- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Titanium AMS 6242 Rod For Aerospace

Brand: CXMET

Place Of Origin: China

Application:Aerospace

Grade:Gr1

Standard: AMS4928

Density: 4.51g/cm3

Technique: Rolled

Shape: Round

Surface: Polished

Color: Sliver

Certificates: ISO 9001:2015

Product Introduction

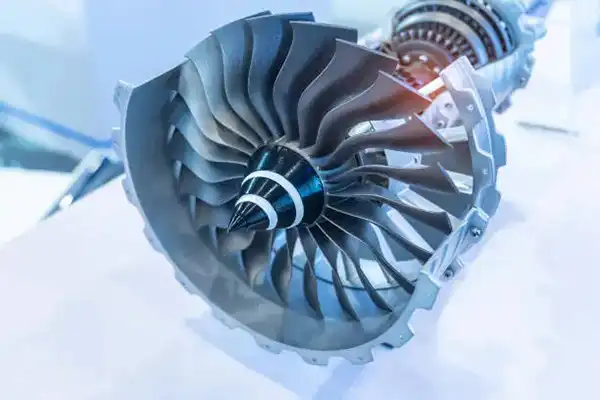

Titanium AMS 6242 Rod is a high-performance titanium alloy rod engineered specifically for demanding aerospace applications. It belongs to the family of alpha-beta titanium alloys and is commonly referred to by its alloy name Ti-6Al-2Sn-4Zr-6Mo. This grade is developed to perform under extreme conditions involving high temperature, high strength, and excellent fatigue resistance.

Shaanxi CXMET Technology Co., Ltd. proudly manufactures and supplies Titanium AMS 6242 rods to aerospace companies and advanced engineering sectors worldwide. With strict adherence to AMS 4919 and AMS 4975 specifications, our titanium rods are ideal for engine components, airframe parts, and high-stress aerospace structures where reliability and longevity are critical.

Product Features

-

High strength-to-weight ratio

-

Excellent fatigue and creep resistance

-

Outstanding thermal stability up to 550°C

-

Exceptional corrosion resistance in harsh environments

-

Precise dimensional tolerance and superior surface quality

-

Fully traceable production with mill test certification

Product Specifications

| Specification | Detail |

|---|---|

| Grade | AMS 6242 (Ti-6Al-2Sn-4Zr-6Mo) |

| Standard | AMS 4919, AMS 4975, ASTM B348 |

| Type | Titanium Alpha-Beta Alloy |

| Diameter Range | 6.0 mm to 120 mm |

| Length | Up to 6000 mm or customized |

| Surface Finish | Turned, polished, or ground |

| Density | 4.55 g/cm³ |

| Tensile Strength | ≥ 1030 MPa |

| Yield Strength | ≥ 1000 MPa |

| Elongation | ≥ 10% |

| Operating Temperature | Up to 550°C |

|

|

Applications

Titanium AMS 6242 rod is primarily used in high-performance aerospace and aviation applications where components must withstand both high temperatures and cyclic loading. Key applications include:

-

Jet engine compressor components

-

Turbine disks and blades

-

Aircraft structural elements

-

Spacecraft load-bearing systems

-

Aerospace fasteners and actuators

-

High-performance motorsport parts

|

|

|

|

|

|

Working Environment

Titanium AMS 6242 Rod operates reliably under extreme mechanical and thermal conditions. It is specifically designed to maintain strength and form in environments with:

-

Continuous exposure to temperatures up to 550°C

-

High-pressure and high-vibration systems

-

Corrosive atmospheres including oxidizing and saline environments

-

Rapid pressure or temperature fluctuations

Its high creep resistance and oxidation stability make it ideal for aerospace engines and high-altitude applications.

Customization Options

At Shaanxi CXMET, we offer full customization of Titanium AMS 6242 rods to meet your exact engineering requirements. Options include:

-

Custom diameters and lengths

-

Specific mechanical properties based on your application

-

Surface treatment and precision machining

-

Cut-to-length and CNC-processed components

-

Tolerance control according to ISO or customer standards

Our experienced R&D and engineering team will work closely with you to ensure your specifications are met with precision.

Key Advantages

-

Superior mechanical performance at elevated temperatures

-

Proven performance in aerospace engines and structures

-

Lightweight properties for fuel-efficient design

-

Long-term cost efficiency due to low maintenance and high durability

-

Seamless integration into critical manufacturing processes

-

Reliable supply chain with short lead times and global logistics

Packaging and Logistics

We pay close attention to every detail during packaging and transportation. Each Titanium AMS 6242 Rod is:

-

Individually protected with plastic sleeves or foam wrap

-

Packed in sturdy wooden crates or steel-framed pallets

-

Labeled with full batch traceability and specification details

-

Shipped with mill test reports and customs documentation

-

Exported to over 60 countries with on-time delivery

Our logistics team ensures safe, compliant, and efficient delivery to your facility worldwide.

|

|

|

|

Company Overview

Shaanxi CXMET Technology Co., Ltd., founded in 2005, is headquartered in China's Titanium Valley and operates a 50,000 m² facility. With 10 million RMB in registered capital and over 80 technical staff, we specialize in R&D, manufacturing, and exporting of non-ferrous and refractory metals, including titanium, nickel, tantalum, niobium, zirconium, molybdenum, and tungsten.

