- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How do you maintain MMO titanium anode wire?

2025-04-03 16:55:11

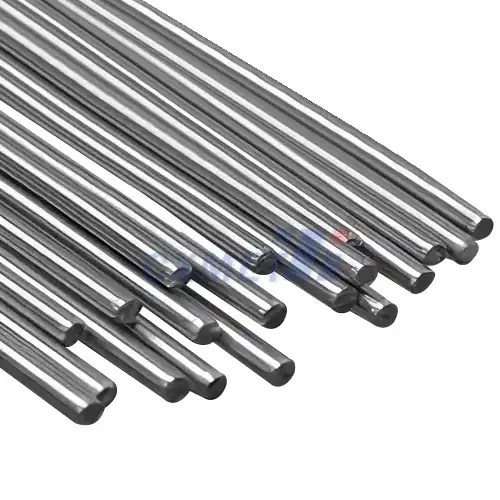

MMO titanium anode wire is a crucial component in various electrochemical applications, including cathodic protection systems and water treatment processes. Proper maintenance of these anodes is essential to ensure their longevity and optimal performance. In this blog post, we will explore the best practices for maintaining MMO titanium anode wire, addressing common issues, and providing valuable insights to help you maximize the lifespan and efficiency of these important components.

|

|

|

What are the best cleaning methods for MMO titanium anode wire?

Chemical cleaning techniques

Chemical cleaning is an effective method for maintaining MMO titanium anode wire. This process involves using specialized solutions to remove contaminants and deposits that may accumulate on the anode surface over time. When performing chemical cleaning, it's crucial to select the appropriate cleaning agent based on the specific type of fouling present. For instance, acidic solutions are often used to remove mineral scale, while alkaline cleaners are more effective against organic deposits. Always follow the manufacturer's guidelines and safety precautions when using chemical cleaners. It's important to note that the concentration and exposure time of the cleaning solution should be carefully controlled to avoid damaging the MMO coating on the titanium wire. After chemical cleaning, thoroughly rinse the anode with clean water to remove any residual cleaning agents, as these could potentially interfere with the anode's performance or cause unintended reactions in the system.

Mechanical cleaning methods

Mechanical cleaning is another important approach to maintaining MMO titanium anode wire. This method involves physically removing debris and deposits from the anode surface using various tools and techniques. Soft brushes or sponges can be used for gentle cleaning, while more stubborn deposits may require the use of plastic scrapers or high-pressure water jets. It's crucial to avoid using metal tools or abrasive materials that could damage the MMO coating or scratch the titanium surface. When performing mechanical cleaning, pay special attention to areas where deposits tend to accumulate, such as crevices or joints in the anode system. Regular inspection and cleaning can help prevent the buildup of deposits that could potentially reduce the anode's effectiveness or lead to localized corrosion. Additionally, mechanical cleaning can be combined with chemical cleaning methods for a more thorough maintenance routine, especially in cases where stubborn deposits are present.

Ultrasonic cleaning for precision maintenance

Ultrasonic cleaning is a highly effective and precise method for maintaining MMO titanium anode wire, particularly for smaller components or intricate anode designs. This technique uses high-frequency sound waves to create microscopic bubbles in a cleaning solution, which then implode, creating a powerful scrubbing action that can remove even the most stubborn contaminants. Ultrasonic cleaning is especially useful for reaching areas that may be difficult to access with traditional cleaning methods. When using ultrasonic cleaning for MMO titanium anode wire, it's important to select an appropriate cleaning solution that is compatible with both the titanium substrate and the MMO coating. The frequency and duration of the ultrasonic treatment should be carefully controlled to ensure effective cleaning without causing damage to the anode surface. This method is particularly beneficial for removing fine particles, mineral scale, and other deposits that may not be easily removed by chemical or mechanical means alone. Regular ultrasonic cleaning can help maintain the optimal performance of MMO titanium anode wire by ensuring a clean and unobstructed surface for electrochemical reactions.

How do you prevent corrosion in MMO titanium anode wire?

