- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

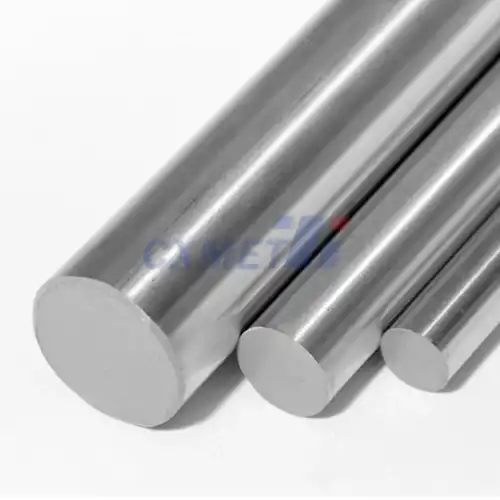

Gr5 Titanium Bar

Place Of Origin: China

Type: Titanium Bars

Application: Industrial

Technique: Hot Rolled

Shape: Round

Length: 50-6000mm

Gr5 Titanium Bar Product Introduction

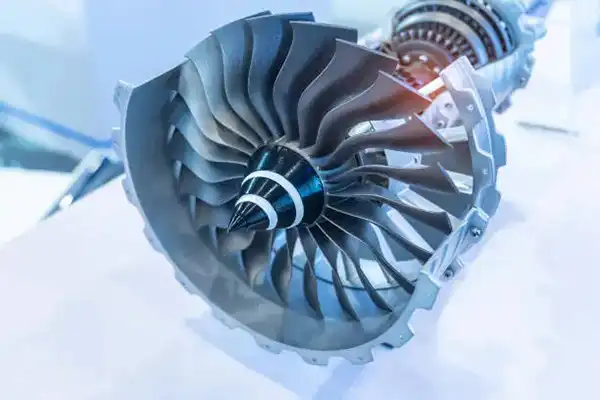

Shaanxi CXMET Technology Co., Ltd. proudly presents the Gr5 Titanium Bar, one of the most sought-after titanium alloy products globally due to its excellent strength-to-weight ratio, superior corrosion resistance, and outstanding heat resistance. Also known as Ti-6Al-4V, Gr5 titanium is an α+β titanium alloy composed of approximately 90% titanium, 6% aluminum, and 4% vanadium. This alloy is recognized as the standard among titanium grades used in aerospace, automotive, medical, chemical, and marine engineering industries.

We offer high-quality Gr5 Titanium Bars in a variety of dimensions and specifications to meet diverse industrial demands. With over 20 years of experience in non-ferrous metal manufacturing, Shaanxi CXMET is your trusted partner for top-performance titanium alloy solutions.

Gr5 Titanium Bar Features

-

High strength with low density

-

Excellent corrosion resistance in chloride and acid environments

-

Great heat resistance and good creep strength

-

Good weldability and workability

-

Biocompatible and non-toxic for medical use

-

Excellent fatigue resistance

Gr5 Titanium Bar Specifications

| Standard | ASTM B348, ASTM F136, AMS 4928, ISO 5832-3 |

|---|---|

| Grade | Gr5 / Ti-6Al-4V |

| Diameter Range | 6 mm to 350 mm |

| Length | 500 mm to 6000 mm (custom lengths available) |

| Surface Finish | Polished, Turned, Peeled, Ground |

| Density | 4.43 g/cm³ |

| Tensile Strength | ≥895 MPa |

| Yield Strength | ≥828 MPa |

| Elongation | ≥10% |

| Heat Treatment | Annealed / Solution Treated and Aged |

|

|

|

|

|

Gr5 Titanium Bar Applications

Due to its unique combination of strength, corrosion resistance, and biocompatibility, Gr5 Titanium Bar is extensively used in various demanding sectors:

-

Aerospace: Aircraft engine components, landing gear, fasteners

-

Automotive: Racing car parts, performance exhaust systems

-

Medical: Orthopedic implants, surgical instruments

-

Chemical Processing: Reactor vessels, heat exchangers

-

Marine Engineering: Subsea equipment, propulsion systems

-

Defense and Military: Armor plating, missile components

|

|

|

|

|

|

Gr5 Titanium Bar Working Environment

Gr5 Titanium Bar is ideal for harsh working environments that require:

-

High mechanical stress

-

Elevated temperatures (up to 400°C)

-

Strong corrosion resistance in seawater and acidic conditions

-

Lightweight materials for dynamic components

Gr5 Titanium Bar Customization

Shaanxi CXMET provides tailor-made solutions based on customer drawings, samples, or specifications. We can customize:

-

Dimensions (diameter, length, tolerance)

-

Surface finish (turning, grinding, polishing)

-

Mechanical properties through heat treatment

-

Certification and testing (Ultrasonic, PMI, Tensile, Hardness, etc.)

Main Advantages of Gr5 Titanium Bar

-

Strength-to-Weight Efficiency: Strong as steel but 45% lighter

-

Extended Service Life: Minimal degradation over time in corrosive settings

-

Cost-Effective Over Time: Reduces replacement frequency and maintenance

-

Biocompatibility: Safe for direct body contact

-

Thermal Stability: Reliable in high-heat applications

-

Eco-Friendly: Non-toxic, recyclable metal

Packaging and Logistics

To ensure product safety and quality during transportation, our Gr5 Titanium Bars are:

-

Packed in strong wooden cases with moisture-proof film

-

Labeled with detailed batch and specification information

-

Shipped with complete documentation (COC, MTC, packing list)

-

Available for global delivery via air, sea, or express logistics

|

|

|

|

Company Overview

Shaanxi CXMET Technology Co., Ltd., founded in 2005, is headquartered in China's Titanium Valley and operates a 50,000 m² facility. With 10 million RMB in registered capital and over 80 technical staff, we specialize in R&D, manufacturing, and exporting of non-ferrous and refractory metals, including titanium, nickel, tantalum, niobium, zirconium, molybdenum, and tungsten.

