- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

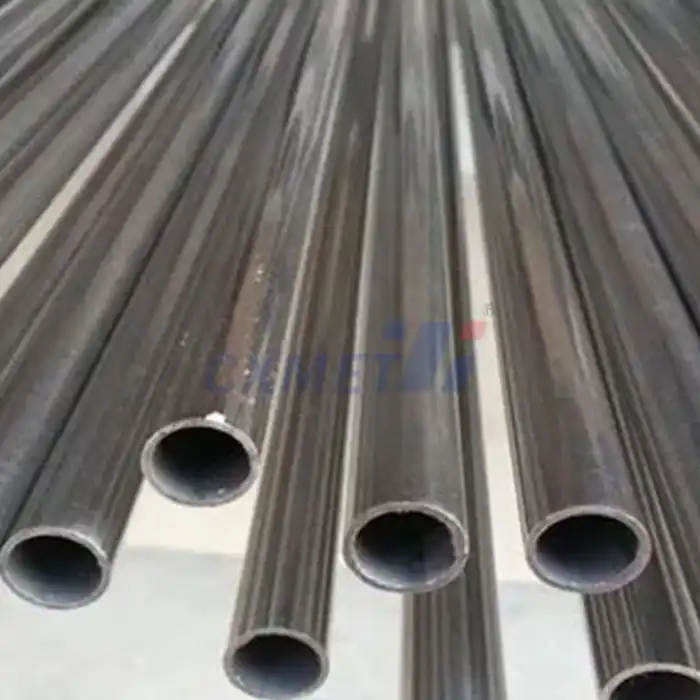

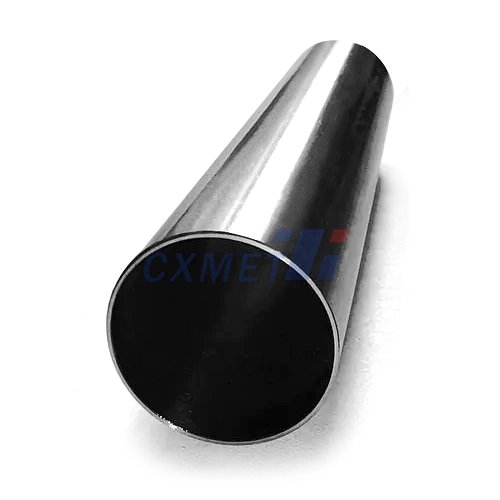

titanium alloy grade 9 pipe

Place Of Origin: China

Outer Diameter: 10mm - 500mm

Wall Thickness 1mm: - 20mm

Length: Customizable

Standard: ASTM B338,ASTM B86,1ASTM B862

Tensile Strength: 620 - 820 MPa

Yield Strength: 438 - 564 MPa

Elongation: 15 - 20%

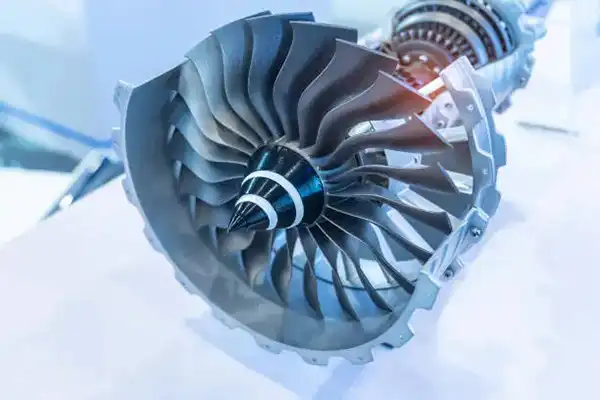

Application: Aerospace,Chemical Processing,Medical

Product Introduction:

Titanium Grade 9 pipe (Ti-3Al-2.5V) is a near-alpha titanium alloy known for its excellent combination of moderate strength, high corrosion resistance, and superior cold-forming capability. It is commonly used in aerospace, marine, chemical processing, and high-performance sporting equipment due to its high strength-to-weight ratio and weldability.