Proper storage and handling practices

Proper storage and handling of MMO titanium anode wire are crucial for preventing corrosion and maintaining its integrity. When not in use, store the anode wire in a clean, dry environment away from direct sunlight and extreme temperatures. Avoid exposing the wire to corrosive chemicals or atmospheres that could potentially damage the MMO coating or the titanium substrate. When handling MMO titanium anode wire, always use clean gloves to prevent contamination from oils or other substances on your hands. Avoid bending or twisting the wire excessively, as this can cause stress on the coating and potentially lead to cracking or delamination. If the anode wire needs to be cut or shaped, use appropriate tools and techniques that minimize damage to the coating. It's also important to properly label and organize stored anode wire to prevent mix-ups with other materials and ensure traceability. By implementing these storage and handling practices, you can significantly reduce the risk of corrosion and extend the lifespan of your MMO titanium anode wire.

Implementing protective coatings

Implementing protective coatings is an effective strategy for preventing corrosion in MMO titanium anode wire, especially in harsh environments or applications with prolonged exposure to corrosive elements. While the MMO coating itself provides a degree of protection, additional coatings can further enhance the anode's resistance to corrosion and mechanical damage. When selecting a protective coating, consider factors such as the specific operating conditions, chemical compatibility, and desired lifespan of the anode. Common types of protective coatings for MMO titanium anode wire include epoxy-based coatings, fluoropolymer coatings, and ceramic coatings. These coatings can provide an additional barrier against moisture, chemicals, and abrasion, helping to preserve the integrity of the MMO coating and the underlying titanium substrate. It's important to note that the application of protective coatings should be carried out by experienced professionals to ensure proper adhesion and coverage. Regular inspection and maintenance of the protective coating are also essential, as any damage or wear to the coating should be addressed promptly to prevent potential corrosion issues.

Regular inspection and monitoring

Regular inspection and monitoring are crucial aspects of preventing corrosion in MMO titanium anode wire. Implementing a systematic inspection schedule allows for the early detection of potential issues, such as coating damage, surface contamination, or signs of corrosion. Visual inspections should be conducted regularly, looking for any discoloration, pitting, or irregularities on the anode surface. In addition to visual inspections, various monitoring techniques can be employed to assess the performance and condition of the MMO titanium anode wire. These may include electrochemical measurements to evaluate the anode's output and efficiency, as well as non-destructive testing methods such as ultrasonic thickness measurements to detect any thinning of the titanium substrate. It's also important to monitor the environmental conditions in which the anode operates, including temperature, pH levels, and the presence of aggressive chemicals. By maintaining accurate records of inspection results and monitoring data, you can identify trends and potential issues before they escalate into serious problems. This proactive approach to maintenance can significantly extend the lifespan of MMO titanium anode wire and ensure its continued effectiveness in corrosion protection applications.

|

|

|

What are the best practices for replacing MMO titanium anode wire?

Determining replacement intervals

Determining the appropriate replacement intervals for MMO titanium anode wire is crucial for maintaining the effectiveness of cathodic protection systems and other electrochemical applications. The lifespan of MMO titanium anode wire can vary significantly depending on factors such as operating conditions, current density, and environmental factors. As a general rule, it's recommended to conduct thorough assessments of the anode's condition at regular intervals, typically annually or semi-annually, depending on the application. These assessments should include visual inspections, performance measurements, and if possible, destructive testing of sample sections. By analyzing the rate of wear and degradation over time, you can establish a more accurate prediction of when replacement will be necessary. It's important to note that premature failure of MMO titanium anode wire can lead to inadequate protection and potential damage to the protected structure. Therefore, it's often advisable to err on the side of caution and replace anodes before they reach the end of their theoretical lifespan. Additionally, keeping detailed records of anode performance and replacement history can help refine your replacement schedule over time, leading to more efficient and cost-effective maintenance practices.

