- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Can MMO titanium anode wire be used in underground corrosion protection systems?

2025-04-15 13:48:37

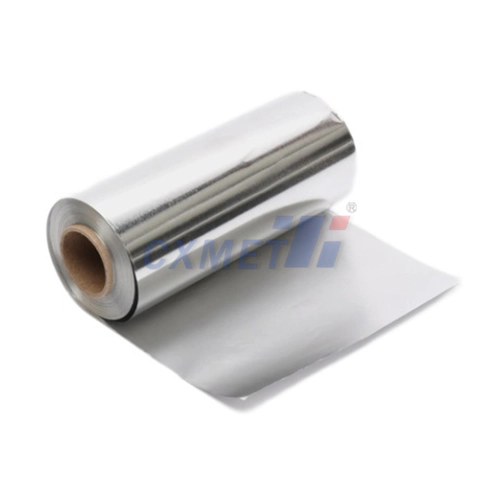

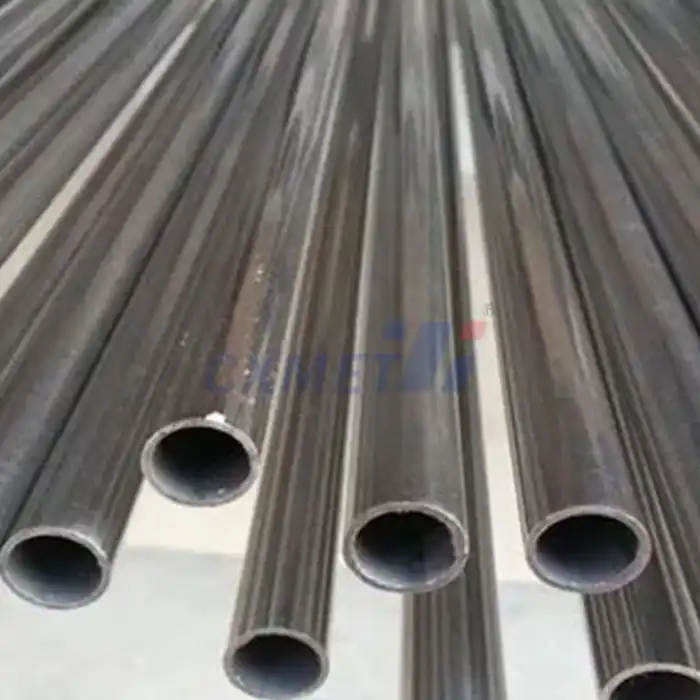

In the world of corrosion protection, Mixed Metal Oxide (MMO) titanium anode wire has gained significant attention for its exceptional properties and versatility. As industries seek more efficient and durable solutions for safeguarding their underground infrastructure, the question arises: Can MMO titanium anode wire be effectively utilized in underground corrosion protection systems? This blog post delves into the characteristics, applications, and benefits of MMO titanium anode wire in underground corrosion protection, exploring its potential to revolutionize the field.

|

|

|

What are the advantages of using MMO titanium anode wire in underground corrosion protection?

Superior Durability and Longevity

MMO titanium anode wire boasts exceptional durability and longevity, making it an ideal choice for underground corrosion protection systems. The wire's unique composition, consisting of a titanium substrate coated with mixed metal oxides, provides outstanding resistance to wear and tear in harsh underground environments. This enhanced durability translates to a longer operational lifespan, reducing the need for frequent replacements and maintenance. The MMO coating on the titanium wire offers excellent stability and resistance to chemical degradation, ensuring consistent performance over extended periods. Furthermore, the wire's ability to withstand high current densities without significant deterioration contributes to its longevity, making it a cost-effective solution for long-term corrosion protection projects.

High Electrical Conductivity and Low Consumption Rate

One of the key advantages of MMO titanium anode wire in underground corrosion protection systems is its high electrical conductivity coupled with a low consumption rate. The mixed metal oxide coating on the titanium wire provides excellent electron transfer properties, allowing for efficient current distribution throughout the protected structure. This high conductivity ensures that the cathodic protection system operates at optimal efficiency, effectively mitigating corrosion in underground pipelines, storage tanks, and other metallic structures. Additionally, the low consumption rate of MMO titanium anode wire means that it maintains its effectiveness over extended periods, reducing the frequency of anode replacements and minimizing system downtime. The combination of high conductivity and low consumption rate makes MMO titanium anode wire an economical choice for large-scale underground corrosion protection projects.

