- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

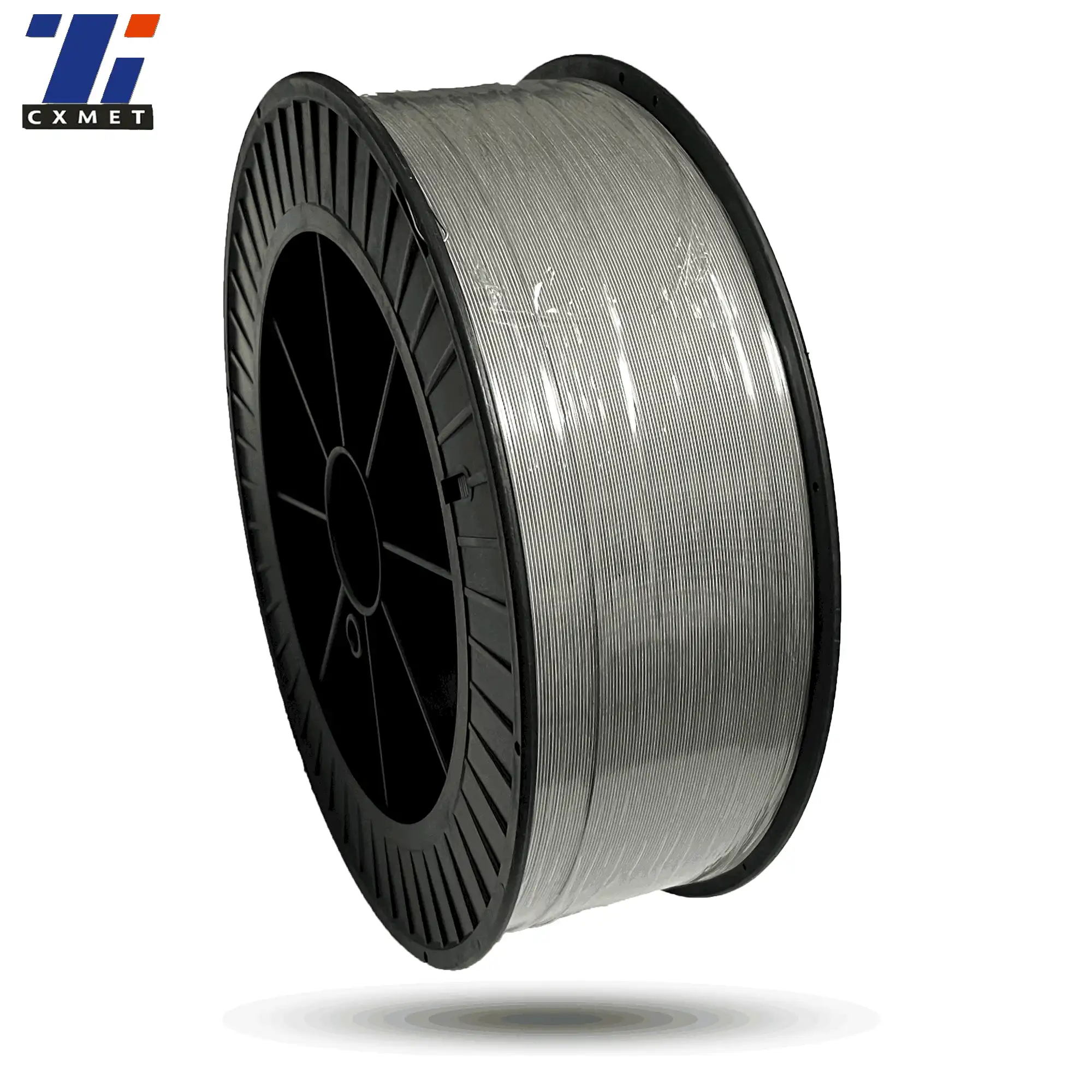

hafnium wire

Hafnium wire, a transition metal wire, is renowned for its exceptional resistance to corrosion, high melting point, and superb mechanical properties. These attributes make it a preferred material for diverse industrial uses such as aerospace, nuclear reactors, and electronics.

Our hafnium wire is produced using state-of-the-art technology, ensuring high purity and consistent quality.

Product Specifications

| Parameter | Value |

|---|---|

| Purity | 99.95% |

| Diameter Range | 0.1mm - 3mm |

| Density | 13.31 g/cm³ |

| Melting Point | 2,233 °C |

| Tensile Strength | 395 MPa |

| Electrical Resistivity | 33.3 nΩ·m |

|

Physical and Chemical Properties

Hafnium wire exhibits exceptional physical and chemical properties that make it suitable for demanding applications. Its high melting point of 2,233 °C and density of 13.31 g/cm³ ensure stability under extreme conditions. The wire's resistance to corrosion and excellent mechanical properties further enhance its reliability and longevity in various industrial uses.