Our materials serve industries ranging from marine and oil & gas to medical, chemical, electronics, and aerospace. We uphold integrity, development, innovation, and excellence in service. Our mission is to create value for clients, benefit our enterprise, and support employee growth. With a forward-looking vision, we strive to innovate and lead the global titanium market.

Factory show

|

|

|

|

Production workshop

|

|

|

|

|

|

Production Equipments

Main Products

Why Choose Us

Shaanxi CXMET Technology Co., Ltd. stands at the forefront of advanced metal manufacturing with over 20 years of experience. We are located in the heart of China Titanium Valley and offer:

-

Extensive product range including titanium, nickel, molybdenum, tungsten, niobium, tantalum, and zirconium

-

Advanced production and processing capabilities with over 80 skilled technicians

-

Continuous innovation and development of new materials

-

Leading technological development in titanium and refractory metals

-

Tailored solutions and international service orientation

Founded in 2005 with a registered capital of 10 million, our factory covers 50,000 square meters and operates under strict quality control and global compliance systems. Our titanium rods are trusted by aerospace, marine, medical, chemical, energy, and electronics industries worldwide.

We are driven by our core values of integrity, development, innovation, and excellence in service. Our mission is to create value for our customers, generate mutual benefits, and contribute to the future of high-performance materials.

FAQ

Q: What certifications do you provide with the Titanium AMS 6242 Rod?

A: We provide mill test certificates, EN10204 3.1, and can arrange third-party inspection reports upon request.

Q: Can you produce Titanium AMS 6242 rods to exact custom sizes?

A: Yes, we offer full customization services including specific diameters, tolerances, and lengths.

Q: What is your typical lead time for AMS 6242 rods?

A: Standard sizes are typically available within 7–10 working days. Custom orders may vary based on complexity.

Q: Do you ship internationally?

A: Yes, we ship globally and can arrange air, sea, or courier logistics depending on your needs.

Q: How can I ensure the quality of your titanium products?

A: Our facility is ISO-certified, and every product undergoes strict in-house inspection and traceable quality control before shipment.

Contact Us

For the latest price, detailed technical support, or a customized offer, please reach out to us. We are happy to assist global buyers in sourcing high-quality titanium materials.

Email: sales@cxmet.com

Tel & WhatsApp: +8615891192169

Partner with Shaanxi CXMET Technology Co., Ltd. today and experience the strength and precision of our Titanium AMS 6242 Rods for aerospace applications. We are committed to delivering quality, reliability, and innovation—your trusted titanium solution provider.

hotTags:Titanium AMS 6242 Rod For Aerospace,supplier,wholesale,China,factory,manufacturer,OEM,Customized,trader,for sale,in stock,free sample,for sale.

YOU MAY LIKE

Titanium Rectangular Bar

Brand: CXMET

Place Of Origin: China

Thickness:4.5

Width: 4.75

Max Length:144

Alloy: 6AL-4V Grade 5

MTR Availability: Yes

Material: Titanium

Shape: Bar-Rectangle

Gr9 Titanium Bar

Brand: CXMET

Place Of Origin: China

Grade: Titanium GR-9

Standard: ASTM B348 / ASME SB348, AMS 4976, AMS 4956

Type: Seamless / Welded / Fabricated / LSAW Pipes

Form : Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forging Etc.

6Al4V AMS 4928 Titanium Bar

Brand: CXMET

Place Of Origin: China

Diameter 2

Max Length 144

Grade: Grade 5

Full Length true

Material: Titanium

Shape: Bar-Round

Custom: Cut Warehouse 1

Alloy: 6AL-4V Grade 5

Titanium Square Bar

Brand: CXMET

Place Of Origin: China

Material: GR1,GR2,GR3,GR4,GR5,6AL4VEli,GR7,GR9,GR12,GR23

Standards: ASTM B348,ASTM F67,ASTM F136

Surface : Polished bright,machined ,grind

Supply condition: Hot rolling ,cold drawing ,annealed

Shape: Square

Titanium Welding Rod

Brand: CXMET

Place Of Origin: China

Grade: Gr1 Gr2 Gr7 Gr5

Ti (Min): 99.6%

Strength: 345MPa

Surface: Pickling Polished

Shape: Spool Coil Straight

Standard: ASTM B863

Certification: ISO9001:2015

Strength: 435MPa

Application: Industrial

Gr23 Ti 6AL4V Eli Medical Titanium Bar

Brand: CXMET

Place Of Origin: China

Grade: Gr23 Ti6AL4V Eli

Standard: ASTM F136

Specification: Dia4~100mm*(1000~3000)mm

Technique: Cold Rolling/Hot Rolling

Surface: Pickling/Polished

Application: industrial

tianium Alloy 6Al-2Sn-4Zr-6Mo Round Bar

Brand: CXMET

Place Of Origin: China

Type: Titanium Bars

Application: Industrial, Medical

Technique: Hot Rolled

Shape: Round

Classification: Commercially Pure

High Quality Gr1 Pure Titanium Bar

Brand: CXMET

Place Of Origin: China

Type: Titanium Bars

Application: Industrial

Technique: Cold Rolled

Grade: GR1

Shape: Round

Transport Package: As Your Requirements