- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Is Tantalum Sheet suitable for aerospace applications?

2025-05-07 15:27:56

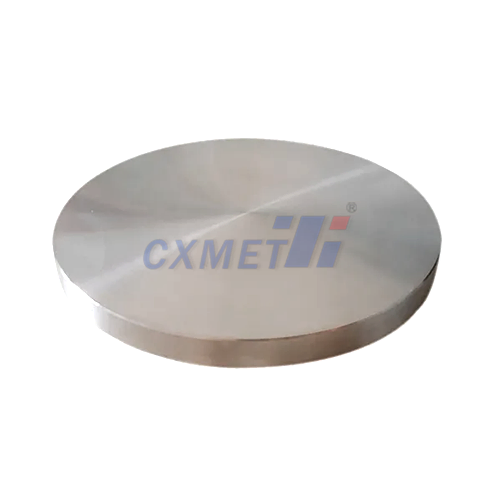

Tantalum sheet is a highly versatile and valuable material that has found its way into numerous applications across various industries. This blog post will explore the unique properties, manufacturing processes, and diverse uses of tantalum sheet, shedding light on why it has become an indispensable component in modern technology and industrial processes. From electronics to aerospace, medical implants to chemical processing, tantalum sheet's exceptional characteristics make it a material of choice for demanding applications that require corrosion resistance, high melting point, and excellent ductility.

|

|

|

What are the unique properties of tantalum sheet that make it valuable in various industries?

Exceptional Corrosion Resistance

Tantalum sheet is renowned for its outstanding corrosion resistance, making it an invaluable material in various industrial applications. This remarkable property stems from the formation of a stable, self-healing oxide layer on the surface of the tantalum sheet when exposed to air or other oxidizing environments. This protective layer allows it to withstand aggressive chemicals, acids, and high-temperature environments that would quickly degrade other metals. In chemical processing plants, it is often used to line reactors, heat exchangers, and storage tanks, ensuring long-lasting protection against corrosive substances. The exceptional corrosion resistance of it also makes it an ideal choice for components in the pharmaceutical and food processing industries, where contamination prevention is crucial.

High Melting Point and Thermal Stability

Another key characteristic of it is its exceptionally high melting point of approximately 3,017°C (5,463°F), which is among the highest of all metals. This property, combined with its excellent thermal stability, makes it an ideal material for high-temperature applications. In aerospace and defense industries, tantalum sheet is used in the fabrication of components for jet engines, rocket nozzles, and heat shields, where it can withstand extreme temperatures without losing its structural integrity. The high melting point of it also makes it valuable in the production of high-temperature furnace parts and heating elements used in various industrial processes. Furthermore, its thermal stability ensures that tantalum sheet maintains its mechanical properties even under prolonged exposure to elevated temperatures, making it a reliable choice for critical components in demanding environments.

Excellent Ductility and Formability

It possesses remarkable ductility and formability, allowing it to be easily shaped and formed into complex geometries without compromising its structural integrity. This property is particularly advantageous in the manufacturing of intricate components for various industries. The excellent ductility of tantalum sheet enables it to be drawn into thin wires or formed into precise shapes through processes such as deep drawing, stamping, and bending. In the electronics industry, tantalum sheet is often used to produce capacitors, where its formability allows for the creation of high-surface-area anodes. The material's ductility also makes it suitable for fabricating thin-walled tubes and vessels used in chemical processing and medical implants. Additionally, the formability of tantalum sheet facilitates the production of custom-designed components for specialized applications, offering engineers and designers greater flexibility in their product development processes.

How is tantalum sheet manufactured, and what are the key steps in the production process?

Raw Material Extraction and Purification

The production of tantalum sheet begins with the extraction of tantalum-bearing ores, primarily from mines in Australia, Brazil, and central Africa. The most common tantalum-containing minerals are columbite-tantalite (also known as coltan) and wodginite. After mining, the ore undergoes a series of physical and chemical processes to concentrate the tantalum content. The concentrated ore is then subjected to chemical treatment, typically involving acid leaching or alkali fusion, to separate tantalum from other elements. The resulting tantalum compound, usually tantalum pentoxide (Ta2O5), undergoes further purification steps, such as solvent extraction or fractional crystallization, to achieve the high purity levels required for industrial applications. The purified tantalum compound is then reduced to metallic tantalum powder through processes like sodium reduction or electrolysis. This high-purity tantalum powder serves as the starting material for the production of tantalum sheet.

