- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

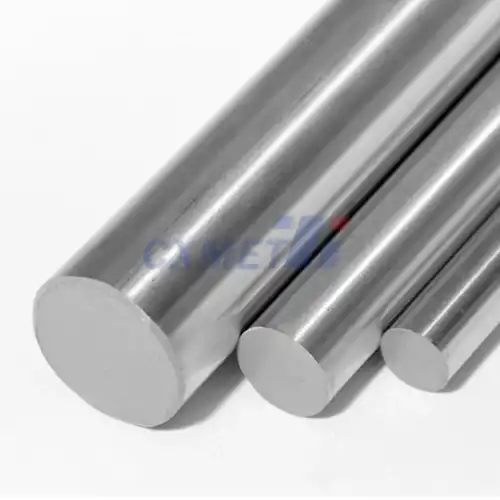

Titanium Square Bar

Place Of Origin: China

Material: GR1,GR2,GR3,GR4,GR5,6AL4VEli,GR7,GR9,GR12,GR23

Standards: ASTM B348,ASTM F67,ASTM F136

Surface : Polished bright,machined ,grind

Supply condition: Hot rolling ,cold drawing ,annealed

Shape: Square

Titanium Square Bar Product Introduction

Shaanxi CXMET Technology Co., Ltd., located in the heart of China's Titanium Valley, proudly introduces our high-performance Titanium Square Bar. Manufactured using state-of-the-art equipment and advanced metallurgical techniques, our titanium square bars are engineered for strength, precision, and corrosion resistance. These bars are a preferred choice across industries requiring lightweight and durable materials such as aerospace, chemical processing, marine, medical, and power generation.

Our titanium square bars are available in a wide range of grades, including commercial pure titanium (Gr1, Gr2, Gr3, Gr4) and titanium alloys (Gr5, Gr7, Gr9, Gr12, Gr19, Gr20, Gr21, Gr22, Gr23). Whether your requirement is for lightweight structural applications or demanding chemical resistance, we can supply the right grade to meet your technical and industrial needs.

Key Features of Titanium Square Bar

-

Excellent strength-to-weight ratio

-

Exceptional resistance to corrosion, especially in seawater, acid, and chlorine environments

-

Superior biocompatibility for medical applications

-

High fatigue resistance and excellent mechanical properties

-

Thermal stability and oxidation resistance at elevated temperatures

-

Non-toxic, recyclable, and environmentally friendly material

Specifications of Titanium Square Bar

-

Dimensions: 4 mm x 4 mm to 200 mm x 200 mm (customizable)

-

Length: Standard 1000 mm to 6000 mm, or custom lengths upon request

-

Surface finish: Polished, pickled, sandblasted, or as required

-

Tolerance: According to ASTM B348, AMS, DIN, or customer specifications

-

Available Grades: Gr1 to Gr23

Grade Comparison

| Grade | Type | Composition | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Key Properties | Application Examples |

|---|---|---|---|---|---|---|---|

| Gr1 | CP Titanium | ≥99.5% Ti | 240 | 170 | 24 | Softest, best corrosion resistance | Chemical, marine, medical |

| Gr2 | CP Titanium | ≥99.2% Ti | 345 | 275 | 20 | Balance of strength and corrosion resistance | Heat exchangers, pipelines |

| Gr3 | CP Titanium | ≥99.0% Ti | 450 | 380 | 18 | Stronger than Gr2, good corrosion resistance | Aerospace structures |

| Gr4 | CP Titanium | ≥98.6% Ti | 550 | 483 | 15 | Highest strength of CP grades | Pressure vessels, chemical reactors |

| Gr5 | α+β Alloy | Ti-6Al-4V | 895 | 828 | 10 | High strength, heat resistance | Aerospace, racing, military |

| Gr7 | CP + Pd | Ti + 0.2% Pd | 340 | 275 | 20 | Outstanding acid resistance | Chloride-rich chemical processes |

| Gr9 | α Alloy | Ti-3Al-2.5V | 620 | 483 | 15 | Lightweight, weldable | Bicycle frames, aircraft tubing |

| Gr12 | α Alloy | Ti-0.3Mo-0.8Ni | 480 | 345 | 18 | Strong with excellent corrosion resistance | Chemical industry, heat exchangers |