Specifications:

-

Material Grade: Ti-3Al-2.5V / Grade 9

-

Standards: ASTM B861, ASTM B862, AMS 4943, AMS 4944

-

Outer Diameter: 6mm – 114mm

-

Wall Thickness: 0.5mm – 10mm

-

Length: Customized or standard (up to 6000mm)

-

Condition: Annealed (M) or Cold Worked & Stress Relieved (R53600)

|

|

Features:

-

Excellent strength-to-weight ratio

-

Superior corrosion resistance in oxidizing and marine environments

-

High fatigue strength

-

Excellent formability and weldability

-

Suitable for high-pressure and high-temperature applications

Applications:

-

Aircraft hydraulic and pneumatic systems

-

Bicycles and sports equipment

-

Heat exchangers and condensers

-

Chemical and marine piping systems

-

Medical structures and equipment

|

|

|

|

|

|

Packaging & Logistics

Our Titanium Grade 9 Pipes are securely packed to ensure protection during international transportation:

-

Packaging Method: Each pipe is wrapped in plastic film to prevent moisture and scratches. Multiple pipes are bundled with anti-rust paper and foam padding. Finally, they are packed in strong export-grade wooden cases.

-

Marking: Product grade, size, heat number, and lot number are clearly marked on each pipe and on the packaging for traceability.

-

Shipping Options:

-

Express (DHL, FedEx, UPS) for urgent small orders

-

Air freight for fast delivery

-

Sea freight (FCL/LCL) for bulk orders

-

-

Delivery Time: Typically 7–15 working days depending on quantity and specifications.

-

Ports: Tianjin, Shanghai, or other designated Chinese ports.

|

|

|

|

Company Overview

Shaanxi CXMET Technology Co., Ltd., founded in 2005, is headquartered in China's Titanium Valley and operates a 50,000 m² facility. With 10 million RMB in registered capital and over 80 technical staff, we specialize in R&D, manufacturing, and exporting of non-ferrous and refractory metals, including titanium, nickel, tantalum, niobium, zirconium, molybdenum, and tungsten.

Our materials serve industries ranging from marine and oil & gas to medical, chemical, electronics, and aerospace. We uphold integrity, development, innovation, and excellence in service. Our mission is to create value for clients, benefit our enterprise, and support employee growth. With a forward-looking vision, we strive to innovate and lead the global titanium market.

Factory show

|

|

|

|

Production workshop

|

|

|

|

|

|

Production Equipments

Main Products

Why Choose Us Shaanxi CXMET Technology Co Ltd.

Extensive Product Range

We supply titanium nickel tantalum niobium tungsten molybdenum zirconium and related alloys

Outstanding Production and Processing Capabilities

Equipped with advanced forging CNC machining and testing equipment across 50000 square meters of production area

Continuous Innovation and Product Development

Dedicated to introducing new titanium-based materials and international processing technologies

Advanced R and D Team

More than 80 experienced technicians and engineers developing reliable and high-performance metal products

Customized Solutions

From standard inventory to tailor-made components we offer one-stop titanium solutions for your project

Company Profile

Founded in 2005 with a registered capital of 10 million yuan located in Baoji China Titanium Valley we focus on global markets and provide consistent quality service and delivery. Our products are trusted worldwide in marine petrochemical medical aerospace vacuum electronics and energy fields.

Corporate Culture

CXMET is driven by integrity development innovation and service excellence. Our mission is to create value for customers generate returns for our business and offer growth for our employees. With vision and responsibility we aim to lead the titanium industry into the future

OEM & Custom Services

We provide comprehensive OEM and customization services to meet specific client requirements:

-

Custom Dimensions: Outer diameter, wall thickness, and length can be produced based on your drawings or specifications.

-

Custom Grades & Standards: Available in ASTM, AMS, DIN, ISO, JIS, and GB standards.

-

Surface Finishing Options: Pickled, polished, sandblasted, or custom-treated surfaces.