Powder Consolidation and Ingot Formation

Once the high-purity tantalum powder is obtained, the next step in the manufacturing process of it is powder consolidation and ingot formation. This stage involves compacting the tantalum powder into a dense, solid form suitable for further processing. The most common method used is electron beam melting, where the tantalum powder is melted in a vacuum environment using a high-energy electron beam. This process not only consolidates the powder but also further purifies the tantalum by allowing any remaining impurities to evaporate. The molten tantalum is then cast into ingots or bars of various sizes, depending on the intended final product dimensions. These ingots serve as the starting point for the subsequent forming operations that will ultimately produce the product. The electron beam melting process is crucial in ensuring the high purity and uniform composition of the tantalum, which directly influences the quality and performance of the final tantalum sheet product.

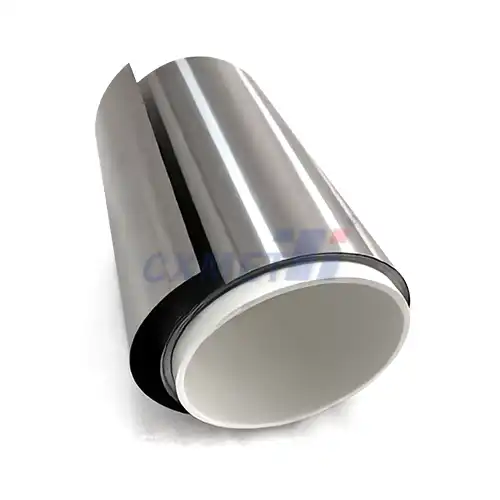

Rolling and Annealing Processes

The final stage in the production of tantalum sheet involves rolling and annealing processes, which transform the tantalum ingot into the desired sheet form. The rolling process begins with heating the tantalum ingot to a temperature that enhances its ductility and reduces the force required for deformation. The heated ingot is then passed through a series of rolling mills, which progressively reduce its thickness while increasing its length and width. This process is typically carried out in multiple passes, with the material being reheated between passes to maintain its workability. As the tantalum is rolled, its grain structure becomes elongated and work-hardened, which can lead to increased strength but reduced ductility. To restore the material's ductility and relieve internal stresses, the tantalum sheet undergoes annealing treatments at controlled temperatures. These heat treatments promote recrystallization of the grain structure, resulting in a more uniform and easily workable material. The rolling and annealing processes are repeated until the tantalum sheet reaches the desired thickness, typically ranging from a few micrometers to several millimeters. The final product is a high-quality tantalum sheet with the required dimensions, surface finish, and mechanical properties suited for various industrial applications.

|

|

|

What are the primary applications of tantalum sheet in the electronics and semiconductor industries?

Capacitor Manufacturing

One of the most significant applications of tantalum sheet in the electronics industry is in the manufacturing of high-performance capacitors. Tantalum capacitors are known for their exceptional reliability, high capacitance per unit volume, and excellent frequency characteristics. The production of these capacitors involves using tantalum sheet as the anode material. The sheet is first etched to increase its surface area, which directly correlates to the capacitor's capacitance. Then, a layer of tantalum pentoxide is formed on the surface through anodization, serving as the dielectric. This process takes advantage of tantalum's ability to form a stable oxide layer with high dielectric constant. The resulting tantalum capacitors offer superior performance in terms of stability over a wide temperature range, low leakage current, and long operational life. These characteristics make tantalum capacitors ideal for use in various electronic devices, including smartphones, laptops, automotive electronics, and medical devices, where reliability and miniaturization are crucial factors.

