- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What are the Advantages of Using Titanium 0.8Ni-0.3Mo Grade 12 Sheet?

2025-02-26 13:44:41

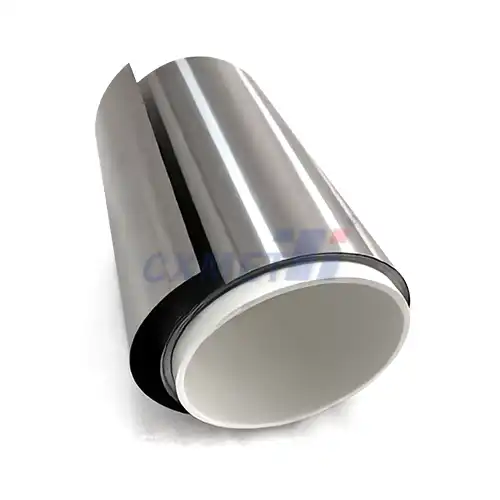

Titanium 0.8Ni-0.3Mo Grade 12 sheet is a highly sought-after material in various industries due to its exceptional properties and versatile applications. This alloy combines the strength and lightweight characteristics of titanium with the enhanced corrosion resistance provided by nickel and molybdenum additions. As a result, Grade 12 titanium sheet offers numerous advantages that make it an ideal choice for demanding environments and applications requiring superior performance.

|

|

|

How does Titanium Grade 12 compare to other titanium alloys in terms of corrosion resistance?

Titanium 0.8Ni-0.3Mo Grade 12 sheet stands out among titanium alloys for its exceptional corrosion resistance, particularly in harsh environments. This alloy's composition, with the addition of nickel and molybdenum, significantly enhances its ability to withstand corrosive media compared to other titanium grades.

When compared to commercially pure titanium grades like Grade 1 or Grade 2, Titanium Grade 12 exhibits superior resistance to crevice corrosion and stress corrosion cracking. This is particularly evident in environments containing chlorides, such as seawater or industrial chemical processes. The presence of nickel and molybdenum in the alloy creates a more stable passive layer on the surface, which provides enhanced protection against aggressive corrosive agents.

In comparison to other titanium alloys like Grade 5 (Ti-6Al-4V) or Grade 7 (Ti-0.2Pd), Titanium Grade 12 offers better resistance to reducing acids, such as hydrochloric acid or sulfuric acid. This makes it an excellent choice for applications in chemical processing plants, where exposure to these acids is common. The alloy's ability to maintain its integrity in such environments translates to longer service life and reduced maintenance costs for equipment and structures.

It's worth noting that while Titanium Grade 12 offers excellent overall corrosion resistance, its performance can vary depending on the specific environmental conditions and concentrations of corrosive agents. In some cases, other titanium alloys might be more suitable for particular applications. For instance, Grade 7 (Ti-0.2Pd) may offer better resistance in extremely aggressive reducing acid environments, while Grade 23 (Ti-6Al-4V ELI) might be preferred for certain biomedical applications due to its biocompatibility and lower modulus of elasticity.

What are the mechanical properties of Titanium Grade 12 sheet that make it suitable for industrial applications?

Titanium 0.8Ni-0.3Mo Grade 12 sheet possesses a unique combination of mechanical properties that make it highly suitable for a wide range of industrial applications. These properties stem from its carefully balanced composition and the synergistic effects of its alloying elements.

First and foremost, Titanium Grade 12 exhibits excellent strength-to-weight ratio. With a density of about 4.5 g/cm³, it is significantly lighter than steel (7.8 g/cm³) and even lighter than some aluminum alloys. Despite its low weight, it maintains high strength levels, with a typical yield strength of around 345 MPa (50 ksi) and ultimate tensile strength of about 483 MPa (70 ksi) in the annealed condition. This combination of low density and high strength makes it an ideal material for applications where weight reduction is crucial without compromising structural integrity, such as in aerospace components or offshore structures.

The alloy also demonstrates good ductility, with elongation typically ranging from 18% to 25%. This property allows for excellent formability, enabling the fabrication of complex shapes through various manufacturing processes like bending, deep drawing, and hydroforming. The good ductility also contributes to the material's toughness, providing resistance to crack propagation and enhancing its overall durability in service.

Titanium Grade 12's fatigue resistance is another key mechanical property that makes it valuable in industrial applications. The alloy exhibits high resistance to cyclic loading, which is crucial in components subjected to repeated stress, such as in pumps, valves, and other equipment in chemical processing plants. This fatigue resistance, combined with its corrosion resistance, ensures long-term reliability and reduced maintenance requirements in demanding operational environments.

Titanium Grade 12 maintains its mechanical properties over a wide temperature range, from cryogenic temperatures to moderately elevated temperatures. This temperature stability makes it suitable for applications in diverse environments, from cold deep-sea operations to hot industrial processes. The alloy's performance at elevated temperatures, while not as high as some beta titanium alloys, is still superior to many conventional materials, maintaining strength and corrosion resistance up to about 300°C (572°F).