Product Functions

Corrosion Resistance: Hafnium wire is highly resistant to corrosion, making it ideal for use in environments where chemical stability is crucial.

High Melting Point: With a melting point of 2,233 °C, hafnium wire can withstand extreme temperatures, making it suitable for high-temperature applications.

Mechanical Strength: The tensile strength of 395 MPa ensures that hafnium wire can endure mechanical stress, providing durability and reliability in structural applications.

Electrical Properties: Hafnium wire has low electrical resistivity, making it an excellent conductor for electrical applications.

Product Applications

Aerospace Industry: Hafnium wire's high melting point and mechanical strength make it suitable for use in aerospace components, such as jet engines and rocket nozzles.

Nuclear Reactors: Its excellent corrosion resistance and stability under high temperatures make hafnium wire ideal for use in control rods and other nuclear reactor components.

Electronics: The wire's electrical properties make it valuable in the manufacture of semiconductors and other electronic devices.

Medical Devices: Hafnium wire's biocompatibility and corrosion resistance make it suitable for use in medical implants and surgical instruments.

Manufacturing Process and Production Flow

Our hafnium wire production process involves several critical steps to ensure the highest quality:

Raw Material Selection: We start with the highest purity hafnium sponge.

Melting and Casting: The hafnium sponge is melted and cast into ingots.

Hot and Cold Working: The ingots undergo hot and cold working processes to achieve the desired wire diameter.

Drawing: The wire is drawn through dies to achieve precise dimensions and surface finish.

Annealing: The wire is annealed to relieve internal stresses and enhance mechanical properties.

Quality Control: Rigorous testing and inspection ensure that the final product meets all specifications and standards.