| Gr23 | α+β Alloy | Ti-6Al-4V ELI | 860 | 795 | 14 | Low impurities, implant-grade | Medical implants, dental equipment |

| Gr19 | β Alloy | Ti-3Al-8V-6Cr-4Mo-4Zr | 950 | 880 | 10 | Ultra-high strength, forgeable | Automotive, aerospace structural parts |

| Gr20 | β Alloy | Ru-modified Gr19 | 960 | 895 | 10 | Enhanced corrosion resistance | Marine equipment |

| Gr21 | α+β Alloy | Ti-15Mo-3Al-2.7Nb-0.2Si | 830 | 760 | 12 | Excellent oxidation resistance | Gas turbines |

| Gr22 | α+β Alloy | Ti-5Al-2.5Sn | 760 | 690 | 13 | Good high-temp creep resistance | Jet engine parts |

|

|

|

|

|

Applications of Titanium Square Bar

-

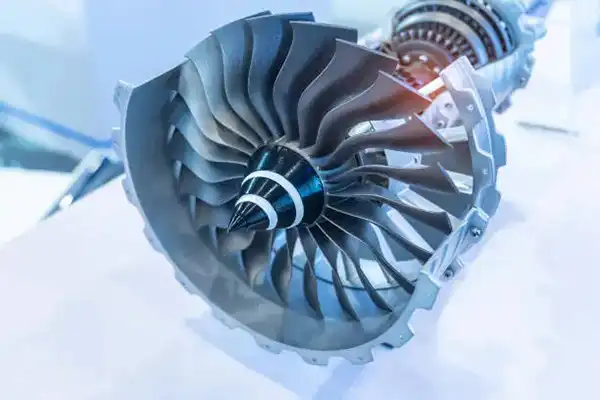

Aerospace: airframes, landing gear, structural components

-

Medical: bone implants, surgical tools, dental prosthetics

-

Chemical processing: heat exchangers, reactors, piping

-

Marine: offshore platforms, desalination systems

-

Automotive: racing parts, suspension elements

-

Sports equipment: bicycle frames, climbing gear

-

Energy: power plants, gas turbines

|

|

|

|

|

|

Working Environments of Titanium Square Bar

Titanium square bars are engineered to withstand the most demanding environments:

-

Saltwater and marine atmospheres

-

Chloride and acidic chemical processing lines

-

High-pressure and high-temperature operations

-

Biomedical environments requiring sterility and biocompatibility

-

Cryogenic conditions in advanced engineering systems

Customization Available

We offer complete customization services:

-

Custom dimensions and tolerances

-

Tailored grades for specific mechanical or chemical requirements

-

Surface treatments for enhanced durability or aesthetic purposes

-

Special packaging for delicate or critical components

-

OEM/ODM services for international clients

Core Advantages of Titanium Square Bar

-

Lightweight yet extremely strong, reducing overall structural weight

-

Long service life in corrosive and high-stress environments

-

Low maintenance cost due to superior corrosion and fatigue resistance

-

Biocompatible and eco-friendly

-

Excellent machinability and formability depending on grade

Packaging and Logistics

-

Each bar is individually wrapped to prevent scratches

-

Bundled and packed in wooden cases or pallets

-

Moisture-resistant and shock-proof packaging

-

Clearly labeled with material grade, size, batch number

-

Fast delivery via air, sea, or courier with complete tracking

|

|

|

|

Company Overview

Shaanxi CXMET Technology Co., Ltd., founded in 2005, is headquartered in China's Titanium Valley and operates a 50,000 m² facility. With 10 million RMB in registered capital and over 80 technical staff, we specialize in R&D, manufacturing, and exporting of non-ferrous and refractory metals, including titanium, nickel, tantalum, niobium, zirconium, molybdenum, and tungsten.

Our materials serve industries ranging from marine and oil & gas to medical, chemical, electronics, and aerospace. We uphold integrity, development, innovation, and excellence in service. Our mission is to create value for clients, benefit our enterprise, and support employee growth. With a forward-looking vision, we strive to innovate and lead the global titanium market.