-

Private Labeling: Laser marking, labeling, and customized logos on pipes or packaging.

-

Documentation: Full set of mill test certificates (EN 10204 3.1), inspection reports, and shipping documents provided.

-

Engineering Support: Technical consulting and CAD drawing services for special projects.

Contact Us:

Email: SALES@CXMET.COM

Tel: +86-917-3381086

hotTags:titanium alloy grade 9 pipe,supplier,wholesale,China,factory,manufacturer,OEM,Customized,trader,for sale,in stock,free sample,for sale.

YOU MAY LIKE

gr2 titanium seamless tube

Brand: CXMET

Place Of Origin: China

Material: Ti alloy

Surface: Treatment Polishing

Usage: Car exhaust/heat exchanger/medical

Shape: Round tube

Thickness: 0.4-12.7mm

Certificate: ISO9001,testing report

Standard: ASTM B338/B861

ASTM B861 titanium tube

Brand: CXMET

Place Of Origin: China

Regular Grades: Gr.1, Gr.2, Gr.7, Gr.9, Gr.13

Seamless Pipe: OD 10-914.4mm WT: 1-32mm

Length: 3,000 – 12,000mm or other economical lengths

Finish: Mill finish, Polished, Annealed

Form: Straight

Type: Seamless

Grade5 titanium alloy tube

Brand: CXMET

Place Of Origin: China

Surface: Polished,bright finished,pickling, Sand-blast etc

Processing: Hot rolled,cold rolled,forge,cold drawn

Type: Tube,foil,roll,plate,rod etc

Test: Eddy Current test,Tensile Strength Test,Hydraulic Press test, etc

Certificates ISO9001:2008

Shape: Round Shape

Application: Industrial, Medical, Petrochemical Industry, etc

Ti3AL2.5VTitanium Alloy tube

Brand: CXMET

Place Of Origin: China

Mechanical Properties Metric

Hardness, Vickers 300

Tensile Strength, Ultimate 620 MPa

Tensile Strength, Yield 530 MPa

Elongation at Break 0.2

Charpy Impact 92.0 J

ASTM B862 titanium tube

Brand: CXMET

Place Of Origin: China

ASTM: B861/2 GR.7 physical

Properties:ASTM B861/2 GR7

Density: 4.51g/cm3

Grain size 3.0-7.0

Tensile strength: 270Mpa≥σb≤410Mpa

Yield strength :σb≥165Mpa

Elongation: δ≥27%

gr16 titanium tube

Brand: CXMET

Place Of Origin: China

Material: Titanium

Outer diameter: 60-210mm

Type: Gr16

Standard: AMS 4941,AMS 4942,AMS 4902,ASTM B337,ASTM B338,ASTM B861

Finish: Pickled,passivation,inside&outside, mechanical,polishing ,electro-polishing

Application:Industrial,medical,avation,salt-making ,petrochemical,metallurgy,electronics

gr12 titanium tube

Brand: CXMET

Place Of Origin: China

Specifications: ASTM B338 B337 B861 B862, ASME, DIN, DMS, JIS

Grade: Gr1, Gr2, Gr12, Gr12, Gr5, Gr7, Gr9, Gr11, Gr12 etc

O.D.: 5-600mm or as Customized

W.T.: 2-120mm or as customized

Length: 5-12m or as Customized

Surface Finish: Black, Bright, Polished, Rough Turned, NO.4 Finish, Matt Finish

Packaging Details: Waterproof bag + wooden case

End: Plain End, Bevelled End, Treaded

gr1 titanium seamless tube

Brand: CXMET

Place Of Origin: China

Material: Titanium

Length: 500~900mm

Application: Industrial

Technique: Seamless

Grade: Titanium Alloy

Processing Service: Bending, Welding, Decoiling, Cutting, Punching, welded

Material :Titanium tube pipes

Surface: Pickled,polished

Density: 4.51 G/cm3

Application: industry,medical

Type: Titanium alloy tube,welding tube pipes,seamless tube