- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How is Titanium Grade 4 Round Bar Produced?

2024-08-16 11:21:50

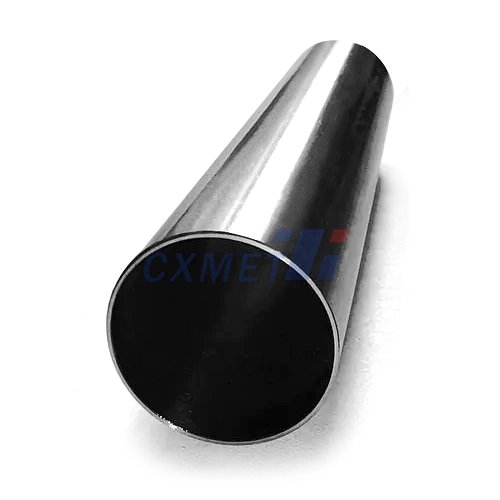

Titanium Grade 4 Round Bar, also known as commercially pure (CP) titanium grade 4, is a high-strength titanium alloy widely used in various industries due to its excellent corrosion resistance, biocompatibility, and mechanical properties. The production of Titanium Grade 4 Round Bar involves a complex process that combines advanced metallurgical techniques and precise manufacturing methods. This blog post will delve into the intricacies of producing this versatile material, exploring the key steps and considerations involved in its manufacture.

What are the key steps in manufacturing Titanium Grade 4 Round Bar?

The production of Titanium Grade 4 Round Bar begins with the extraction of titanium from its ore, typically ilmenite or rutile. This process, known as the Kroll process, involves several stages to obtain pure titanium sponge. The titanium sponge is then melted and alloyed with small amounts of iron, carbon, nitrogen, and oxygen to achieve the specific composition of Grade 4 titanium.

Once the alloy composition is achieved, the material undergoes a series of forming processes to create the round bar shape. This typically starts with ingot casting, where the molten titanium alloy is poured into molds and allowed to solidify. The resulting ingots are then subjected to primary forming operations such as forging or rolling to break down the cast structure and improve the material's mechanical properties.

The next crucial step in the manufacturing process is hot working. The titanium alloy is heated to temperatures above its recrystallization point (typically around 800-950°C for Grade 4 titanium) and then shaped using various techniques such as extrusion, rolling, or forging. This hot working process helps to refine the grain structure, improve uniformity, and enhance the material's overall strength and ductility.

After hot working, the titanium round bar may undergo cold working processes to further refine its dimensions and surface finish. This can include cold drawing or turning operations, which help achieve tighter tolerances and improve the material's mechanical properties through work hardening.

Throughout the manufacturing process, strict quality control measures are implemented to ensure the Titanium Grade 4 Round Bar meets the required specifications. This includes regular testing of chemical composition, microstructure analysis, and mechanical property evaluations to verify that the material conforms to industry standards such as ASTM B348 or AMS 4928.

How does heat treatment affect the properties of Titanium Grade 4 Round Bar?

Heat treatment plays a crucial role in optimizing the properties of Titanium Grade 4 Round Bar. While Grade 4 titanium is not typically heat-treatable in the same way as some other titanium alloys, specific heat treatment processes can be applied to achieve desired characteristics and relieve internal stresses induced during manufacturing.

One common heat treatment process for Titanium Grade 4 Round Bar is stress relieving. This involves heating the material to temperatures between 480-650°C for a specified time, followed by slow cooling. Stress relieving helps to reduce residual stresses that may have developed during forming or machining operations, improving dimensional stability and reducing the risk of warpage or distortion in subsequent processing or service.

Annealing is another heat treatment process that can be applied to Titanium Grade 4 Round Bar. Full annealing typically involves heating the material to temperatures around 700-785°C, holding for a specific time, and then slow cooling. This process helps to soften the material, increase ductility, and improve machinability. Annealing can be particularly beneficial when the round bar needs to undergo extensive machining or forming operations.

It's important to note that heat treatment of Titanium Grade 4 Round Bar must be carefully controlled to avoid excessive grain growth or contamination. The high affinity of titanium for oxygen and nitrogen at elevated temperatures necessitates the use of protective atmospheres or vacuum heat treatment methods to prevent surface embrittlement.

The heat treatment process can also influence the microstructure of the Titanium Grade 4 Round Bar, affecting its mechanical properties and corrosion resistance. By carefully controlling the heating and cooling rates, manufacturers can optimize the balance between strength and ductility to meet specific application requirements.

What are the challenges in quality control for Titanium Grade 4 Round Bar production?

