- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

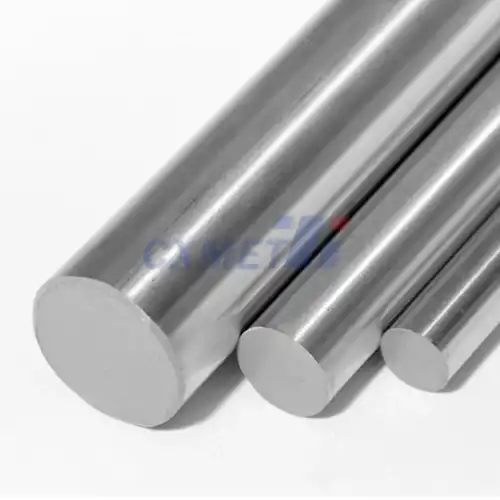

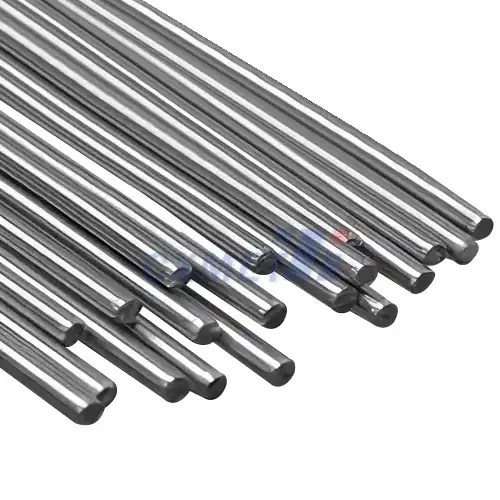

Gr9 Titanium Bar

Place Of Origin: China

Grade: Titanium GR-9

Standard: ASTM B348 / ASME SB348, AMS 4976, AMS 4956

Type: Seamless / Welded / Fabricated / LSAW Pipes

Form : Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forging Etc.

Gr9 Titanium Bar Product Introduction

Shaanxi CXMET Technology Co., Ltd. proudly supplies high-performance Gr9 Titanium Bars to clients worldwide. As a lightweight, strong, and corrosion-resistant alpha titanium alloy, Gr9 (Ti-3Al-2.5V) is widely utilized in industries demanding both strength and formability. Known for its excellent weldability and moderate strength, Gr9 Titanium Bars have become a material of choice in aerospace structures, sporting goods, and high-end industrial tubing. At CXMET, we offer precision manufacturing, strict quality control, and global supply capabilities to meet the evolving needs of the titanium market.

Gr9 Titanium Bar Specifications

-

Grade: Gr9 (Ti-3Al-2.5V)

-

Standard: ASTM B348, AMS 4943, AMS 4944

-

Diameter: 6mm to 120mm (customizable)

-

Length: 1000mm to 6000mm (or as required)

-

Surface Finish: Polished, Pickled, Turned, Ground

-

Condition: Annealed (M), Cold Worked, Hot Rolled

-

Tolerance: h9, h10, or as per request

Features of Gr9 Titanium Bar

-

Excellent strength-to-weight ratio

-

Superior corrosion resistance in various environments including marine and acidic conditions

-

Good formability and cold working properties

-

Excellent weldability with minimal cracking

-

Thermal stability and moderate fatigue resistance

-

Biocompatible and non-toxic, suitable for contact with humans

Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | ≥620 MPa |

| Yield Strength | ≥483 MPa |

| Elongation | ≥15% |

| Density | 4.48 g/cm³ |

| Hardness (HV) | 200-250 |

|

|

Applications of Gr9 Titanium Bar

Gr9 Titanium Bar is extensively used in industries such as:

