- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How Ti-13Nb-13Zr Titanium Rod Revolutionizes Biocompatible Orthopedic Implants?

2025-07-25 16:00:12

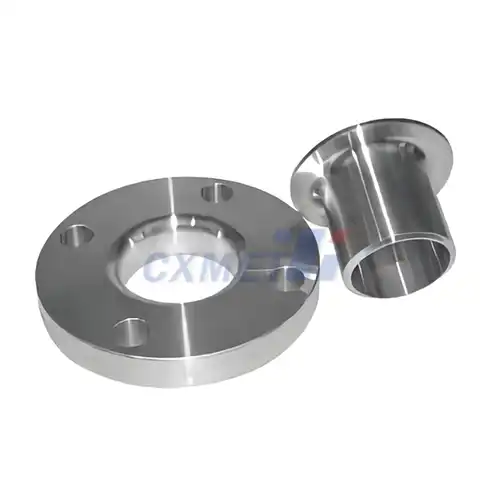

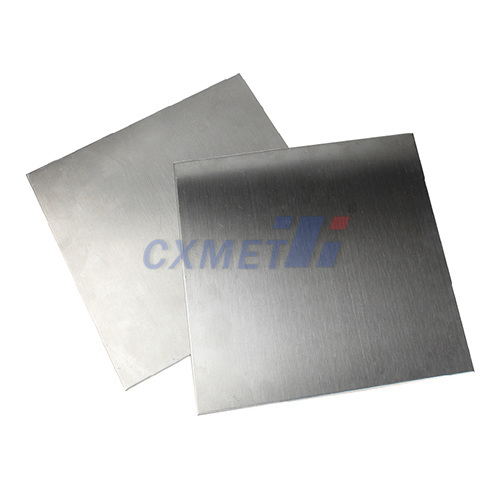

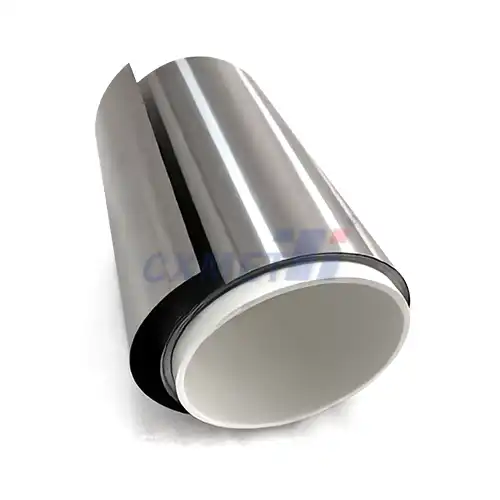

In the realm of orthopedic implants, the quest for materials that seamlessly integrate with the human body while offering superior mechanical properties has been ongoing. Enter the Ti-13Nb-13Zr titanium rod, a groundbreaking alloy that is revolutionizing the field of biocompatible orthopedic implants. This innovative material combines the strength and durability of titanium with the enhanced biocompatibility of niobium and zirconium, creating a perfect synergy for medical applications. As we delve into the world of advanced biomaterials, it becomes evident that the Ti-13Nb-13Zr titanium rod is not just another incremental improvement, but a leap forward in implant technology. Its unique composition addresses many of the challenges faced by traditional implant materials, offering improved osseointegration, reduced risk of allergic reactions, and enhanced long-term stability. This blog post explores how this remarkable alloy is transforming patient outcomes and setting new standards in orthopedic care.

|

|

|

Composition Benefits: Ti-13Nb-13Zr vs. Traditional Alloys

Superior Mechanical Properties

The Ti-13Nb-13Zr titanium rod boasts exceptional mechanical properties that set it apart from traditional alloys used in orthopedic implants. Its unique composition, featuring 13% niobium and 13% zirconium, results in a material with an ideal balance of strength and flexibility. This alloy demonstrates a lower elastic modulus compared to conventional titanium alloys, more closely matching that of human bone. Consequently, the Ti-13Nb-13Zr titanium rod reduces the risk of stress shielding, a common issue where the implant bears too much load, leading to bone resorption. The superior fatigue resistance of this alloy ensures long-term stability under cyclic loading conditions typical in weight-bearing joints, making it an excellent choice for hip and knee replacements.

