- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How is Gr23 ERTi-23 Titanium Wire Used in Surgical Implants?

2025-03-22 15:07:49

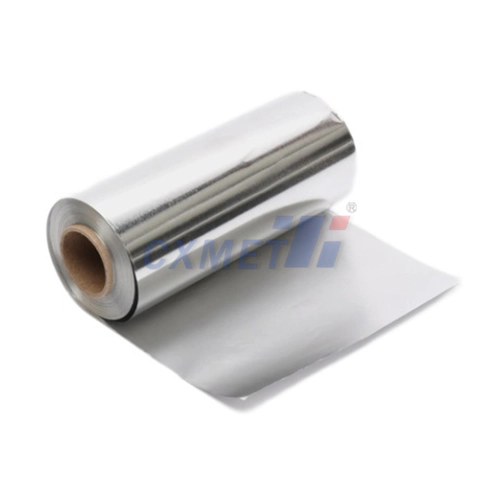

Gr23 ERTi-27 Medical Titanium Wire is a highly specialized material that has found extensive use in the field of surgical implants. This advanced titanium alloy combines exceptional strength, biocompatibility, and corrosion resistance, making it an ideal choice for various medical applications. In this blog post, we will explore the unique properties of Gr23 ERTi-23 Titanium Wire and its specific uses in surgical implants, focusing on how it enhances patient outcomes and revolutionizes medical procedures.

|

|

|

What are the advantages of using Gr23 ERTi-23 Titanium Wire in orthopedic implants?

Gr23 ERTi-27 Medical Titanium Wire offers numerous advantages when used in orthopedic implants, making it a preferred choice among surgeons and medical device manufacturers. Its exceptional properties contribute to improved patient outcomes and long-lasting implant performance.

One of the primary advantages of Gr23 ERTi-23 Titanium Wire is its outstanding strength-to-weight ratio. This characteristic allows for the creation of implants that are both strong and lightweight, reducing the overall burden on the patient's body while ensuring structural integrity. The high strength of the material enables it to withstand the significant stresses and loads experienced in orthopedic applications, such as joint replacements or spinal fusion devices.

Another crucial advantage is the material's excellent biocompatibility. Gr23 ERTi-23 Titanium Wire has a low risk of allergic reactions or rejection by the human body, making it safe for long-term implantation. This biocompatibility is attributed to the formation of a stable oxide layer on the surface of the titanium, which prevents corrosion and minimizes the release of metal ions into the surrounding tissues.

The corrosion resistance of Gr23 ERTi-23 Titanium Wire is particularly beneficial in the harsh environment of the human body. It can withstand the presence of bodily fluids and maintain its structural integrity over extended periods, reducing the need for revision surgeries and improving the overall lifespan of the implant.

Furthermore, the material's ability to osseointegrate is a significant advantage in orthopedic applications. Gr23 ERTi-23 Titanium Wire promotes bone ingrowth and attachment, leading to better fixation and stability of the implant. This property is especially crucial in applications such as dental implants, where a strong bond between the implant and the surrounding bone is essential for long-term success.

The versatility of Gr23 ERTi-23 Titanium Wire allows for its use in various orthopedic implants, including hip and knee replacements, spinal fusion cages, bone plates, and screws. Its ability to be easily machined and formed into complex shapes enables the creation of custom-designed implants tailored to individual patient needs, further improving surgical outcomes and patient satisfaction.

How does Gr23 ERTi-23 Titanium Wire contribute to the durability of cardiovascular implants?