-

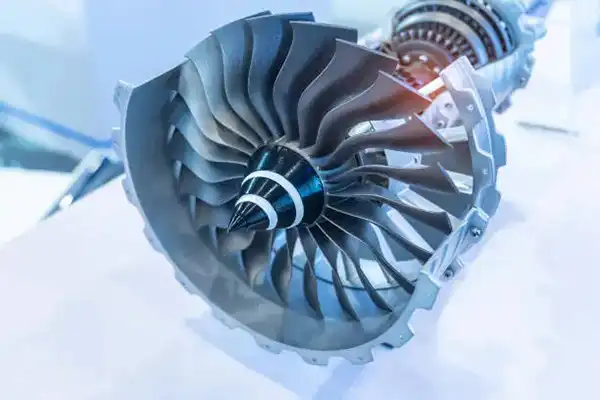

Aerospace: Hydraulic tubing, lightweight frames, and aircraft exhaust systems

-

Bicycles & Sports Equipment: Bicycle frames, golf clubs, and other lightweight sporting components

-

Medical Devices: Prosthetic supports, orthopedic pins, and surgical tools

-

Chemical Processing: Heat exchangers, condensers, and reactors

-

Marine Engineering: Ship structures, underwater pipelines, and offshore platforms

-

Energy Systems: Nuclear reactors and heat recovery systems

|

|

|

|

|

|

Working Environment

Gr9 Titanium Bar performs reliably in:

-

Marine and saltwater environments

-

Acidic or oxidizing chemical atmospheres

-

High humidity industrial areas

-

Temperature ranges from -253°C to 400°C

-

Welding-intensive fabrication scenarios

Customization Available

At Shaanxi CXMET Technology Co., Ltd., we offer:

-

Diameter and length customization

-

Special surface treatments

-

Precision machining and CNC cutting

-

Mechanical property optimization based on end-use

-

Packaging to client specifications

Key Advantages of Gr9 Titanium Bar

-

Lightweight: Up to 45% lighter than stainless steel

-

High Strength: Ideal for structural applications requiring durability

-

Long Lifespan: Exceptional resistance to corrosion extends operational life

-

Low Maintenance: Reduces downtime and replacement costs

-

Eco-Friendly: 100% recyclable and non-toxic

-

Good Weldability: Supports clean and secure joints in complex assemblies

Packaging and Logistics

-

Standard: Plywood cases or steel frame packing with plastic wrapping

-

Custom labels and markings as per order

-

Shock-proof and moisture-resistant packaging

-

Global logistics support via sea, air, and rail

-

Fast delivery schedules with full tracking capability

|

|

|

|

Company Overview

Shaanxi CXMET Technology Co., Ltd., founded in 2005, is headquartered in China's Titanium Valley and operates a 50,000 m² facility. With 10 million RMB in registered capital and over 80 technical staff, we specialize in R&D, manufacturing, and exporting of non-ferrous and refractory metals, including titanium, nickel, tantalum, niobium, zirconium, molybdenum, and tungsten.

Our materials serve industries ranging from marine and oil & gas to medical, chemical, electronics, and aerospace. We uphold integrity, development, innovation, and excellence in service. Our mission is to create value for clients, benefit our enterprise, and support employee growth. With a forward-looking vision, we strive to innovate and lead the global titanium market.

Factory show

|

|

|

|

Production workshop

|

|

|

|

|

|

Production Equipments

Main Products

Why Choose Us: Company Advantages

Shaanxi CXMET Technology Co., Ltd. offers unmatched advantages for global buyers:

-

Extensive Product Range: Titanium, nickel, tantalum, niobium, molybdenum, zirconium alloys

-

Outstanding Manufacturing Capability: Advanced equipment, CNC systems, precision forging

-

Continuous Innovation: Focus on R&D and international technology integration

-

Leading Technological Expertise: Over 80 engineers and technical specialists

-

Customization Capability: End-to-end design and engineering support

Company Background

Founded in 2005, Shaanxi CXMET Technology Co., Ltd. is located in the heart of China's Titanium Valley. With 50000 square meters of advanced facilities and 10 million RMB registered capital, our company is a cornerstone in the titanium industry. We uphold values of integrity, development, innovation, and service excellence, continuously delivering high-quality solutions to global clients in aerospace, energy, medicine, chemical processing, and marine sectors. Our mission is to create value, promote growth, and lead the future of titanium innovation.