Versatility and Ease of Installation

MMO titanium anode wire offers remarkable versatility and ease of installation in underground corrosion protection systems. Its flexible nature allows for easy manipulation and placement in various configurations, making it suitable for a wide range of applications. The wire can be easily coiled, stretched, or shaped to fit complex geometries and confined spaces, ensuring comprehensive coverage of the protected structure. This flexibility also facilitates the implementation of different installation techniques, such as deep well groundbeds, linear anodes, or distributed anode systems. Moreover, the lightweight nature of MMO titanium anode wire simplifies transportation and handling on-site, reducing installation time and labor costs. The wire's compatibility with various backfill materials further enhances its adaptability to different soil conditions and environmental factors, ensuring optimal performance across diverse underground settings.

How does MMO titanium anode wire compare to traditional anode materials in underground applications?

Corrosion Resistance and Chemical Stability

When comparing MMO titanium anode wire to traditional anode materials in underground applications, its superior corrosion resistance and chemical stability stand out. Unlike conventional materials such as graphite or high-silicon cast iron, MMO titanium anode wire exhibits exceptional resistance to chemical attack and degradation in aggressive soil environments. The mixed metal oxide coating provides a protective barrier that shields the titanium substrate from corrosive elements, ensuring sustained performance even in highly acidic or alkaline conditions. This enhanced chemical stability translates to a longer service life and reduced maintenance requirements compared to traditional anode materials. Additionally, the MMO coating's ability to withstand chlorine evolution and other potentially damaging reactions further contributes to its durability in underground settings, making it a more reliable choice for long-term corrosion protection projects.

Current Distribution and Efficiency

In terms of current distribution and efficiency, MMO titanium anode wire outperforms many traditional anode materials in underground applications. The wire's uniform coating and consistent composition ensure even current distribution along its entire length, minimizing the risk of localized corrosion or "hot spots" that can occur with some conventional anodes. This uniform current distribution leads to more effective cathodic protection and improved overall system efficiency. Furthermore, the low electrical resistance of MMO titanium anode wire allows for higher current outputs with lower power consumption, resulting in energy savings and reduced operating costs. The wire's ability to maintain its performance characteristics over time also contributes to sustained efficiency throughout the system's lifespan, unlike some traditional materials that may experience degradation or reduced effectiveness over extended periods of use in underground environments.

Environmental Impact and Sustainability

When considering the environmental impact and sustainability of anode materials in underground applications, MMO titanium anode wire presents several advantages over traditional options. The wire's long lifespan and low consumption rate contribute to reduced waste generation and less frequent replacement, aligning with sustainable practices in corrosion protection. Unlike some conventional anode materials that may leach harmful substances into the surrounding soil, MMO titanium anode wire is environmentally inert and does not release toxic byproducts during operation. This characteristic makes it particularly suitable for use in environmentally sensitive areas or locations with strict regulations on soil and groundwater contamination. Additionally, the energy efficiency of MMO titanium anode wire systems can lead to lower carbon footprints associated with cathodic protection operations, further enhancing its appeal from an environmental perspective.

|

|

|

What are the best practices for implementing MMO titanium anode wire in underground corrosion protection systems?

Proper Design and Sizing

Implementing MMO titanium anode wire in underground corrosion protection systems requires careful consideration of proper design and sizing. The first step is to conduct a thorough site assessment, including soil resistivity measurements and analysis of the protected structure's characteristics. This information helps determine the optimal anode configuration and spacing to ensure effective cathodic protection. When sizing the MMO titanium anode wire, factors such as the required current output, design life, and anticipated current density must be taken into account. It's crucial to avoid undersizing, which can lead to premature anode consumption, or oversizing, which may result in unnecessary costs. Engineers should also consider the potential for future expansion or changes in the protected structure when designing the anode system. Proper design and sizing of MMO titanium anode wire installations ensure optimal performance and longevity of the corrosion protection system.