Ensuring consistent quality in the production of Titanium Grade 4 Round Bar presents several challenges that manufacturers must address through rigorous quality control measures. One of the primary concerns is maintaining the precise chemical composition specified for Grade 4 titanium. This requires careful control of alloying elements and impurities throughout the melting and casting processes.

Non-destructive testing (NDT) plays a crucial role in quality control for Titanium Grade 4 Round Bar. Techniques such as ultrasonic testing, eddy current inspection, and radiographic examination are employed to detect internal defects, inclusions, or inhomogeneities that could compromise the material's performance. These NDT methods allow manufacturers to identify and address potential issues without sacrificing the integrity of the product.

Surface quality is another critical aspect of Titanium Grade 4 Round Bar production that requires careful monitoring. The high reactivity of titanium at elevated temperatures can lead to surface contamination or the formation of an alpha case layer, which can negatively impact the material's properties. Manufacturers must implement stringent controls during hot working and heat treatment processes to minimize these issues and may employ techniques such as acid pickling or mechanical removal to eliminate any compromised surface layers.

Dimensional accuracy and consistency are also key challenges in Titanium Grade 4 Round Bar production. The material's high strength-to-weight ratio and unique mechanical properties can make it more difficult to achieve tight tolerances compared to some other metals. Advanced machining techniques, precise process control, and regular dimensional inspections are essential to ensure that the round bars meet the required specifications.

Microstructure control is another critical aspect of quality assurance in Titanium Grade 4 Round Bar production. The grain size, orientation, and distribution can significantly influence the material's mechanical properties and performance. Manufacturers must carefully manage the thermomechanical processing parameters to achieve the desired microstructure and may employ techniques such as optical microscopy or electron backscatter diffraction (EBSD) to verify the material's microstructural characteristics.

Lastly, lot traceability and documentation present ongoing challenges in the production of Titanium Grade 4 Round Bar. Given the material's critical applications in industries such as aerospace and medical devices, maintaining comprehensive records of raw material sources, processing parameters, and test results is essential. Implementing robust tracking systems and adhering to industry standards for documentation helps ensure that each batch of Titanium Grade 4 Round Bar can be traced back to its origin and that all quality requirements have been met.

By addressing these challenges through advanced manufacturing techniques, stringent process controls, and comprehensive quality assurance programs, producers of Titanium Grade 4 Round Bar can consistently deliver high-quality materials that meet the exacting standards of their customers across various industries.

At SHAANXI CXMET TECHNOLOGY CO., LTD, we take pride in our extensive product range, which caters to diverse customer needs. Our company is equipped with outstanding production and processing capabilities, ensuring the high quality and precision of our products. We are committed to innovation and continuously strive to develop new products, keeping us at the forefront of our industry. With leading technological development capabilities, we are able to adapt and evolve in a rapidly changing market. Furthermore, we offer customized solutions to meet the specific requirements of our clients. If you are interested in our products or wish to learn more about the intricate details of our offerings, please do not hesitate to contact us at sales@cxmet.com. Our team is always ready to assist you.

References:

1. ASTM International. (2020). ASTM B348 - Standard Specification for Titanium and Titanium Alloy Bars and Billets.

2. Boyer, R., Welsch, G., & Collings, E. W. (1994). Materials Properties Handbook: Titanium Alloys. ASM International.

3. Froes, F. H. (2015). Titanium: Physical Metallurgy, Processing, and Applications. ASM International.

4. Leyens, C., & Peters, M. (Eds.). (2003). Titanium and Titanium Alloys: Fundamentals and Applications. John Wiley & Sons.

5. Lütjering, G., & Williams, J. C. (2007). Titanium. Springer Science & Business Media.

6. Matthew, J., & Donachie, J. (2000). Titanium: A Technical Guide. ASM International.

7. Peters, M., Hemptenmacher, J., Kumpfert, J., & Leyens, C. (2003). Structure and Properties of Titanium and Titanium Alloys. In Titanium and Titanium Alloys: Fundamentals and Applications (pp. 1-36). Wiley-VCH.

8. Rack, H. J., & Qazi, J. I. (2006). Titanium alloys for biomedical applications. Materials Science and Engineering: C, 26(8), 1269-1277.

9. Seagle, S. R., & Wood, J. R. (1994). Titanium and Titanium Alloys. In ASM Handbook, Volume 2: Properties and Selection: Nonferrous Alloys and Special-Purpose Materials (pp. 592-633). ASM International.

10. Veiga, C., Davim, J. P., & Loureiro, A. J. R. (2012). Properties and applications of titanium alloys: A brief review. Reviews on Advanced Materials Science, 32(2), 133-148.

.webp)