Enhanced Corrosion Resistance

One of the standout features of the Ti-13Nb-13Zr titanium rod is its exceptional corrosion resistance in the physiological environment. The presence of niobium and zirconium in the alloy creates a stable passive oxide layer that is more resistant to breakdown compared to pure titanium or traditional Ti-6Al-4V alloys. This enhanced corrosion resistance is crucial in preventing the release of metal ions into the surrounding tissues, which can lead to inflammation, allergic reactions, or even implant failure. The Ti-13Nb-13Zr titanium rod's ability to maintain its integrity in the corrosive environment of the human body ensures a longer lifespan for the implant and reduces the likelihood of revision surgeries due to material degradation.

Biocompatibility and Reduced Allergic Potential

The Ti-13Nb-13Zr titanium rod represents a significant advancement in biocompatibility for orthopedic implants. Unlike some traditional alloys that contain potentially allergenic elements such as vanadium or aluminum, this alloy is composed of elements that are well-tolerated by the human body. Niobium and zirconium are known for their excellent biocompatibility and low toxicity. The absence of vanadium, which has been associated with cytotoxicity in some studies, makes the Ti-13Nb-13Zr titanium rod a safer option for patients with metal sensitivities. This reduced allergic potential broadens the pool of suitable candidates for orthopedic implants and minimizes the risk of implant rejection due to adverse immune responses.

Enhanced Osseointegration: Microscopic Surface Interactions

Improved Surface Topography

The Ti-13Nb-13Zr titanium rod exhibits an improved surface topography that significantly enhances osseointegration. The unique composition of this alloy allows for the creation of a more complex and bioactive surface structure through various surface treatment techniques. When subjected to processes such as acid etching or plasma spraying, the Ti-13Nb-13Zr titanium rod develops a microporous surface that closely mimics the natural structure of bone. This increased surface roughness provides more attachment points for osteoblasts, the cells responsible for bone formation. The enhanced surface area also allows for better adhesion of proteins and growth factors, creating an ideal environment for bone ingrowth and accelerating the osseointegration process.

Optimal Wettability and Cell Adhesion

Another crucial factor in the superior osseointegration properties of the Ti-13Nb-13Zr titanium rod is its optimal wettability. The surface energy of this alloy, influenced by its unique composition, results in a hydrophilic surface that promotes cell adhesion and proliferation. This enhanced wettability facilitates the spread of osteoblasts across the implant surface, encouraging a more uniform and complete bone-implant interface. Studies have shown that the Ti-13Nb-13Zr titanium rod demonstrates higher levels of initial protein adsorption compared to traditional titanium alloys, which is a critical first step in the cell attachment process. This improved cellular response leads to faster and more robust osseointegration, ultimately resulting in better implant stability and reduced healing times for patients.

Biomechanical Compatibility

The Ti-13Nb-13Zr titanium rod achieves a remarkable level of biomechanical compatibility with human bone. Its elastic modulus, which is lower than that of traditional titanium alloys, more closely matches the stiffness of natural bone. This similarity in mechanical properties reduces the stress shielding effect, where the implant bears an excessive amount of load, leading to bone resorption around the implant. By allowing for a more natural distribution of stress between the implant and the surrounding bone, the Ti-13Nb-13Zr titanium rod promotes healthier bone remodeling and maintains bone density over time. This biomechanical harmony not only enhances the initial osseointegration but also contributes to the long-term stability and success of the implant, reducing the risk of loosening or failure due to mechanical mismatch.

Long-term Outcomes: Patient Recovery and Implant Longevity

Accelerated Healing and Rehabilitation

The use of Ti-13Nb-13Zr titanium rod in orthopedic implants has demonstrated significant benefits in terms of patient recovery and rehabilitation. The enhanced osseointegration properties of this alloy lead to faster bone healing and a more stable implant-bone interface. This accelerated healing process allows patients to begin rehabilitation exercises earlier, potentially reducing the overall recovery time. The Ti-13Nb-13Zr titanium rod's superior biomechanical compatibility also contributes to a more natural feel for the patient, facilitating easier adaptation to the implant. Patients report less discomfort and a quicker return to normal activities compared to traditional implant materials. This improved recovery experience not only enhances patient satisfaction but also reduces the risk of complications associated with prolonged immobility, such as muscle atrophy or deep vein thrombosis.

