- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

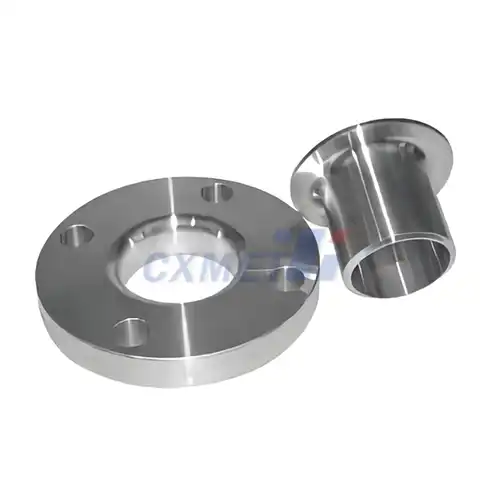

Titanium Weld Neck Flange

Place Of Origin: China

Connection: Threaded

Material: Titanium

Application: General

Color: Silver

Size: 1/8"--4"

Certification: ISO 9001

Standard: ANSI

Body Material: titanium

Packaging Details: Wooden box

Titanium Weld Neck Flange

At SHAANXI CXMET TECHNOLOGY CO., LTD., we pride ourselves on being a premier manufacturer and supplier of Titanium Weld Neck Flanges, catering to the needs of professional buyers and global dealers. Our ribs are fastidiously made to meet the most noteworthy measures of quality and execution, advertising unparalleled unwavering quality and toughness in different mechanical applications..

Basic Details:

- Material: Titanium

- Type: Weld Neck Flange

- Size Range: 1/2" to 48"

- Pressure Ratings: ANSI Class 150 to 2500, PN6 to PN100

- Standards: ASME B16.5, ASME B16.47 Series A & B, DIN, EN, JIS, BS, GOST, etc.

Material Properties:

| Property | Value |

|---|---|

| Density | 4.51 g/cm³ |

| Melting Point | 1,668°C (3,034°F) |

| Tensile Strength | 240 MPa |

| Young's Modulus | 116 GPa |

| Thermal Conductivity | 21.9 W/(m·K) |

| Coefficient of Thermal Expansion | 8.6 × 10^-6 /°C |

Dimensions:

| Nominal Pipe Size (NPS) | Outside Diameter (OD) | Raised Face Diameter (RF) | Hub Diameter (HD) | Bolt Circle Diameter (BC) | Number of Bolt Holes | Bolt Hole Diameter |

|---|---|---|---|---|---|---|

| 1/2" | 88.9 mm | 30.2 mm | 47.8 mm | 66.5 mm | 4 | 15.9 mm |

| 3/4" | 98.6 mm | 38.1 mm | 52.6 mm | 73.2 mm | 4 | 15.9 mm |

| 1" | 108 mm | 47.8 mm | 58.7 mm | 82.6 mm | 4 | 15.9 mm |

| 1 1/2" | 127 mm | 66.5 mm | 69.9 mm | 88.9 mm | 4 | 15.9 mm |

| 2" | 152 mm | 76.2 mm | 84.1 mm | 101.6 mm | 4 | 19.1 mm |

| ... | ... | ... | ... | ... | ... | ... |

|

|

|

Attributes:

- Corrosion Resistance: Titanium's exceptional corrosion resistance makes our Titanium Weld Neck Flange suitable for use in harsh environments, including chemical processing, marine, and offshore applications.

- High Strength-to-Weight Ratio: Titanium's high strength-to-weight ratio ensures structural integrity while minimizing overall weight, making handling and installation easier.

- Temperature Resistance: Our titanium weld neck flanges maintain their mechanical properties even at elevated temperatures, making them ideal for high-temperature and high-pressure applications.

- Longevity: Titanium's inherent durability ensures long-term performance and minimal maintenance requirements, resulting in cost savings over the product's lifecycle.

Functions:

- Connect Pipeline Components: Weld neck flanges provide a secure connection between pipes, valves, and other equipment in a piping system.

- Distribute Pressure: The raised face design of our Titanium WN Flange ensures uniform distribution of pressure, reducing the risk of leaks and ensuring system integrity.

- Facilitate Maintenance: The weld neck design allows for easy access to the weld area, simplifying inspection, maintenance, and repairs.

Features:

- Precision Engineering: Our weld neck flanges are precision machined to exact specifications, ensuring tight tolerances and optimal performance.