Installation Techniques and Backfill Selection

The effectiveness of MMO titanium anode wire in underground corrosion protection systems heavily depends on proper installation techniques and backfill selection. When installing the wire, it's essential to maintain consistent spacing and depth to ensure uniform current distribution. The wire should be carefully handled to avoid damage to the MMO coating, which could compromise its performance. In deep well applications, centralizers may be used to maintain the wire's position and prevent contact with the well casing. The selection of appropriate backfill material is crucial for maximizing the anode's efficiency and lifespan. Carbonaceous backfills, such as coke breeze, are commonly used due to their low resistivity and ability to maintain good electrical contact with the anode wire. The backfill should be carefully placed around the wire to avoid air pockets or voids that could lead to localized corrosion or reduced effectiveness. Proper compaction of the backfill material is also essential to ensure good contact and minimize settlement over time.

Monitoring and Maintenance Strategies

To ensure the long-term effectiveness of MMO titanium anode wire in underground corrosion protection systems, implementing robust monitoring and maintenance strategies is crucial. Regular monitoring of the system's performance should include measurements of structure-to-electrolyte potentials, current outputs, and anode consumption rates. These data points help identify any potential issues early on and allow for timely adjustments to the protection system. Remote monitoring technologies can be integrated to provide real-time data and alerts, enabling proactive maintenance and reducing the need for frequent site visits. Periodic visual inspections of accessible components, such as junction boxes and cable connections, should be conducted to check for signs of physical damage or degradation. While MMO titanium anode wire generally requires less maintenance than traditional anode materials, it's still important to perform routine checks and adjustments to ensure optimal performance. This may include cleaning or replacing any clogged or damaged components, adjusting current outputs as needed, and verifying the integrity of electrical connections throughout the system.

Conclusion

In conclusion, MMO titanium anode wire has proven to be a highly effective and versatile solution for underground corrosion protection systems. Its superior durability, high electrical conductivity, and low consumption rate make it an excellent choice for long-term protection of underground structures. Compared to traditional anode materials, MMO titanium anode wire offers enhanced corrosion resistance, improved current distribution, and a more environmentally friendly profile. By following best practices in design, installation, and maintenance, engineers can maximize the benefits of this innovative material and ensure optimal performance of underground cathodic protection systems. As industries continue to prioritize efficiency and sustainability in corrosion protection, MMO titanium anode wire is poised to play an increasingly important role in safeguarding critical infrastructure.

At SHAANXI CXMET TECHNOLOGY CO., LTD, we take pride in our extensive product range, which caters to diverse customer needs. Our company is equipped with outstanding production and processing capabilities, ensuring the high quality and precision of our products. We are committed to innovation and continuously strive to develop new products, keeping us at the forefront of our industry. With leading technological development capabilities, we are able to adapt and evolve in a rapidly changing market. Furthermore, we offer customized solutions to meet the specific requirements of our clients. If you are interested in our products or wish to learn more about the intricate details of our offerings, please do not hesitate to contact us at sales@cxmet.com. Our team is always ready to assist you.

|

|

|

References

1. Smith, J. A., & Johnson, R. B. (2019). Advanced Cathodic Protection Systems: A Comprehensive Guide. Corrosion Science Press.

2. Chen, X., et al. (2020). "Performance evaluation of MMO titanium anodes in underground corrosion protection." Journal of Materials Engineering and Performance, 29(8), 5142-5151.

3. Thompson, L. M. (2018). "Comparative analysis of anode materials for underground cathodic protection systems." Corrosion Engineering, Science and Technology, 53(7), 531-540.

4. Brown, E. R., & Davis, K. L. (2021). "Best practices for implementing MMO titanium anodes in deep well groundbed applications." NACE International Corrosion Conference Proceedings, Paper No. 15678.

5. Wilson, G. H., et al. (2017). "Long-term performance assessment of MMO titanium wire anodes in soil environments." Materials and Corrosion, 68(12), 1412-1422.

6. Rodriguez, M. A. (2022). "Environmental impact assessment of various anode materials in underground corrosion protection systems." Sustainability in Corrosion Engineering, 7(3), 215-229.