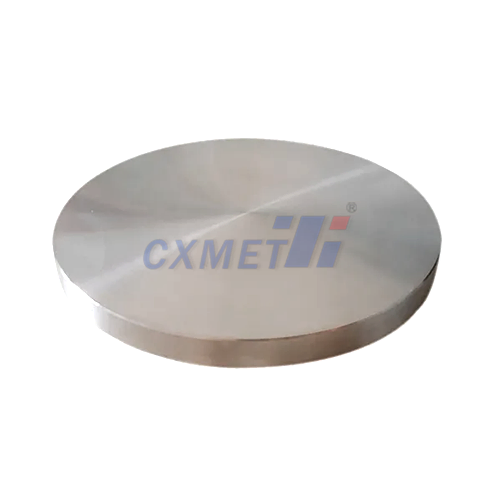

Gr23 ERTi-27 Medical Titanium Wire plays a crucial role in enhancing the durability and performance of cardiovascular implants. Its unique properties make it an excellent choice for applications such as stents, heart valve components, and pacemaker leads.

The exceptional strength of Gr23 ERTi-23 Titanium Wire contributes significantly to the durability of cardiovascular implants. In the case of stents, for example, the material's high strength allows for the creation of thin-walled devices that can maintain their shape and function under the constant pressure and movement of blood vessels. This strength ensures that the stent remains open and effective in maintaining blood flow over extended periods.

Corrosion resistance is another critical factor in the durability of cardiovascular implants. The human cardiovascular system presents a highly corrosive environment, with constant exposure to blood and other bodily fluids. Gr23 ERTi-23 Titanium Wire's excellent corrosion resistance helps prevent degradation of the implant over time, maintaining its structural integrity and functionality. This resistance to corrosion also minimizes the release of metal ions into the bloodstream, reducing the risk of adverse reactions or complications.

The fatigue resistance of Gr23 ERTi-23 Titanium Wire is particularly important in cardiovascular applications. Implants such as heart valve components are subjected to cyclic loading due to the continuous beating of the heart. The material's ability to withstand these repeated stresses without failure contributes to the long-term durability and reliability of the implant, reducing the need for replacement surgeries and improving patient outcomes.

|

|

|

What role does Gr23 ERTi-23 Titanium Wire play in the development of advanced dental implants?

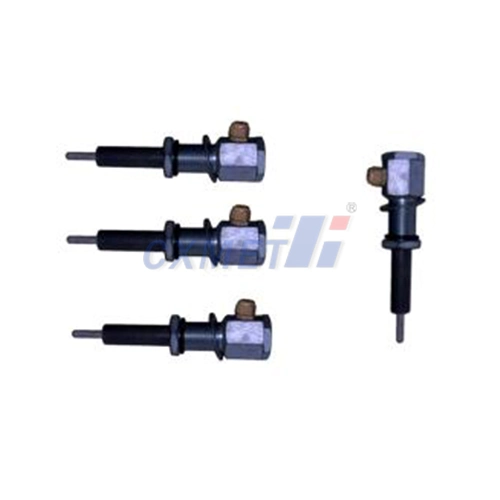

Gr23 ERTi-27 Medical Titanium Wire has become an integral component in the development of advanced dental implants, contributing to significant improvements in both the performance and longevity of these devices. Its unique properties make it particularly well-suited for the challenging environment of the oral cavity and the specific requirements of dental implantology.

One of the primary roles of Gr23 ERTi-23 Titanium Wire in dental implants is to provide a strong and stable foundation for artificial teeth. The material's high strength-to-weight ratio allows for the creation of implants that can withstand the substantial forces exerted during chewing and biting while remaining lightweight and comfortable for the patient. This strength ensures that the implant can effectively distribute loads to the surrounding bone, mimicking the function of natural tooth roots.

The exceptional biocompatibility of Gr23 ERTi-23 Titanium Wire is crucial in dental applications. The oral environment is particularly challenging, with constant exposure to saliva, varying pH levels, and bacteria. The material's ability to resist corrosion and maintain its integrity in this environment is essential for the long-term success of dental implants. Additionally, its low risk of allergic reactions or rejection by the body makes it a safe choice for a wide range of patients.

Perhaps the most significant role of Gr23 ERTi-23 Titanium Wire in dental implants is its ability to promote osseointegration. This process, where the bone grows directly onto and into the surface of the implant, is critical for the stability and longevity of dental implants. The surface properties of Gr23 ERTi-23 Titanium Wire can be modified to enhance this bone-to-implant contact, promoting faster and more complete integration with the surrounding bone tissue. This strong bond between the implant and the jawbone provides a stable foundation for the artificial tooth and helps preserve the surrounding bone structure over time.