- Smooth Surface Finish: Each flange undergoes a meticulous finishing process to achieve a smooth surface, minimizing friction and preventing particle buildup.

- Leak-Free Seal: The raised face design and accurate machining of sealing surfaces ensure a tight, leak-free seal, enhancing system reliability.

Advantages and Highlights:

- Exceptional Corrosion Resistance: Titanium's resistance to corrosion ensures long-term performance in aggressive environments.

- High Strength: Titanium's high strength-to-weight ratio allows for lighter-weight designs without sacrificing structural integrity.

- Temperature Stability: Our Weld Neck Flange in Titanium maintain their mechanical properties over a wide temperature range, ensuring reliability in extreme conditions.

Application Areas:

- Chemical Processing

- Oil and Gas

- Petrochemical

- Aerospace

- Marine

- Power Generation

Packaging of Titanium Weld Neck Flange

-

Individual Wrapping

Each titanium weld neck flange is carefully wrapped with anti-corrosion plastic film or placed in a sealed moisture-proof bag to protect against humidity, dust, and surface scratches. -

Sealing Surface & Neck Protection

The raised face and neck area are protected with plastic or rubber covers, foam padding, or edge guards to prevent deformation or damage during handling and shipping. -

Grouped Packaging

Flanges of the same type and dimensions are grouped and securely fastened with nylon straps or soft separators. Each group includes labeling with:-

Titanium Grade (e.g., Gr2, Gr5, Gr7)

-

Size & Pressure Class (e.g., 2" Class 150)

-

Quantity

-

Heat Number & Production Batch

-

-

Outer Crates or Pallets

-

Small Batches: Packed in strong, non-fumigated plywood crates with foam cushioning inside.

-

Bulk Orders: Stacked neatly on export-grade wooden pallets, wrapped in stretch film, and secured with steel bands for sea/air freight.

-

-

Labeling & Documentation

External packaging includes clear labels with product description, net/gross weight, destination, and order information for easy identification and customs clearance. -

Export Compliance

All packaging materials conform to international standards (e.g., ISPM 15) for global shipping by sea, air, or land. -

OEM & Custom Packaging

Custom branding, barcode labeling, or specific packaging formats (e.g., vacuum packaging or reinforced edge guards) are available based on customer needs.

|

|

|

|

Company Overview

Shaanxi CXMET Technology Co., Ltd., founded in 2005, is headquartered in China's Titanium Valley and operates a 50,000 m² facility. With 10 million RMB in registered capital and over 80 technical staff, we specialize in R&D, manufacturing, and exporting of non-ferrous and refractory metals, including titanium, nickel, tantalum, niobium, zirconium, molybdenum, and tungsten.

Our materials serve industries ranging from marine and oil & gas to medical, chemical, electronics, and aerospace. We uphold integrity, development, innovation, and excellence in service. Our mission is to create value for clients, benefit our enterprise, and support employee growth. With a forward-looking vision, we strive to innovate and lead the global titanium market.

Factory show

|

|

|

|

Production workshop

|

|

|

|

|

|

Production Equipments

Main Products

Why Choose Us Shaanxi CXMET Technology Co Ltd.

Extensive Product Range

We supply titanium nickel tantalum niobium tungsten molybdenum zirconium and related alloys

Outstanding Production and Processing Capabilities

Equipped with advanced forging CNC machining and testing equipment across 50000 square meters of production area

Continuous Innovation and Product Development

Dedicated to introducing new titanium-based materials and international processing technologies

Advanced R and D Team

More than 80 experienced technicians and engineers developing reliable and high-performance metal products

Customized Solutions

From standard inventory to tailor-made components we offer one-stop titanium solutions for your project

Company Profile

Founded in 2005 with a registered capital of 10 million yuan located in Baoji China Titanium Valley we focus on global markets and provide consistent quality service and delivery. Our products are trusted worldwide in marine petrochemical medical aerospace vacuum electronics and energy fields.