FAQ

Q1: What standards do your Gr9 Titanium Bars follow?

A1: ASTM B348, AMS 4943, AMS 4944.

Q2: Can you supply customized sizes?

A2: Yes, we provide tailor-made sizes in both length and diameter.

Q3: How do you ensure quality?

A3: Strict QC procedures, third-party inspection, full traceability, and mill certificates.

Q4: What is the typical lead time?

A4: Standard sizes ship within 7–10 days. Customized orders may vary.

Q5: Can you export globally?

A5: Yes, we ship to North America, Europe, Southeast Asia, the Middle East, and more.

Contact Us for the Latest Quote and Custom Solution

Ready to source premium Gr9 Titanium Bar? Contact our sales team today for the latest pricing, free consultation, and custom manufacturing support.

Email: sales@cxmet.com

Tel & WhatsApp: +8615891192169

Shaanxi CXMET Technology Co., Ltd. — Forging Excellence in Titanium.

hotTags:Gr9 Titanium Bar,supplier,wholesale,China,factory,manufacturer,OEM,Customized,trader,for sale,in stock,free sample,for sale.

YOU MAY LIKE

titanium 6Al-4V Grade 5 Round Bar

Brand: CXMET

Place Of Origin: China

Type: Titanium Bars

Application: Medical

Technique: Hot Rolled

Grade: GR5

Shape: Round

Outer Diameter: 6-200mm

Grade 6 Titanium Bar

Product Name: Grade 6 titanium

Brand: CXMET

Place Of Origin: China

Material: Titanium

Surface: Polished/Pickling

Type: Round

Shape: Round bar

Standard: ASTM B348, ASTM F136, AMS 4920

6Al4V AMS 4928 Titanium Bar

Brand: CXMET

Place Of Origin: China

Diameter 2

Max Length 144

Grade: Grade 5

Full Length true

Material: Titanium

Shape: Bar-Round

Custom: Cut Warehouse 1

Alloy: 6AL-4V Grade 5

Gr7 Titanium Rod

Brand: CXMET

Place Of Origin: China

Standrd: ASTM B348 ASTM F136 AMS4928 ASTMF1295

Specifaction φ>6mm Length(Max)6000mm

Surface :Bright

Technology: Forging/Rolling

Content of Pb: 0.12---0.25%

Application: Medical, Aviation, Petrochemical, Metallurgy, Electroplating

Vacuum: Coating, Sports and other Industries.

Gr23 Ti 6AL4V Eli Medical Titanium Bar

Brand: CXMET

Place Of Origin: China

Grade: Gr23 Ti6AL4V Eli

Standard: ASTM F136

Specification: Dia4~100mm*(1000~3000)mm

Technique: Cold Rolling/Hot Rolling

Surface: Pickling/Polished

Application: industrial

High Standard Gr12 Titanium Alloy Bar

Brand: CXMET

Place Of Origin: China

Gr12 Titanium Alloy Bar/Titanium Sheet/Titanium Tube

Product specification range: Diameter 6-500mm, Length 0.5-30m

Product Specification Range: Thickness 0.5-80mm, length 1-12m, width 0.5-3m

Product Specification Range: OD 6-530mm, wall thickness 0.5-50mm

Length 1-12m

Shape: Round

tianium Alloy 6Al-2Sn-4Zr-6Mo Round Bar

Brand: CXMET

Place Of Origin: China

Type: Titanium Bars

Application: Industrial, Medical

Technique: Hot Rolled

Shape: Round

Classification: Commercially Pure

titanium Grade 4 Round Bar

Brand: CXMET

Place Of Origin: China

Type: Titanium Bars

Application: Industrial, Medical

Technique: Cold Drawn/Hot Rolled/Forged

Grade: Gr4

Shape: Round/Square/Hexagonal/Wire

Diameter: 1-450 mm