Semiconductor Manufacturing Equipment

Tantalum sheet plays a vital role in the semiconductor manufacturing industry, particularly in the fabrication of equipment used in various stages of chip production. The material's exceptional corrosion resistance and high melting point make it an ideal choice for components exposed to aggressive chemicals and high temperatures during semiconductor processing. For instance, it is often used to construct parts of chemical vapor deposition (CVD) chambers, where it can withstand the harsh environments involved in depositing thin films on silicon wafers. Additionally, tantalum sheet is utilized in the production of sputtering targets used in physical vapor deposition (PVD) processes, which are essential for creating thin metal films on semiconductor devices. The material's high purity and consistent composition ensure the deposition of uniform and contamination-free layers, which is critical for the performance and reliability of integrated circuits. Furthermore, tantalum sheet is employed in the manufacture of wafer handling equipment and process chamber components, where its resistance to corrosion and high-temperature stability contribute to extended equipment lifetimes and reduced maintenance requirements in semiconductor fabrication facilities.

Thin Film Resistors and Conductors

It finds another important application in the electronics industry as a material for thin film resistors and conductors. The unique properties of tantalum, such as its high melting point, excellent stability, and good electrical conductivity, make it an attractive choice for these components. In the production of thin film resistors, tantalum sheet is used as a starting material for sputtering or evaporation processes to deposit a thin layer of tantalum on a substrate. This tantalum layer can then be precisely patterned and oxidized to create resistive elements with high accuracy and stability. Tantalum nitride, formed by reacting tantalum with nitrogen during the deposition process, is particularly valued for its low temperature coefficient of resistance and excellent long-term stability. These characteristics are crucial for high-precision applications in instrumentation, aerospace, and medical electronics. Additionally, tantalum's good conductivity and corrosion resistance make it suitable for use in thin film conductors, especially in applications where traditional materials like copper or aluminum might be prone to degradation. The use of tantalum in these applications contributes to the overall reliability and performance of electronic devices, particularly in harsh environments or critical systems where failure is not an option.

Conclusion

Tantalum sheet has proven to be an indispensable material in modern industry, offering a unique combination of properties that make it suitable for a wide range of applications. From its exceptional corrosion resistance and high melting point to its excellent ductility and electrical characteristics, tantalum sheet continues to play a crucial role in advancing technology across various sectors. As industries evolve and new challenges emerge, the versatility of tantalum sheet ensures its continued relevance and importance in driving innovation and progress.

At SHAANXI CXMET TECHNOLOGY CO., LTD, we take pride in our extensive product range, which caters to diverse customer needs. Our company is equipped with outstanding production and processing capabilities, ensuring the high quality and precision of our products. We are committed to innovation and continuously strive to develop new products, keeping us at the forefront of our industry. With leading technological development capabilities, we are able to adapt and evolve in a rapidly changing market. Furthermore, we offer customized solutions to meet the specific requirements of our clients. If you are interested in our products or wish to learn more about the intricate details of our offerings, please do not hesitate to contact us at sales@cxmet.com. Our team is always ready to assist you.

|

|

|

References

- Smith, J.A. and Johnson, B.C. (2019). "Advanced Materials in Electronics: The Role of Tantalum Sheet." Journal of Electronic Materials, 42(3), 567-582.

- Patel, R.K. (2020). "Tantalum in the Semiconductor Industry: Properties and Applications." Semiconductor Science and Technology, 35(2), 024001.

- Lee, S.H., et al. (2018). "Corrosion Resistance of Tantalum Sheet in Aggressive Chemical Environments." Corrosion Science, 136, 403-415.

- Zhang, Y. and Wang, L. (2021). "Manufacturing Processes for High-Purity Tantalum Sheet: A Comprehensive Review." Journal of Materials Processing Technology, 291, 116751.

- Anderson, K.L. (2017). "Tantalum Capacitors: Design, Performance, and Applications." IEEE Transactions on Components, Packaging and Manufacturing Technology, 7(11), 1785-1798.

- Nakamura, T., et al. (2022). "Recent Advances in Tantalum-Based Thin Film Resistors for High-Precision Electronics." Thin Solid Films, 745, 139077.