The combination of these mechanical properties with the alloy's excellent corrosion resistance makes Titanium Grade 12 sheet an ideal material for various industrial applications. It finds extensive use in chemical processing equipment, heat exchangers, marine hardware, and components for offshore oil and gas production. The material's ability to withstand harsh environments while maintaining its mechanical integrity over long periods translates to increased equipment lifespan, reduced downtime, and lower lifecycle costs in many industrial settings.

How does the cost-effectiveness of Titanium Grade 12 sheet compare to other materials in long-term industrial use?

When evaluating the cost-effectiveness of titanium 0.8Ni-0.3Mo Grade 12 sheet for long-term industrial use, it's essential to consider not just the initial material cost but also the total lifecycle costs and performance benefits. While the upfront cost of Titanium Grade 12 is generally higher than that of many conventional materials like stainless steel or some nickel alloys, its long-term cost-effectiveness often proves superior in many industrial applications.

The primary factor contributing to the cost-effectiveness of Titanium Grade 12 is its exceptional corrosion resistance. In aggressive environments where other materials might rapidly deteriorate, Titanium Grade 12 can maintain its integrity for extended periods. This longevity translates to reduced frequency of replacements, lower maintenance costs, and minimized downtime for repairs or replacements. For instance, in chemical processing plants or desalination facilities, where exposure to corrosive media is constant, the use of Titanium Grade 12 can significantly extend the operational life of equipment, potentially lasting decades where other materials might require replacement in just a few years.

Energy efficiency is another aspect where Titanium Grade 12 can prove cost-effective in the long run. Its excellent heat transfer properties make it an ideal material for heat exchangers and condensers. The superior corrosion resistance allows for the use of thinner walls in these applications, further enhancing heat transfer efficiency. This improved efficiency can lead to significant energy savings over the lifecycle of the equipment, particularly in large-scale industrial processes where energy costs are a major operational expense.

The versatility of Titanium Grade 12 also contributes to its cost-effectiveness. Its ability to perform well in a wide range of environments means that it can be used across various applications within a single facility or industry. This versatility can simplify inventory management, reduce the need for multiple material types, and potentially lead to economies of scale in procurement.

When comparing the cost-effectiveness of Titanium Grade 12 to other materials, it's important to consider specific application requirements. For instance, in seawater applications, Titanium Grade 12 often proves more cost-effective than high-grade stainless steels or copper-nickel alloys due to its superior corrosion resistance and longer service life. In chemical processing applications, while its initial cost might be higher than that of lined carbon steel equipment, the elimination of liner replacement and reduced risk of leakage can result in lower total ownership costs over time.

It's worth noting that the cost-effectiveness of titanium 0.8Ni-0.3Mo Grade 12 sheet can vary depending on the specific application and operating conditions. In some cases, where corrosion resistance requirements are less stringent or where the service life is expected to be relatively short, other materials might prove more cost-effective. Therefore, a thorough lifecycle cost analysis, considering factors such as initial material cost, fabrication expenses, maintenance requirements, expected service life, and potential downtime costs, is crucial in determining the most cost-effective material choice for a given industrial application.

At SHAANXI CXMET TECHNOLOGY CO., LTD, we take pride in our extensive product range, which caters to diverse customer needs. Our company is equipped with outstanding production and processing capabilities, ensuring the high quality and precision of our products. We are committed to innovation and continuously strive to develop new products, keeping us at the forefront of our industry. With leading technological development capabilities, we are able to adapt and evolve in a rapidly changing market. Furthermore, we offer customized solutions to meet the specific requirements of our clients. If you are interested in our products or wish to learn more about the intricate details of our offerings, please do not hesitate to contact us at sales@cxmet.com. Our team is always ready to assist you.

|

|

|

|

References

- ASTM International. (2021). ASTM B265 - Standard Specification for Titanium and Titanium Alloy Strip, Sheet, and Plate.

- Leyens, C., & Peters, M. (Eds.). (2003). Titanium and titanium alloys: fundamentals and applications. John Wiley & Sons.

- Schutz, R. W., & Thomas, D. E. (1987). Corrosion of titanium and titanium alloys. ASM Handbook, 13, 669-706.

- Donachie, M. J. (2000). Titanium: a technical guide. ASM international.

- Boyer, R., Welsch, G., & Collings, E. W. (Eds.). (1994). Materials properties handbook: titanium alloys. ASM international.

- Lutjering, G., & Williams, J. C. (2007). Titanium (engineering materials and processes). Springer.

- Titanium Information Group. (2021). Titanium Alloy Guide. Retrieved from [URL]

- NACE International. (2018). Corrosion of Titanium and Titanium Alloys. NACE International Publication 5A192.

- Peters, M., Kumpfert, J., Ward, C. H., & Leyens, C. (2003). Titanium alloys for aerospace applications. Advanced engineering materials, 5(6), 419-427.

- Azom.com. (2021). Titanium Alloys - Applications and Properties of Grade 12 Ti Alloy. Retrieved from [URL]