum, and tungsten.

Our materials serve industries ranging from marine and oil & gas to medical, chemical, electronics, and aerospace. We uphold integrity, development, innovation, and excellence in service. Our mission is to create value for clients, benefit our enterprise, and support employee growth. With a forward-looking vision, we strive to innovate and lead the global titanium market.

Factory show

|

|

|

|

Production workshop

|

|

|

|

|

|

Production Equipments

Main Products

Why Choose Us Shaanxi CXMET Technology Co Ltd.

Extensive Product Range

We supply titanium nickel tantalum niobium tungsten molybdenum zirconium and related alloys

Outstanding Production and Processing Capabilities

Equipped with advanced forging CNC machining and testing equipment across 50000 square meters of production area

Continuous Innovation and Product Development

Dedicated to introducing new titanium-based materials and international processing technologies

Advanced R and D Team

More than 80 experienced technicians and engineers developing reliable and high-performance metal products

Customized Solutions

From standard inventory to tailor-made components we offer one-stop titanium solutions for your project

Company Profile

Founded in 2005 with a registered capital of 10 million yuan located in Baoji China Titanium Valley we focus on global markets and provide consistent quality service and delivery. Our products are trusted worldwide in marine petrochemical medical aerospace vacuum electronics and energy fields.

Corporate Culture

CXMET is driven by integrity development innovation and service excellence. Our mission is to create value for customers generate returns for our business and offer growth for our employees. With vision and responsibility we aim to lead the titanium industry into the future

OEM Services

SHANXI CXMET TECHNOLOGY CO., LTD. offers tailored solutions for niobium wire production. OEM services include:

Custom diameters, lengths, and surface finishes.

Private labeling and branding.

Specific packaging solutions for safe transport.

Fast turnaround times and global shipping.

FAQs

Q: What is the purity of your niobium wire? A: Our niobium wire has a minimum purity of 99.95%, ensuring high performance and reliability.

Q: Can you produce custom wire diameters? A: Yes, we can manufacture niobium wire in custom diameters ranging from 0.05 mm to 5.0 mm.

Q: Do you provide test reports with the product? A: Yes, comprehensive test reports, including material composition and mechanical properties, are provided with every order.

Q: What is the delivery time for niobium wire? A: Standard sizes are available for immediate shipment, while customized orders typically require 2-4 weeks.

Q: How do you ensure the quality of the wire? A: Our niobium wire undergoes rigorous quality checks, including dimensional inspections, surface analysis, and mechanical testing.

Contact Us

For inquiries, including requests for platinum-coated titanium electrodes, contact us at sales@cxmet.com.

hotTags:niobium wire,supplier,wholesale,China,factory,manufacturer,OEM,Customized,trader,for sale,in stock,free sample,for sale.

YOU MAY LIKE

niobium bar

Brand: CXMET

Place Of Origin: China

Shape: Round

Grade:Gr5

Processing Service: Bending, Welding, Decoiling, Cutting, Punching

Package Standard: waterproof transport packaging

Surface: Polished

MOQ: 500kg

Color: Copper Color

niobium tube

Brand: CXMET

Place Of Origin: China

Shape: Tube, Pipe

Material: Niobium

Standard: ASTM B394

Purity: 99.95% min

Color: Silver Gray

Density: 8.6g/cm3

Application: Chemical, mechanical, aerospace

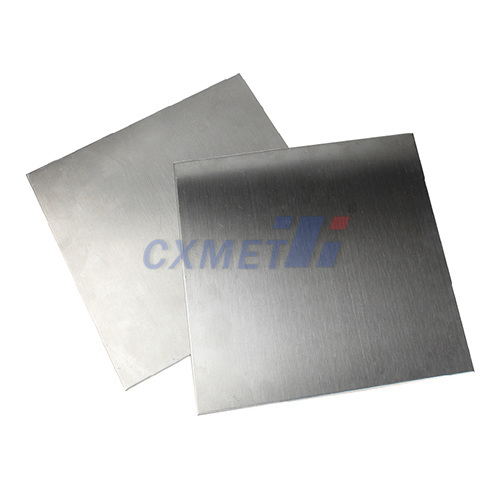

niobium sheet

Brand: CXMET

Place Of Origin: China

Shape: Sheet,Plate,Foil,Strip,Cube,Block,Square,Ingot

Material: Pure niobium and niobium alloy sheet plate

Chemical Composition: Nb, C, O, N, H

Tantalum Disc

Brand: CXMET

Place Of Origin: China

Shape: Round disc

Material: Pure tantalum

Color: Metal Color

Purity: >99.93%

Standard: ASTM B708

Surface: Cold rolled or Machined

MOQ: 1KG

Tantalum Foil

Brand: CXMET

Place Of Origin: China

Material: Pure and alloy tantalum

Purity: 99.95%min

Density: 16.65g/cm3

Standard: ASTM B708

Condition: Hot Rolled,Cold Rolled, Annealed,Grinding,Mirror surface

Package: Wooden case

Tantalum Bar

Brand: CXMET

Place Of Origin: China

Shape: Round bar,

Material: Tantalum

Purity 99.95%

Package: Wooden Cases

Density: 16.6g/cm3

Color: Silver Gray

Tantalum Tube

Brand: CXMET

Place Of Origin: China

Standard: ASTM B521

Density: 16.6g.cm3

Purity: 99.95% Min

Technique: Forging

Features :Good corrosion resistance

Application: Heat insulation parts

Surface: Polished

tantalum sheet

Brand: CXMET

Place Of Origin: China

Material: Pure Tantalum

Purity: 99.9% Min

Size: 0-3mm 10-50mm 50-100mm

Usage: Iron Casting

Color: Silver Gray

MOQ: 1kg

Standard: ASTM B708

Density: 16.6g/cm3

Surface: Grinding Polished