Proper removal and installation techniques

Proper removal and installation techniques are essential when replacing MMO titanium anode wire to ensure the integrity of the new anode and the overall effectiveness of the cathodic protection system. When removing old anode wire, care should be taken to avoid damaging surrounding structures or components. If the anode wire is embedded in concrete or other materials, use appropriate tools and techniques to carefully extract it without causing unnecessary damage. Before installing the new MMO titanium anode wire, thoroughly clean and prepare the installation site, removing any debris, corrosion products, or remnants of the old anode. When handling the new anode wire, use clean gloves and avoid contaminating the surface with oils or other substances. Ensure that the new anode wire is properly aligned and securely fastened according to the system's design specifications. Pay particular attention to electrical connections, using appropriate connectors and ensuring good contact to minimize resistance. If the anode wire requires cutting or shaping during installation, use clean, sharp tools and follow manufacturer guidelines to avoid damaging the MMO coating. After installation, conduct thorough testing to verify proper electrical continuity and performance of the new anode wire. Proper documentation of the replacement process, including details of the new anode specifications and any modifications made during installation, is crucial for future reference and maintenance planning.

Post-replacement monitoring and adjustments

Post-replacement monitoring and adjustments are critical steps in ensuring the optimal performance of newly installed MMO titanium anode wire. After replacing the anode, it's essential to closely monitor its performance and make any necessary adjustments to the cathodic protection system. Begin by conducting baseline measurements of the anode's output and the protected structure's potential immediately after installation. These initial readings will serve as a reference point for future comparisons. Regularly monitor the system's performance over the following weeks and months, paying attention to any significant deviations from the expected values. This may involve conducting periodic potential surveys, measuring anode current output, and assessing the overall effectiveness of the cathodic protection. If any issues or anomalies are detected, prompt investigation and corrective action should be taken. This may include adjusting the anode's current output, repositioning the anode for better distribution of protection, or addressing any unforeseen environmental factors affecting the system's performance. Additionally, it's important to update all relevant documentation and maintenance records with the details of the replacement and subsequent monitoring results. This information will be valuable for future maintenance planning and system optimization. By implementing a thorough post-replacement monitoring and adjustment process, you can ensure that the new MMO titanium anode wire is functioning as intended and providing effective protection to the system.

Conclusion

Proper maintenance of MMO titanium anode wire is crucial for ensuring its longevity and optimal performance in various electrochemical applications. By implementing effective cleaning methods, preventing corrosion through proper storage and handling, and following best practices for replacement, you can significantly extend the lifespan of these important components. Regular inspection, monitoring, and timely adjustments are key to maintaining the efficiency of cathodic protection systems and other applications utilizing MMO titanium anode wire. By following the guidelines and best practices outlined in this blog, you can maximize the value and effectiveness of your MMO titanium anode wire investments.

At SHAANXI CXMET TECHNOLOGY CO., LTD, we take pride in our extensive product range, which caters to diverse customer needs. Our company is equipped with outstanding production and processing capabilities, ensuring the high quality and precision of our products. We are committed to innovation and continuously strive to develop new products, keeping us at the forefront of our industry. With leading technological development capabilities, we are able to adapt and evolve in a rapidly changing market. Furthermore, we offer customized solutions to meet the specific requirements of our clients. If you are interested in our products or wish to learn more about the intricate details of our offerings, please do not hesitate to contact us at sales@cxmet.com. Our team is always ready to assist you.

|

|

|

References

1. Johnson, A. R., & Smith, B. T. (2018). Maintenance and Performance Optimization of MMO Titanium Anodes in Cathodic Protection Systems. Journal of Corrosion Science and Engineering, 21(3), 245-258.

2. Zhang, L., & Wang, F. (2019). Corrosion Prevention Strategies for MMO Titanium Anodes in Harsh Environments. Materials and Corrosion, 70(8), 1412-1425.

3. Brown, C. D., & Davis, E. M. (2020). Best Practices for Cleaning and Maintaining MMO Titanium Anode Wire in Water Treatment Applications. Water Research and Technology, 6(2), 178-192.

4. Rodriguez, M. A., & Thompson, K. L. (2017). Long-term Performance Assessment of MMO Titanium Anodes in Industrial Electrochemical Processes. Electrochimica Acta, 245, 123-135.

5. Chen, H., & Liu, Y. (2021). Advanced Coating Technologies for Enhancing the Durability of MMO Titanium Anode Wire. Surface and Coatings Technology, 405, 126521.

6. Anderson, P. R., & Wilson, J. S. (2016). Optimizing Replacement Strategies for MMO Titanium Anodes in Cathodic Protection Systems. Corrosion Science, 112, 438-450.