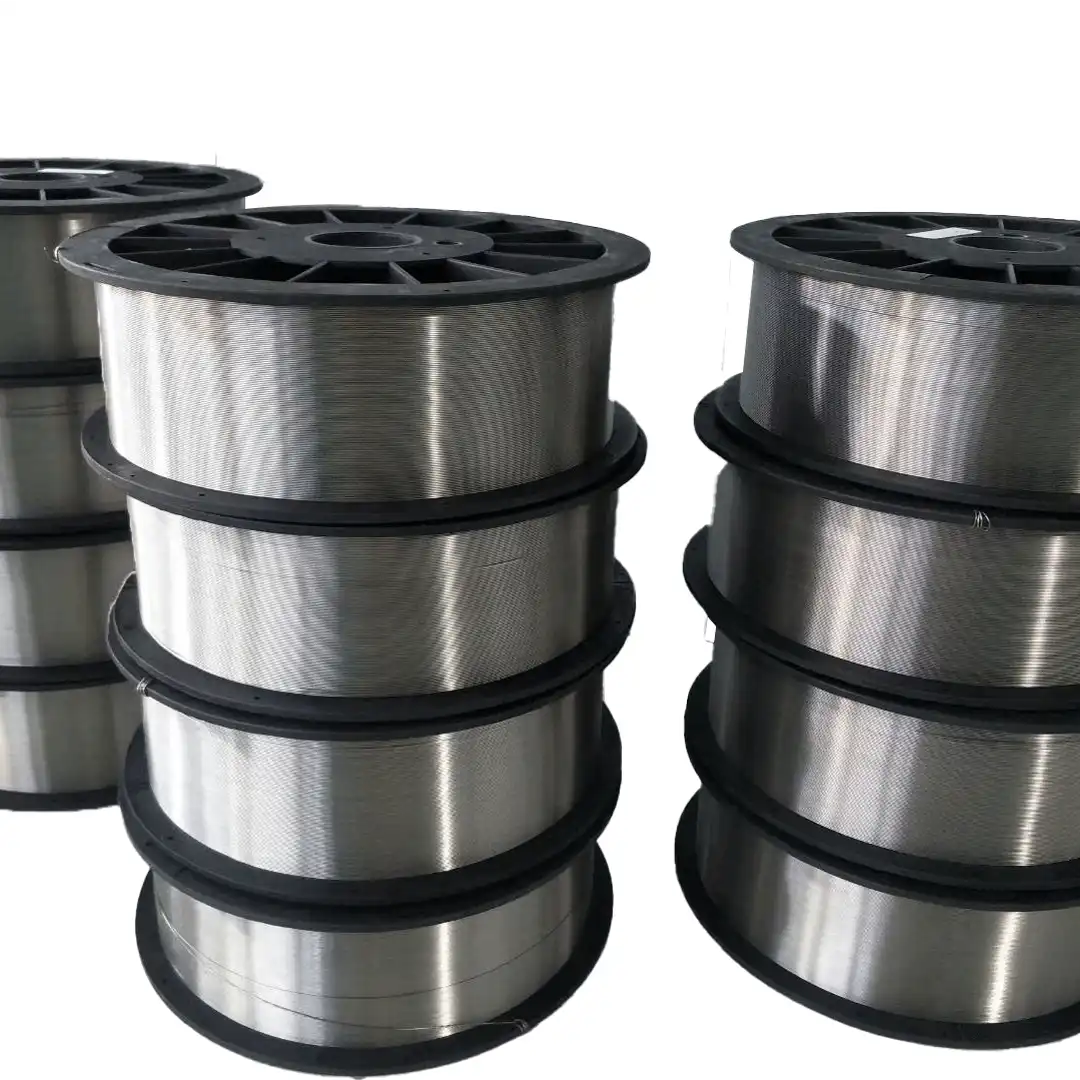

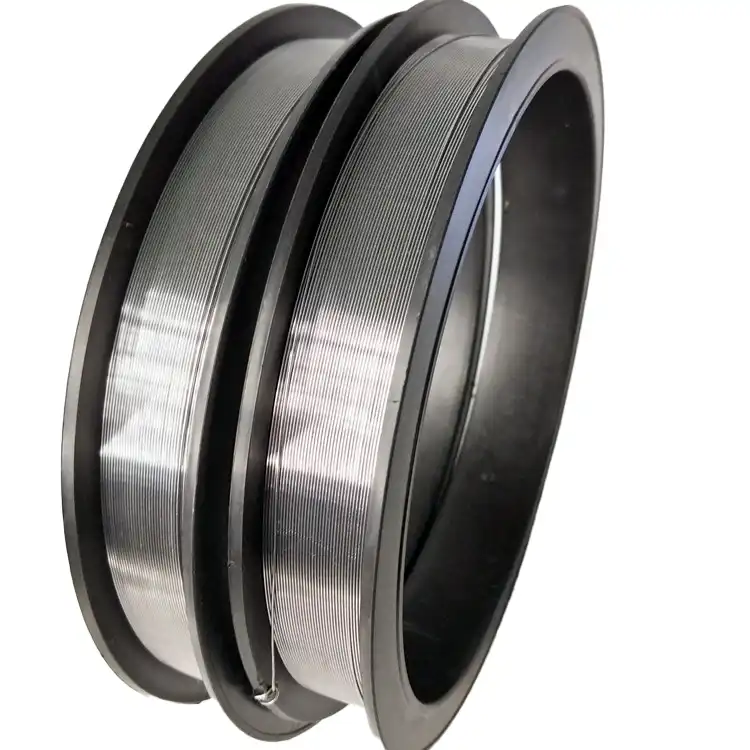

Packaging of Hafnium Wire

To ensure the safety, cleanliness, and structural integrity of hafnium wire during transportation and storage, we apply the following standardized and professional packaging methods:

-

Surface Cleaning and Initial Protection

Before packaging, the hafnium wire is ultrasonically cleaned and dried to remove any oil, dust, or surface contaminants. It is then carefully coiled or cut to length, depending on customer requirements. -

Vacuum or Argon Sealed Bag

The cleaned wire is wrapped in polyethylene (PE) film or placed inside a corrosion-resistant bag, then sealed under vacuum or filled with inert gas (argon) to prevent oxidation and moisture intrusion. -

Anti-Collision Cushioning

The sealed wire is surrounded with high-density foam, bubble wrap, or anti-static cushioning materials to protect it from mechanical shock, bending, or deformation during transit. -

Inner Packaging – Plastic Spool or Clean Pouch

-

For long continuous wire: It is wound onto a plastic or metal spool and fixed securely.

-

For cut lengths: Wires are grouped and placed in clean plastic pouches or tubes.

-

-

Outer Packaging – Export-Grade Carton or Plywood Box

The inner package is placed in a strong carton or fumigation-free plywood box. Outer packaging is:-

Moisture-proof and impact-resistant

-

Clearly labeled with product name, material grade, dimensions, batch number, and handling instructions (e.g., “Fragile”, “Keep Dry”)

-

Suitable for international air or sea freight

-

-

Optional Customization

-

Custom logos, labels, and barcodes are available on request.

-

COA (Certificate of Analysis), MSDS, and packing lists can be included per order requirements.

-

|

|

|

|

Company Overview

Shaanxi CXMET Technology Co., Ltd., founded in 2005, is headquartered in China's Titanium Valley and operates a 50,000 m² facility. With 10 million RMB in registered capital and over 80 technical staff, we specialize in R&D, manufacturing, and exporting of non-ferrous and refractory metals, including titanium, nickel, tantalum, niobium, zirconium, molybdenum, and tungsten.