In the development of advanced dental implants, Gr23 ERTi-23 Titanium Wire has enabled the creation of more sophisticated designs. Its machinability allows for the production of implants with precise micro-textures and complex geometries that can further enhance osseointegration and biomechanical performance. This includes the development of implants with threaded designs for improved initial stability and surface treatments that mimic the natural structure of bone.

The material's properties also contribute to the versatility of dental implants. Gr23 ERTi-23 Titanium Wire can be used to create implants of various sizes and shapes, allowing for customized solutions to meet individual patient needs. This flexibility is particularly important in cases where bone volume is limited or in complex reconstructive procedures.

Furthermore, the use of Gr23 ERTi-23 Titanium Wire in dental implants has facilitated the development of immediate loading protocols. The material's strength and osseointegration properties allow for the placement of temporary or permanent crowns immediately after implant insertion in suitable cases, reducing treatment times and improving patient satisfaction.

In conclusion, Gr23 ERTi-27 Medical Titanium Wire has revolutionized the field of surgical implants, particularly in orthopedics, cardiovascular applications, and dentistry. Its unique combination of strength, biocompatibility, corrosion resistance, and osseointegration properties has enabled the development of more durable, effective, and patient-friendly implants. As research continues and manufacturing techniques advance, we can expect to see even more innovative applications of this remarkable material in the future, further improving patient outcomes and quality of life.

At SHAANXI CXMET TECHNOLOGY CO., LTD, we take pride in our extensive product range, which caters to diverse customer needs. Our company is equipped with outstanding production and processing capabilities, ensuring the high quality and precision of our products. We are committed to innovation and continuously strive to develop new products, keeping us at the forefront of our industry. With leading technological development capabilities, we are able to adapt and evolve in a rapidly changing market. Furthermore, we offer customized solutions to meet the specific requirements of our clients. If you are interested in our products or wish to learn more about the intricate details of our offerings, please do not hesitate to contact us at sales@cxmet.com. Our team is always ready to assist you.

|

|

|

|

References

- Niinomi, M. (2019). Titanium Alloys for Biomedical Applications. In Titanium in Medical and Dental Applications (pp. 355-382). Woodhead Publishing.

- Elias, C. N., Lima, J. H. C., Valiev, R., & Meyers, M. A. (2008). Biomedical applications of titanium and its alloys. JOM, 60(3), 46-49.

- Ratner, B. D., Hoffman, A. S., Schoen, F. J., & Lemons, J. E. (Eds.). (2013). Biomaterials science: an introduction to materials in medicine. Academic press.

- Rack, H. J., & Qazi, J. I. (2006). Titanium alloys for biomedical applications. Materials Science and Engineering: C, 26(8), 1269-1277.

- Brunette, D. M., Tengvall, P., Textor, M., & Thomsen, P. (Eds.). (2012). Titanium in medicine: material science, surface science, engineering, biological responses and medical applications. Springer Science & Business Media.

- Geetha, M., Singh, A. K., Asokamani, R., & Gogia, A. K. (2009). Ti based biomaterials, the ultimate choice for orthopaedic implants–a review. Progress in materials science, 54(3), 397-425.

- Hanawa, T. (2019). Titanium-tissue interface reaction and its control with surface treatment. Frontiers in bioengineering and biotechnology, 7, 170.

- Liu, X., Chu, P. K., & Ding, C. (2004). Surface modification of titanium, titanium alloys, and related materials for biomedical applications. Materials Science and Engineering: R: Reports, 47(3-4), 49-121.

- Oshida, Y. (2013). Bioscience and bioengineering of titanium materials. Elsevier.

- Oldani, C., & Dominguez, A. (2012). Titanium as a biomaterial for implants. In Recent advances in arthroplasty. IntechOpen.