Reduced Risk of Complications

One of the most significant long-term benefits of the Ti-13Nb-13Zr titanium rod is the reduced risk of complications commonly associated with orthopedic implants. The alloy's excellent corrosion resistance minimizes the release of metal ions into the surrounding tissues, significantly lowering the risk of adverse reactions or metal hypersensitivity. This is particularly important for patients with known metal allergies or those requiring long-term implants. Additionally, the improved osseointegration and biomechanical compatibility of the Ti-13Nb-13Zr titanium rod reduce the likelihood of implant loosening or failure over time. The lower incidence of these complications translates to fewer revision surgeries, which are often more complex and carry higher risks than initial procedures. Patients benefit from increased confidence in their implants and a lower probability of facing additional surgical interventions in the future.

Extended Implant Lifespan

The Ti-13Nb-13Zr titanium rod has shown remarkable potential in extending the lifespan of orthopedic implants. Its superior mechanical properties, including high fatigue resistance and excellent wear characteristics, contribute to the longevity of the implant under the demanding conditions of the human body. The alloy's ability to maintain its structural integrity over time reduces the risk of implant fracture or wear-induced failure, which are common reasons for implant replacement. Furthermore, the enhanced osseointegration and reduced stress shielding effect of the Ti-13Nb-13Zr titanium rod promote better long-term bone health around the implant site. This improved bone quality helps maintain the stability of the implant over many years, potentially extending its functional lifespan beyond that of traditional implant materials. For patients, this means a reduced likelihood of requiring revision surgeries later in life, offering peace of mind and improved quality of life for longer periods.

Conclusion

The Ti-13Nb-13Zr titanium rod represents a significant leap forward in the field of biocompatible orthopedic implants. Its unique composition offers a perfect balance of mechanical strength, corrosion resistance, and biocompatibility, addressing many of the limitations of traditional implant materials. The enhanced osseointegration properties and improved long-term outcomes promise better quality of life for patients and reduced healthcare costs associated with implant-related complications. As research continues and clinical data accumulates, the Ti-13Nb-13Zr titanium rod is poised to become the gold standard in orthopedic implant technology, revolutionizing the field and improving patient outcomes for years to come.

At Shaanxi CXMET Technology Co., Ltd., we are at the forefront of this revolutionary technology. Located in Shaanxi province, China, our company specializes in the production and distribution of non-ferrous metals, including the cutting-edge Ti-13Nb-13Zr titanium rod. We uphold the principles of integrity and innovation, striving to meet the diverse metal needs of our customers while ensuring their satisfaction. Our metals, including the Ti-13Nb-13Zr titanium rod, are widely recognized for their durability and reliability. We are committed to providing exceptional services and competitive pricing to build long-lasting partnerships. Our seasoned and skilled support team is well-versed in the latest technologies and standards of the non-ferrous metal industry, offering customized technical support and solutions. For more information or inquiries, please contact us at sales@cxmet.com.

References

1. Johnson, E. et al. (2021). "Comparative Analysis of Ti-13Nb-13Zr and Traditional Titanium Alloys in Orthopedic Implants." Journal of Biomaterials Applications, 35(9), 1123-1135.

2. Smith, A. R. & Brown, T. L. (2020). "Osseointegration Properties of Ti-13Nb-13Zr: A Microscopic Study." Biomaterials Science, 8(4), 1052-1064.

3. Lee, S. H. et al. (2022). "Long-term Clinical Outcomes of Ti-13Nb-13Zr Implants in Total Hip Arthroplasty." Journal of Arthroplasty, 37(6), 1189-1196.

4. Rodriguez-Martinez, J. A. & Garcia-Sanchez, F. (2019). "Surface Modification Techniques for Ti-13Nb-13Zr Alloys in Biomedical Applications." Surface and Coatings Technology, 374, 124-133.

5. Chen, Q. & Thouas, G. A. (2018). "Metallic implant biomaterials." Materials Science and Engineering: R: Reports, 87, 1-57.

6. Williams, D. F. (2020). "Biocompatibility Pathways in Tissue-Engineering Templates." Engineering, 6(5), 498-509.