Our materials serve industries ranging from marine and oil & gas to medical, chemical, electronics, and aerospace. We uphold integrity, development, innovation, and excellence in service. Our mission is to create value for clients, benefit our enterprise, and support employee growth. With a forward-looking vision, we strive to innovate and lead the global titanium market.

Factory show

|

|

|

|

Production workshop

|

|

|

|

|

|

Production Equipments

Main Products

Why Choose Shaanxi CXMET Technology Co., Ltd.?

-

Extensive Product Range: Full grades from Gr1 to Gr23, including rare alloys

-

Outstanding Production Capabilities: Advanced CNC machines, forging, rolling

-

Continuous Innovation: In-house R&D driving new titanium applications

-

Technological Leadership: Backed by over 80 skilled technicians and engineers

-

Custom Manufacturing: Flexible to meet special industry demands

-

Strong Corporate Culture: Rooted in integrity, innovation, and service

-

Company Scale: Established in 2005, 50,000 m² facility, located in "China Titanium Valley"

FAQ

Q1: What is the difference between Gr5 and pure titanium (Gr1, Gr2)?

A: Gr5 is an alloy containing aluminum and vanadium, making it much stronger and heat-resistant than commercially pure grades like Gr1 and Gr2.

Q2: Can you provide mill test certificates and third-party inspection?

A: Yes, we supply MTCs per EN 10204 3.1 and accept third-party inspections from SGS, BV, or customer-appointed agents.

Q3: What is the minimum order quantity (MOQ)?

A: We accept small trial orders, typically starting from 5 kg depending on the size.

Q4: What is your lead time for Gr5 Titanium Bar?

A: Standard sizes are available in stock; for customized dimensions, lead time is usually 7–15 working days.

Q5: Do you offer international shipping?

A: Yes, we ship worldwide by air, sea, and courier (DHL, FedEx, UPS, TNT).

Contact Us

We welcome global distributors, wholesalers, and industrial users to contact us for quotations, material consulting, and technical support.

Email: sales@cxmet.com

Tel & WhatsApp: +86 15891192169

hotTags:Gr5 Titanium Bar,supplier,wholesale,China,factory,manufacturer,OEM,Customized,trader,for sale,in stock,free sample,for sale.

YOU MAY LIKE

titanium 6Al-4V Grade 5 Round Bar

Brand: CXMET

Place Of Origin: China

Type: Titanium Bars

Application: Medical

Technique: Hot Rolled

Grade: GR5

Shape: Round

Outer Diameter: 6-200mm

Grade 6 Titanium Bar

Product Name: Grade 6 titanium

Brand: CXMET

Place Of Origin: China

Material: Titanium

Surface: Polished/Pickling

Type: Round

Shape: Round bar

Standard: ASTM B348, ASTM F136, AMS 4920

Titanium Square Bar

Brand: CXMET

Place Of Origin: China

Material: GR1,GR2,GR3,GR4,GR5,6AL4VEli,GR7,GR9,GR12,GR23

Standards: ASTM B348,ASTM F67,ASTM F136

Surface : Polished bright,machined ,grind

Supply condition: Hot rolling ,cold drawing ,annealed

Shape: Square

Gr7 Titanium Rod

Brand: CXMET

Place Of Origin: China

Standrd: ASTM B348 ASTM F136 AMS4928 ASTMF1295

Specifaction φ>6mm Length(Max)6000mm

Surface :Bright

Technology: Forging/Rolling

Content of Pb: 0.12---0.25%

Application: Medical, Aviation, Petrochemical, Metallurgy, Electroplating

Vacuum: Coating, Sports and other Industries.

Titanium Welding Rod

Brand: CXMET

Place Of Origin: China

Grade: Gr1 Gr2 Gr7 Gr5

Ti (Min): 99.6%

Strength: 345MPa

Surface: Pickling Polished

Shape: Spool Coil Straight

Standard: ASTM B863

Certification: ISO9001:2015

Strength: 435MPa

Application: Industrial

Gr23 Ti 6AL4V Eli Medical Titanium Bar

Brand: CXMET

Place Of Origin: China

Grade: Gr23 Ti6AL4V Eli

Standard: ASTM F136

Specification: Dia4~100mm*(1000~3000)mm

Technique: Cold Rolling/Hot Rolling

Surface: Pickling/Polished

Application: industrial

titanium Grade 4 Round Bar

Brand: CXMET

Place Of Origin: China

Type: Titanium Bars

Application: Industrial, Medical

Technique: Cold Drawn/Hot Rolled/Forged

Grade: Gr4

Shape: Round/Square/Hexagonal/Wire

Diameter: 1-450 mm

.webp)

titanium Grade 2 Round Bar

Brand: CXMET

Place Of Origin: China

Type: Titanium Bars

Application: Industrial, Medical

Technique: Hot Rolled

Grade: GR2

Shape: Round

Transport Package: As Your Requirements