Factory show

|

|

|

|

Production workshop

|

|

|

|

|

|

Production Equipments

Main Products

Why Choose Us - Corporate Advantages

-

Extensive Product Range: From Gr1 to Gr23, we supply all major titanium grades

-

Advanced Capabilities: Leading production, testing, and machining facilities

-

Innovative Development: Continuously launching new materials and products

-

Customization Expertise: Tailor-made products for different global markets

-

Trusted Manufacturer: Established in 2005 with a registered capital of 10 million RMB

-

Large Facility: 50,000 m2 factory located in the heart of China’s Titanium Valley

-

Strong Team: Over 80 skilled professionals and engineers

-

Global Reach: Widely recognized in chemical, aerospace, medical, and marine industries

FAQ

Q1: What is the minimum order quantity?

A1: We accept both small trial orders and bulk quantities. MOQ is negotiable.

Q2: Can I get free samples?

A2: Samples are available upon request, with cost refundable upon bulk order confirmation.

Q3: How do you ensure product quality?

A3: Strict quality control with material traceability, in-house testing, and third-party inspection available.

Q4: Do you provide customized sizes?

A4: Yes, dimensions and surface treatments can be tailored to customer requirements.

Q5: What is your lead time?

A5: Standard sizes ship within 7-10 days. Customized items typically ship within 15-25 days.

Contact Us for the Latest Quotation and Custom Solutions

Shaanxi CXMET Technology Co., Ltd.

Email: sales@cxmet.com

Tel & WhatsApp: +86 15891192169

We welcome global procurement partners to collaborate with Shaanxi CXMET. Let us help you create high-performance, titanium-based solutions that meet the future of engineering.

hotTags:Titanium Square Bar,supplier,wholesale,China,factory,manufacturer,OEM,Customized,trader,for sale,in stock,free sample,for sale.

YOU MAY LIKE

Grade 6 Titanium Bar

Product Name: Grade 6 titanium

Brand: CXMET

Place Of Origin: China

Material: Titanium

Surface: Polished/Pickling

Type: Round

Shape: Round bar

Standard: ASTM B348, ASTM F136, AMS 4920

Titanium Rectangular Bar

Brand: CXMET

Place Of Origin: China

Thickness:4.5

Width: 4.75

Max Length:144

Alloy: 6AL-4V Grade 5

MTR Availability: Yes

Material: Titanium

Shape: Bar-Rectangle

Titanium Hex Bar For Sale

Brand: CXMET

Place Of Origin: China

Material: Pure titanium titanium alloy

Grade: Gr1,Gr2,Gr5,Gr7,Gr12,etc

Color: Ti Natural

Applacation: Industry Diameter:60-50mm

Length <6000mm(nomal size)

Gr9 Titanium Bar

Brand: CXMET

Place Of Origin: China

Grade: Titanium GR-9

Standard: ASTM B348 / ASME SB348, AMS 4976, AMS 4956

Type: Seamless / Welded / Fabricated / LSAW Pipes

Form : Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forging Etc.

Gr5 Titanium Bar

Brand: CXMET

Place Of Origin: China

Type: Titanium Bars

Application: Industrial

Technique: Hot Rolled

Shape: Round

Length: 50-6000mm

Titanium Welding Rod

Brand: CXMET

Place Of Origin: China

Grade: Gr1 Gr2 Gr7 Gr5

Ti (Min): 99.6%

Strength: 345MPa

Surface: Pickling Polished

Shape: Spool Coil Straight

Standard: ASTM B863

Certification: ISO9001:2015

Strength: 435MPa

Application: Industrial

Gr23 Ti 6AL4V Eli Medical Titanium Bar

Brand: CXMET

Place Of Origin: China

Grade: Gr23 Ti6AL4V Eli

Standard: ASTM F136

Specification: Dia4~100mm*(1000~3000)mm

Technique: Cold Rolling/Hot Rolling

Surface: Pickling/Polished

Application: industrial

High Standard Gr12 Titanium Alloy Bar

Brand: CXMET

Place Of Origin: China

Gr12 Titanium Alloy Bar/Titanium Sheet/Titanium Tube

Product specification range: Diameter 6-500mm, Length 0.5-30m

Product Specification Range: Thickness 0.5-80mm, length 1-12m, width 0.5-3m

Product Specification Range: OD 6-530mm, wall thickness 0.5-50mm

Length 1-12m

Shape: Round