Corporate Culture

CXMET is driven by integrity development innovation and service excellence. Our mission is to create value for customers generate returns for our business and offer growth for our employees. With vision and responsibility we aim to lead the titanium industry into the future

OEM Services:

In our commitment to meeting diverse industrial needs, we extend comprehensive OEM services, enabling customers to tailor flanges precisely to their requirements. From selecting the optimal material grade to specifying dimensions and surface finishes, our offerings are crafted to empower clients with utmost customization flexibility. Our seasoned team of professionals engages in collaborative partnerships, diligently understanding and interpreting client specifications to deliver bespoke solutions. Be it modifying existing designs or innovating new ones, we leverage our expertise and state-of-the-art facilities to ensure exacting standards are met. With a focus on agility and responsiveness, we efficiently cater to both small-scale modifications and large-scale production demands, ensuring timely delivery without compromising quality. At SHAANXI CXMET TECHNOLOGY CO., LTD., our OEM services epitomize dedication to customer-centricity, offering reliability, precision, and performance tailored to each client's unique needs and specifications. Trust us as your partner in achieving unparalleled customization and excellence in flange solutions.

FAQs:

- What is the maximum temperature our titanium weld neck flanges can withstand?

- Our flanges are designed to maintain their mechanical properties up to temperatures of 600°C (1112°F).

- Can you provide material certifications and test reports?

- Yes, we provide complete material certifications and test reports with every order to ensure product quality and traceability.

- Do you support expedited delivery?

- Yes, we offer fast delivery options to meet urgent project deadlines.

For more information or to inquire about our platinum-coated titanium electrode, please contact us at sales@cxmet.com.

hotTags:Titanium Weld Neck Flange,supplier,wholesale,China,factory,manufacturer,OEM,Customized,trader,for sale,in stock,free sample,for sale.