Our materials serve industries ranging from marine and oil & gas to medical, chemical, electronics, and aerospace. We uphold integrity, development, innovation, and excellence in service. Our mission is to create value for clients, benefit our enterprise, and support employee growth. With a forward-looking vision, we strive to innovate and lead the global titanium market.

Factory show

|

|

|

|

Production workshop

|

|

|

|

|

|

Production Equipments

Main Products

Why Choose Us Shaanxi CXMET Technology Co Ltd.

Extensive Product Range

We supply titanium nickel tantalum niobium tungsten molybdenum zirconium and related alloys

Outstanding Production and Processing Capabilities

Equipped with advanced forging CNC machining and testing equipment across 50000 square meters of production area

Continuous Innovation and Product Development

Dedicated to introducing new titanium-based materials and international processing technologies

Advanced R and D Team

More than 80 experienced technicians and engineers developing reliable and high-performance metal products

Customized Solutions

From standard inventory to tailor-made components we offer one-stop titanium solutions for your project

Company Profile

Founded in 2005 with a registered capital of 10 million yuan located in Baoji China Titanium Valley we focus on global markets and provide consistent quality service and delivery. Our products are trusted worldwide in marine petrochemical medical aerospace vacuum electronics and energy fields.

Corporate Culture

CXMET is driven by integrity development innovation and service excellence. Our mission is to create value for customers generate returns for our business and offer growth for our employees. With vision and responsibility we aim to lead the titanium industry into the future

OEM/ODM Services

Shaanxi CXMET Technology Co., Ltd. offers customized processing services to meet the specific needs of our clients. Our OEM/ODM services include product design, material selection, and production, ensuring that we can deliver tailor-made solutions that meet your requirements.

FAQ

What is the purity of your hafnium wire?

Our hafnium wire has a purity of 99.95%.

What is the diameter range available for hafnium wire?

We offer hafnium wire with diameters ranging from 0.1mm to 3mm.

Can you provide customized packaging?

Yes, we offer custom packaging options to meet your specific requirements.

What industries use hafnium wire?

Hafnium wire is used in aerospace, nuclear reactors, electronics, and medical devices.

Do you provide OEM/ODM services?

Yes, we offer comprehensive OEM/ODM services to meet the unique needs of our clients.

Email: sales@cxmet.com

hotTags:hafnium wire ,supplier,wholesale,China,factory,manufacturer,OEM,Customized,trader,for sale,in stock,free sample,for sale.

YOU MAY LIKE

Gr5 Titanium Bar

Brand: CXMET

Place Of Origin: China

Type: Titanium Bars

Application: Industrial

Technique: Hot Rolled

Shape: Round

Length: 50-6000mm

3D Printing Titanium Alloy Impeller

Brand: CXMET

Place Of Origin: China

Type: Gas Turbine Wheel

Engine Model: Custom

Condition: New

Engine Type: Gasoline/Diesel/Natural Gas

Certification: ISO9001:2008/TS 16949

Service: CXMET Customised

Hafnium oxide HfO2 tablet

Product name: Hafnium oxide HfO2 granule/tablet for vacuum coating

Brand Name: CXMET

Place of Origin: China

Application: Vacuum coating

Shape: Granule/Tablet

Color: Black

Purity: 99.99%

Density: 9.68g/cm3

Melting Point(°C): 2810

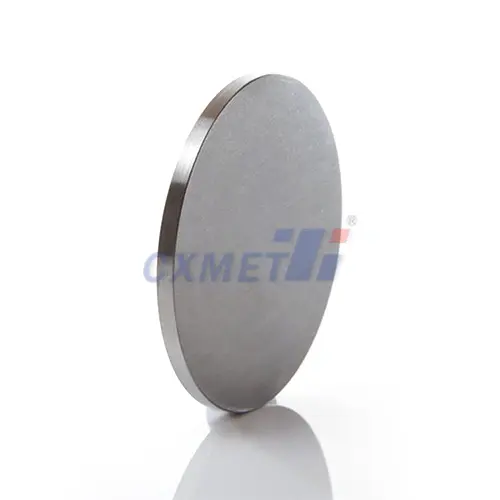

hafnium sputtering target

Product name: Hot sale hafnium sputtering target

Brand Name: CXMET

Place of Origin: China

Shape: Sheet, Foil

Material: Hafnium

Chemical Composition: 99.99% Hafnium

Purity 99.99%

Density 13.31 g/cm³

Usage: Aerospace, Electronics, Nuclear, etc.

Color: Metal grey