YOU MAY LIKE

Titanium Lap Joint Flange

Brand: CXMET

Place Of Origin: China

Shape:Flange

Material:Titanium

Standards: ASME A182, ASME B16.5

Flange Thickness:11/16 in

Class/Pressure: Class 150

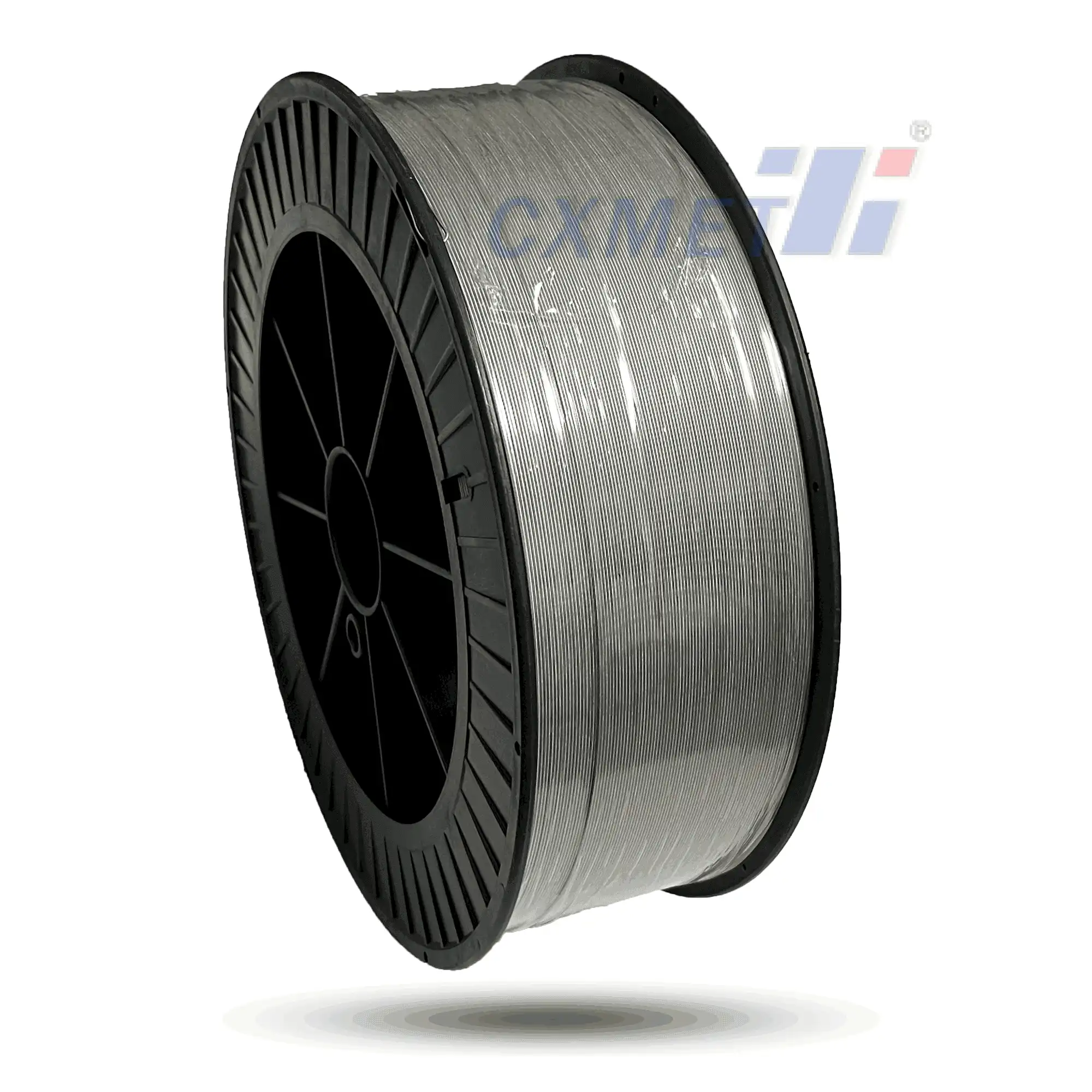

Gr23 titanium wire

Brand: CXMET

Place Of Origin: China

Material: Gr5 Gr23

Certificate: ISO9001:2008,SGS

Surface Treatment:Polishing, Pickling

Color: Metal colour

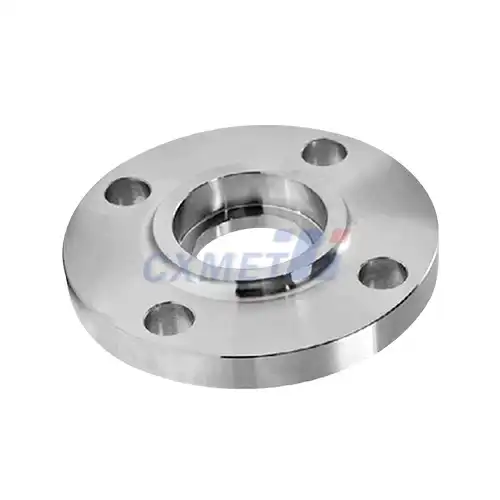

Titanium Socket Weld Flange

Brand: CXMET

Place Of Origin: China

Type: Titanium Tube Titanium Prices

Surface: Pickling

Shape: Round.Square.Rectangle

Processing: Processed

Test: Eddy Current Test

Advantage: High Performance

MOQ: 1pcs

Certificates: ISO9001:2008

Color: Sliver

Titanium Slip-On Flange

Product name: Titanium Reducing Flanges

Brand: CXMET

Place Of Origin: China

Titanium Reducing Flange

ASTM B381 Titanium Reducing Flanges

Titanium Reducing Flange

Brand: CXMET

Place Of Origin: China

Material: Titanium Gr1, Gr2, Gr7, Gr12

Pressure: Class150/300/600/900//1500/2500

Size: All size

Color: Silver

MOQ: 1pcs

Application: Gas Oil Water System

Package: Plywooden Case

Titanium Flange Tube Sheet

Brand: CXMET

Place Of Origin:China

Material: Gr2

Size:Customized

Supply Condition: M (Anneal)

Standard: ASME B16.47 ANSI B16.5

Pressure Rating: 0.6~32Mpa

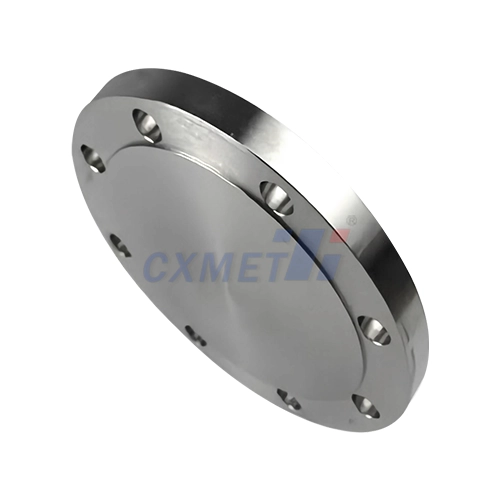

Titanium Blind Flange

Brand: CXMET

Place Of Origin: China

Material: Titanium

Size: Customized Size

MOQ: 50pcs

Package: Wooden Boxes Package

Stangard: ASTM B381